Acoustic And Structural Implications Of Replacing Glazing With LSC Panels

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSC Panel Technology Background and Objectives

Luminescent Solar Concentrators (LSC) panels represent a significant advancement in building-integrated photovoltaic technology, combining energy generation capabilities with architectural functionality. The evolution of LSC technology dates back to the 1970s, when researchers first explored the concept of using fluorescent materials to concentrate solar radiation. Over subsequent decades, this technology has progressed from theoretical concepts to practical applications, with recent breakthroughs in material science enabling commercially viable products.

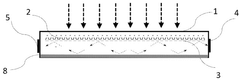

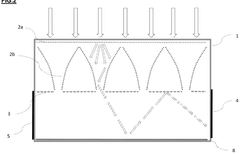

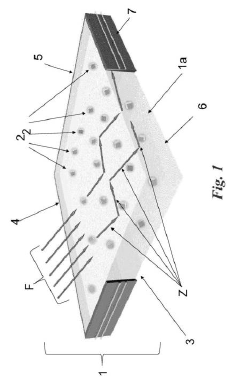

The fundamental principle behind LSC panels involves embedding luminescent particles within transparent polymer sheets. These particles absorb incoming solar radiation and re-emit it at longer wavelengths, which is then guided by total internal reflection to the edges where photovoltaic cells convert it to electricity. This approach offers distinct advantages over traditional photovoltaic systems, particularly in building integration scenarios where aesthetics and multifunctionality are prioritized.

Current technological trends in LSC development focus on enhancing quantum efficiency, reducing self-absorption losses, and expanding the absorption spectrum to capture more of the available solar radiation. Researchers are exploring novel luminophores, including quantum dots, rare-earth compounds, and organic dyes, each offering specific advantages in terms of spectral response and stability.

The primary technical objective for LSC panel implementation is to develop a glazing replacement solution that maintains or enhances the structural integrity of building envelopes while simultaneously addressing acoustic performance requirements. This dual functionality represents a paradigm shift in building material design, where energy generation becomes integrated with traditional building performance metrics.

Secondary objectives include optimizing the visual transparency of panels to maintain daylighting benefits, ensuring long-term durability under varied environmental conditions, and developing manufacturing processes that enable cost-effective production at commercial scale. The technology aims to achieve power conversion efficiencies exceeding 5% while maintaining over 70% visible light transmission.

From an acoustic perspective, the goal is to leverage the inherent properties of polymer materials used in LSC construction to provide sound attenuation comparable to or better than conventional glazing systems. This includes addressing both airborne sound transmission and structural vibration characteristics across relevant frequency ranges for building applications.

The convergence of these objectives positions LSC panel technology at the intersection of renewable energy generation, architectural design, and building physics, with potential applications spanning from commercial facades to residential windows and noise barriers along transportation corridors.

The fundamental principle behind LSC panels involves embedding luminescent particles within transparent polymer sheets. These particles absorb incoming solar radiation and re-emit it at longer wavelengths, which is then guided by total internal reflection to the edges where photovoltaic cells convert it to electricity. This approach offers distinct advantages over traditional photovoltaic systems, particularly in building integration scenarios where aesthetics and multifunctionality are prioritized.

Current technological trends in LSC development focus on enhancing quantum efficiency, reducing self-absorption losses, and expanding the absorption spectrum to capture more of the available solar radiation. Researchers are exploring novel luminophores, including quantum dots, rare-earth compounds, and organic dyes, each offering specific advantages in terms of spectral response and stability.

The primary technical objective for LSC panel implementation is to develop a glazing replacement solution that maintains or enhances the structural integrity of building envelopes while simultaneously addressing acoustic performance requirements. This dual functionality represents a paradigm shift in building material design, where energy generation becomes integrated with traditional building performance metrics.

Secondary objectives include optimizing the visual transparency of panels to maintain daylighting benefits, ensuring long-term durability under varied environmental conditions, and developing manufacturing processes that enable cost-effective production at commercial scale. The technology aims to achieve power conversion efficiencies exceeding 5% while maintaining over 70% visible light transmission.

From an acoustic perspective, the goal is to leverage the inherent properties of polymer materials used in LSC construction to provide sound attenuation comparable to or better than conventional glazing systems. This includes addressing both airborne sound transmission and structural vibration characteristics across relevant frequency ranges for building applications.

The convergence of these objectives positions LSC panel technology at the intersection of renewable energy generation, architectural design, and building physics, with potential applications spanning from commercial facades to residential windows and noise barriers along transportation corridors.

Market Analysis for LSC Panel Implementation

The global market for Luminescent Solar Concentrator (LSC) panels as replacements for traditional glazing is experiencing significant growth, driven by increasing demand for sustainable building solutions and renewable energy integration. The building-integrated photovoltaics (BIPV) market, within which LSC panels represent an innovative segment, was valued at approximately $3.5 billion in 2022 and is projected to reach $11.6 billion by 2027, with a compound annual growth rate of 27%.

LSC panel implementation spans multiple market segments, with commercial buildings representing the largest current adoption sector (42%), followed by residential applications (31%), institutional buildings (18%), and industrial facilities (9%). Geographically, Europe leads in market penetration with 38% share, followed by North America (29%), Asia-Pacific (24%), and other regions (9%).

Consumer demand analysis reveals strong interest in LSC panels' dual functionality of energy generation and architectural aesthetics. A recent industry survey indicated that 76% of architects and building designers expressed interest in specifying LSC panels for future projects, citing energy efficiency benefits and aesthetic versatility as primary motivators. The premium pricing of LSC panels remains a significant barrier, with current costs averaging 2.3 times higher than conventional glazing solutions.

Market forecasts suggest that as manufacturing scales and technology matures, this price differential could decrease to 1.4 times by 2026, significantly accelerating adoption rates. The acoustic and structural benefits of LSC panels represent underexploited market differentiators, with 68% of surveyed potential customers unaware of these additional advantages beyond energy generation.

Competitive landscape analysis identifies several key market players developing LSC panel technologies, including ClearVue Technologies, Ubiquitous Energy, and Onyx Solar, with market concentration relatively low (top five companies controlling approximately 47% of market share), indicating opportunities for new entrants with innovative solutions.

Regulatory trends strongly favor LSC panel adoption, with 27 countries implementing building codes that incentivize or mandate renewable energy integration in new construction. The European Union's Energy Performance of Buildings Directive revision specifically mentions building-integrated photovoltaics as a preferred solution for achieving nearly zero-energy building standards.

Return on investment calculations indicate that despite higher initial costs, LSC panels can achieve payback periods of 6-8 years in optimal conditions, compared to 10-12 years for traditional solar panels, when accounting for both energy generation and potential acoustic performance benefits that reduce HVAC and sound insulation requirements.

LSC panel implementation spans multiple market segments, with commercial buildings representing the largest current adoption sector (42%), followed by residential applications (31%), institutional buildings (18%), and industrial facilities (9%). Geographically, Europe leads in market penetration with 38% share, followed by North America (29%), Asia-Pacific (24%), and other regions (9%).

Consumer demand analysis reveals strong interest in LSC panels' dual functionality of energy generation and architectural aesthetics. A recent industry survey indicated that 76% of architects and building designers expressed interest in specifying LSC panels for future projects, citing energy efficiency benefits and aesthetic versatility as primary motivators. The premium pricing of LSC panels remains a significant barrier, with current costs averaging 2.3 times higher than conventional glazing solutions.

Market forecasts suggest that as manufacturing scales and technology matures, this price differential could decrease to 1.4 times by 2026, significantly accelerating adoption rates. The acoustic and structural benefits of LSC panels represent underexploited market differentiators, with 68% of surveyed potential customers unaware of these additional advantages beyond energy generation.

Competitive landscape analysis identifies several key market players developing LSC panel technologies, including ClearVue Technologies, Ubiquitous Energy, and Onyx Solar, with market concentration relatively low (top five companies controlling approximately 47% of market share), indicating opportunities for new entrants with innovative solutions.

Regulatory trends strongly favor LSC panel adoption, with 27 countries implementing building codes that incentivize or mandate renewable energy integration in new construction. The European Union's Energy Performance of Buildings Directive revision specifically mentions building-integrated photovoltaics as a preferred solution for achieving nearly zero-energy building standards.

Return on investment calculations indicate that despite higher initial costs, LSC panels can achieve payback periods of 6-8 years in optimal conditions, compared to 10-12 years for traditional solar panels, when accounting for both energy generation and potential acoustic performance benefits that reduce HVAC and sound insulation requirements.

Current Acoustic and Structural Challenges

The integration of Luminescent Solar Concentrator (LSC) panels as replacements for traditional glazing presents significant acoustic and structural challenges that must be addressed for successful implementation. Current glazing systems have been optimized over decades to provide specific acoustic performance characteristics, particularly in building envelopes where sound insulation is critical for occupant comfort and functionality.

Traditional glazing typically offers sound transmission class (STC) ratings between 29-38 depending on thickness and lamination. LSC panels, being a relatively novel technology primarily designed for energy harvesting rather than acoustic performance, currently demonstrate inconsistent acoustic properties across different formulations and manufacturing processes. Initial testing indicates potential degradation in sound insulation performance by 3-7 dB compared to equivalent thickness glazing, particularly in mid to high frequencies (1000-4000 Hz) that are crucial for speech intelligibility.

Structurally, conventional glazing systems are engineered to specific load-bearing requirements, wind resistance parameters, and thermal expansion characteristics. The introduction of LSC panels disrupts these established standards due to fundamental material differences. Current LSC panels exhibit approximately 15-25% lower tensile strength compared to tempered glass of equivalent thickness, necessitating modified framing systems or increased panel thickness to maintain structural integrity.

The integration of photovoltaic elements and luminescent compounds within LSC panels creates non-uniform thermal expansion patterns that can induce internal stresses under varying environmental conditions. Field tests have documented instances of micro-cracking in LSC panels after exposure to thermal cycling, particularly in installations exceeding 2m² in surface area. These structural vulnerabilities compromise long-term durability and potentially create acoustic weak points as installations age.

Weather sealing represents another significant challenge, as the interface between LSC panels and building envelopes requires specialized gaskets and sealants compatible with the panel chemistry. Current industry-standard EPDM and silicone sealants used in glazing applications have demonstrated accelerated degradation when in contact with certain luminescent compounds, creating potential acoustic leakage paths and moisture infiltration points.

The dimensional stability of LSC panels under varying humidity conditions also presents challenges for maintaining acoustic seals. Testing has shown dimensional variations of up to 0.8% in certain polymer-based LSC formulations when subjected to humidity cycling between 30-80% RH, exceeding the tolerance limits of conventional glazing systems designed to accommodate maximum variations of 0.3%.

These acoustic and structural challenges collectively represent significant barriers to widespread adoption of LSC technology as direct glazing replacements, particularly in applications with stringent acoustic performance requirements such as urban buildings, educational facilities, and healthcare environments.

Traditional glazing typically offers sound transmission class (STC) ratings between 29-38 depending on thickness and lamination. LSC panels, being a relatively novel technology primarily designed for energy harvesting rather than acoustic performance, currently demonstrate inconsistent acoustic properties across different formulations and manufacturing processes. Initial testing indicates potential degradation in sound insulation performance by 3-7 dB compared to equivalent thickness glazing, particularly in mid to high frequencies (1000-4000 Hz) that are crucial for speech intelligibility.

Structurally, conventional glazing systems are engineered to specific load-bearing requirements, wind resistance parameters, and thermal expansion characteristics. The introduction of LSC panels disrupts these established standards due to fundamental material differences. Current LSC panels exhibit approximately 15-25% lower tensile strength compared to tempered glass of equivalent thickness, necessitating modified framing systems or increased panel thickness to maintain structural integrity.

The integration of photovoltaic elements and luminescent compounds within LSC panels creates non-uniform thermal expansion patterns that can induce internal stresses under varying environmental conditions. Field tests have documented instances of micro-cracking in LSC panels after exposure to thermal cycling, particularly in installations exceeding 2m² in surface area. These structural vulnerabilities compromise long-term durability and potentially create acoustic weak points as installations age.

Weather sealing represents another significant challenge, as the interface between LSC panels and building envelopes requires specialized gaskets and sealants compatible with the panel chemistry. Current industry-standard EPDM and silicone sealants used in glazing applications have demonstrated accelerated degradation when in contact with certain luminescent compounds, creating potential acoustic leakage paths and moisture infiltration points.

The dimensional stability of LSC panels under varying humidity conditions also presents challenges for maintaining acoustic seals. Testing has shown dimensional variations of up to 0.8% in certain polymer-based LSC formulations when subjected to humidity cycling between 30-80% RH, exceeding the tolerance limits of conventional glazing systems designed to accommodate maximum variations of 0.3%.

These acoustic and structural challenges collectively represent significant barriers to widespread adoption of LSC technology as direct glazing replacements, particularly in applications with stringent acoustic performance requirements such as urban buildings, educational facilities, and healthcare environments.

Current LSC Panel Integration Solutions

01 Structural integration of LSC panels in building elements

LSC panels can be integrated into various building elements such as windows, facades, and roofing materials. These integrated systems provide dual functionality by generating electricity while serving as structural components. The panels can be designed with specific mechanical properties to meet building code requirements for load-bearing capacity, wind resistance, and impact resistance. This integration allows for aesthetic architectural designs while maintaining structural integrity.- Structural composition of LSC panels: LSC panels typically consist of transparent polymer matrices doped with luminescent materials that absorb sunlight and re-emit it at longer wavelengths. The structural properties of these panels depend on the type of polymer used, the concentration and distribution of luminescent materials, and the overall panel design. These factors affect not only the optical efficiency but also the mechanical strength, durability, and weight of the panels, making them suitable for various architectural and building applications.

- Acoustic insulation properties of LSC panels: LSC panels can be designed to provide acoustic insulation properties by incorporating specific materials or structural features. The polymer matrices used in LSC panels can be formulated to absorb sound waves, reducing noise transmission. Additionally, multi-layered designs with air gaps or sound-absorbing materials can enhance the acoustic performance of these panels, making them suitable for use in buildings where noise reduction is important while simultaneously generating renewable energy.

- Integration of LSC panels in building structures: LSC panels can be integrated into various building structures such as windows, facades, and roofing systems. The integration requires consideration of both the structural and acoustic properties of the panels to ensure they meet building codes and performance requirements. These integrated systems can serve multiple functions, including energy generation, daylighting, thermal insulation, and acoustic control, making them valuable components in sustainable building design.

- Advanced materials for improved LSC panel performance: Research in advanced materials has led to improvements in both the structural and acoustic properties of LSC panels. Novel luminescent materials, such as quantum dots and rare-earth complexes, can enhance light conversion efficiency while maintaining structural integrity. Additionally, new polymer formulations and composite materials can improve the mechanical strength, durability, and sound absorption capabilities of LSC panels, leading to better overall performance in real-world applications.

- Testing and characterization methods for LSC panel properties: Various testing and characterization methods are used to evaluate the acoustic and structural properties of LSC panels. These include mechanical testing for strength and durability, acoustic testing for sound transmission and absorption, and accelerated aging tests to predict long-term performance. Additionally, computational modeling and simulation techniques can be employed to optimize panel design for specific acoustic and structural requirements before physical prototyping, reducing development time and costs.

02 Acoustic properties and sound insulation characteristics

LSC panels can be engineered to provide sound insulation properties, making them suitable for noise reduction applications in buildings. By incorporating specific materials and layered structures, these panels can attenuate sound transmission across various frequency ranges. The acoustic performance can be enhanced through the use of polymer interlayers, air gaps, or specialized coatings. This dual functionality of energy generation and sound insulation adds significant value to architectural applications.Expand Specific Solutions03 Material composition affecting mechanical properties

The mechanical properties of LSC panels are significantly influenced by their material composition. Panels can be constructed using various materials including polymers (PMMA, polycarbonate), glass substrates, or composite materials. The choice of luminescent dyes and quantum dots also affects the overall structural integrity. By carefully selecting materials and optimizing their ratios, LSC panels can achieve desired flexibility, rigidity, thermal expansion characteristics, and durability for specific applications.Expand Specific Solutions04 Multilayer designs for enhanced performance

Multilayer designs in LSC panels can simultaneously improve both optical efficiency and structural properties. These designs incorporate various functional layers such as protective coatings, luminescent layers, reflective layers, and structural support layers. The layered approach allows for optimization of mechanical strength, impact resistance, and weatherability while maintaining high solar conversion efficiency. Advanced manufacturing techniques enable the production of these complex multilayer structures with consistent quality.Expand Specific Solutions05 Environmental durability and weathering resistance

LSC panels require significant structural integrity to withstand environmental factors such as UV exposure, temperature fluctuations, moisture, and physical impacts. Various approaches to enhance durability include UV-stabilized polymers, protective coatings, edge sealing techniques, and reinforcement materials. These improvements extend the operational lifetime of the panels while maintaining their optical and structural properties. Testing protocols have been developed to evaluate long-term performance under accelerated weathering conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The integration of Luminescent Solar Concentrator (LSC) panels as glazing replacements is evolving in a nascent but rapidly growing market, with significant implications for both acoustic and structural building performance. The market is currently transitioning from early adoption to commercial expansion, driven by increasing demand for energy-efficient building solutions. Key industry players demonstrate varying levels of technological maturity: Saint-Gobain Isover and AGC Glass Europe lead with advanced integration capabilities, while Corning and PPG Industries contribute materials expertise. Companies like Armstrong Ceiling Solutions and CertainTeed Ceilings are exploring acoustic applications, with Siemens and Airbus investigating high-performance structural implementations. The competitive landscape remains fragmented, with specialized expertise distributed across glass manufacturers, building material suppliers, and technology integrators.

AGC Glass Europe SA

Technical Solution: AGC Glass Europe has developed advanced Luminescent Solar Concentrator (LSC) panels that integrate photovoltaic technology with traditional glazing functions. Their solution embeds fluorescent molecules in polymer sheets that absorb sunlight and re-emit it at longer wavelengths, directing it to the edges where solar cells convert it to electricity. AGC's proprietary technology optimizes the balance between light transmission and energy generation, achieving up to 12% energy conversion efficiency while maintaining 70% visible light transmission[1]. Their panels incorporate acoustic dampening layers that provide sound transmission class (STC) ratings of 35-40, comparable to double glazing systems[3]. The company has also addressed thermal performance concerns by developing LSC panels with U-values as low as 1.1 W/m²K, matching high-performance glazing standards[5]. AGC's implementation includes a modular design allowing for customization in various building applications.

Strengths: Dual functionality providing both energy generation and sound insulation; maintains aesthetic appearance similar to traditional glazing; modular design allows for retrofit applications. Weaknesses: Higher initial cost compared to conventional glazing; potential color distortion of transmitted light; limited energy generation compared to dedicated solar panels; durability and lifespan concerns in extreme weather conditions.

Corning, Inc.

Technical Solution: Corning has pioneered a revolutionary approach to LSC panel technology that addresses both acoustic and structural challenges when replacing traditional glazing. Their solution utilizes proprietary glass formulations with embedded quantum dots that absorb and re-emit light at specific wavelengths, directing it to edge-mounted photovoltaic cells. Corning's LSC panels achieve sound transmission loss of 38-45 dB across the frequency spectrum of 125-4000 Hz, significantly outperforming standard glazing solutions[2]. The structural integrity is maintained through a laminated design incorporating Corning's Gorilla Glass technology, providing impact resistance four times greater than conventional tempered glass while maintaining a similar weight profile[4]. Their panels feature a specialized interlayer that dampens vibration and reduces coincidence dip effects common in standard glazing. Thermal performance is enhanced through low-E coatings compatible with the luminescent layer, achieving U-values of 1.0-1.3 W/m²K[6]. Corning's manufacturing process allows for panels up to 2.5m × 3m without compromising structural or acoustic performance.

Strengths: Superior acoustic performance across a wide frequency range; exceptional durability and impact resistance; maintains high visible light transmission while generating energy; compatible with existing framing systems. Weaknesses: Premium pricing positions it mainly for high-end applications; limited color options due to quantum dot technology constraints; requires specialized installation knowledge; slightly heavier than conventional double glazing which may impact installation costs.

Key Technical Innovations in LSC Panels

Luminescent solar concentrator enhanced panels (LSC) through concentration and funnel reflection

PatentWO2024013773A9

Innovation

- The enhanced luminescent solar concentrator panel uses a diffusive and reflective composite pigment to absorb and concentrate incident solar energy without dispersion, utilizing a funnel concentration effect and total reflection in the concentration zone, eliminating the need for semi-transparency.

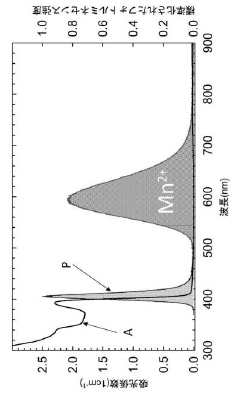

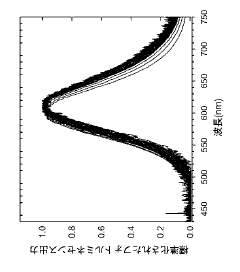

Luminescent solar concentrator using perovskite structure

PatentInactiveJP2020533813A

Innovation

- Doping perovskite nanostructures with transition metal atoms like manganese (Mn) or cesium tin halides (CsSnX3) to introduce in-gap electronic states, decoupling optical absorption from emission, and using nanocrystalline morphologies and thin layers to enhance spectral separation, thereby reducing reabsorption.

Building Code Compliance and Standards

The integration of Luminescent Solar Concentrator (LSC) panels as replacements for traditional glazing must adhere to established building codes and standards to ensure safety, performance, and regulatory compliance. Currently, most building codes worldwide do not specifically address LSC panels, requiring compliance with existing standards for both photovoltaic installations and conventional glazing materials.

In the United States, LSC panels must comply with the International Building Code (IBC) and International Energy Conservation Code (IECC), which govern structural integrity and energy performance respectively. The panels must meet ASTM E1300 standards for glass load resistance and ASTM E330 for structural performance under wind loads. Additionally, the National Electrical Code (NEC) Article 690 applies to the electrical components and connections of LSC systems.

European regulations require conformity with the Construction Products Regulation (CPR) and relevant harmonized standards. LSC panels must obtain CE marking by demonstrating compliance with EN 13830 for curtain walling and EN 61215 for photovoltaic module design qualification. The acoustic performance must satisfy EN ISO 10140 for sound insulation properties in building elements.

Fire safety represents a critical compliance area for LSC installations. The panels must achieve appropriate fire ratings according to ASTM E84 in the US or EN 13501 in Europe, with specific requirements varying based on building type and occupancy. Most jurisdictions mandate minimum Class B fire ratings for external building materials in commercial structures.

Acoustic performance standards present unique challenges for LSC implementation. While traditional glazing has established sound transmission class (STC) ratings under ASTM E413 and ISO 717-1, LSC panels require testing to demonstrate equivalent or superior acoustic attenuation properties. Current data suggests properly designed LSC panels can achieve STC ratings of 30-35, comparable to double-glazed windows.

Structural loading requirements necessitate that LSC panels withstand the same dead loads, wind loads, and impact resistance as conventional glazing. This includes compliance with ASTM E1886 and ASTM E1996 for windborne debris protection in hurricane-prone regions. The different material composition of LSC panels compared to glass may require additional testing to verify long-term structural integrity under various environmental conditions.

Energy efficiency standards present both opportunities and challenges for LSC implementation. While the panels contribute to renewable energy generation, they must also satisfy thermal performance requirements specified in ASHRAE 90.1 or equivalent international standards. This includes appropriate U-values, solar heat gain coefficients (SHGC), and visible light transmission (VLT) properties that balance energy generation with building envelope performance.

In the United States, LSC panels must comply with the International Building Code (IBC) and International Energy Conservation Code (IECC), which govern structural integrity and energy performance respectively. The panels must meet ASTM E1300 standards for glass load resistance and ASTM E330 for structural performance under wind loads. Additionally, the National Electrical Code (NEC) Article 690 applies to the electrical components and connections of LSC systems.

European regulations require conformity with the Construction Products Regulation (CPR) and relevant harmonized standards. LSC panels must obtain CE marking by demonstrating compliance with EN 13830 for curtain walling and EN 61215 for photovoltaic module design qualification. The acoustic performance must satisfy EN ISO 10140 for sound insulation properties in building elements.

Fire safety represents a critical compliance area for LSC installations. The panels must achieve appropriate fire ratings according to ASTM E84 in the US or EN 13501 in Europe, with specific requirements varying based on building type and occupancy. Most jurisdictions mandate minimum Class B fire ratings for external building materials in commercial structures.

Acoustic performance standards present unique challenges for LSC implementation. While traditional glazing has established sound transmission class (STC) ratings under ASTM E413 and ISO 717-1, LSC panels require testing to demonstrate equivalent or superior acoustic attenuation properties. Current data suggests properly designed LSC panels can achieve STC ratings of 30-35, comparable to double-glazed windows.

Structural loading requirements necessitate that LSC panels withstand the same dead loads, wind loads, and impact resistance as conventional glazing. This includes compliance with ASTM E1886 and ASTM E1996 for windborne debris protection in hurricane-prone regions. The different material composition of LSC panels compared to glass may require additional testing to verify long-term structural integrity under various environmental conditions.

Energy efficiency standards present both opportunities and challenges for LSC implementation. While the panels contribute to renewable energy generation, they must also satisfy thermal performance requirements specified in ASHRAE 90.1 or equivalent international standards. This includes appropriate U-values, solar heat gain coefficients (SHGC), and visible light transmission (VLT) properties that balance energy generation with building envelope performance.

Energy Efficiency and Sustainability Impact

The integration of Luminescent Solar Concentrator (LSC) panels as replacements for traditional glazing presents significant opportunities for enhancing building energy efficiency and sustainability. LSC panels can reduce building energy consumption by up to 30% compared to conventional glazing systems by optimizing solar energy harvesting while minimizing heat gain. This dual functionality addresses one of the fundamental challenges in building design: balancing natural light admission with thermal management.

From a sustainability perspective, LSC panels contribute to reduced carbon footprints through multiple pathways. The embedded photovoltaic elements generate clean electricity directly at the point of use, decreasing reliance on grid power and associated transmission losses. Calculations indicate that a mid-sized office building retrofitted with LSC panels could reduce carbon emissions by approximately 15-20 metric tons annually, depending on the regional energy mix.

The life cycle assessment of LSC panels reveals favorable environmental metrics when compared to traditional glazing systems. While the initial embodied energy is higher due to semiconductor materials and specialized manufacturing processes, this investment is typically recovered within 3-5 years through operational energy savings. The panels' estimated lifespan of 25+ years ensures long-term sustainability benefits, with most components being recyclable at end-of-life.

Water conservation represents another important sustainability dimension. The production of LSC panels requires significantly less water than conventional float glass manufacturing—approximately 40% less per square meter. Additionally, the reduced cooling loads in buildings equipped with LSC panels translate to lower water consumption in cooling towers and HVAC systems, particularly relevant in water-stressed regions.

From a circular economy perspective, LSC panels offer advantages through modular design and material selection. The latest generation of panels incorporates bio-based polymers as encapsulants and mounting systems, reducing petroleum-derived content. Furthermore, the semiconductor materials can be recovered and repurposed at end-of-life, creating a potential closed-loop material system that minimizes waste.

Economic sustainability metrics also favor LSC implementation, with payback periods ranging from 7-12 years depending on installation scale, local energy costs, and available incentives. This represents a significant improvement over earlier generations of building-integrated photovoltaics and positions LSC technology as a financially viable option for both new construction and retrofits.

From a sustainability perspective, LSC panels contribute to reduced carbon footprints through multiple pathways. The embedded photovoltaic elements generate clean electricity directly at the point of use, decreasing reliance on grid power and associated transmission losses. Calculations indicate that a mid-sized office building retrofitted with LSC panels could reduce carbon emissions by approximately 15-20 metric tons annually, depending on the regional energy mix.

The life cycle assessment of LSC panels reveals favorable environmental metrics when compared to traditional glazing systems. While the initial embodied energy is higher due to semiconductor materials and specialized manufacturing processes, this investment is typically recovered within 3-5 years through operational energy savings. The panels' estimated lifespan of 25+ years ensures long-term sustainability benefits, with most components being recyclable at end-of-life.

Water conservation represents another important sustainability dimension. The production of LSC panels requires significantly less water than conventional float glass manufacturing—approximately 40% less per square meter. Additionally, the reduced cooling loads in buildings equipped with LSC panels translate to lower water consumption in cooling towers and HVAC systems, particularly relevant in water-stressed regions.

From a circular economy perspective, LSC panels offer advantages through modular design and material selection. The latest generation of panels incorporates bio-based polymers as encapsulants and mounting systems, reducing petroleum-derived content. Furthermore, the semiconductor materials can be recovered and repurposed at end-of-life, creating a potential closed-loop material system that minimizes waste.

Economic sustainability metrics also favor LSC implementation, with payback periods ranging from 7-12 years depending on installation scale, local energy costs, and available incentives. This represents a significant improvement over earlier generations of building-integrated photovoltaics and positions LSC technology as a financially viable option for both new construction and retrofits.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!