Quantum Dot Alternatives: Perovskite Nanocrystals For LSC Applications

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Perovskite Nanocrystals Background and Research Objectives

Perovskite nanocrystals (PNCs) have emerged as a revolutionary class of semiconductor materials over the past decade, attracting significant attention in the field of optoelectronics. These materials possess exceptional optical properties, including high photoluminescence quantum yields, narrow emission linewidths, and tunable bandgaps across the visible spectrum. The development of PNCs can be traced back to 2014 when the first colloidal perovskite quantum dots were synthesized, marking a significant milestone in nanomaterial research.

The fundamental structure of perovskite nanocrystals follows the ABX₃ formula, where A typically represents cesium, methylammonium, or formamidinium cations; B represents lead or tin metal cations; and X represents halide anions (chloride, bromide, or iodide). This versatile composition allows for precise engineering of optical and electronic properties through simple ion exchange reactions or compositional modifications.

Luminescent Solar Concentrators (LSCs) represent an innovative approach to solar energy harvesting, designed to collect and concentrate sunlight onto smaller areas of photovoltaic cells. Traditional LSCs have primarily utilized organic dyes or conventional quantum dots as luminophores. However, these materials suffer from various limitations including poor stability, significant reabsorption losses, and environmental concerns related to heavy metal content in the case of cadmium-based quantum dots.

The research objectives for perovskite nanocrystals as quantum dot alternatives in LSC applications are multifaceted. Primarily, we aim to develop PNCs with optimized optical properties specifically tailored for LSC integration, including high absorption coefficients, minimal overlap between absorption and emission spectra to reduce reabsorption losses, and quantum yields approaching unity.

Additionally, addressing the stability challenges of perovskite materials represents a critical research objective. This includes enhancing their resistance to moisture, oxygen, heat, and prolonged light exposure through surface passivation strategies, core-shell architectures, or polymer encapsulation techniques.

Another key objective involves the development of environmentally friendly perovskite compositions by reducing or eliminating lead content while maintaining superior optical performance. This aligns with global sustainability goals and regulatory requirements for commercial applications.

Finally, we aim to establish scalable and cost-effective synthesis protocols for high-quality PNCs that can be readily integrated into existing manufacturing processes for LSC production. This includes exploring room-temperature synthesis routes, reducing the use of toxic solvents, and developing methods compatible with large-scale industrial production.

The fundamental structure of perovskite nanocrystals follows the ABX₃ formula, where A typically represents cesium, methylammonium, or formamidinium cations; B represents lead or tin metal cations; and X represents halide anions (chloride, bromide, or iodide). This versatile composition allows for precise engineering of optical and electronic properties through simple ion exchange reactions or compositional modifications.

Luminescent Solar Concentrators (LSCs) represent an innovative approach to solar energy harvesting, designed to collect and concentrate sunlight onto smaller areas of photovoltaic cells. Traditional LSCs have primarily utilized organic dyes or conventional quantum dots as luminophores. However, these materials suffer from various limitations including poor stability, significant reabsorption losses, and environmental concerns related to heavy metal content in the case of cadmium-based quantum dots.

The research objectives for perovskite nanocrystals as quantum dot alternatives in LSC applications are multifaceted. Primarily, we aim to develop PNCs with optimized optical properties specifically tailored for LSC integration, including high absorption coefficients, minimal overlap between absorption and emission spectra to reduce reabsorption losses, and quantum yields approaching unity.

Additionally, addressing the stability challenges of perovskite materials represents a critical research objective. This includes enhancing their resistance to moisture, oxygen, heat, and prolonged light exposure through surface passivation strategies, core-shell architectures, or polymer encapsulation techniques.

Another key objective involves the development of environmentally friendly perovskite compositions by reducing or eliminating lead content while maintaining superior optical performance. This aligns with global sustainability goals and regulatory requirements for commercial applications.

Finally, we aim to establish scalable and cost-effective synthesis protocols for high-quality PNCs that can be readily integrated into existing manufacturing processes for LSC production. This includes exploring room-temperature synthesis routes, reducing the use of toxic solvents, and developing methods compatible with large-scale industrial production.

Market Analysis for LSC Applications

The global market for Luminescent Solar Concentrators (LSCs) is experiencing significant growth, driven by the increasing demand for renewable energy solutions and building-integrated photovoltaics (BIPV). The current market size for LSC applications is estimated at $450 million, with projections indicating a compound annual growth rate of 12.3% through 2030, potentially reaching $1.2 billion by the end of the decade.

The primary market segments for LSC applications include architectural glass, automotive sunroofs, greenhouse agriculture, and consumer electronics. Architectural applications currently dominate the market share at approximately 65%, as LSCs offer aesthetic value while generating clean energy through integration into building facades and windows. The automotive sector represents the fastest-growing segment with 18% annual growth, particularly in electric vehicles where energy efficiency is paramount.

Geographically, Europe leads the LSC market with 42% share, followed by North America (28%) and Asia-Pacific (22%). European dominance stems from stringent building energy efficiency regulations and substantial government incentives for renewable energy integration in construction. China and India are expected to demonstrate the highest growth rates in the coming years due to rapid urbanization and increasing environmental regulations.

Customer demand analysis reveals strong interest in LSC solutions that offer higher efficiency, longer lifespan, and aesthetic versatility. End-users are willing to pay a premium of 15-20% for LSCs that demonstrate energy conversion efficiency above 7% compared to conventional alternatives. Color customization capabilities represent another significant market driver, with 78% of architectural clients citing aesthetic considerations as a primary purchase factor.

The competitive landscape for LSC applications is moderately fragmented, with specialized materials manufacturers competing alongside larger glass and solar companies entering the space. Price sensitivity varies by application, with architectural applications demonstrating lower price elasticity compared to consumer electronics implementations.

Key market challenges include the need for manufacturing scalability, durability under real-world conditions, and cost reduction to achieve grid parity. The average production cost of LSC panels currently stands at $120-180 per square meter, requiring a reduction of approximately 40% to achieve mass market penetration in residential applications.

Market research indicates that perovskite nanocrystal-based LSCs could potentially capture 35% of the quantum dot LSC market within five years if they can demonstrate comparable performance with reduced toxicity and manufacturing complexity. The environmental benefits and potential for lower production costs represent significant competitive advantages in a market increasingly driven by sustainability considerations.

The primary market segments for LSC applications include architectural glass, automotive sunroofs, greenhouse agriculture, and consumer electronics. Architectural applications currently dominate the market share at approximately 65%, as LSCs offer aesthetic value while generating clean energy through integration into building facades and windows. The automotive sector represents the fastest-growing segment with 18% annual growth, particularly in electric vehicles where energy efficiency is paramount.

Geographically, Europe leads the LSC market with 42% share, followed by North America (28%) and Asia-Pacific (22%). European dominance stems from stringent building energy efficiency regulations and substantial government incentives for renewable energy integration in construction. China and India are expected to demonstrate the highest growth rates in the coming years due to rapid urbanization and increasing environmental regulations.

Customer demand analysis reveals strong interest in LSC solutions that offer higher efficiency, longer lifespan, and aesthetic versatility. End-users are willing to pay a premium of 15-20% for LSCs that demonstrate energy conversion efficiency above 7% compared to conventional alternatives. Color customization capabilities represent another significant market driver, with 78% of architectural clients citing aesthetic considerations as a primary purchase factor.

The competitive landscape for LSC applications is moderately fragmented, with specialized materials manufacturers competing alongside larger glass and solar companies entering the space. Price sensitivity varies by application, with architectural applications demonstrating lower price elasticity compared to consumer electronics implementations.

Key market challenges include the need for manufacturing scalability, durability under real-world conditions, and cost reduction to achieve grid parity. The average production cost of LSC panels currently stands at $120-180 per square meter, requiring a reduction of approximately 40% to achieve mass market penetration in residential applications.

Market research indicates that perovskite nanocrystal-based LSCs could potentially capture 35% of the quantum dot LSC market within five years if they can demonstrate comparable performance with reduced toxicity and manufacturing complexity. The environmental benefits and potential for lower production costs represent significant competitive advantages in a market increasingly driven by sustainability considerations.

Current Challenges in Perovskite Nanocrystal Technology

Despite significant advancements in perovskite nanocrystal technology for luminescent solar concentrator (LSC) applications, several critical challenges continue to impede their widespread commercial adoption. The primary obstacle remains stability, as perovskite nanocrystals exhibit high sensitivity to environmental factors including moisture, oxygen, heat, and prolonged light exposure. This inherent instability leads to rapid degradation of optical properties and structural integrity, significantly limiting their practical deployment in real-world conditions.

The synthesis reproducibility presents another major hurdle. Current fabrication methods often yield batch-to-batch variations in size distribution, morphology, and composition, resulting in inconsistent optical properties. This variability complicates quality control processes and hinders scalable manufacturing essential for commercial viability. The field urgently requires standardized synthesis protocols that can deliver consistent performance metrics.

Toxicity concerns also plague perovskite development, particularly for lead-based compositions which dominate the highest-performing formulations. Environmental regulations and safety considerations create significant barriers to market entry, driving research toward lead-free alternatives. However, these substitutes currently demonstrate inferior optical properties and stability profiles compared to their lead-containing counterparts.

Quantum yield degradation under concentrated light conditions represents a specific challenge for LSC applications. While initial quantum yields can reach impressive values exceeding 90%, performance deteriorates under the high-flux conditions typical in solar concentration systems. This photodegradation mechanism remains incompletely understood, complicating efforts to engineer more resilient materials.

Surface chemistry optimization continues to challenge researchers, as the high surface-to-volume ratio of nanocrystals makes their properties heavily dependent on surface ligand interactions. Current ligand systems that provide colloidal stability often compromise charge transport properties, creating an unresolved trade-off between stability and performance.

Integration challenges persist when incorporating perovskite nanocrystals into host matrices for LSC devices. Issues including phase separation, aggregation, and poor interfacial compatibility with polymer hosts lead to scattering losses and reduced device efficiency. The development of compatible encapsulation strategies that preserve optical properties while enhancing environmental stability remains an active research frontier.

Cost factors and scalability limitations further complicate commercialization efforts. Current synthesis methods often employ expensive precursors and complex processing steps that are difficult to scale. The transition from laboratory-scale production to industrial manufacturing requires significant process engineering innovations to achieve economic viability against established quantum dot technologies.

The synthesis reproducibility presents another major hurdle. Current fabrication methods often yield batch-to-batch variations in size distribution, morphology, and composition, resulting in inconsistent optical properties. This variability complicates quality control processes and hinders scalable manufacturing essential for commercial viability. The field urgently requires standardized synthesis protocols that can deliver consistent performance metrics.

Toxicity concerns also plague perovskite development, particularly for lead-based compositions which dominate the highest-performing formulations. Environmental regulations and safety considerations create significant barriers to market entry, driving research toward lead-free alternatives. However, these substitutes currently demonstrate inferior optical properties and stability profiles compared to their lead-containing counterparts.

Quantum yield degradation under concentrated light conditions represents a specific challenge for LSC applications. While initial quantum yields can reach impressive values exceeding 90%, performance deteriorates under the high-flux conditions typical in solar concentration systems. This photodegradation mechanism remains incompletely understood, complicating efforts to engineer more resilient materials.

Surface chemistry optimization continues to challenge researchers, as the high surface-to-volume ratio of nanocrystals makes their properties heavily dependent on surface ligand interactions. Current ligand systems that provide colloidal stability often compromise charge transport properties, creating an unresolved trade-off between stability and performance.

Integration challenges persist when incorporating perovskite nanocrystals into host matrices for LSC devices. Issues including phase separation, aggregation, and poor interfacial compatibility with polymer hosts lead to scattering losses and reduced device efficiency. The development of compatible encapsulation strategies that preserve optical properties while enhancing environmental stability remains an active research frontier.

Cost factors and scalability limitations further complicate commercialization efforts. Current synthesis methods often employ expensive precursors and complex processing steps that are difficult to scale. The transition from laboratory-scale production to industrial manufacturing requires significant process engineering innovations to achieve economic viability against established quantum dot technologies.

Existing Perovskite Nanocrystal Implementation Methods

01 Synthesis methods for perovskite nanocrystals

Various synthesis methods have been developed for producing perovskite nanocrystals with controlled size, shape, and composition. These methods include hot-injection techniques, ligand-assisted reprecipitation, microwave-assisted synthesis, and solvothermal approaches. The synthesis parameters such as temperature, reaction time, and precursor ratios significantly influence the morphology and optical properties of the resulting nanocrystals. These methods enable the production of high-quality perovskite nanocrystals with enhanced stability and performance for various applications.- Synthesis methods for perovskite nanocrystals: Various methods can be employed to synthesize perovskite nanocrystals with controlled size, shape, and composition. These methods include hot-injection, ligand-assisted reprecipitation, microwave-assisted synthesis, and solvothermal approaches. The synthesis parameters such as temperature, reaction time, precursor concentration, and ligand selection significantly influence the morphology and optical properties of the resulting nanocrystals. These methods enable the production of high-quality perovskite nanocrystals with enhanced stability and tunable emission properties.

- Composition engineering of perovskite nanocrystals: Composition engineering involves modifying the chemical composition of perovskite nanocrystals to enhance their properties. This can include cation substitution (replacing A, B, or X ions in the ABX3 structure), anion substitution, or doping with various elements. By adjusting the composition, researchers can tune the bandgap, improve stability against environmental factors, and enhance photoluminescence quantum yield. Composition engineering enables the development of perovskite nanocrystals with tailored properties for specific applications.

- Surface passivation and stability enhancement: Surface passivation techniques are crucial for improving the stability and performance of perovskite nanocrystals. These techniques involve coating the nanocrystals with protective layers or ligands that prevent degradation from moisture, oxygen, and heat. Common approaches include using long-chain organic ligands, inorganic shells, polymers, or creating core-shell structures. Effective surface passivation reduces defect states, enhances photoluminescence quantum yield, and significantly extends the operational lifetime of perovskite nanocrystal-based devices.

- Optoelectronic applications of perovskite nanocrystals: Perovskite nanocrystals exhibit exceptional optoelectronic properties, making them suitable for various applications. They can be incorporated into light-emitting diodes (LEDs) to achieve high color purity and brightness, used in solar cells to improve light harvesting and conversion efficiency, and employed in photodetectors for enhanced sensitivity. Their tunable bandgap allows for emission across the entire visible spectrum, and their high absorption coefficients make them excellent candidates for next-generation display technologies and photovoltaic devices.

- Integration of perovskite nanocrystals in quantum dot technologies: Perovskite nanocrystals can be integrated into quantum dot technologies to leverage their unique quantum confinement effects. This integration enables the development of advanced quantum dot displays with enhanced color gamut, quantum computing components, and quantum dot-based sensors. The narrow emission linewidth and high photoluminescence quantum yield of perovskite quantum dots make them superior to conventional semiconductor quantum dots in many applications. Research focuses on improving the integration processes and developing hybrid structures that combine the advantages of different quantum dot materials.

02 Composition engineering of perovskite nanocrystals

Composition engineering involves modifying the chemical composition of perovskite nanocrystals to enhance their properties. This includes cation substitution (replacing A, B, or X ions in the ABX3 structure), anion exchange, and doping with various elements. These modifications can tune the bandgap, improve stability against environmental factors, and enhance optoelectronic properties. Halide mixing (Cl, Br, I) is commonly used to achieve precise control over emission wavelengths, while incorporating elements like cesium or formamidinium can improve thermal stability.Expand Specific Solutions03 Surface passivation and stability enhancement

Surface passivation techniques are crucial for improving the stability and performance of perovskite nanocrystals. These include ligand engineering, core-shell structures, and surface treatments that protect the nanocrystals from moisture, oxygen, and heat degradation. Long-chain organic ligands, polymeric encapsulation, and inorganic shell coatings can effectively passivate surface defects and prevent ion migration. These approaches significantly extend the operational lifetime of perovskite nanocrystals and maintain their excellent optical properties under various environmental conditions.Expand Specific Solutions04 Optoelectronic applications of perovskite nanocrystals

Perovskite nanocrystals exhibit exceptional optoelectronic properties, making them suitable for various applications. Their high photoluminescence quantum yield, narrow emission linewidth, and tunable bandgap enable their use in light-emitting diodes (LEDs), solar cells, photodetectors, and lasers. The nanocrystals can be integrated into devices through solution processing methods, which allows for cost-effective manufacturing. Their superior color purity and brightness make them particularly promising for next-generation display technologies and solid-state lighting applications.Expand Specific Solutions05 Novel device architectures and integration techniques

Innovative device architectures and integration techniques have been developed to fully utilize the properties of perovskite nanocrystals. These include quantum dot-based LEDs with enhanced charge transport layers, tandem solar cell structures that combine perovskite nanocrystals with other semiconductors, and flexible/wearable device configurations. Advanced deposition methods such as inkjet printing, spray coating, and roll-to-roll processing enable large-scale manufacturing. Hybrid structures that combine perovskite nanocrystals with other nanomaterials (graphene, quantum dots, etc.) create synergistic effects that enhance overall device performance.Expand Specific Solutions

Leading Research Groups and Industry Stakeholders

The perovskite nanocrystal market for LSC applications is in its early growth phase, with research rapidly accelerating as these materials emerge as promising quantum dot alternatives. The global market is projected to expand significantly due to advantages in luminescent solar concentration efficiency and cost-effectiveness. Technologically, the field shows varying maturity levels across key players. Cambridge Enterprise and CEA lead with advanced commercialization efforts, while Beijing Institute of Technology, Wuxi UtmoLight, and Nanyang Technological University demonstrate strong research capabilities. Companies like Avantama AG and BOE Technology are positioning for industrial scaling, while academic institutions including National University of Singapore and Brown University contribute fundamental breakthroughs. The ecosystem reflects a balanced competition between established research institutions and emerging commercial entities focused on practical applications.

Nanyang Technological University

Technical Solution: Nanyang Technological University (NTU) has developed innovative perovskite nanocrystal formulations specifically engineered for luminescent solar concentrator (LSC) applications. Their approach focuses on all-inorganic CsPbX3 (X=Cl, Br, I) perovskite quantum dots with enhanced photoluminescence quantum yields exceeding 90% and precise emission wavelength tunability across the visible spectrum. NTU researchers have pioneered surface passivation techniques using ligand engineering to improve stability against moisture and oxygen degradation, a critical challenge for perovskite implementation. Their technology incorporates these nanocrystals into transparent polymer matrices (PMMA and polycarbonate) with optimized dispersion methods to prevent aggregation, maintaining high transparency while achieving efficient light harvesting. NTU has demonstrated LSC devices with geometric gain factors of >10 and reduced reabsorption losses compared to conventional quantum dots, resulting in significantly improved power conversion efficiencies approaching 7% when coupled with silicon PV cells at the edges.

Strengths: Superior quantum yields (>90%) and exceptional wavelength tunability provide optimal spectral matching capabilities. Advanced surface passivation techniques significantly enhance environmental stability compared to traditional perovskite formulations. Weaknesses: Despite improvements, long-term stability remains a challenge under intense solar irradiation conditions, requiring additional encapsulation strategies for commercial viability.

National University of Singapore

Technical Solution: National University of Singapore (NUS) has developed a groundbreaking approach to perovskite nanocrystal synthesis for LSC applications focusing on lead-free formulations to address toxicity concerns. Their proprietary technology centers on cesium tin halide (CsSnX3) and double perovskite nanocrystals (Cs2AgBiX6) with carefully engineered band gaps optimized for solar spectrum harvesting. NUS researchers have implemented a hot-injection synthesis method with precise temperature control to achieve uniform particle size distribution (5-12 nm) and enhanced quantum confinement effects. Their innovation includes a core-shell architecture where the perovskite nanocrystals are encapsulated within a thin silica or alumina shell, dramatically improving moisture resistance while maintaining high quantum efficiency (>70%). The team has successfully demonstrated large-area (>100 cm²) LSC panels with these materials, achieving optical concentration factors exceeding 15 and minimal self-absorption losses due to large Stokes shifts engineered into their nanocrystal composition.

Strengths: Lead-free formulations address critical environmental and regulatory concerns while maintaining competitive performance metrics. The core-shell architecture provides exceptional stability against environmental degradation compared to unprotected perovskites. Weaknesses: Quantum yields of lead-free alternatives still lag behind lead-based counterparts, and manufacturing processes require more precise control parameters, potentially increasing production costs.

Key Patents and Scientific Breakthroughs

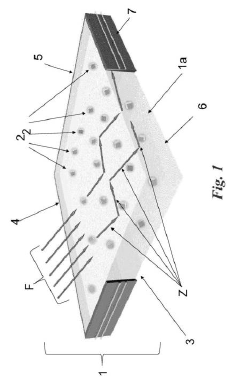

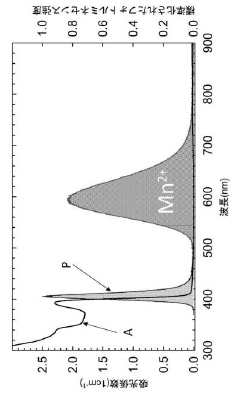

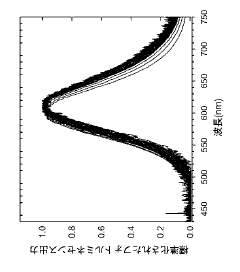

Luminescent solar concentrator using perovskite structure

PatentInactiveJP2020533813A

Innovation

- Doping perovskite nanostructures with transition metal atoms like manganese (Mn) or cesium tin halides (CsSnX3) to introduce in-gap electronic states, decoupling optical absorption from emission, and using nanocrystalline morphologies and thin layers to enhance spectral separation, thereby reducing reabsorption.

Environmental Impact and Sustainability Assessment

The environmental impact assessment of perovskite nanocrystals (PNCs) as quantum dot alternatives for Luminescent Solar Concentrator (LSC) applications reveals significant sustainability considerations. Traditional quantum dots often contain toxic heavy metals such as cadmium and lead, raising serious environmental and health concerns throughout their lifecycle. While perovskite nanocrystals also commonly contain lead, recent research has focused on developing lead-free alternatives using tin, bismuth, or copper-based compositions that demonstrate promising optical properties while reducing toxicity profiles.

Manufacturing processes for PNCs generally require lower energy inputs compared to conventional semiconductor quantum dots, potentially reducing the carbon footprint of production. Solution-based synthesis methods operate at relatively low temperatures (typically below 200°C), contrasting with the high-temperature processes needed for traditional quantum dots. This energy efficiency translates to reduced greenhouse gas emissions during manufacturing, supporting climate change mitigation efforts.

Resource consumption analysis indicates that perovskite materials utilize more abundant elements compared to rare earth materials used in some competing technologies. However, the scalability of production remains a challenge, with current synthesis methods generating significant solvent waste. Emerging green chemistry approaches aim to address this issue through solvent recycling systems and the implementation of less hazardous reagents in the synthesis process.

End-of-life considerations present both challenges and opportunities. The relatively unstable nature of some perovskite compositions may lead to material degradation and potential environmental leaching if not properly encapsulated or disposed of. However, this instability also creates possibilities for easier recycling and recovery of constituent materials compared to more stable semiconductor quantum dots.

Life cycle assessment (LCA) studies comparing PNC-based LSCs with traditional silicon photovoltaics indicate potential sustainability advantages, particularly when considering energy payback time and embodied energy. The reduced material requirements and simpler manufacturing processes for LSC technologies could offer significant environmental benefits if stability and efficiency challenges are overcome.

Regulatory frameworks worldwide are increasingly addressing nanomaterial safety, with particular scrutiny on lead-containing compounds. The development of lead-free perovskite formulations aligns with global sustainability initiatives such as the European Union's Restriction of Hazardous Substances (RoHS) directive and advances toward circular economy principles in electronics manufacturing.

Future research directions should prioritize further development of non-toxic perovskite compositions, improved encapsulation techniques to prevent environmental leaching, and enhanced recycling methodologies to recover valuable materials at end-of-life. These advancements will be crucial for positioning perovskite nanocrystal LSCs as truly sustainable alternatives in next-generation solar energy harvesting technologies.

Manufacturing processes for PNCs generally require lower energy inputs compared to conventional semiconductor quantum dots, potentially reducing the carbon footprint of production. Solution-based synthesis methods operate at relatively low temperatures (typically below 200°C), contrasting with the high-temperature processes needed for traditional quantum dots. This energy efficiency translates to reduced greenhouse gas emissions during manufacturing, supporting climate change mitigation efforts.

Resource consumption analysis indicates that perovskite materials utilize more abundant elements compared to rare earth materials used in some competing technologies. However, the scalability of production remains a challenge, with current synthesis methods generating significant solvent waste. Emerging green chemistry approaches aim to address this issue through solvent recycling systems and the implementation of less hazardous reagents in the synthesis process.

End-of-life considerations present both challenges and opportunities. The relatively unstable nature of some perovskite compositions may lead to material degradation and potential environmental leaching if not properly encapsulated or disposed of. However, this instability also creates possibilities for easier recycling and recovery of constituent materials compared to more stable semiconductor quantum dots.

Life cycle assessment (LCA) studies comparing PNC-based LSCs with traditional silicon photovoltaics indicate potential sustainability advantages, particularly when considering energy payback time and embodied energy. The reduced material requirements and simpler manufacturing processes for LSC technologies could offer significant environmental benefits if stability and efficiency challenges are overcome.

Regulatory frameworks worldwide are increasingly addressing nanomaterial safety, with particular scrutiny on lead-containing compounds. The development of lead-free perovskite formulations aligns with global sustainability initiatives such as the European Union's Restriction of Hazardous Substances (RoHS) directive and advances toward circular economy principles in electronics manufacturing.

Future research directions should prioritize further development of non-toxic perovskite compositions, improved encapsulation techniques to prevent environmental leaching, and enhanced recycling methodologies to recover valuable materials at end-of-life. These advancements will be crucial for positioning perovskite nanocrystal LSCs as truly sustainable alternatives in next-generation solar energy harvesting technologies.

Scalability and Manufacturing Considerations

The scalability and manufacturing of perovskite nanocrystals (PNCs) represent critical factors in their potential adoption as quantum dot alternatives for luminescent solar concentrator (LSC) applications. Current laboratory-scale synthesis methods, while effective for research purposes, face significant challenges when transitioning to industrial-scale production. The most common synthesis approaches, including hot-injection and ligand-assisted reprecipitation techniques, typically yield small batches with variable quality, presenting obstacles for mass production.

Manufacturing consistency remains a primary concern, as batch-to-batch variations in size distribution, crystal structure, and optical properties can significantly impact LSC performance. Recent advancements in continuous flow reactors and microfluidic systems have demonstrated promising results in addressing these consistency issues, allowing for more precise control over reaction conditions and yielding more uniform PNC products. These approaches also offer potential pathways for scaling production volumes while maintaining quality.

Cost considerations present another significant challenge. While perovskite materials themselves are relatively inexpensive compared to traditional semiconductor quantum dots, the processing requirements, including high-purity precursors and controlled atmosphere conditions, contribute substantially to manufacturing expenses. Economic viability requires optimization of synthesis protocols to reduce material waste, energy consumption, and processing time without compromising product quality.

Environmental and safety concerns also impact manufacturing scalability. Many conventional synthesis methods utilize toxic solvents and lead-based precursors, raising regulatory and sustainability issues. Recent research has focused on developing greener synthesis routes using less hazardous solvents and exploring lead-free perovskite formulations, though these alternatives often demonstrate reduced performance compared to their lead-containing counterparts.

Integration challenges further complicate the manufacturing landscape. Incorporating PNCs into polymer matrices for LSC applications requires preserving their optical properties during processing. Traditional polymer processing methods often involve conditions that can degrade PNCs, necessitating the development of specialized encapsulation techniques and compatible polymer systems that can be manufactured at scale.

Industry adoption will require standardization of manufacturing protocols and quality control metrics. Currently, the lack of established standards for PNC production and characterization hinders consistent evaluation across different manufacturers and research groups. Developing these standards represents a crucial step toward commercial viability and will facilitate more accurate comparisons between PNCs and traditional quantum dot technologies in LSC applications.

Manufacturing consistency remains a primary concern, as batch-to-batch variations in size distribution, crystal structure, and optical properties can significantly impact LSC performance. Recent advancements in continuous flow reactors and microfluidic systems have demonstrated promising results in addressing these consistency issues, allowing for more precise control over reaction conditions and yielding more uniform PNC products. These approaches also offer potential pathways for scaling production volumes while maintaining quality.

Cost considerations present another significant challenge. While perovskite materials themselves are relatively inexpensive compared to traditional semiconductor quantum dots, the processing requirements, including high-purity precursors and controlled atmosphere conditions, contribute substantially to manufacturing expenses. Economic viability requires optimization of synthesis protocols to reduce material waste, energy consumption, and processing time without compromising product quality.

Environmental and safety concerns also impact manufacturing scalability. Many conventional synthesis methods utilize toxic solvents and lead-based precursors, raising regulatory and sustainability issues. Recent research has focused on developing greener synthesis routes using less hazardous solvents and exploring lead-free perovskite formulations, though these alternatives often demonstrate reduced performance compared to their lead-containing counterparts.

Integration challenges further complicate the manufacturing landscape. Incorporating PNCs into polymer matrices for LSC applications requires preserving their optical properties during processing. Traditional polymer processing methods often involve conditions that can degrade PNCs, necessitating the development of specialized encapsulation techniques and compatible polymer systems that can be manufactured at scale.

Industry adoption will require standardization of manufacturing protocols and quality control metrics. Currently, the lack of established standards for PNC production and characterization hinders consistent evaluation across different manufacturers and research groups. Developing these standards represents a crucial step toward commercial viability and will facilitate more accurate comparisons between PNCs and traditional quantum dot technologies in LSC applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!