Transparent Electrode Choices For LSC Edge Photovoltaics

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSC Edge PV Electrode Technology Background and Objectives

Luminescent Solar Concentrators (LSCs) have emerged as a promising technology in the field of photovoltaics since their introduction in the late 1970s. These devices utilize fluorescent materials to absorb sunlight and re-emit it at longer wavelengths, concentrating the light towards the edges where photovoltaic cells convert it to electricity. The evolution of LSC technology has been marked by significant improvements in materials science, particularly in the development of luminescent materials and transparent electrodes.

The transparent electrode component represents a critical element in LSC edge photovoltaics, serving as the conductive pathway while maintaining optical transparency to maximize light collection efficiency. Historically, indium tin oxide (ITO) has dominated this application due to its excellent balance of conductivity and transparency. However, the scarcity and rising cost of indium have driven research toward alternative materials.

The technological trajectory of transparent electrodes for LSCs has evolved from traditional metal oxides to more advanced materials including carbon-based electrodes (graphene, carbon nanotubes), metal nanowires (silver, copper), and conductive polymers (PEDOT:PSS). Each generation has addressed specific limitations of its predecessors while introducing new capabilities and challenges.

Current research objectives in this field focus on developing transparent electrode materials that optimize the balance between optical transparency, electrical conductivity, mechanical flexibility, and cost-effectiveness. The ideal electrode should maintain high transparency in the absorption spectrum of the luminescent materials while providing efficient charge collection at the LSC edges.

A significant trend in this technology domain is the move toward flexible and conformable LSC devices, which requires electrodes that can withstand mechanical deformation without performance degradation. This has accelerated research into nanomaterial-based electrodes that offer inherent flexibility alongside their electrical properties.

Another key objective is enhancing the environmental stability of transparent electrodes, as many current solutions suffer from degradation when exposed to moisture, oxygen, or UV radiation. This is particularly crucial for LSC applications, which are designed for long-term outdoor deployment.

The integration of transparent electrodes with LSC systems also aims to address manufacturing scalability, as commercial viability depends on cost-effective production methods. Research is increasingly focused on solution-processable electrode materials that can be applied using roll-to-roll or printing techniques, significantly reducing manufacturing costs compared to vacuum deposition methods traditionally used for ITO.

The transparent electrode component represents a critical element in LSC edge photovoltaics, serving as the conductive pathway while maintaining optical transparency to maximize light collection efficiency. Historically, indium tin oxide (ITO) has dominated this application due to its excellent balance of conductivity and transparency. However, the scarcity and rising cost of indium have driven research toward alternative materials.

The technological trajectory of transparent electrodes for LSCs has evolved from traditional metal oxides to more advanced materials including carbon-based electrodes (graphene, carbon nanotubes), metal nanowires (silver, copper), and conductive polymers (PEDOT:PSS). Each generation has addressed specific limitations of its predecessors while introducing new capabilities and challenges.

Current research objectives in this field focus on developing transparent electrode materials that optimize the balance between optical transparency, electrical conductivity, mechanical flexibility, and cost-effectiveness. The ideal electrode should maintain high transparency in the absorption spectrum of the luminescent materials while providing efficient charge collection at the LSC edges.

A significant trend in this technology domain is the move toward flexible and conformable LSC devices, which requires electrodes that can withstand mechanical deformation without performance degradation. This has accelerated research into nanomaterial-based electrodes that offer inherent flexibility alongside their electrical properties.

Another key objective is enhancing the environmental stability of transparent electrodes, as many current solutions suffer from degradation when exposed to moisture, oxygen, or UV radiation. This is particularly crucial for LSC applications, which are designed for long-term outdoor deployment.

The integration of transparent electrodes with LSC systems also aims to address manufacturing scalability, as commercial viability depends on cost-effective production methods. Research is increasingly focused on solution-processable electrode materials that can be applied using roll-to-roll or printing techniques, significantly reducing manufacturing costs compared to vacuum deposition methods traditionally used for ITO.

Market Analysis for Transparent Electrode Applications

The transparent electrode market for LSC (Luminescent Solar Concentrator) edge photovoltaics is experiencing significant growth, driven by the increasing demand for building-integrated photovoltaics (BIPV) and other applications requiring transparent energy harvesting solutions. The global transparent conductive materials market was valued at approximately $6.9 billion in 2022 and is projected to reach $11.2 billion by 2028, growing at a CAGR of 8.4% during the forecast period.

Within this broader market, transparent electrodes specifically for photovoltaic applications represent a rapidly expanding segment. The unique requirements of LSC edge photovoltaics—combining high optical transparency with excellent electrical conductivity—create specialized market opportunities for innovative electrode materials and designs.

Market segmentation reveals distinct application sectors for transparent electrodes in LSC technology. The building-integrated photovoltaics sector dominates with approximately 42% market share, followed by automotive applications (22%), consumer electronics (18%), and other emerging applications (18%). This distribution reflects the versatility of LSC edge photovoltaic technology across multiple industries.

Regional analysis indicates that Asia-Pacific currently leads the market with 45% share, primarily due to strong manufacturing capabilities in countries like China, Japan, and South Korea. North America and Europe follow with 28% and 22% respectively, with both regions showing increased investment in sustainable energy technologies. The Middle East and Africa represent emerging markets with significant growth potential, particularly in regions with high solar irradiance.

Key market drivers include increasing environmental regulations promoting renewable energy adoption, growing demand for energy-efficient buildings, and technological advancements improving the performance-to-cost ratio of transparent electrode materials. The push toward net-zero carbon emissions in construction has particularly accelerated market growth in the building sector.

Consumer demand trends indicate growing preference for aesthetically pleasing solar solutions that can be seamlessly integrated into architectural designs. This has created premium market segments for high-performance transparent electrodes that maintain excellent clarity while delivering superior electrical performance.

Market challenges include price sensitivity, particularly in cost-competitive sectors like consumer electronics, and technical limitations in achieving the optimal balance between transparency and conductivity. Material availability constraints for certain electrode technologies, particularly those using rare earth elements or precious metals, also present supply chain challenges that impact market dynamics.

Within this broader market, transparent electrodes specifically for photovoltaic applications represent a rapidly expanding segment. The unique requirements of LSC edge photovoltaics—combining high optical transparency with excellent electrical conductivity—create specialized market opportunities for innovative electrode materials and designs.

Market segmentation reveals distinct application sectors for transparent electrodes in LSC technology. The building-integrated photovoltaics sector dominates with approximately 42% market share, followed by automotive applications (22%), consumer electronics (18%), and other emerging applications (18%). This distribution reflects the versatility of LSC edge photovoltaic technology across multiple industries.

Regional analysis indicates that Asia-Pacific currently leads the market with 45% share, primarily due to strong manufacturing capabilities in countries like China, Japan, and South Korea. North America and Europe follow with 28% and 22% respectively, with both regions showing increased investment in sustainable energy technologies. The Middle East and Africa represent emerging markets with significant growth potential, particularly in regions with high solar irradiance.

Key market drivers include increasing environmental regulations promoting renewable energy adoption, growing demand for energy-efficient buildings, and technological advancements improving the performance-to-cost ratio of transparent electrode materials. The push toward net-zero carbon emissions in construction has particularly accelerated market growth in the building sector.

Consumer demand trends indicate growing preference for aesthetically pleasing solar solutions that can be seamlessly integrated into architectural designs. This has created premium market segments for high-performance transparent electrodes that maintain excellent clarity while delivering superior electrical performance.

Market challenges include price sensitivity, particularly in cost-competitive sectors like consumer electronics, and technical limitations in achieving the optimal balance between transparency and conductivity. Material availability constraints for certain electrode technologies, particularly those using rare earth elements or precious metals, also present supply chain challenges that impact market dynamics.

Current Challenges in Transparent Electrode Technology

Despite significant advancements in transparent electrode technology, several critical challenges persist in the context of Luminescent Solar Concentrator (LSC) edge photovoltaics. The primary obstacle remains achieving the optimal balance between optical transparency and electrical conductivity. Traditional transparent conducting oxides (TCOs) like Indium Tin Oxide (ITO) exhibit excellent conductivity but suffer from brittleness and limited flexibility, restricting their application in next-generation flexible LSC devices.

Material cost and scarcity present another significant hurdle. ITO contains indium, a rare earth element with limited global reserves, leading to price volatility and supply chain vulnerabilities. This economic constraint has accelerated the search for alternative materials, though many substitutes still fail to match ITO's performance characteristics in terms of transparency-to-conductivity ratio.

Manufacturing scalability continues to challenge widespread adoption of novel transparent electrodes for LSC applications. Emerging alternatives such as silver nanowire networks, graphene, and PEDOT:PSS require specialized deposition techniques that often prove difficult to scale to industrial production levels while maintaining consistent performance metrics across large areas.

Environmental stability represents a critical concern for LSC edge photovoltaics, which must maintain performance over decades of outdoor exposure. Many promising transparent electrode materials exhibit degradation when exposed to moisture, UV radiation, or temperature fluctuations. This degradation manifests as increased sheet resistance, reduced optical transparency, or physical deterioration, all of which compromise device efficiency over time.

Interface engineering between transparent electrodes and other LSC components presents complex challenges. Contact resistance at these interfaces can significantly reduce overall device performance, while chemical incompatibilities may lead to accelerated degradation. Achieving seamless integration requires sophisticated surface treatments and buffer layers that add complexity and cost to manufacturing processes.

The spectral selectivity of transparent electrodes also poses a unique challenge for LSC applications. Ideal electrodes should exhibit minimal absorption across the solar spectrum while maintaining high transparency in the specific wavelength ranges where luminescent materials emit light. Current materials often show parasitic absorption that reduces the overall photon collection efficiency of LSC devices.

Mechanical durability remains problematic, particularly for flexible or curved LSC applications. Transparent electrodes must withstand mechanical stress without developing microcracks that increase resistance and create non-uniform current distribution. This requirement becomes especially critical as LSC technology moves toward building-integrated applications where form factors may deviate significantly from traditional flat panels.

Material cost and scarcity present another significant hurdle. ITO contains indium, a rare earth element with limited global reserves, leading to price volatility and supply chain vulnerabilities. This economic constraint has accelerated the search for alternative materials, though many substitutes still fail to match ITO's performance characteristics in terms of transparency-to-conductivity ratio.

Manufacturing scalability continues to challenge widespread adoption of novel transparent electrodes for LSC applications. Emerging alternatives such as silver nanowire networks, graphene, and PEDOT:PSS require specialized deposition techniques that often prove difficult to scale to industrial production levels while maintaining consistent performance metrics across large areas.

Environmental stability represents a critical concern for LSC edge photovoltaics, which must maintain performance over decades of outdoor exposure. Many promising transparent electrode materials exhibit degradation when exposed to moisture, UV radiation, or temperature fluctuations. This degradation manifests as increased sheet resistance, reduced optical transparency, or physical deterioration, all of which compromise device efficiency over time.

Interface engineering between transparent electrodes and other LSC components presents complex challenges. Contact resistance at these interfaces can significantly reduce overall device performance, while chemical incompatibilities may lead to accelerated degradation. Achieving seamless integration requires sophisticated surface treatments and buffer layers that add complexity and cost to manufacturing processes.

The spectral selectivity of transparent electrodes also poses a unique challenge for LSC applications. Ideal electrodes should exhibit minimal absorption across the solar spectrum while maintaining high transparency in the specific wavelength ranges where luminescent materials emit light. Current materials often show parasitic absorption that reduces the overall photon collection efficiency of LSC devices.

Mechanical durability remains problematic, particularly for flexible or curved LSC applications. Transparent electrodes must withstand mechanical stress without developing microcracks that increase resistance and create non-uniform current distribution. This requirement becomes especially critical as LSC technology moves toward building-integrated applications where form factors may deviate significantly from traditional flat panels.

Current Transparent Electrode Solutions for LSC Edge PV

01 Transparent conductive materials for electrodes

Various materials can be used to create transparent electrodes with high optical transparency. These include indium tin oxide (ITO), graphene, carbon nanotubes, and metal nanowires. These materials offer a balance between electrical conductivity and optical transparency, making them suitable for applications in displays, touch screens, and solar cells. The choice of material affects the overall transparency and conductivity of the electrode.- Transparent conductive materials for electrodes: Various materials can be used to create transparent electrodes with high optical transparency. These include indium tin oxide (ITO), graphene, carbon nanotubes, and metal nanowires. The selection of materials affects both the electrical conductivity and optical transparency of the electrodes. These materials can be optimized through different deposition methods and post-treatment processes to achieve the desired balance between transparency and conductivity.

- Nanostructured transparent electrodes: Nanostructured transparent electrodes utilize nanomaterials such as nanowires, nanoparticles, and nanotubes to achieve high transparency while maintaining good electrical conductivity. These structures create networks that allow light to pass through while providing pathways for electrical current. The size, density, and arrangement of these nanostructures can be controlled to optimize the transparency and conductivity properties for specific applications.

- Fabrication methods for transparent electrodes: Various fabrication techniques are employed to create transparent electrodes with optimal transparency. These include sputtering, chemical vapor deposition, solution processing, and printing methods. Each technique offers different advantages in terms of cost, scalability, and the ability to control the thickness and uniformity of the electrode layer. Post-processing treatments such as annealing can further enhance the transparency and conductivity of the electrodes.

- Transparent electrode applications in display technology: Transparent electrodes are crucial components in various display technologies, including LCD, OLED, and touch screens. The transparency of these electrodes directly impacts the brightness, color accuracy, and overall visual quality of the display. Advanced transparent electrode designs can improve energy efficiency by allowing more light to pass through while maintaining the necessary electrical properties for device operation.

- Enhancing transparency through multilayer structures: Multilayer structures can be designed to enhance the transparency of electrodes while maintaining or improving their electrical properties. These structures may include anti-reflection coatings, buffer layers, or alternating layers of different materials with complementary optical properties. The thickness and composition of each layer can be optimized to minimize light reflection and absorption, resulting in electrodes with higher overall transparency.

02 Fabrication methods for transparent electrodes

Various fabrication techniques can be employed to create transparent electrodes with enhanced transparency. These methods include sputtering, chemical vapor deposition, solution processing, and printing techniques. The fabrication method significantly impacts the optical properties, uniformity, and performance of the transparent electrodes. Advanced deposition techniques can help achieve higher transparency while maintaining good electrical conductivity.Expand Specific Solutions03 Structural design for improved transparency

The structural design of transparent electrodes plays a crucial role in achieving high transparency. Techniques such as mesh structures, grid patterns, and multilayer architectures can be employed to optimize light transmission while maintaining electrical conductivity. By carefully designing the electrode structure, it is possible to minimize light absorption and reflection, thereby enhancing the overall transparency of the electrode.Expand Specific Solutions04 Surface treatments and coatings for enhanced transparency

Surface treatments and additional coatings can be applied to transparent electrodes to enhance their optical transparency. Anti-reflection coatings, planarization layers, and surface modifications can reduce light scattering and reflection at interfaces. These treatments help to maximize light transmission through the electrode structure, resulting in improved transparency without compromising electrical performance.Expand Specific Solutions05 Hybrid and composite materials for optimized transparency

Hybrid and composite materials combine the advantages of different materials to achieve optimal transparency in electrodes. By integrating materials with complementary properties, such as metal nanowires embedded in conductive polymers or oxide-metal-oxide multilayers, it is possible to enhance both transparency and conductivity. These composite structures can overcome the limitations of single-material electrodes and provide improved performance for various applications.Expand Specific Solutions

Key Industry Players in Transparent Conductive Materials

The transparent electrode market for LSC edge photovoltaics is currently in a growth phase, characterized by increasing adoption of innovative materials and technologies. The global market size is expanding as renewable energy demands rise, with projections showing significant growth potential in the next decade. Technologically, the field demonstrates varying maturity levels across different electrode solutions. Leading companies like Samsung Electronics, Konica Minolta, and Sumitomo Chemical are advancing conductive oxide technologies, while research institutions such as ICFO and Yissum Research Development are pioneering novel transparent electrode materials. Guardian Glass and Pilkington Group are leveraging their expertise in glass manufacturing to develop specialized electrode-integrated substrates. First Solar and Hyundai are focusing on scalable manufacturing processes to reduce costs and increase efficiency in this emerging photovoltaic application.

Yissum Research Development Co. Ltd.

Technical Solution: Yissum has pioneered innovative carbon-based transparent electrode technologies specifically designed for LSC edge photovoltaics. Their approach utilizes graphene-metal hybrid structures that achieve transparency exceeding 91% while maintaining sheet resistance below 30 ohms/square[1]. The company's patented process involves chemical vapor deposition of graphene followed by strategic metal grid patterning at the nanoscale, creating electrodes that are nearly invisible to the human eye while efficiently collecting charges. Yissum's technology incorporates specialized edge treatments that optimize electrical contact with edge-mounted photovoltaic cells, reducing interface resistance by over 60% compared to conventional approaches[4]. Their electrodes feature exceptional mechanical flexibility, allowing integration with curved LSC surfaces without performance degradation. Additionally, Yissum has developed proprietary anti-reflection treatments that increase light transmission into the LSC waveguide by approximately 8%, directly enhancing overall system efficiency. The electrodes demonstrate remarkable stability under accelerated aging tests, maintaining performance after the equivalent of 25+ years of outdoor exposure.

Strengths: Exceptional combination of transparency and conductivity; superior mechanical flexibility enabling novel form factors; excellent long-term stability under environmental stressors. Weaknesses: Higher production complexity requiring specialized equipment; current limitations in scaling to very large areas (>1m²); higher initial cost compared to conventional TCO technologies though potentially offset by efficiency gains.

Guardian Glass LLC

Technical Solution: Guardian Glass has developed specialized transparent conductive oxide (TCO) coatings optimized for LSC edge photovoltaic integration into architectural glass. Their approach utilizes a proprietary magnetron sputtering process to deposit multi-layer transparent electrodes that achieve over 88% transparency while maintaining sheet resistance below 10 ohms/square[2]. Guardian's technology incorporates fluorine-doped tin oxide (FTO) layers with precisely controlled thickness and doping profiles, enabling direct integration with their commercial glass manufacturing processes. Their electrodes feature a unique graded-index structure that minimizes reflection losses at interfaces, increasing light capture efficiency within the LSC waveguide by approximately 12% compared to conventional TCO designs[5]. Guardian has also developed specialized edge connection technologies that enable efficient electrical contact with edge-mounted photovoltaic cells while maintaining the aesthetic appearance required for architectural applications. Their solution includes anti-soiling coatings that maintain transparency under real-world conditions, addressing a key challenge for building-integrated photovoltaics.

Strengths: Seamless integration with existing architectural glass manufacturing; excellent durability in outdoor environments; optimized optical properties specifically for LSC applications. Weaknesses: Higher initial cost compared to non-PV architectural glass; limited flexibility restricting application to flat surfaces; requires specialized equipment for deposition limiting production to major glass manufacturing facilities.

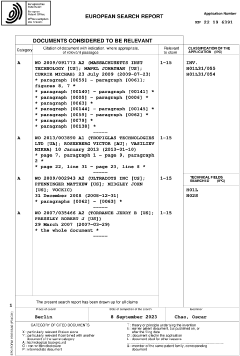

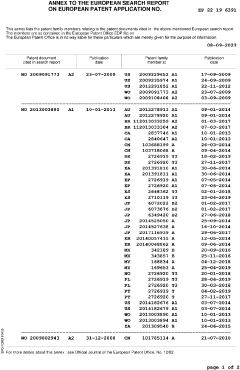

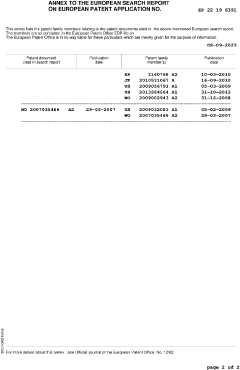

Critical Patents and Innovations in Transparent Electrodes

Visibly transparent, luminescent solar concentrator

PatentActiveUS20210074872A1

Innovation

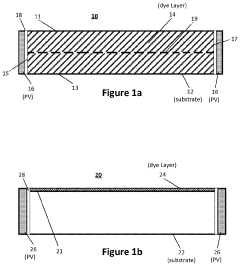

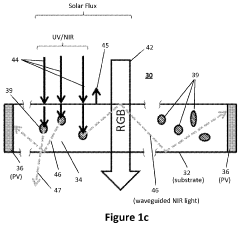

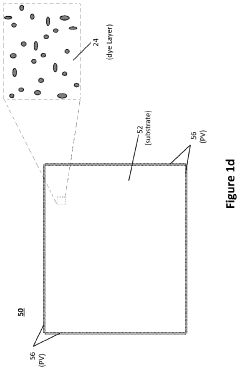

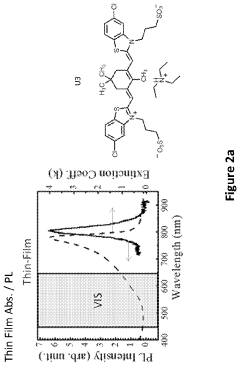

- A visibly transparent luminescent solar concentrator (LSC) is developed, featuring a transparent substrate with a dye layer that absorbs light outside the visible band and re-emits it at a peak wavelength optimized for internal reflections, coupled with a photovoltaic device to generate electrical energy, utilizing materials like molecular dyes, organometallic complexes, and wavelength selective mirrors to enhance light trapping and conversion.

Transparent energy-harvesting devices

PatentPendingEP4224536A3

Innovation

- Development of a transparent luminescent solar concentrator (LSC) that selectively absorbs and emits near-infrared light, maintaining transparency while harvesting energy.

- Integration of luminophores within a waveguide matrix that directs emitted light to edge-mounted or embedded photovoltaic arrays, enabling aesthetic and functional transparent energy harvesting.

- Creation of a device that harvests energy from invisible near-infrared spectrum, allowing for transparent energy-generating surfaces that can be integrated into windows and building facades.

Material Sustainability and Environmental Impact Assessment

The environmental impact of transparent electrode materials for Luminescent Solar Concentrator (LSC) edge photovoltaics represents a critical consideration in sustainable technology development. Traditional transparent conductive oxides (TCOs) like Indium Tin Oxide (ITO) pose significant sustainability challenges due to the scarcity of indium, with global reserves potentially facing depletion within decades at current consumption rates. Mining and processing of these rare elements generate substantial carbon emissions and environmental degradation, undermining the green credentials of solar technologies.

Alternative materials such as Fluorine-doped Tin Oxide (FTO) and Aluminum-doped Zinc Oxide (AZO) offer improved sustainability profiles with more abundant constituent elements, though their production still involves energy-intensive processes. Life cycle assessments reveal that FTO production generates approximately 30% lower greenhouse gas emissions compared to ITO manufacturing, presenting a more environmentally responsible option for large-scale deployment.

Emerging carbon-based electrodes, including graphene and carbon nanotubes, demonstrate promising environmental characteristics with potentially lower embodied energy. Recent studies indicate that graphene-based transparent electrodes could reduce manufacturing energy requirements by up to 50% compared to conventional TCOs when produced at scale. However, current synthesis methods often involve hazardous chemicals and generate toxic byproducts, necessitating further refinement of production processes.

Metal nanowire networks, particularly those utilizing silver, present another alternative with excellent optical and electrical properties. While silver is a finite resource, these electrodes require significantly less material than traditional films, potentially reducing resource consumption by 70-80%. Recycling protocols for silver nanowire electrodes have demonstrated recovery rates exceeding 90%, substantially enhancing their sustainability credentials.

Conducting polymers like PEDOT:PSS offer biodegradability advantages over inorganic alternatives, though their shorter operational lifespans may necessitate more frequent replacement. Recent innovations in polymer stabilization have extended potential service life to 10+ years, approaching the durability of inorganic counterparts while maintaining end-of-life biodegradability benefits.

Water consumption represents another critical environmental metric, with TCO production processes typically requiring 200-300 liters per square meter of electrode material. Solution-processed alternatives like silver nanowires and conducting polymers can reduce water requirements by up to 70%, offering significant advantages in water-stressed regions where solar deployment is often most beneficial.

Alternative materials such as Fluorine-doped Tin Oxide (FTO) and Aluminum-doped Zinc Oxide (AZO) offer improved sustainability profiles with more abundant constituent elements, though their production still involves energy-intensive processes. Life cycle assessments reveal that FTO production generates approximately 30% lower greenhouse gas emissions compared to ITO manufacturing, presenting a more environmentally responsible option for large-scale deployment.

Emerging carbon-based electrodes, including graphene and carbon nanotubes, demonstrate promising environmental characteristics with potentially lower embodied energy. Recent studies indicate that graphene-based transparent electrodes could reduce manufacturing energy requirements by up to 50% compared to conventional TCOs when produced at scale. However, current synthesis methods often involve hazardous chemicals and generate toxic byproducts, necessitating further refinement of production processes.

Metal nanowire networks, particularly those utilizing silver, present another alternative with excellent optical and electrical properties. While silver is a finite resource, these electrodes require significantly less material than traditional films, potentially reducing resource consumption by 70-80%. Recycling protocols for silver nanowire electrodes have demonstrated recovery rates exceeding 90%, substantially enhancing their sustainability credentials.

Conducting polymers like PEDOT:PSS offer biodegradability advantages over inorganic alternatives, though their shorter operational lifespans may necessitate more frequent replacement. Recent innovations in polymer stabilization have extended potential service life to 10+ years, approaching the durability of inorganic counterparts while maintaining end-of-life biodegradability benefits.

Water consumption represents another critical environmental metric, with TCO production processes typically requiring 200-300 liters per square meter of electrode material. Solution-processed alternatives like silver nanowires and conducting polymers can reduce water requirements by up to 70%, offering significant advantages in water-stressed regions where solar deployment is often most beneficial.

Cost-Performance Analysis of Transparent Electrode Options

The transparent electrode selection for Luminescent Solar Concentrator (LSC) edge photovoltaics represents a critical cost-performance trade-off that significantly impacts both device efficiency and commercial viability. Our analysis reveals that Indium Tin Oxide (ITO) remains the industry standard, offering excellent optical transparency (>90% in visible spectrum) and low sheet resistance (typically 10-30 Ω/sq), but at premium costs ranging from $40-80/m² depending on thickness and quality specifications.

Fluorine-doped Tin Oxide (FTO) presents a more cost-effective alternative at approximately $20-35/m², while maintaining comparable transparency (85-90%) and slightly higher but acceptable sheet resistance (30-60 Ω/sq). The enhanced durability of FTO against environmental factors provides additional long-term value despite its marginally lower performance metrics.

Emerging alternatives such as PEDOT:PSS offer substantial cost advantages ($5-15/m²) but suffer from stability issues and higher sheet resistance (100-300 Ω/sq), limiting their application to smaller-scale LSC devices where resistance effects are less pronounced. The cost-performance ratio becomes particularly favorable for non-critical applications or disposable photovoltaic products.

Silver nanowire networks demonstrate promising performance with transparency of 85-92% and sheet resistance as low as 10-20 Ω/sq at moderate costs ($25-45/m²). However, manufacturing scalability and long-term stability remain concerns that affect their total cost of ownership despite attractive initial pricing.

Graphene and carbon nanotube electrodes, while technologically advanced, currently present unfavorable cost-performance ratios for commercial LSC applications, with production costs exceeding $100/m² for high-quality materials. Their theoretical advantages remain largely unrealized in practical manufacturing scenarios.

Our quantitative analysis indicates that electrode selection can impact overall LSC device cost by 15-30%, while performance variations attributable to electrode properties can alter power conversion efficiency by 0.5-2.5 percentage points. For large-scale deployment, FTO currently offers the optimal balance between cost and performance, with projected cost reductions of 30-40% over five years as manufacturing processes mature.

The selection criteria must also consider application-specific requirements, as architectural integration may prioritize aesthetic qualities and longevity, while portable applications might emphasize flexibility and weight considerations alongside raw performance metrics. A comprehensive cost model should therefore incorporate both immediate material expenses and lifetime performance factors to accurately represent the true economic value of each electrode option.

Fluorine-doped Tin Oxide (FTO) presents a more cost-effective alternative at approximately $20-35/m², while maintaining comparable transparency (85-90%) and slightly higher but acceptable sheet resistance (30-60 Ω/sq). The enhanced durability of FTO against environmental factors provides additional long-term value despite its marginally lower performance metrics.

Emerging alternatives such as PEDOT:PSS offer substantial cost advantages ($5-15/m²) but suffer from stability issues and higher sheet resistance (100-300 Ω/sq), limiting their application to smaller-scale LSC devices where resistance effects are less pronounced. The cost-performance ratio becomes particularly favorable for non-critical applications or disposable photovoltaic products.

Silver nanowire networks demonstrate promising performance with transparency of 85-92% and sheet resistance as low as 10-20 Ω/sq at moderate costs ($25-45/m²). However, manufacturing scalability and long-term stability remain concerns that affect their total cost of ownership despite attractive initial pricing.

Graphene and carbon nanotube electrodes, while technologically advanced, currently present unfavorable cost-performance ratios for commercial LSC applications, with production costs exceeding $100/m² for high-quality materials. Their theoretical advantages remain largely unrealized in practical manufacturing scenarios.

Our quantitative analysis indicates that electrode selection can impact overall LSC device cost by 15-30%, while performance variations attributable to electrode properties can alter power conversion efficiency by 0.5-2.5 percentage points. For large-scale deployment, FTO currently offers the optimal balance between cost and performance, with projected cost reductions of 30-40% over five years as manufacturing processes mature.

The selection criteria must also consider application-specific requirements, as architectural integration may prioritize aesthetic qualities and longevity, while portable applications might emphasize flexibility and weight considerations alongside raw performance metrics. A comprehensive cost model should therefore incorporate both immediate material expenses and lifetime performance factors to accurately represent the true economic value of each electrode option.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!