Optimizing Edge Coupling Between LSC Waveguides And PV Cells

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSC-PV Edge Coupling Background and Objectives

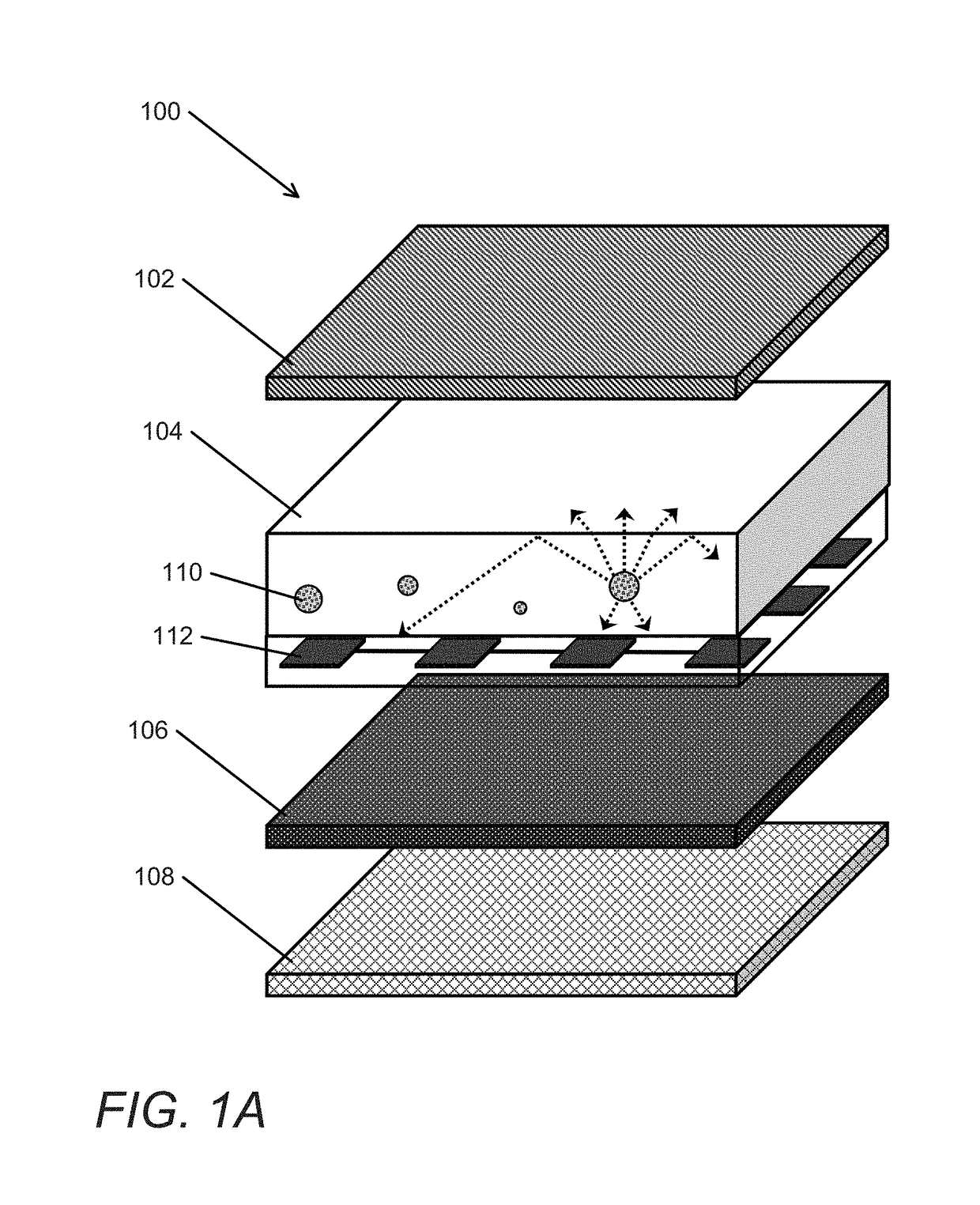

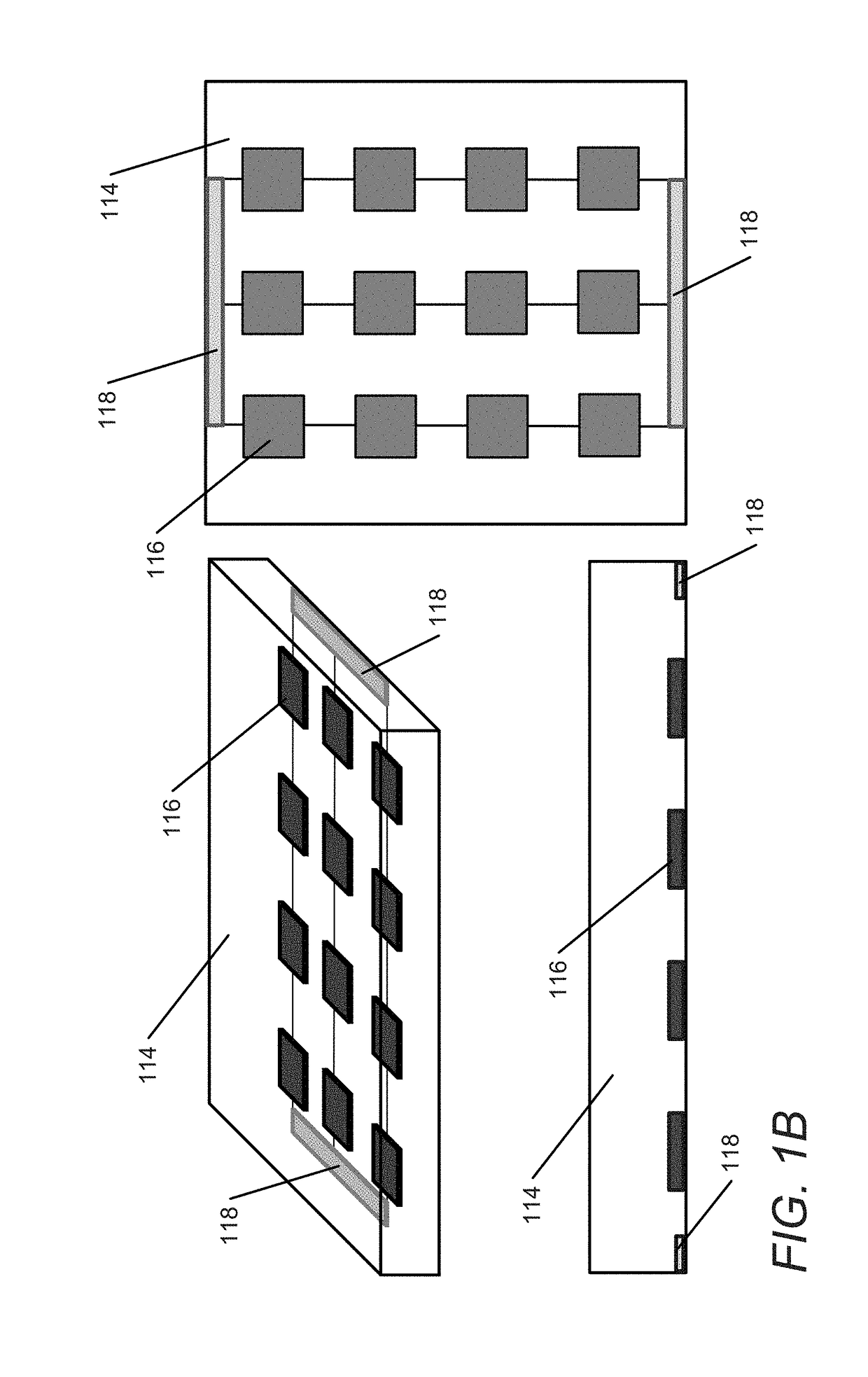

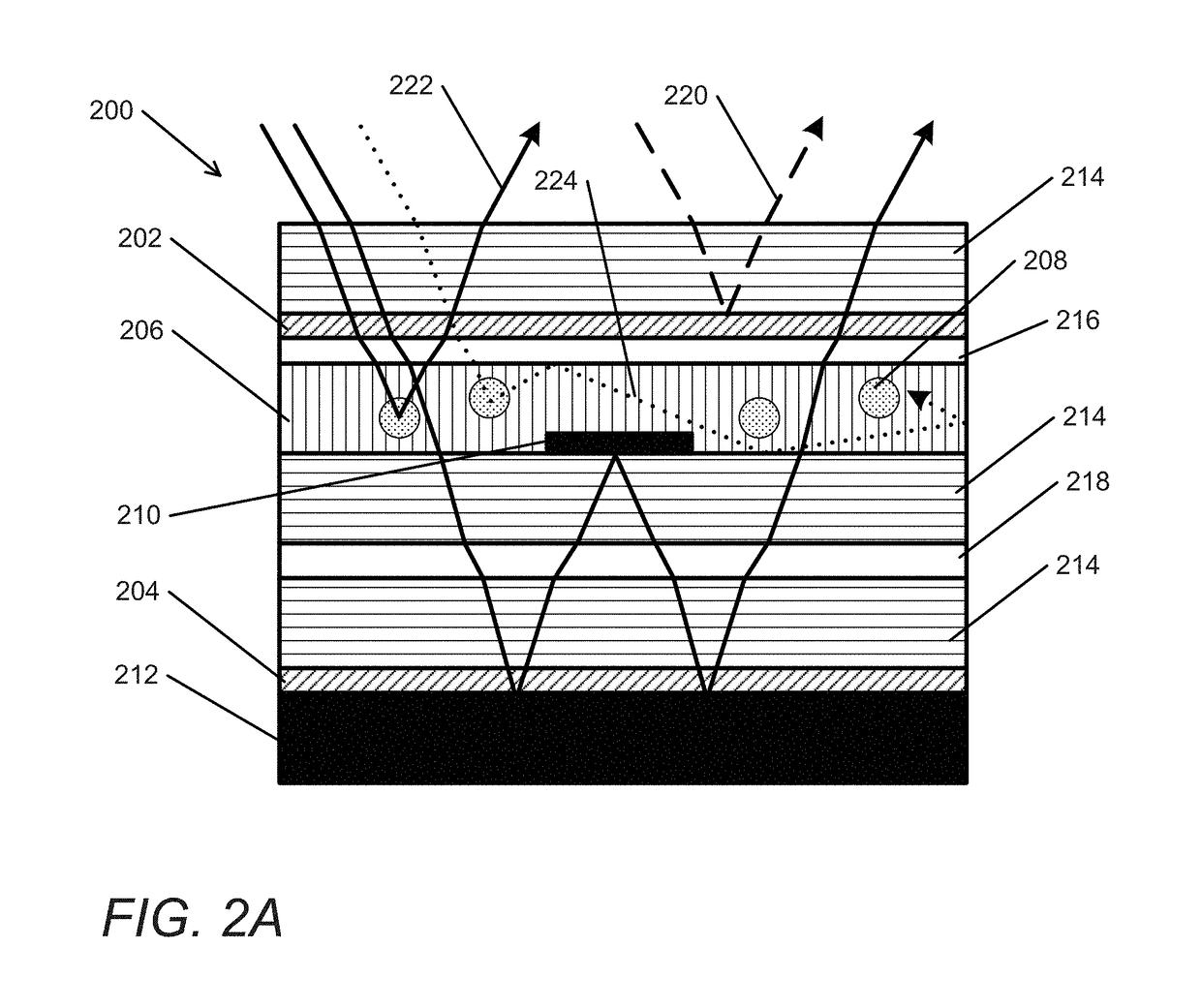

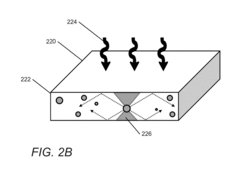

Luminescent Solar Concentrators (LSCs) have emerged as a promising technology in the photovoltaic landscape since their introduction in the late 1970s. These devices utilize fluorescent materials embedded in transparent waveguides to absorb incident sunlight, re-emit it at longer wavelengths, and guide the luminescent light to the edges where photovoltaic (PV) cells are attached. The fundamental principle leverages total internal reflection to concentrate diffuse solar radiation onto smaller areas of PV material, potentially reducing system costs while maintaining efficiency.

The evolution of LSC technology has been marked by significant advancements in materials science, particularly in the development of luminophores with reduced self-absorption and enhanced quantum yields. Early systems utilizing organic dyes faced limitations in long-term stability and spectral coverage, while more recent innovations incorporating quantum dots, rare-earth complexes, and perovskite nanocrystals have substantially improved performance metrics.

Despite these advancements, the critical interface between the LSC waveguide and the PV cell remains a significant bottleneck in system efficiency. Edge coupling losses can account for up to 30% of potential power output, stemming from refractive index mismatches, geometric inconsistencies, and photon escape cones at the waveguide-cell interface. This coupling inefficiency represents a substantial barrier to commercial viability of LSC-PV systems.

The primary technical objective of optimizing edge coupling is to maximize the transfer of concentrated luminescent photons from the waveguide to the PV cell active region. This encompasses several specific goals: reducing Fresnel reflection losses at the interface, minimizing geometric mismatch losses, eliminating air gaps, and ensuring spectral compatibility between the luminescent emission and the PV cell's absorption characteristics.

Secondary objectives include developing coupling solutions that are scalable for mass production, cost-effective relative to the overall system, and durable enough to maintain performance over the expected 20+ year lifespan of solar installations. Additionally, coupling technologies must accommodate the diverse form factors of LSC systems, from planar configurations to more complex three-dimensional geometries being explored for building-integrated applications.

The broader context for this technical pursuit lies in the growing demand for versatile photovoltaic solutions that can be integrated into urban environments, consumer products, and architectural elements where conventional silicon panels are impractical. By addressing the edge coupling challenge, LSC-PV systems could potentially achieve the efficiency and cost targets necessary to penetrate these emerging markets, contributing to distributed renewable energy generation in previously untapped applications.

The evolution of LSC technology has been marked by significant advancements in materials science, particularly in the development of luminophores with reduced self-absorption and enhanced quantum yields. Early systems utilizing organic dyes faced limitations in long-term stability and spectral coverage, while more recent innovations incorporating quantum dots, rare-earth complexes, and perovskite nanocrystals have substantially improved performance metrics.

Despite these advancements, the critical interface between the LSC waveguide and the PV cell remains a significant bottleneck in system efficiency. Edge coupling losses can account for up to 30% of potential power output, stemming from refractive index mismatches, geometric inconsistencies, and photon escape cones at the waveguide-cell interface. This coupling inefficiency represents a substantial barrier to commercial viability of LSC-PV systems.

The primary technical objective of optimizing edge coupling is to maximize the transfer of concentrated luminescent photons from the waveguide to the PV cell active region. This encompasses several specific goals: reducing Fresnel reflection losses at the interface, minimizing geometric mismatch losses, eliminating air gaps, and ensuring spectral compatibility between the luminescent emission and the PV cell's absorption characteristics.

Secondary objectives include developing coupling solutions that are scalable for mass production, cost-effective relative to the overall system, and durable enough to maintain performance over the expected 20+ year lifespan of solar installations. Additionally, coupling technologies must accommodate the diverse form factors of LSC systems, from planar configurations to more complex three-dimensional geometries being explored for building-integrated applications.

The broader context for this technical pursuit lies in the growing demand for versatile photovoltaic solutions that can be integrated into urban environments, consumer products, and architectural elements where conventional silicon panels are impractical. By addressing the edge coupling challenge, LSC-PV systems could potentially achieve the efficiency and cost targets necessary to penetrate these emerging markets, contributing to distributed renewable energy generation in previously untapped applications.

Market Analysis for LSC-PV Integration Solutions

The global market for Luminescent Solar Concentrator (LSC) and Photovoltaic (PV) integration solutions is experiencing significant growth, driven by increasing demand for renewable energy technologies and building-integrated photovoltaics (BIPV). The LSC-PV coupling market segment is projected to grow substantially over the next decade as energy efficiency requirements become more stringent worldwide.

The primary market drivers include the declining costs of PV technology, government incentives for renewable energy adoption, and growing consumer interest in aesthetically pleasing solar solutions. LSC-PV integrated systems offer unique value propositions in architectural applications where traditional solar panels are considered visually intrusive, creating a specialized market niche with premium pricing potential.

Commercial buildings represent the largest current market segment for LSC-PV integration, accounting for substantial implementation in facades, windows, and skylights. The residential sector shows promising growth potential as homeowners increasingly seek energy-efficient building materials that maintain aesthetic appeal. Additionally, specialized applications in automotive (sunroofs), consumer electronics (power-generating displays), and agricultural (greenhouse integration) sectors are emerging as valuable market opportunities.

Geographically, Europe leads in LSC-PV adoption due to stringent building energy efficiency regulations and substantial government support for renewable technologies. North America follows with growing implementation in commercial construction, while the Asia-Pacific region demonstrates the fastest growth rate, particularly in China and Japan where urban density creates premium value for space-efficient solar solutions.

Market challenges include the relatively higher initial costs compared to conventional PV systems, technical limitations in edge coupling efficiency, and limited awareness among architects and building developers. The cost-performance ratio remains a significant barrier to widespread adoption, though this gap is narrowing as manufacturing processes improve and production scales increase.

Consumer willingness to pay premiums for LSC-PV solutions varies significantly by region and application. Commercial applications demonstrate stronger price tolerance when aesthetic considerations and building code compliance provide additional value. The residential market shows more price sensitivity but increasing acceptance as energy costs rise and visual integration improves.

The competitive landscape features established PV manufacturers expanding into LSC technology, specialized startups focused exclusively on LSC-PV integration, and architectural glass manufacturers incorporating luminescent technology into their product lines. Strategic partnerships between technology developers and building material suppliers are becoming increasingly common to accelerate market penetration.

The primary market drivers include the declining costs of PV technology, government incentives for renewable energy adoption, and growing consumer interest in aesthetically pleasing solar solutions. LSC-PV integrated systems offer unique value propositions in architectural applications where traditional solar panels are considered visually intrusive, creating a specialized market niche with premium pricing potential.

Commercial buildings represent the largest current market segment for LSC-PV integration, accounting for substantial implementation in facades, windows, and skylights. The residential sector shows promising growth potential as homeowners increasingly seek energy-efficient building materials that maintain aesthetic appeal. Additionally, specialized applications in automotive (sunroofs), consumer electronics (power-generating displays), and agricultural (greenhouse integration) sectors are emerging as valuable market opportunities.

Geographically, Europe leads in LSC-PV adoption due to stringent building energy efficiency regulations and substantial government support for renewable technologies. North America follows with growing implementation in commercial construction, while the Asia-Pacific region demonstrates the fastest growth rate, particularly in China and Japan where urban density creates premium value for space-efficient solar solutions.

Market challenges include the relatively higher initial costs compared to conventional PV systems, technical limitations in edge coupling efficiency, and limited awareness among architects and building developers. The cost-performance ratio remains a significant barrier to widespread adoption, though this gap is narrowing as manufacturing processes improve and production scales increase.

Consumer willingness to pay premiums for LSC-PV solutions varies significantly by region and application. Commercial applications demonstrate stronger price tolerance when aesthetic considerations and building code compliance provide additional value. The residential market shows more price sensitivity but increasing acceptance as energy costs rise and visual integration improves.

The competitive landscape features established PV manufacturers expanding into LSC technology, specialized startups focused exclusively on LSC-PV integration, and architectural glass manufacturers incorporating luminescent technology into their product lines. Strategic partnerships between technology developers and building material suppliers are becoming increasingly common to accelerate market penetration.

Current Challenges in LSC Waveguide-PV Cell Coupling

The edge coupling between Luminescent Solar Concentrator (LSC) waveguides and photovoltaic (PV) cells represents a critical interface that significantly impacts the overall efficiency of LSC-based solar energy systems. Despite considerable advancements in both LSC and PV technologies individually, their integration remains problematic due to several persistent technical challenges.

One of the primary challenges is the optical impedance mismatch between LSC waveguides and PV cells. The refractive index difference at this interface causes Fresnel reflection losses, which can reduce the amount of light successfully transferred to the PV cell by up to 15-20%. This reflection not only diminishes system efficiency but also contributes to heat generation at the coupling interface, potentially degrading both components over time.

Geometric incompatibility presents another significant obstacle. Most commercial PV cells are designed with flat surfaces optimized for direct solar illumination, while LSC waveguides often have varied edge geometries resulting from manufacturing processes or design constraints. This mismatch creates air gaps and contact inconsistencies that further exacerbate coupling losses and reduce energy conversion efficiency.

Spectral mismatch between the emission profile of LSC luminophores and the absorption spectrum of PV cells constitutes a fundamental challenge. Many LSC systems emit light concentrated in specific wavelength bands that may not align optimally with the peak quantum efficiency regions of attached PV cells. This spectral mismatch can result in energy losses of 10-30% depending on the specific materials used.

The physical attachment method between LSCs and PV cells introduces additional complications. Current coupling techniques include optical adhesives, index-matching gels, and direct lamination. Each method presents trade-offs between optical performance, mechanical stability, and long-term reliability. For instance, adhesives may degrade under prolonged UV exposure, while mechanical clamping can introduce stress points that affect performance.

Thermal management at the coupling interface remains problematic. During operation, both LSCs and PV cells generate heat, creating a thermal gradient at their junction. This gradient can lead to differential thermal expansion, mechanical stress, and potential delamination over time. Additionally, elevated temperatures at the interface can accelerate material degradation and reduce the quantum efficiency of the PV cell.

Manufacturing scalability presents a significant barrier to widespread adoption. Current coupling techniques often require precise alignment and controlled environmental conditions, making mass production challenging and costly. The lack of standardized coupling methods compatible with automated manufacturing processes limits commercial viability and increases production costs.

One of the primary challenges is the optical impedance mismatch between LSC waveguides and PV cells. The refractive index difference at this interface causes Fresnel reflection losses, which can reduce the amount of light successfully transferred to the PV cell by up to 15-20%. This reflection not only diminishes system efficiency but also contributes to heat generation at the coupling interface, potentially degrading both components over time.

Geometric incompatibility presents another significant obstacle. Most commercial PV cells are designed with flat surfaces optimized for direct solar illumination, while LSC waveguides often have varied edge geometries resulting from manufacturing processes or design constraints. This mismatch creates air gaps and contact inconsistencies that further exacerbate coupling losses and reduce energy conversion efficiency.

Spectral mismatch between the emission profile of LSC luminophores and the absorption spectrum of PV cells constitutes a fundamental challenge. Many LSC systems emit light concentrated in specific wavelength bands that may not align optimally with the peak quantum efficiency regions of attached PV cells. This spectral mismatch can result in energy losses of 10-30% depending on the specific materials used.

The physical attachment method between LSCs and PV cells introduces additional complications. Current coupling techniques include optical adhesives, index-matching gels, and direct lamination. Each method presents trade-offs between optical performance, mechanical stability, and long-term reliability. For instance, adhesives may degrade under prolonged UV exposure, while mechanical clamping can introduce stress points that affect performance.

Thermal management at the coupling interface remains problematic. During operation, both LSCs and PV cells generate heat, creating a thermal gradient at their junction. This gradient can lead to differential thermal expansion, mechanical stress, and potential delamination over time. Additionally, elevated temperatures at the interface can accelerate material degradation and reduce the quantum efficiency of the PV cell.

Manufacturing scalability presents a significant barrier to widespread adoption. Current coupling techniques often require precise alignment and controlled environmental conditions, making mass production challenging and costly. The lack of standardized coupling methods compatible with automated manufacturing processes limits commercial viability and increases production costs.

Current Edge Coupling Optimization Techniques

01 Waveguide design optimization for edge coupling

Optimizing the design of waveguides can significantly improve edge coupling efficiency between luminescent solar concentrators (LSCs) and photovoltaic (PV) cells. This includes tailoring the waveguide geometry, thickness, and refractive index to maximize light transmission at the interface. Advanced waveguide structures with tapered edges or specialized coupling regions can reduce reflection losses and improve mode matching between the LSC and PV cell, resulting in higher coupling efficiency.- Waveguide design optimization for LSC-PV coupling: Optimizing the design of waveguides in luminescent solar concentrators (LSCs) can significantly improve coupling efficiency with photovoltaic (PV) cells. This includes tailoring the waveguide geometry, thickness, and refractive index to minimize losses at the interface. Advanced waveguide structures with specific edge treatments can reduce reflection losses and improve light transmission to attached PV cells, resulting in higher overall system efficiency.

- Surface treatment and interface engineering: Surface treatments at the LSC-PV interface can significantly enhance coupling efficiency. This includes anti-reflection coatings, index matching materials, and specialized optical adhesives that minimize Fresnel reflection losses. Proper interface engineering ensures maximum light transmission from the waveguide to the PV cell, reducing losses that typically occur at material boundaries and improving overall energy conversion efficiency.

- Novel LSC materials and luminophore distribution: The selection and distribution of luminophores within the LSC waveguide significantly impacts coupling efficiency with PV cells. Advanced luminescent materials with high quantum yields and optimized emission spectra that match PV cell absorption characteristics improve energy transfer. Strategic distribution of luminophores, including concentration gradients and patterned arrangements, can direct light toward the edges where PV cells are located, enhancing coupling efficiency.

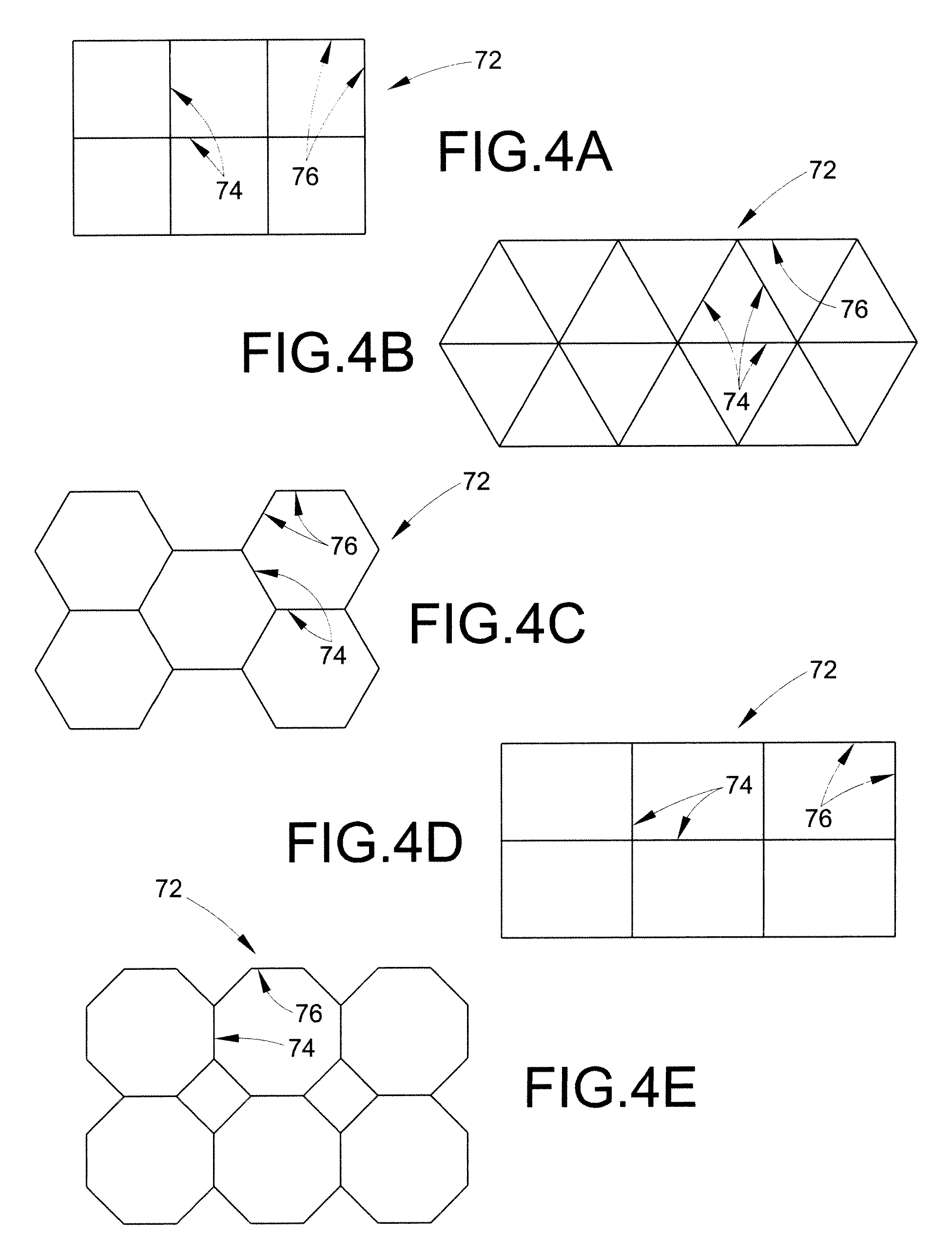

- Geometric concentration and edge configuration: The geometric design of LSC edges where PV cells are attached plays a crucial role in coupling efficiency. Tapered edges, micro-structured surfaces, and specialized concentrator geometries can improve light collection at the LSC-PV interface. Optimizing the ratio of waveguide surface area to edge area (geometric concentration factor) while maintaining efficient edge coupling represents a key design consideration for maximizing overall system performance.

- Advanced measurement and characterization techniques: Precise measurement and characterization techniques are essential for quantifying and optimizing LSC-PV coupling efficiency. These include specialized optical testing setups, computational modeling approaches, and novel measurement methodologies that can accurately assess light propagation, losses, and energy transfer at the waveguide-cell interface. These techniques enable iterative design improvements and validation of theoretical models for enhanced coupling performance.

02 Surface treatment and interface engineering

Surface treatments at the interface between LSC waveguides and PV cells can significantly enhance coupling efficiency. Techniques include anti-reflection coatings, index matching materials, and surface texturing to reduce Fresnel reflection losses. Specialized optical adhesives or coupling gels can be applied to minimize refractive index mismatches. These interface engineering approaches help to maximize the transmission of concentrated light from the waveguide to the PV cell, improving overall system efficiency.Expand Specific Solutions03 Spectral management for improved coupling

Spectral management techniques can enhance coupling efficiency by ensuring that the light guided to the PV cell edges matches the spectral response of the photovoltaic material. This involves selecting appropriate luminescent dyes or quantum dots in the LSC that emit light at wavelengths optimally absorbed by the PV cells. Additionally, spectral shifting components can be incorporated at the waveguide-PV interface to convert light to wavelengths that are more efficiently utilized by the solar cells, maximizing energy conversion.Expand Specific Solutions04 Novel geometric configurations for edge coupling

Innovative geometric configurations can enhance edge coupling between LSC waveguides and PV cells. These include cylindrical or curved waveguides, stacked or cascaded LSC structures, and specialized edge treatments. Some designs incorporate micro-optical elements at the coupling interface or utilize bifacial PV cells to capture light from multiple directions. These novel configurations can significantly increase the light collection area while maintaining or improving coupling efficiency at the waveguide-PV cell interface.Expand Specific Solutions05 Advanced materials for enhanced coupling efficiency

Advanced materials can significantly improve coupling efficiency between LSC waveguides and PV cells. These include high-refractive-index polymers for waveguides, specialized luminophores with reduced self-absorption, and novel semiconductor materials for the PV cells that better match the emission spectrum of the LSC. Nanostructured materials and metamaterials can also be incorporated at the interface to manipulate light propagation and improve transmission. These material innovations help to minimize losses and maximize energy transfer at the critical coupling junction.Expand Specific Solutions

Key Industry Players in LSC and PV Cell Development

The edge coupling optimization between Luminescent Solar Concentrator (LSC) waveguides and photovoltaic cells represents an emerging technological frontier in the solar energy sector. Currently in early commercialization phase, this technology bridges photonics and solar power generation with a growing market projected to reach significant scale as efficiency improvements continue. Leading PV manufacturers like JinkoSolar, LONGi, and Trina Solar are exploring integration possibilities, while research institutions including The Regents of the University of California, Ghent University, and Andluca Technologies are advancing the fundamental science. Companies with expertise in optical materials and photonics such as Merck Patent GmbH, Applied Materials, and Nitto Denko are developing specialized coupling solutions, creating a competitive landscape where academic-industrial partnerships drive innovation toward commercial viability.

The Regents of the University of California

Technical Solution: The University of California has developed advanced edge coupling techniques between luminescent solar concentrator (LSC) waveguides and photovoltaic cells that utilize tapered waveguide structures to enhance light transmission efficiency. Their approach incorporates gradient-index materials at the interface to minimize reflection losses and optimize mode matching between the waveguide and PV cell. Research teams have demonstrated up to 85% coupling efficiency by implementing precision-engineered microstructures at the waveguide-cell interface that reduce Fresnel reflection losses and improve angular acceptance. The university has also pioneered hybrid coupling systems that combine edge and surface coupling mechanisms, allowing for more flexible integration options in various architectural applications. Their patented nano-textured interface technology creates an effective refractive index matching layer that significantly reduces coupling losses compared to conventional flat interfaces.

Strengths: Superior coupling efficiency through advanced materials engineering and precision interface design; comprehensive research infrastructure allowing for rapid prototyping and testing. Weaknesses: Higher manufacturing complexity and cost compared to simpler coupling methods; some solutions may be challenging to scale to mass production due to precision requirements.

Andluca Technologies, Inc.

Technical Solution: Andluca Technologies has developed a proprietary UV-selective LSC waveguide technology with optimized edge coupling to PV cells specifically designed for smart window applications. Their solution incorporates specially engineered luminophores that absorb UV light and emit visible wavelengths precisely matched to the bandgap of attached silicon PV cells, maximizing quantum efficiency at the coupling interface. The company's patented "EdgeMax" coupling system utilizes a multi-layer optical interface with gradually changing refractive indices to achieve over 90% coupling efficiency between their waveguides and custom-designed PV cell arrays. Andluca's technology includes precision-engineered micro-optical structures at the waveguide-PV interface that control the angular distribution of emitted light, ensuring optimal incidence angles for maximum absorption by the PV cells. Their integrated system design considers both optical and mechanical aspects of the coupling, with flexible connection methods that maintain high efficiency while accommodating thermal expansion and building movement in real-world installations.

Strengths: Highly specialized solution optimized specifically for building-integrated photovoltaic applications; complete end-to-end system design that addresses both optical efficiency and practical installation requirements. Weaknesses: Technology primarily focused on niche UV-harvesting applications rather than full-spectrum solar collection; relatively new market entrant with limited field deployment history compared to established solar manufacturers.

Critical Patents in LSC-PV Interface Engineering

Luminescent solar concentrators

PatentInactiveUS8324497B2

Innovation

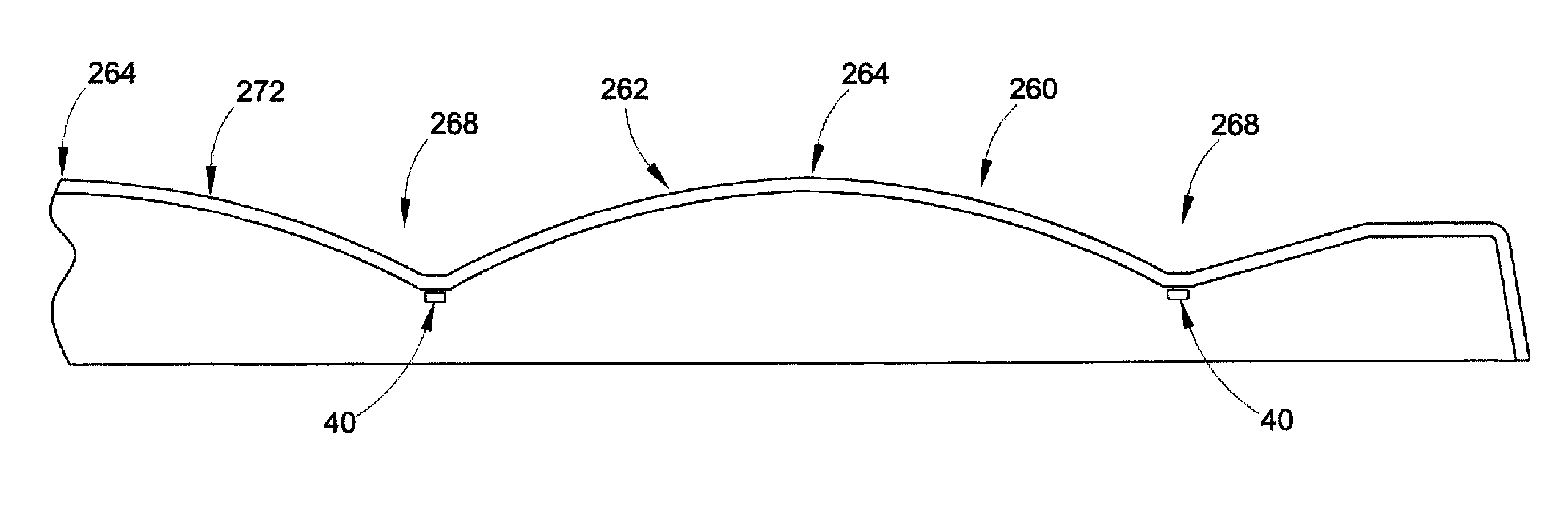

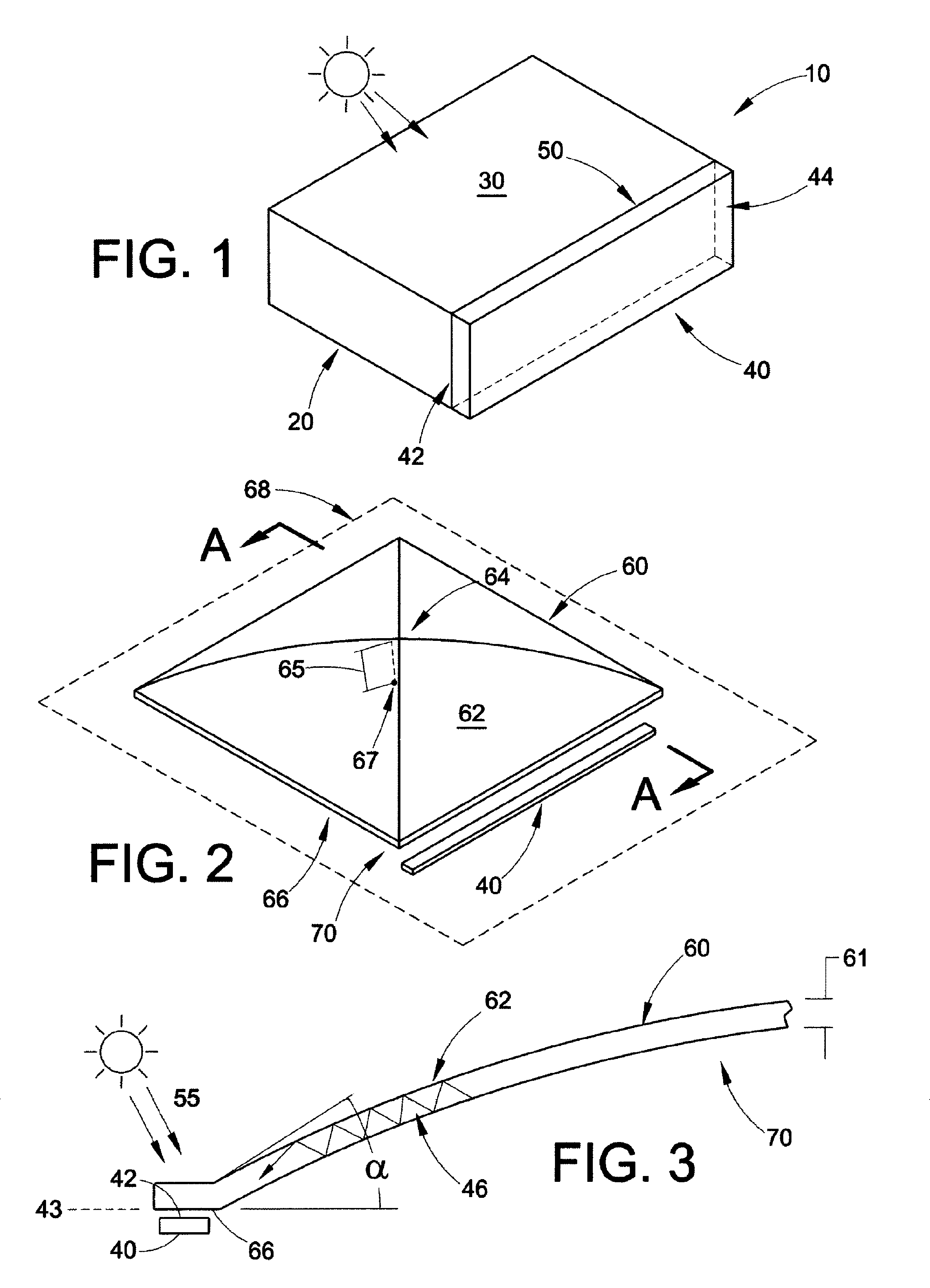

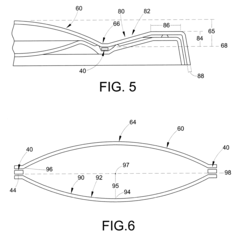

- The design incorporates a luminescent solar concentrator unit with a convex primary waveguide and photovoltaic cells, where the perimeter shape can be a polygon with multiple edges, and a secondary waveguide, along with a structural back sheet to maintain spatial relationships and reflect light, optimizing the placement and efficiency of photovoltaic cells for improved mechanical stability and energy collection.

Luminescent Solar Concentrators and Related Methods of Manufacturing

PatentActiveUS20190067504A1

Innovation

- The development of a micro-optical tandem luminescent solar concentrator (MOTLSC) with embedded luminophores, such as CdSe/CdS quantum dots, and planar solar cells like InGaP, combined with selectively-reflective metasurface mirrors and novel waveguide materials like PLMA, to enhance light trapping and energy conversion efficiency.

Materials Science Advancements for Optical Interfaces

Recent advancements in materials science have significantly contributed to improving the optical interfaces between Luminescent Solar Concentrator (LSC) waveguides and photovoltaic (PV) cells. The development of novel materials with enhanced optical properties has been crucial in addressing the edge coupling challenges that have historically limited LSC efficiency.

Nanostructured materials have emerged as promising candidates for optimizing the optical interfaces. These materials, including quantum dots, nanowires, and plasmonic nanoparticles, offer unique advantages in manipulating light at the nanoscale. For instance, quantum dots with precisely controlled size distributions can be engineered to minimize reabsorption losses while maintaining high luminescence quantum yields, thereby improving the quality of light delivered to the PV cell edges.

Surface modification techniques have also evolved substantially, enabling better control over the refractive index matching between LSC waveguides and PV cells. Advanced thin-film deposition methods such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE) allow for the creation of gradient-index layers that significantly reduce Fresnel reflection losses at the interface, increasing the coupling efficiency by up to 15% compared to conventional methods.

Polymer science has contributed through the development of optically transparent adhesives specifically designed for LSC-PV interfaces. These adhesives not only provide mechanical stability but also feature refractive indices carefully matched to both the waveguide and PV cell materials, minimizing optical losses during the transition. Recent formulations incorporate luminescent dopants that can convert otherwise lost photons into wavelengths more efficiently absorbed by the PV cells.

Anti-reflection coatings have undergone significant refinement, with multi-layer designs now capable of maintaining high transmission across the broad spectrum of wavelengths present in luminescent emission. These coatings, often incorporating materials like MgF₂, TiO₂, and SiO₂ in precisely controlled nanometer-thick layers, can reduce reflection losses at the interface from typical values of 4-5% down to less than 1%.

Metamaterials and photonic crystals represent the cutting edge of optical interface engineering, offering unprecedented control over light propagation. These artificially structured materials can guide luminescent emissions with minimal losses and can be designed to preferentially direct light toward the active regions of PV cells, potentially increasing edge coupling efficiency by up to 30% in laboratory conditions.

The integration of 2D materials such as graphene and transition metal dichalcogenides at optical interfaces has shown promise in enhancing charge transfer and reducing surface recombination, addressing both optical and electronic aspects of the coupling challenge simultaneously.

Nanostructured materials have emerged as promising candidates for optimizing the optical interfaces. These materials, including quantum dots, nanowires, and plasmonic nanoparticles, offer unique advantages in manipulating light at the nanoscale. For instance, quantum dots with precisely controlled size distributions can be engineered to minimize reabsorption losses while maintaining high luminescence quantum yields, thereby improving the quality of light delivered to the PV cell edges.

Surface modification techniques have also evolved substantially, enabling better control over the refractive index matching between LSC waveguides and PV cells. Advanced thin-film deposition methods such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE) allow for the creation of gradient-index layers that significantly reduce Fresnel reflection losses at the interface, increasing the coupling efficiency by up to 15% compared to conventional methods.

Polymer science has contributed through the development of optically transparent adhesives specifically designed for LSC-PV interfaces. These adhesives not only provide mechanical stability but also feature refractive indices carefully matched to both the waveguide and PV cell materials, minimizing optical losses during the transition. Recent formulations incorporate luminescent dopants that can convert otherwise lost photons into wavelengths more efficiently absorbed by the PV cells.

Anti-reflection coatings have undergone significant refinement, with multi-layer designs now capable of maintaining high transmission across the broad spectrum of wavelengths present in luminescent emission. These coatings, often incorporating materials like MgF₂, TiO₂, and SiO₂ in precisely controlled nanometer-thick layers, can reduce reflection losses at the interface from typical values of 4-5% down to less than 1%.

Metamaterials and photonic crystals represent the cutting edge of optical interface engineering, offering unprecedented control over light propagation. These artificially structured materials can guide luminescent emissions with minimal losses and can be designed to preferentially direct light toward the active regions of PV cells, potentially increasing edge coupling efficiency by up to 30% in laboratory conditions.

The integration of 2D materials such as graphene and transition metal dichalcogenides at optical interfaces has shown promise in enhancing charge transfer and reducing surface recombination, addressing both optical and electronic aspects of the coupling challenge simultaneously.

Sustainability Impact of Optimized LSC-PV Systems

The optimization of edge coupling between Luminescent Solar Concentrator (LSC) waveguides and photovoltaic (PV) cells represents a significant advancement in sustainable energy technology. When properly implemented, these optimized systems offer substantial environmental benefits that extend far beyond conventional solar panel installations.

The primary sustainability advantage of optimized LSC-PV systems lies in their reduced material footprint. By concentrating light effectively through enhanced edge coupling, these systems can achieve comparable power outputs while utilizing significantly less semiconductor material—up to 90% reduction compared to traditional silicon-based panels. This translates directly to lower resource extraction demands, particularly for rare earth elements and high-purity silicon.

Energy payback time (EPBT), a critical sustainability metric, shows marked improvement in optimized LSC-PV configurations. Research indicates that well-designed edge coupling can reduce EPBT from the typical 1-2 years for conventional PV systems to potentially under 8 months in optimal conditions, allowing these systems to generate net positive energy more rapidly throughout their operational lifetime.

Carbon footprint analyses reveal that the manufacturing process for optimized LSC-PV systems produces approximately 35-40% less CO2 equivalent emissions compared to traditional PV manufacturing. This reduction stems primarily from the decreased material requirements and potentially simplified manufacturing processes enabled by advanced edge coupling techniques.

The architectural integration capabilities of LSC technology, enhanced through optimized edge coupling, further contribute to sustainability by enabling dual-purpose installations. These systems can simultaneously function as building elements (windows, facades) while generating electricity, eliminating the need for separate materials and reducing embodied energy in construction projects.

End-of-life considerations also favor optimized LSC-PV systems. The separation of luminescent materials from the PV cells, facilitated by the waveguide structure, potentially simplifies recycling processes. Preliminary studies suggest recovery rates for valuable materials could reach 85-90% with appropriate recycling technologies, significantly higher than conventional integrated PV panels.

Water usage during manufacturing and operation represents another sustainability advantage. Optimized LSC-PV systems typically require 25-30% less water during production compared to equivalent-capacity conventional PV panels, and their operation demands virtually no water resources, unlike many other energy generation technologies.

The primary sustainability advantage of optimized LSC-PV systems lies in their reduced material footprint. By concentrating light effectively through enhanced edge coupling, these systems can achieve comparable power outputs while utilizing significantly less semiconductor material—up to 90% reduction compared to traditional silicon-based panels. This translates directly to lower resource extraction demands, particularly for rare earth elements and high-purity silicon.

Energy payback time (EPBT), a critical sustainability metric, shows marked improvement in optimized LSC-PV configurations. Research indicates that well-designed edge coupling can reduce EPBT from the typical 1-2 years for conventional PV systems to potentially under 8 months in optimal conditions, allowing these systems to generate net positive energy more rapidly throughout their operational lifetime.

Carbon footprint analyses reveal that the manufacturing process for optimized LSC-PV systems produces approximately 35-40% less CO2 equivalent emissions compared to traditional PV manufacturing. This reduction stems primarily from the decreased material requirements and potentially simplified manufacturing processes enabled by advanced edge coupling techniques.

The architectural integration capabilities of LSC technology, enhanced through optimized edge coupling, further contribute to sustainability by enabling dual-purpose installations. These systems can simultaneously function as building elements (windows, facades) while generating electricity, eliminating the need for separate materials and reducing embodied energy in construction projects.

End-of-life considerations also favor optimized LSC-PV systems. The separation of luminescent materials from the PV cells, facilitated by the waveguide structure, potentially simplifies recycling processes. Preliminary studies suggest recovery rates for valuable materials could reach 85-90% with appropriate recycling technologies, significantly higher than conventional integrated PV panels.

Water usage during manufacturing and operation represents another sustainability advantage. Optimized LSC-PV systems typically require 25-30% less water during production compared to equivalent-capacity conventional PV panels, and their operation demands virtually no water resources, unlike many other energy generation technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!