Durable Polymer Matrices For Improved QD Dispersion And Lifetime

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Technology Evolution and Objectives

Quantum dots (QDs) have emerged as a revolutionary class of semiconductor nanocrystals since their initial discovery in the early 1980s. These nanoscale particles, typically ranging from 2-10 nanometers in diameter, exhibit unique size-dependent optical and electronic properties due to quantum confinement effects. The evolution of QD technology has progressed through several distinct phases, from fundamental research to commercial applications across multiple industries.

The first generation of QDs focused primarily on cadmium-based materials (CdSe, CdS, CdTe), which demonstrated excellent optical properties but raised significant toxicity concerns. This led to the development of second-generation QDs with reduced or eliminated heavy metal content, including indium phosphide (InP) and copper indium sulfide (CIS) based alternatives. The third generation has expanded to include perovskite QDs and carbon dots, offering new property profiles and application possibilities.

A critical challenge throughout QD development has been their integration into stable matrices for practical applications. Early QD implementations suffered from rapid degradation when exposed to oxygen, moisture, and UV radiation, severely limiting their commercial viability. The development of durable polymer matrices for QD dispersion represents a crucial technological advancement aimed at overcoming these fundamental limitations.

The primary objectives in developing improved polymer matrices for QDs include enhancing dispersion uniformity, preventing agglomeration, protecting QDs from environmental degradation factors, and maintaining their exceptional optical properties over extended periods. These objectives directly address the core challenges that have historically limited QD adoption in commercial applications requiring long operational lifetimes.

Current research trends focus on developing polymer matrices that can provide both physical protection and chemical compatibility with various QD compositions. Advanced encapsulation strategies using cross-linked polymers, nanocomposites, and hybrid organic-inorganic materials are being explored to significantly extend QD lifetimes from months to years or even decades.

The technological trajectory is moving toward multifunctional polymer matrices that not only protect QDs but also enhance their performance characteristics. These include matrices with tailored refractive indices to improve light extraction, matrices with controlled charge transport properties for electronic applications, and biocompatible matrices for medical applications.

The ultimate goal of this technological evolution is to develop QD-polymer systems with predictable, consistent performance over operational lifetimes exceeding 50,000 hours for display applications, 10+ years for lighting applications, and similar durability metrics for emerging applications in solar energy conversion, security printing, and biomedical imaging.

The first generation of QDs focused primarily on cadmium-based materials (CdSe, CdS, CdTe), which demonstrated excellent optical properties but raised significant toxicity concerns. This led to the development of second-generation QDs with reduced or eliminated heavy metal content, including indium phosphide (InP) and copper indium sulfide (CIS) based alternatives. The third generation has expanded to include perovskite QDs and carbon dots, offering new property profiles and application possibilities.

A critical challenge throughout QD development has been their integration into stable matrices for practical applications. Early QD implementations suffered from rapid degradation when exposed to oxygen, moisture, and UV radiation, severely limiting their commercial viability. The development of durable polymer matrices for QD dispersion represents a crucial technological advancement aimed at overcoming these fundamental limitations.

The primary objectives in developing improved polymer matrices for QDs include enhancing dispersion uniformity, preventing agglomeration, protecting QDs from environmental degradation factors, and maintaining their exceptional optical properties over extended periods. These objectives directly address the core challenges that have historically limited QD adoption in commercial applications requiring long operational lifetimes.

Current research trends focus on developing polymer matrices that can provide both physical protection and chemical compatibility with various QD compositions. Advanced encapsulation strategies using cross-linked polymers, nanocomposites, and hybrid organic-inorganic materials are being explored to significantly extend QD lifetimes from months to years or even decades.

The technological trajectory is moving toward multifunctional polymer matrices that not only protect QDs but also enhance their performance characteristics. These include matrices with tailored refractive indices to improve light extraction, matrices with controlled charge transport properties for electronic applications, and biocompatible matrices for medical applications.

The ultimate goal of this technological evolution is to develop QD-polymer systems with predictable, consistent performance over operational lifetimes exceeding 50,000 hours for display applications, 10+ years for lighting applications, and similar durability metrics for emerging applications in solar energy conversion, security printing, and biomedical imaging.

Market Analysis for QD-Enhanced Polymer Applications

The quantum dot (QD) enhanced polymer market has experienced significant growth in recent years, driven by increasing demand for advanced display technologies, lighting solutions, and photovoltaic applications. The global market for QD-enhanced polymers was valued at approximately $4.5 billion in 2022 and is projected to reach $12.3 billion by 2028, representing a compound annual growth rate of 18.2% during the forecast period.

Display technologies currently dominate the QD-enhanced polymer market, accounting for nearly 65% of total market share. This segment is primarily driven by the superior color gamut, brightness, and energy efficiency that QD technology offers compared to traditional display solutions. Major electronics manufacturers have increasingly adopted QD-enhanced displays in premium television models, monitors, and mobile devices.

Lighting applications represent the second-largest market segment at 20%, with significant growth potential as energy efficiency regulations become more stringent globally. The ability of QD-enhanced polymers to produce high-quality, tunable white light with improved efficiency positions them as strong competitors to traditional LED and OLED lighting solutions.

The photovoltaic sector, while currently smaller at 10% market share, shows the highest growth potential due to ongoing research demonstrating QD-polymer composites can significantly improve solar cell efficiency. The remaining 5% encompasses emerging applications in biomedical imaging, security features, and sensors.

Regionally, Asia-Pacific dominates the market with 45% share, driven by the concentration of display manufacturing facilities in countries like South Korea, Japan, and China. North America follows at 30%, with strong research initiatives and early commercial adoption, while Europe accounts for 20% with growing demand in automotive and lighting sectors.

Key market challenges include price sensitivity, as QD-enhanced polymers typically command a premium of 30-40% over conventional alternatives. Additionally, environmental and regulatory concerns regarding heavy metal content in certain QD formulations have prompted increased investment in cadmium-free alternatives, which currently represent approximately 35% of the market.

Consumer electronics remains the primary end-user industry, but automotive applications are experiencing the fastest growth rate at 25% annually, particularly for interior lighting and display systems. Industrial applications are also expanding as QD-polymer composites demonstrate superior durability and performance in harsh operating environments.

Display technologies currently dominate the QD-enhanced polymer market, accounting for nearly 65% of total market share. This segment is primarily driven by the superior color gamut, brightness, and energy efficiency that QD technology offers compared to traditional display solutions. Major electronics manufacturers have increasingly adopted QD-enhanced displays in premium television models, monitors, and mobile devices.

Lighting applications represent the second-largest market segment at 20%, with significant growth potential as energy efficiency regulations become more stringent globally. The ability of QD-enhanced polymers to produce high-quality, tunable white light with improved efficiency positions them as strong competitors to traditional LED and OLED lighting solutions.

The photovoltaic sector, while currently smaller at 10% market share, shows the highest growth potential due to ongoing research demonstrating QD-polymer composites can significantly improve solar cell efficiency. The remaining 5% encompasses emerging applications in biomedical imaging, security features, and sensors.

Regionally, Asia-Pacific dominates the market with 45% share, driven by the concentration of display manufacturing facilities in countries like South Korea, Japan, and China. North America follows at 30%, with strong research initiatives and early commercial adoption, while Europe accounts for 20% with growing demand in automotive and lighting sectors.

Key market challenges include price sensitivity, as QD-enhanced polymers typically command a premium of 30-40% over conventional alternatives. Additionally, environmental and regulatory concerns regarding heavy metal content in certain QD formulations have prompted increased investment in cadmium-free alternatives, which currently represent approximately 35% of the market.

Consumer electronics remains the primary end-user industry, but automotive applications are experiencing the fastest growth rate at 25% annually, particularly for interior lighting and display systems. Industrial applications are also expanding as QD-polymer composites demonstrate superior durability and performance in harsh operating environments.

Current Challenges in QD-Polymer Integration

Despite significant advancements in quantum dot (QD) technology, the integration of QDs with polymer matrices continues to present substantial challenges that impede widespread commercial application. The primary obstacle remains achieving uniform dispersion of QDs within polymer matrices. QDs inherently tend to aggregate due to their high surface energy and van der Waals interactions, resulting in uneven distribution and compromised optical properties. This aggregation phenomenon is particularly pronounced at higher QD concentrations, which are often necessary for optimal device performance.

Surface compatibility between QDs and host polymers represents another critical challenge. Most high-performance QDs possess hydrophobic ligands that may be incompatible with hydrophilic polymer systems, creating interfacial tension that further promotes phase separation and aggregation. Conversely, when ligand exchange is performed to improve compatibility, it frequently results in decreased quantum yield and altered optoelectronic properties.

The long-term stability of QD-polymer composites under operational conditions presents significant concerns. Environmental factors such as heat, humidity, oxygen, and UV exposure can trigger degradation mechanisms that affect both the QDs and the polymer matrix. Thermal cycling during device operation can induce differential expansion between QDs and polymers, creating microstresses that compromise structural integrity and accelerate degradation pathways.

Processing conditions introduce additional complexities. Traditional polymer processing techniques often involve high temperatures, mechanical shear forces, or exposure to solvents that can damage QD structures or strip surface ligands. Finding processing windows that preserve QD integrity while achieving desired polymer properties remains challenging, particularly for mass production scenarios.

The encapsulation efficiency of polymers in protecting QDs from environmental degradation factors varies significantly across different polymer systems. Oxygen and moisture permeability of many polymers is insufficient to provide adequate protection for sensitive QD materials, especially for applications requiring years of operational stability.

Scale-up and manufacturing consistency represent substantial hurdles for commercial implementation. Batch-to-batch variations in QD synthesis and polymer properties can lead to inconsistent composite performance. Additionally, the cost-effectiveness of current integration approaches remains problematic for price-sensitive applications, with high-quality QDs and specialty polymers contributing significantly to overall material costs.

Regulatory and environmental considerations further complicate development efforts. Many high-performance QDs contain heavy metals subject to increasing regulatory restrictions, while some polymer processing techniques involve environmentally problematic solvents or additives that may face future limitations.

Surface compatibility between QDs and host polymers represents another critical challenge. Most high-performance QDs possess hydrophobic ligands that may be incompatible with hydrophilic polymer systems, creating interfacial tension that further promotes phase separation and aggregation. Conversely, when ligand exchange is performed to improve compatibility, it frequently results in decreased quantum yield and altered optoelectronic properties.

The long-term stability of QD-polymer composites under operational conditions presents significant concerns. Environmental factors such as heat, humidity, oxygen, and UV exposure can trigger degradation mechanisms that affect both the QDs and the polymer matrix. Thermal cycling during device operation can induce differential expansion between QDs and polymers, creating microstresses that compromise structural integrity and accelerate degradation pathways.

Processing conditions introduce additional complexities. Traditional polymer processing techniques often involve high temperatures, mechanical shear forces, or exposure to solvents that can damage QD structures or strip surface ligands. Finding processing windows that preserve QD integrity while achieving desired polymer properties remains challenging, particularly for mass production scenarios.

The encapsulation efficiency of polymers in protecting QDs from environmental degradation factors varies significantly across different polymer systems. Oxygen and moisture permeability of many polymers is insufficient to provide adequate protection for sensitive QD materials, especially for applications requiring years of operational stability.

Scale-up and manufacturing consistency represent substantial hurdles for commercial implementation. Batch-to-batch variations in QD synthesis and polymer properties can lead to inconsistent composite performance. Additionally, the cost-effectiveness of current integration approaches remains problematic for price-sensitive applications, with high-quality QDs and specialty polymers contributing significantly to overall material costs.

Regulatory and environmental considerations further complicate development efforts. Many high-performance QDs contain heavy metals subject to increasing regulatory restrictions, while some polymer processing techniques involve environmentally problematic solvents or additives that may face future limitations.

State-of-the-Art Polymer Matrices for QD Dispersion

01 Polymer matrices for enhanced quantum dot stability

Specific polymer matrices can be used to enhance the stability and lifetime of quantum dots by protecting them from environmental factors such as oxygen and moisture. These polymers create a protective barrier around the quantum dots, preventing degradation and maintaining their optical properties over time. The polymer matrices can be designed with specific functional groups that interact favorably with the quantum dot surface, further improving stability without compromising the quantum dots' luminescent properties.- Polymer matrices for enhanced quantum dot stability: Specific polymer matrices can be used to enhance the stability and lifetime of quantum dots by protecting them from environmental factors such as oxygen and moisture. These polymers create a protective barrier around the quantum dots, preventing degradation and maintaining their optical properties over time. The polymer matrices can be designed with specific functional groups that interact favorably with the quantum dot surface, further improving stability and preventing aggregation.

- Dispersion techniques for quantum dots in polymer matrices: Various techniques can be employed to achieve uniform dispersion of quantum dots within polymer matrices, which is crucial for optimal performance in applications. These techniques include surface modification of quantum dots, use of compatibilizers, solvent-assisted dispersion methods, and in-situ polymerization around quantum dots. Proper dispersion prevents aggregation and ensures consistent optical and electronic properties throughout the material.

- Polymer-quantum dot composites for optoelectronic applications: Polymer-quantum dot composites are specifically designed for optoelectronic applications such as LEDs, displays, and photovoltaic devices. These composites combine the processability and flexibility of polymers with the unique optical properties of quantum dots. The polymer matrices can be engineered to enhance charge transport, light extraction, and quantum yield of the embedded quantum dots, leading to improved device performance and efficiency.

- Cross-linkable polymer matrices for quantum dot encapsulation: Cross-linkable polymer matrices provide enhanced mechanical stability and environmental protection for quantum dots. These polymers can be cured after quantum dot incorporation, forming a rigid network that immobilizes the quantum dots and prevents leaching. The cross-linking process can be initiated by heat, light, or chemical means, and the degree of cross-linking can be controlled to optimize properties such as hardness, flexibility, and permeability to oxygen and moisture.

- Nanocomposite structures with controlled quantum dot distribution: Advanced nanocomposite structures can be designed with controlled quantum dot distribution within polymer matrices. These structures may include layered architectures, gradient distributions, or patterned arrangements of quantum dots. Control over quantum dot distribution enables tailoring of optical and electronic properties for specific applications. Techniques such as block copolymer self-assembly, nanoimprint lithography, and selective deposition can be used to achieve the desired quantum dot arrangement within the polymer matrix.

02 Dispersion techniques for quantum dots in polymer matrices

Various techniques can be employed to achieve uniform dispersion of quantum dots within polymer matrices, which is crucial for maintaining their optical properties and preventing aggregation. These techniques include surface modification of quantum dots, use of compatible solvents, and specialized mixing methods. Proper dispersion ensures that the quantum dots maintain their individual properties and do not form clusters that could lead to self-quenching or reduced efficiency in the final application.Expand Specific Solutions03 Polymer-quantum dot composites for optoelectronic applications

Polymer-quantum dot composites can be specifically formulated for optoelectronic applications such as LEDs, solar cells, and displays. These composites combine the processability and flexibility of polymers with the unique optical and electronic properties of quantum dots. The polymer matrix not only serves as a host for the quantum dots but can also be designed to enhance charge transport, light extraction, or other application-specific properties, leading to improved device performance and lifetime.Expand Specific Solutions04 Cross-linkable polymer systems for quantum dot encapsulation

Cross-linkable polymer systems offer enhanced protection for quantum dots by forming a more rigid and impermeable matrix after curing. These systems typically involve polymers with functional groups that can be cross-linked through heat, light, or chemical initiators. The cross-linked network provides superior barrier properties against oxygen and moisture, significantly extending the lifetime of the quantum dots while maintaining their optical properties. Additionally, these systems often offer improved mechanical stability and thermal resistance.Expand Specific Solutions05 Nanocomposite structures with controlled quantum dot distribution

Advanced nanocomposite structures can be designed with controlled quantum dot distribution within polymer matrices to optimize specific properties. These structures may include layered architectures, gradient distributions, or patterned arrangements of quantum dots. By precisely controlling the spatial arrangement of quantum dots within the polymer matrix, properties such as light emission, absorption, or energy transfer can be tailored for specific applications. These structured nanocomposites often demonstrate superior performance compared to randomly dispersed systems.Expand Specific Solutions

Leading Companies in QD-Polymer Composite Industry

The quantum dot (QD) dispersion and lifetime improvement market is currently in a growth phase, characterized by increasing adoption across display technologies and expanding applications in consumer electronics. The market size is projected to grow significantly as QD technology becomes more mainstream in premium displays and lighting solutions. Technologically, the field is advancing from early commercial adoption to broader implementation, with companies at varying maturity levels. Leading players like Samsung Electronics and Apple are driving commercial adoption, while specialized materials companies including Nanoco Technologies, Merck Patent GmbH, and BASF are developing advanced polymer matrices for QD stabilization. Asian manufacturers such as Najing Technology and Nanjing Bready Electronics are rapidly advancing in QD display applications, while established chemical companies like Shin-Etsu Chemical and Dow Global Technologies provide expertise in polymer development critical for improving QD dispersion and durability.

Nanoco Technologies Ltd.

Technical Solution: Nanoco has developed proprietary CFQD® (cadmium-free quantum dot) technology with polymer matrices specifically designed for enhanced dispersion and stability. Their approach involves surface functionalization of quantum dots with ligands that are compatible with various polymer systems, creating strong interfacial interactions between QDs and polymer matrices. The company utilizes a core-shell architecture for their QDs, where the shell is chemically modified to improve compatibility with polymers like PMMA, polystyrene, and polyolefins. This technology enables uniform dispersion of QDs within the polymer matrix, preventing agglomeration that typically leads to performance degradation. Nanoco has also developed cross-linkable ligands that can form covalent bonds with the polymer matrix, significantly improving the durability and environmental stability of the composite materials.

Strengths: Cadmium-free formulation addresses environmental and regulatory concerns; proprietary surface modification technology enables excellent dispersion in various polymer systems. Weaknesses: May require specialized processing conditions; performance in extreme environmental conditions might still be limited compared to traditional technologies.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has pioneered quantum dot technology for display applications through their QLED technology, focusing on polymer encapsulation methods to enhance QD stability and lifetime. Their approach involves embedding QDs in a specialized polymer matrix that shields them from oxygen and moisture, the primary degradation factors. Samsung's technology utilizes a multi-layer polymer structure where an inner layer provides optimal QD dispersion through compatible functional groups, while outer layers offer barrier properties against environmental factors. The company has developed proprietary cross-linking techniques that create a three-dimensional polymer network around QDs, significantly improving thermal stability and preventing leaching during temperature fluctuations. This technology has enabled Samsung to achieve QD displays with enhanced color purity, brightness stability over time, and resistance to high-temperature operating conditions common in display applications.

Strengths: Extensive commercial implementation experience; highly optimized for display applications with proven long-term stability. Weaknesses: Primarily focused on display applications rather than broader QD applications; proprietary nature limits wider adoption across the industry.

Critical Patents in QD-Polymer Interface Engineering

Stable quantum dot compositions

PatentActiveUS20210371733A1

Innovation

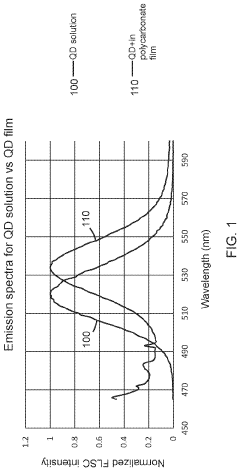

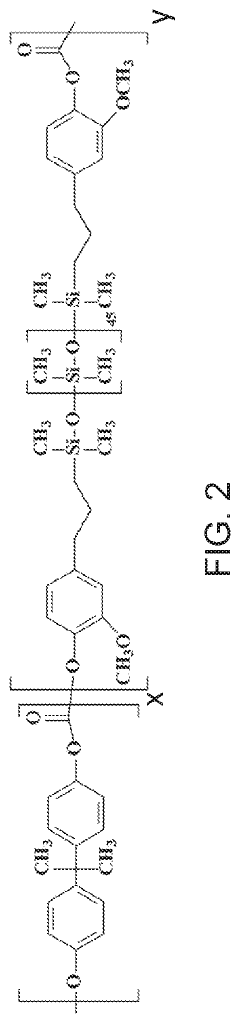

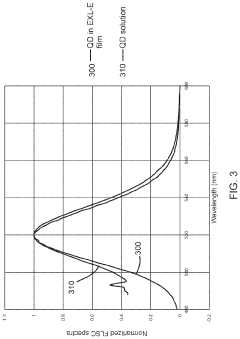

- A nano-composite is developed using a thermoplastic copolymer with a polycarbonate copolymer containing repeating siloxane units and a low percentage of quantum dots, where the siloxane domains provide a compatible region for quantum dots to retain quantum yield and mechanical properties, reducing the need for barrier films and enhancing dispersion.

Quantum dot-polymer composite particles and method for preparing same

PatentWO2021054654A1

Innovation

- A quantum dot-polymer composite particle is developed, where quantum dots are coated with a (meth)acrylic polymer layer containing polar functional groups, which enhances stability and luminous efficiency, and allows for direct application in LED packaging by preventing interference with the curing of silicone resin.

Environmental Impact of QD-Polymer Composites

The environmental impact of quantum dot-polymer composites represents a critical consideration in their development and application. These materials, while offering significant technological advantages, pose unique environmental challenges throughout their lifecycle. The production phase of QD-polymer composites often involves heavy metal precursors such as cadmium, lead, or indium, which are known environmental toxins. Manufacturing processes typically require organic solvents and energy-intensive conditions, contributing to their environmental footprint.

During the use phase, properly encapsulated QDs in durable polymer matrices demonstrate relatively low environmental impact. However, the potential for leaching of toxic components remains a concern, particularly when these composites are exposed to harsh environmental conditions or mechanical stress. The stability of the polymer matrix directly correlates with the containment of potentially harmful QD materials, highlighting the importance of developing more durable polymer systems.

End-of-life management presents perhaps the most significant environmental challenge. Current recycling infrastructure is largely unprepared for the complex nature of QD-polymer composites. The presence of heavy metals and specialized polymers complicates traditional recycling processes, often resulting in these materials being directed to landfills or incineration facilities, where they may release toxic components into soil, water, or air.

Recent research has focused on developing more environmentally benign QD-polymer systems. This includes the exploration of heavy-metal-free quantum dots using elements like silicon, carbon, or zinc, which present lower toxicity profiles. Additionally, biodegradable or bio-based polymers are being investigated as matrices for QDs, potentially offering more sustainable end-of-life pathways.

Life cycle assessment (LCA) studies of QD-polymer composites remain limited but are increasingly recognized as essential for understanding their true environmental impact. Preliminary assessments suggest that the environmental benefits of QD-enhanced products, such as energy-efficient lighting or solar cells, may offset the environmental costs of production and disposal, though this balance depends heavily on the specific application and lifecycle management.

Regulatory frameworks governing these materials are still evolving. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are beginning to address quantum dot materials, particularly those containing cadmium or lead. These regulatory pressures are driving innovation toward greener QD-polymer composite technologies that maintain performance while reducing environmental hazards.

During the use phase, properly encapsulated QDs in durable polymer matrices demonstrate relatively low environmental impact. However, the potential for leaching of toxic components remains a concern, particularly when these composites are exposed to harsh environmental conditions or mechanical stress. The stability of the polymer matrix directly correlates with the containment of potentially harmful QD materials, highlighting the importance of developing more durable polymer systems.

End-of-life management presents perhaps the most significant environmental challenge. Current recycling infrastructure is largely unprepared for the complex nature of QD-polymer composites. The presence of heavy metals and specialized polymers complicates traditional recycling processes, often resulting in these materials being directed to landfills or incineration facilities, where they may release toxic components into soil, water, or air.

Recent research has focused on developing more environmentally benign QD-polymer systems. This includes the exploration of heavy-metal-free quantum dots using elements like silicon, carbon, or zinc, which present lower toxicity profiles. Additionally, biodegradable or bio-based polymers are being investigated as matrices for QDs, potentially offering more sustainable end-of-life pathways.

Life cycle assessment (LCA) studies of QD-polymer composites remain limited but are increasingly recognized as essential for understanding their true environmental impact. Preliminary assessments suggest that the environmental benefits of QD-enhanced products, such as energy-efficient lighting or solar cells, may offset the environmental costs of production and disposal, though this balance depends heavily on the specific application and lifecycle management.

Regulatory frameworks governing these materials are still evolving. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations worldwide are beginning to address quantum dot materials, particularly those containing cadmium or lead. These regulatory pressures are driving innovation toward greener QD-polymer composite technologies that maintain performance while reducing environmental hazards.

Manufacturing Scalability of Durable QD-Polymer Systems

The scalability of manufacturing processes for durable quantum dot-polymer systems represents a critical challenge for commercial viability. Current laboratory-scale production methods often fail to translate effectively to industrial settings, creating significant barriers to market entry. The transition from small-batch to mass production requires careful consideration of multiple factors including equipment compatibility, process parameters, and quality control mechanisms.

Existing manufacturing approaches typically involve solution processing techniques such as spin coating, blade coating, or screen printing for thin-film applications. For bulk materials, methods like extrusion compounding, injection molding, and in-situ polymerization are commonly employed. Each method presents unique challenges when incorporating quantum dots into polymer matrices while maintaining uniform dispersion and preventing aggregation.

Cost considerations significantly impact manufacturing scalability. The high price of high-quality quantum dots (ranging from $2,000-10,000 per gram for research-grade materials) necessitates efficient incorporation processes that minimize material waste. Recent advances in continuous flow synthesis of QDs have shown promise in reducing production costs by up to 60% compared to traditional batch processes, potentially enabling more economically viable large-scale manufacturing.

Equipment modification represents another crucial aspect of scalability. Standard polymer processing equipment often requires significant adaptation to handle quantum dot materials safely and effectively. Specialized mixing chambers, controlled atmosphere processing environments, and modified extrusion systems have been developed to address these challenges. Companies like Nanosys and QD Vision have pioneered custom manufacturing lines that maintain QD stability throughout the production process.

Quality control and consistency present persistent challenges in scaled production. Variations in quantum dot dispersion quality can dramatically affect final product performance, necessitating robust in-line monitoring systems. Recent developments in real-time spectroscopic analysis and machine learning-based quality prediction models have improved production consistency, with reported defect rates decreasing from 15-20% to below 5% in optimized manufacturing lines.

Environmental and safety considerations also impact manufacturing scalability. The potential toxicity of certain quantum dot materials (particularly those containing cadmium or lead) requires specialized handling protocols and waste management systems. Several companies have developed closed-loop manufacturing processes that capture and recycle over 90% of solvents and unreacted materials, addressing both environmental concerns and economic efficiency in large-scale production.

Existing manufacturing approaches typically involve solution processing techniques such as spin coating, blade coating, or screen printing for thin-film applications. For bulk materials, methods like extrusion compounding, injection molding, and in-situ polymerization are commonly employed. Each method presents unique challenges when incorporating quantum dots into polymer matrices while maintaining uniform dispersion and preventing aggregation.

Cost considerations significantly impact manufacturing scalability. The high price of high-quality quantum dots (ranging from $2,000-10,000 per gram for research-grade materials) necessitates efficient incorporation processes that minimize material waste. Recent advances in continuous flow synthesis of QDs have shown promise in reducing production costs by up to 60% compared to traditional batch processes, potentially enabling more economically viable large-scale manufacturing.

Equipment modification represents another crucial aspect of scalability. Standard polymer processing equipment often requires significant adaptation to handle quantum dot materials safely and effectively. Specialized mixing chambers, controlled atmosphere processing environments, and modified extrusion systems have been developed to address these challenges. Companies like Nanosys and QD Vision have pioneered custom manufacturing lines that maintain QD stability throughout the production process.

Quality control and consistency present persistent challenges in scaled production. Variations in quantum dot dispersion quality can dramatically affect final product performance, necessitating robust in-line monitoring systems. Recent developments in real-time spectroscopic analysis and machine learning-based quality prediction models have improved production consistency, with reported defect rates decreasing from 15-20% to below 5% in optimized manufacturing lines.

Environmental and safety considerations also impact manufacturing scalability. The potential toxicity of certain quantum dot materials (particularly those containing cadmium or lead) requires specialized handling protocols and waste management systems. Several companies have developed closed-loop manufacturing processes that capture and recycle over 90% of solvents and unreacted materials, addressing both environmental concerns and economic efficiency in large-scale production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!