Encapsulation Materials To Prevent Photodegradation Of Quantum Dots

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Encapsulation Background and Objectives

Quantum dots (QDs) have emerged as revolutionary nanomaterials since their discovery in the early 1980s, evolving from laboratory curiosities to key components in cutting-edge display technologies, biomedical imaging, and photovoltaic applications. These semiconductor nanocrystals, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects, allowing precise tuning of emission wavelengths across the visible spectrum and beyond.

Despite their remarkable properties, quantum dots face a significant challenge that has hindered broader commercial adoption: photodegradation. When exposed to oxygen and light, QDs undergo photochemical reactions that lead to surface oxidation, resulting in decreased quantum yield, emission wavelength shifts, and ultimately, complete luminescence quenching. This vulnerability to environmental factors has been particularly problematic for applications requiring long-term stability, such as displays, lighting, and solar cells.

The evolution of encapsulation strategies has closely followed the development trajectory of quantum dots themselves. Early approaches focused on simple core-shell structures, where a shell of wider bandgap material (such as ZnS around CdSe cores) provided minimal protection. As applications demanded greater stability, more sophisticated multi-layer architectures and surface ligand engineering techniques emerged, gradually improving resistance to photodegradation while maintaining optical performance.

The technical objectives for quantum dot encapsulation materials have become increasingly demanding as applications diversify. Modern encapsulation solutions must simultaneously achieve multiple goals: prevent oxygen and moisture penetration, maintain high quantum yield, preserve narrow emission linewidths, ensure compatibility with host matrices, and withstand operational conditions specific to each application (such as high current densities in electroluminescent devices or elevated temperatures in displays).

Recent technological advances have shifted focus toward environmentally benign encapsulation materials that can protect heavy-metal-free quantum dots, aligning with global sustainability initiatives and regulatory requirements. Additionally, there is growing interest in encapsulation strategies that not only prevent degradation but actively enhance QD performance through mechanisms such as plasmon coupling or energy transfer.

The ultimate goal of current research efforts is to develop universal encapsulation platforms that can be tailored to specific quantum dot compositions and applications while providing robust protection against photodegradation under diverse environmental conditions. Success in this endeavor would unlock the full potential of quantum dots across multiple industries, enabling next-generation displays with unprecedented color gamut, highly efficient lighting solutions, advanced biomedical imaging techniques, and improved photovoltaic technologies.

Despite their remarkable properties, quantum dots face a significant challenge that has hindered broader commercial adoption: photodegradation. When exposed to oxygen and light, QDs undergo photochemical reactions that lead to surface oxidation, resulting in decreased quantum yield, emission wavelength shifts, and ultimately, complete luminescence quenching. This vulnerability to environmental factors has been particularly problematic for applications requiring long-term stability, such as displays, lighting, and solar cells.

The evolution of encapsulation strategies has closely followed the development trajectory of quantum dots themselves. Early approaches focused on simple core-shell structures, where a shell of wider bandgap material (such as ZnS around CdSe cores) provided minimal protection. As applications demanded greater stability, more sophisticated multi-layer architectures and surface ligand engineering techniques emerged, gradually improving resistance to photodegradation while maintaining optical performance.

The technical objectives for quantum dot encapsulation materials have become increasingly demanding as applications diversify. Modern encapsulation solutions must simultaneously achieve multiple goals: prevent oxygen and moisture penetration, maintain high quantum yield, preserve narrow emission linewidths, ensure compatibility with host matrices, and withstand operational conditions specific to each application (such as high current densities in electroluminescent devices or elevated temperatures in displays).

Recent technological advances have shifted focus toward environmentally benign encapsulation materials that can protect heavy-metal-free quantum dots, aligning with global sustainability initiatives and regulatory requirements. Additionally, there is growing interest in encapsulation strategies that not only prevent degradation but actively enhance QD performance through mechanisms such as plasmon coupling or energy transfer.

The ultimate goal of current research efforts is to develop universal encapsulation platforms that can be tailored to specific quantum dot compositions and applications while providing robust protection against photodegradation under diverse environmental conditions. Success in this endeavor would unlock the full potential of quantum dots across multiple industries, enabling next-generation displays with unprecedented color gamut, highly efficient lighting solutions, advanced biomedical imaging techniques, and improved photovoltaic technologies.

Market Analysis for Photostable Quantum Dot Applications

The quantum dot (QD) market has experienced significant growth in recent years, with applications spanning display technologies, lighting, biomedical imaging, and photovoltaics. The global quantum dot market was valued at approximately $4.5 billion in 2022 and is projected to reach $16.8 billion by 2028, representing a compound annual growth rate (CAGR) of 24.6% during the forecast period. This robust growth trajectory is primarily driven by increasing adoption in consumer electronics, particularly in display technologies.

Display applications currently dominate the QD market, accounting for nearly 65% of total market share. Major manufacturers including Samsung, LG, and TCL have incorporated quantum dot technology into their premium television and monitor product lines, leveraging the superior color gamut and energy efficiency offered by QDs. The QD-enhanced display market alone is expected to grow at a CAGR of 29.8% through 2027.

Photostability remains a critical challenge limiting broader market penetration across applications. Industry surveys indicate that approximately 78% of potential industrial adopters cite concerns about QD degradation as a significant barrier to implementation. This creates a substantial market opportunity for photostable quantum dot solutions, particularly those utilizing advanced encapsulation materials.

The healthcare and biomedical imaging segment represents the fastest-growing application area for photostable quantum dots, with a projected CAGR of 32.4% through 2028. Enhanced photostability enables longer imaging sessions and more accurate diagnostics, driving demand in this premium market segment where performance often outweighs cost considerations.

Regionally, North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by expanding manufacturing capabilities and increasing adoption of QD technologies in consumer electronics production hubs like China, South Korea, and Taiwan.

Consumer demand for higher-performance displays with improved energy efficiency continues to drive market growth, with surveys indicating 67% of consumers are willing to pay premium prices for devices with superior visual performance. This trend particularly benefits photostable quantum dot applications, as they enable longer device lifespans and more consistent performance over time.

The automotive industry represents an emerging high-potential market for photostable quantum dots, with applications in heads-up displays, dashboard instrumentation, and interior lighting. Market analysts project this segment to grow from $189 million in 2022 to over $1.2 billion by 2028, representing one of the highest growth rates across all application categories.

Display applications currently dominate the QD market, accounting for nearly 65% of total market share. Major manufacturers including Samsung, LG, and TCL have incorporated quantum dot technology into their premium television and monitor product lines, leveraging the superior color gamut and energy efficiency offered by QDs. The QD-enhanced display market alone is expected to grow at a CAGR of 29.8% through 2027.

Photostability remains a critical challenge limiting broader market penetration across applications. Industry surveys indicate that approximately 78% of potential industrial adopters cite concerns about QD degradation as a significant barrier to implementation. This creates a substantial market opportunity for photostable quantum dot solutions, particularly those utilizing advanced encapsulation materials.

The healthcare and biomedical imaging segment represents the fastest-growing application area for photostable quantum dots, with a projected CAGR of 32.4% through 2028. Enhanced photostability enables longer imaging sessions and more accurate diagnostics, driving demand in this premium market segment where performance often outweighs cost considerations.

Regionally, North America currently leads the market with approximately 38% share, followed by Asia-Pacific at 34% and Europe at 22%. However, the Asia-Pacific region is expected to witness the highest growth rate, driven by expanding manufacturing capabilities and increasing adoption of QD technologies in consumer electronics production hubs like China, South Korea, and Taiwan.

Consumer demand for higher-performance displays with improved energy efficiency continues to drive market growth, with surveys indicating 67% of consumers are willing to pay premium prices for devices with superior visual performance. This trend particularly benefits photostable quantum dot applications, as they enable longer device lifespans and more consistent performance over time.

The automotive industry represents an emerging high-potential market for photostable quantum dots, with applications in heads-up displays, dashboard instrumentation, and interior lighting. Market analysts project this segment to grow from $189 million in 2022 to over $1.2 billion by 2028, representing one of the highest growth rates across all application categories.

Current Challenges in Quantum Dot Photostability

Despite significant advancements in quantum dot (QD) technology, photostability remains one of the most critical challenges hindering widespread commercial applications. Quantum dots exhibit exceptional optical properties, including high quantum yield, narrow emission spectra, and tunable bandgaps. However, these properties deteriorate significantly when QDs are exposed to light, oxygen, and moisture, a phenomenon known as photodegradation.

The primary mechanism of photodegradation involves photooxidation, where light exposure generates reactive oxygen species that attack the QD surface, creating trap states and reducing quantum yield. This process is particularly problematic for core-only QDs, where surface atoms are directly exposed to environmental factors. The degradation manifests as spectral shifts, broadening of emission peaks, and dramatic decreases in luminescence intensity, severely compromising device performance and longevity.

Current commercial QD applications face significant stability limitations, with typical operational lifetimes ranging from hundreds to a few thousand hours under standard conditions—far below the 50,000+ hours required for consumer electronics. This stability gap represents a major barrier to market adoption, particularly in display technologies and lighting applications where consistent performance is paramount.

Material-specific challenges vary considerably across different QD compositions. Cadmium-based QDs (CdSe, CdS) demonstrate relatively better stability but face regulatory restrictions due to toxicity concerns. Indium phosphide (InP) QDs, while less toxic, exhibit significantly poorer photostability, requiring more sophisticated encapsulation strategies. Perovskite QDs show promising optical properties but are extremely sensitive to moisture and oxygen, presenting unique encapsulation challenges.

The interface between QDs and encapsulation materials introduces additional complications. Chemical incompatibilities can lead to ligand displacement, surface reconstruction, or unwanted electronic interactions that compromise optical performance. Many polymeric encapsulants suffer from oxygen permeability issues, while inorganic encapsulants may introduce mechanical stress due to thermal expansion coefficient mismatches.

Manufacturing scalability presents another significant hurdle. Laboratory-scale encapsulation techniques often employ complex, multi-step processes that are difficult to scale industrially. The trade-off between hermeticity and processability remains unresolved, with highly effective barrier materials typically requiring specialized deposition techniques incompatible with high-throughput production.

Cost considerations further complicate matters, as advanced encapsulation solutions utilizing atomic layer deposition or specialized barrier films significantly increase production expenses, potentially pricing QD technologies out of consumer markets. Finding cost-effective encapsulation strategies that maintain performance remains a critical industry challenge.

The primary mechanism of photodegradation involves photooxidation, where light exposure generates reactive oxygen species that attack the QD surface, creating trap states and reducing quantum yield. This process is particularly problematic for core-only QDs, where surface atoms are directly exposed to environmental factors. The degradation manifests as spectral shifts, broadening of emission peaks, and dramatic decreases in luminescence intensity, severely compromising device performance and longevity.

Current commercial QD applications face significant stability limitations, with typical operational lifetimes ranging from hundreds to a few thousand hours under standard conditions—far below the 50,000+ hours required for consumer electronics. This stability gap represents a major barrier to market adoption, particularly in display technologies and lighting applications where consistent performance is paramount.

Material-specific challenges vary considerably across different QD compositions. Cadmium-based QDs (CdSe, CdS) demonstrate relatively better stability but face regulatory restrictions due to toxicity concerns. Indium phosphide (InP) QDs, while less toxic, exhibit significantly poorer photostability, requiring more sophisticated encapsulation strategies. Perovskite QDs show promising optical properties but are extremely sensitive to moisture and oxygen, presenting unique encapsulation challenges.

The interface between QDs and encapsulation materials introduces additional complications. Chemical incompatibilities can lead to ligand displacement, surface reconstruction, or unwanted electronic interactions that compromise optical performance. Many polymeric encapsulants suffer from oxygen permeability issues, while inorganic encapsulants may introduce mechanical stress due to thermal expansion coefficient mismatches.

Manufacturing scalability presents another significant hurdle. Laboratory-scale encapsulation techniques often employ complex, multi-step processes that are difficult to scale industrially. The trade-off between hermeticity and processability remains unresolved, with highly effective barrier materials typically requiring specialized deposition techniques incompatible with high-throughput production.

Cost considerations further complicate matters, as advanced encapsulation solutions utilizing atomic layer deposition or specialized barrier films significantly increase production expenses, potentially pricing QD technologies out of consumer markets. Finding cost-effective encapsulation strategies that maintain performance remains a critical industry challenge.

Existing Encapsulation Solutions for Photodegradation Prevention

01 Inorganic shell encapsulation for quantum dots

Inorganic materials such as silica, zinc sulfide, and metal oxides can be used to form protective shells around quantum dots to prevent photodegradation. These inorganic shells act as physical barriers that protect the quantum dot core from oxygen, moisture, and other environmental factors that can cause degradation. The shell thickness and composition can be optimized to provide maximum protection while maintaining the optical properties of the quantum dots.- Inorganic shell encapsulation for quantum dots: Inorganic materials such as silica, metal oxides, and semiconductor shells can be used to encapsulate quantum dots to prevent photodegradation. These materials form a protective barrier around the quantum dots, shielding them from oxygen, moisture, and UV radiation that can cause degradation. The core-shell structure enhances stability while maintaining the optical properties of the quantum dots, making them suitable for long-term applications in displays, lighting, and photovoltaics.

- Polymer-based encapsulation systems: Polymer materials offer flexible and effective encapsulation solutions for quantum dots. Various polymers including PMMA, polystyrene, polyvinyl alcohol, and specialized copolymers can be used to create protective matrices around quantum dots. These polymer encapsulants prevent oxygen and moisture penetration while offering advantages such as processability, transparency, and compatibility with existing manufacturing techniques. The polymer encapsulation can be achieved through methods like in-situ polymerization, solution blending, or layer-by-layer deposition.

- Hybrid organic-inorganic encapsulation materials: Hybrid encapsulation systems combine the benefits of both organic and inorganic materials to protect quantum dots from photodegradation. These systems typically involve silsesquioxanes, metal-organic frameworks, or polymer-inorganic composites that create multiple barrier layers. The organic components provide flexibility and processability while the inorganic components offer superior barrier properties against oxygen and moisture. This synergistic approach results in enhanced photostability and extended lifetime of quantum dot devices.

- Surface ligand engineering for quantum dot protection: Surface ligand engineering involves modifying the quantum dot surface with specialized molecules that prevent photodegradation. By replacing or supplementing native ligands with photostable alternatives such as phosphonic acids, thiols with bulky groups, or silane coupling agents, the quantum dots gain improved resistance to oxidation and photobleaching. These engineered ligands create a protective layer that maintains electronic passivation while blocking reactive species that could degrade the quantum dot core.

- Multilayer encapsulation strategies: Multilayer encapsulation approaches utilize sequential layers of different materials to create comprehensive protection for quantum dots. These systems typically combine moisture barriers, oxygen scavengers, UV blockers, and mechanical protection layers in a strategic arrangement. Each layer serves a specific protective function, creating redundancy in the protection mechanism. Advanced multilayer systems may incorporate active components that neutralize degradation triggers or self-healing materials that repair damage to maintain long-term photostability of quantum dots.

02 Polymer-based encapsulation materials

Polymeric materials offer flexible and versatile options for quantum dot encapsulation. Materials such as polyvinyl alcohol (PVA), polymethyl methacrylate (PMMA), polystyrene, and other specialized polymers can be used to create protective matrices around quantum dots. These polymers can be engineered to have specific properties such as oxygen impermeability, UV resistance, and thermal stability, which help prevent photodegradation of the encapsulated quantum dots while maintaining their luminescent properties.Expand Specific Solutions03 Core-shell-shell multi-layer protection systems

Advanced multi-layer encapsulation systems involve creating multiple protective shells around quantum dots. These typically consist of an inner shell that passivates the quantum dot surface, a middle shell that provides electronic isolation, and an outer shell that offers environmental protection. This multi-layered approach provides comprehensive protection against various degradation mechanisms including photo-oxidation, energy transfer to oxygen, and physical damage, significantly enhancing the photostability of quantum dots.Expand Specific Solutions04 Hybrid organic-inorganic encapsulation materials

Hybrid encapsulation systems combine the benefits of both organic and inorganic materials to protect quantum dots from photodegradation. These materials often incorporate inorganic nanoparticles or compounds within organic polymer matrices, creating composite structures with enhanced barrier properties. The organic components provide flexibility and processability, while the inorganic components improve resistance to oxygen permeation and UV radiation, resulting in superior protection against photodegradation.Expand Specific Solutions05 Surface ligand engineering for photostability

Surface ligand engineering involves modifying the organic molecules attached to the quantum dot surface to enhance photostability. By carefully selecting and attaching specific ligands, the surface chemistry of quantum dots can be altered to reduce reactivity with oxygen and other degradative species. These ligands can include long-chain hydrocarbons, phosphines, thiols, and specially designed molecules that create a protective layer directly on the quantum dot surface, preventing access of reactive species while maintaining the quantum dots' optical properties.Expand Specific Solutions

Leading Companies in Quantum Dot Encapsulation Industry

The quantum dot encapsulation materials market is in a growth phase, with increasing demand driven by the need to prevent photodegradation in display, lighting, and energy applications. The market is expanding rapidly as quantum dot technology matures, with projections suggesting significant growth over the next decade. Technologically, companies are at varying stages of development, with specialized players like Nanoco Technologies and Nexdot SAS leading in quantum dot innovation, while larger corporations such as Samsung Electronics, Merck Patent GmbH, and 3M Innovative Properties focus on integration and mass production capabilities. Research institutions including Ghent University and Industrial Technology Research Institute are advancing fundamental solutions, while Asian manufacturers like BOE Technology and Najing Technology are scaling commercial applications, creating a competitive landscape balanced between specialized innovation and industrial implementation.

Nexdot SAS

Technical Solution: Nexdot has developed innovative encapsulation materials for quantum dots based on sol-gel chemistry and specialized silica matrices. Their approach utilizes a multi-step encapsulation process that first creates a thin inorganic shell directly on quantum dot surfaces, followed by incorporation into a modified silica matrix with tailored porosity. This dual-layer protection system effectively isolates quantum dots from oxygen and moisture while maintaining their optical properties. Nexdot's technology incorporates proprietary surface ligands that chemically bond to both the quantum dot surface and the encapsulation matrix, creating strong interfaces that resist degradation under photonic stress. Their materials feature specialized additives that absorb harmful UV radiation and dissipate the energy as heat rather than transferring it to the quantum dots. Nexdot has also developed scalable manufacturing processes for their encapsulation materials that are compatible with roll-to-roll production methods, enabling cost-effective implementation in large-area display and lighting applications.

Strengths: Nexdot's sol-gel approach provides exceptional barrier properties against environmental factors while maintaining high transparency and thermal stability. Their materials offer excellent compatibility with various quantum dot compositions. Weaknesses: The multi-step encapsulation process may increase production complexity and processing time compared to single-step encapsulation methods, potentially affecting manufacturing throughput.

Nanoco Technologies Ltd.

Technical Solution: Nanoco Technologies has developed specialized encapsulation materials specifically designed for their cadmium-free CFQD® quantum dots. Their approach utilizes proprietary polymer matrices with carefully engineered chemical structures that provide both physical protection and chemical passivation of quantum dot surfaces. Nanoco's encapsulation technology incorporates UV-absorbing compounds that selectively filter harmful radiation while allowing efficient light emission from the quantum dots. Their materials feature oxygen-scavenging components that create a protective microenvironment around each quantum dot, significantly reducing oxidative degradation pathways. Nanoco has also developed specialized cross-linking chemistries that create robust, three-dimensional networks around quantum dots, providing mechanical stability while maintaining optical clarity. Their recent innovations include the development of hybrid encapsulation systems that combine the benefits of different material classes to achieve optimal protection against multiple degradation mechanisms simultaneously.

Strengths: Nanoco's materials are specifically optimized for cadmium-free quantum dots, addressing both environmental concerns and regulatory requirements. Their encapsulation technology enables long-term stability in display applications. Weaknesses: The specialized nature of their materials may limit broader applicability across different quantum dot compositions and manufacturing processes compared to more universal encapsulation approaches.

Key Innovations in Quantum Dot Protection Materials

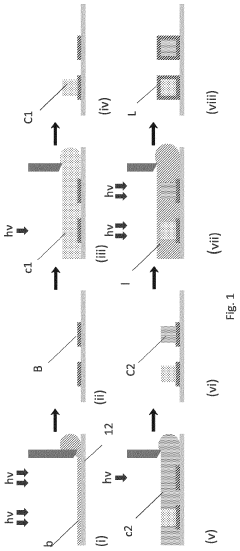

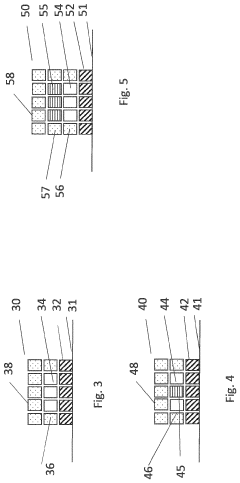

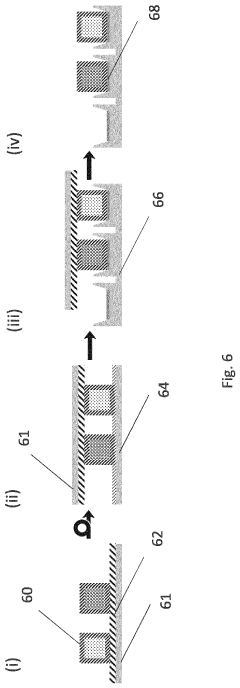

A method to prepare pockets of encapsulated material comprising a core surrounded by an encapsulation

PatentPendingUS20240072215A1

Innovation

- A method for preparing pockets of encapsulated material where core quantum dots are fully surrounded by a barrier material, using a process involving the formation of bases, core deposits, and lids, with localized curing and removal of uncured materials, allowing for versatile shapes and scalable fabrication without the need for multilayered encapsulation techniques.

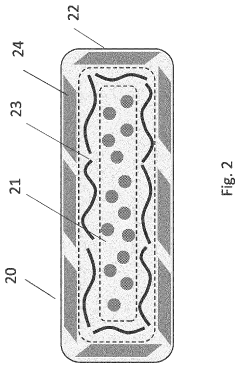

Ink comprising encapsulated nanoparticles

PatentWO2018220168A2

Innovation

- Development of an ink comprising nanoparticles encapsulated in a protective material that prevents mechanical and chemical abrasion, using a dual encapsulation approach to maintain the properties of the nanoparticles while ensuring compatibility with the liquid vehicle, thereby enhancing stability and photoluminescence quantum yield.

Environmental Impact and Sustainability Considerations

The environmental impact of quantum dot technologies extends beyond their performance characteristics to their entire lifecycle. Traditional quantum dot materials often contain heavy metals such as cadmium, lead, or mercury, which pose significant environmental and health risks if improperly managed. The encapsulation materials used to prevent photodegradation must therefore be evaluated not only for their protective efficacy but also for their environmental footprint.

Current encapsulation approaches frequently utilize petroleum-based polymers that present end-of-life disposal challenges. These materials can persist in the environment for decades or centuries, contributing to microplastic pollution when quantum dot-containing products are discarded. Additionally, the synthesis processes for many encapsulation materials involve toxic solvents and energy-intensive manufacturing steps, further increasing their environmental burden.

Recent research has focused on developing bio-based and biodegradable alternatives for quantum dot encapsulation. Materials such as cellulose derivatives, chitosan, and other polysaccharides show promising protective properties while offering improved environmental profiles. These biomaterials can degrade under appropriate conditions, reducing long-term environmental accumulation. However, challenges remain in matching the barrier properties and optical transparency of conventional synthetic polymers.

Life cycle assessment (LCA) studies indicate that the environmental impact of encapsulation materials varies significantly depending on raw material sourcing, manufacturing processes, and end-of-life scenarios. Water-based encapsulation systems generally demonstrate lower environmental impacts compared to solvent-based alternatives, though they may require additional energy for processing or exhibit reduced performance characteristics.

Regulatory frameworks worldwide are increasingly addressing the sustainability aspects of nanomaterials, including quantum dots and their encapsulation systems. The European Union's REACH regulations and similar initiatives in other regions are driving manufacturers toward greener encapsulation solutions that minimize hazardous substance content and improve recyclability.

Circular economy principles are beginning to influence encapsulation material design, with growing interest in materials that facilitate quantum dot recovery and recycling at end-of-life. This approach is particularly important given the scarcity of some elements used in quantum dot production. Encapsulation systems that allow for separation and recovery of valuable materials represent a significant opportunity for improving the sustainability profile of quantum dot technologies.

Future research directions should prioritize encapsulation materials that balance performance requirements with reduced environmental footprint, considering both production impacts and end-of-life management strategies. This holistic approach will be essential for ensuring that quantum dot technologies can deliver their potential benefits without creating disproportionate environmental costs.

Current encapsulation approaches frequently utilize petroleum-based polymers that present end-of-life disposal challenges. These materials can persist in the environment for decades or centuries, contributing to microplastic pollution when quantum dot-containing products are discarded. Additionally, the synthesis processes for many encapsulation materials involve toxic solvents and energy-intensive manufacturing steps, further increasing their environmental burden.

Recent research has focused on developing bio-based and biodegradable alternatives for quantum dot encapsulation. Materials such as cellulose derivatives, chitosan, and other polysaccharides show promising protective properties while offering improved environmental profiles. These biomaterials can degrade under appropriate conditions, reducing long-term environmental accumulation. However, challenges remain in matching the barrier properties and optical transparency of conventional synthetic polymers.

Life cycle assessment (LCA) studies indicate that the environmental impact of encapsulation materials varies significantly depending on raw material sourcing, manufacturing processes, and end-of-life scenarios. Water-based encapsulation systems generally demonstrate lower environmental impacts compared to solvent-based alternatives, though they may require additional energy for processing or exhibit reduced performance characteristics.

Regulatory frameworks worldwide are increasingly addressing the sustainability aspects of nanomaterials, including quantum dots and their encapsulation systems. The European Union's REACH regulations and similar initiatives in other regions are driving manufacturers toward greener encapsulation solutions that minimize hazardous substance content and improve recyclability.

Circular economy principles are beginning to influence encapsulation material design, with growing interest in materials that facilitate quantum dot recovery and recycling at end-of-life. This approach is particularly important given the scarcity of some elements used in quantum dot production. Encapsulation systems that allow for separation and recovery of valuable materials represent a significant opportunity for improving the sustainability profile of quantum dot technologies.

Future research directions should prioritize encapsulation materials that balance performance requirements with reduced environmental footprint, considering both production impacts and end-of-life management strategies. This holistic approach will be essential for ensuring that quantum dot technologies can deliver their potential benefits without creating disproportionate environmental costs.

Standardization and Testing Protocols for Encapsulation Materials

The standardization and testing protocols for encapsulation materials used in quantum dot protection represent a critical aspect of quality assurance and performance validation in this emerging field. Currently, the industry faces significant challenges due to the lack of universally accepted testing methodologies specifically designed for quantum dot encapsulation systems.

Accelerated aging tests have emerged as the primary approach for evaluating encapsulation effectiveness, with protocols typically involving exposure to elevated temperatures (85-150°C), high humidity (85-95% RH), and intense UV radiation (300-400 nm wavelength range). However, the correlation between these accelerated conditions and real-world performance remains inadequately established, creating uncertainty in lifetime predictions.

Several international organizations are working toward standardization, with the International Electrotechnical Commission (IEC) developing standards specifically addressing quantum dot-based display technologies. ASTM International has also introduced testing protocols for barrier films and encapsulation materials, though these require adaptation for quantum dot-specific applications.

Key performance metrics that require standardized measurement include oxygen transmission rate (OTR), water vapor transmission rate (WVTR), photoluminescence quantum yield (PLQY) retention, and color shift parameters. The industry currently lacks consensus on threshold values that define acceptable performance across these metrics, particularly for different application environments.

Interlaboratory comparison studies have revealed significant variations in test results between facilities, highlighting the urgent need for reference materials and calibration standards. The National Institute of Standards and Technology (NIST) has initiated programs to develop reference quantum dot materials with known degradation characteristics to serve as benchmarks for encapsulation testing.

Advanced characterization techniques including time-resolved photoluminescence spectroscopy, cross-sectional electron microscopy, and nanoscale chemical mapping are increasingly being incorporated into testing protocols. These methods provide deeper insights into degradation mechanisms but require specialized equipment and expertise not universally available.

The development of in-situ monitoring capabilities represents a frontier in testing methodology, allowing real-time observation of degradation processes without disrupting the encapsulation system. Such approaches could significantly reduce testing timeframes and improve the accuracy of lifetime predictions.

Harmonization of testing protocols across geographic regions remains challenging, with different regulatory frameworks in North America, Europe, and Asia influencing test requirements. Industry consortia are working to bridge these differences through collaborative research initiatives and round-robin testing programs.

Accelerated aging tests have emerged as the primary approach for evaluating encapsulation effectiveness, with protocols typically involving exposure to elevated temperatures (85-150°C), high humidity (85-95% RH), and intense UV radiation (300-400 nm wavelength range). However, the correlation between these accelerated conditions and real-world performance remains inadequately established, creating uncertainty in lifetime predictions.

Several international organizations are working toward standardization, with the International Electrotechnical Commission (IEC) developing standards specifically addressing quantum dot-based display technologies. ASTM International has also introduced testing protocols for barrier films and encapsulation materials, though these require adaptation for quantum dot-specific applications.

Key performance metrics that require standardized measurement include oxygen transmission rate (OTR), water vapor transmission rate (WVTR), photoluminescence quantum yield (PLQY) retention, and color shift parameters. The industry currently lacks consensus on threshold values that define acceptable performance across these metrics, particularly for different application environments.

Interlaboratory comparison studies have revealed significant variations in test results between facilities, highlighting the urgent need for reference materials and calibration standards. The National Institute of Standards and Technology (NIST) has initiated programs to develop reference quantum dot materials with known degradation characteristics to serve as benchmarks for encapsulation testing.

Advanced characterization techniques including time-resolved photoluminescence spectroscopy, cross-sectional electron microscopy, and nanoscale chemical mapping are increasingly being incorporated into testing protocols. These methods provide deeper insights into degradation mechanisms but require specialized equipment and expertise not universally available.

The development of in-situ monitoring capabilities represents a frontier in testing methodology, allowing real-time observation of degradation processes without disrupting the encapsulation system. Such approaches could significantly reduce testing timeframes and improve the accuracy of lifetime predictions.

Harmonization of testing protocols across geographic regions remains challenging, with different regulatory frameworks in North America, Europe, and Asia influencing test requirements. Industry consortia are working to bridge these differences through collaborative research initiatives and round-robin testing programs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!