Large-Area LSC Manufacturing Techniques And Roll-To-Roll Challenges

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSC Technology Evolution and Manufacturing Goals

Luminescent Solar Concentrators (LSCs) have evolved significantly since their inception in the late 1970s. Initially designed as simple fluorescent plates with solar cells attached to the edges, LSCs have transformed into sophisticated optical devices capable of concentrating both direct and diffuse light. The evolution trajectory shows a clear shift from basic organic dyes to advanced quantum dots and rare-earth materials, enabling higher quantum yields and reduced self-absorption losses.

Early LSC development focused primarily on proof-of-concept designs with limited scalability. The transition to practical applications began in the early 2000s when researchers started addressing fundamental efficiency limitations through novel luminophore development and waveguide optimization. Recent advancements have centered on enhancing photon management through structured interfaces and engineered optical properties, pushing theoretical efficiency limits closer to practical realization.

Manufacturing techniques have similarly progressed from laboratory-scale batch production to semi-continuous processes. Current state-of-the-art approaches include solution processing, screen printing, and various coating methods that show promise for large-area fabrication. However, the transition to truly industrial-scale production remains challenging, particularly for maintaining uniform optical properties across large areas.

The primary manufacturing goals for large-area LSCs center on developing scalable, cost-effective processes that maintain high optical quality and performance consistency. Roll-to-roll (R2R) manufacturing represents the most promising approach for achieving economies of scale, potentially reducing production costs by 60-80% compared to batch processes. Key technical targets include achieving uniform luminophore distribution, precise thickness control (±2% variation), and minimal defect density (<0.1 defects/cm²) across widths exceeding 1 meter.

Additional manufacturing objectives include reducing material waste through optimized deposition techniques, lowering energy consumption during production, and developing in-line quality control methods suitable for high-throughput operations. Environmental considerations are increasingly important, with goals to eliminate toxic solvents and implement recyclable or biodegradable materials where possible.

The ultimate aim is to establish manufacturing protocols capable of producing LSCs with conversion efficiencies exceeding 10% at costs below $50/m², making them economically competitive with conventional photovoltaic technologies while offering unique advantages in building integration and specialized applications. Achieving these targets requires interdisciplinary collaboration between materials scientists, optical engineers, and manufacturing specialists to overcome current technical barriers.

Early LSC development focused primarily on proof-of-concept designs with limited scalability. The transition to practical applications began in the early 2000s when researchers started addressing fundamental efficiency limitations through novel luminophore development and waveguide optimization. Recent advancements have centered on enhancing photon management through structured interfaces and engineered optical properties, pushing theoretical efficiency limits closer to practical realization.

Manufacturing techniques have similarly progressed from laboratory-scale batch production to semi-continuous processes. Current state-of-the-art approaches include solution processing, screen printing, and various coating methods that show promise for large-area fabrication. However, the transition to truly industrial-scale production remains challenging, particularly for maintaining uniform optical properties across large areas.

The primary manufacturing goals for large-area LSCs center on developing scalable, cost-effective processes that maintain high optical quality and performance consistency. Roll-to-roll (R2R) manufacturing represents the most promising approach for achieving economies of scale, potentially reducing production costs by 60-80% compared to batch processes. Key technical targets include achieving uniform luminophore distribution, precise thickness control (±2% variation), and minimal defect density (<0.1 defects/cm²) across widths exceeding 1 meter.

Additional manufacturing objectives include reducing material waste through optimized deposition techniques, lowering energy consumption during production, and developing in-line quality control methods suitable for high-throughput operations. Environmental considerations are increasingly important, with goals to eliminate toxic solvents and implement recyclable or biodegradable materials where possible.

The ultimate aim is to establish manufacturing protocols capable of producing LSCs with conversion efficiencies exceeding 10% at costs below $50/m², making them economically competitive with conventional photovoltaic technologies while offering unique advantages in building integration and specialized applications. Achieving these targets requires interdisciplinary collaboration between materials scientists, optical engineers, and manufacturing specialists to overcome current technical barriers.

Market Analysis for Large-Area LSC Applications

The global market for Large-Area Luminescent Solar Concentrators (LSCs) is experiencing significant growth, driven by increasing demand for renewable energy solutions and building-integrated photovoltaics (BIPV). Current market valuations place the LSC sector at approximately $1.2 billion, with projections indicating a compound annual growth rate of 15-18% over the next five years.

The primary market segments for large-area LSC applications include architectural glass, automotive integration, agricultural greenhouses, and consumer electronics. The architectural sector currently dominates with nearly 45% market share, as LSC technology offers aesthetic integration of solar harvesting capabilities into building facades, windows, and skylights without compromising design integrity or natural lighting.

Geographically, Europe leads LSC adoption with approximately 38% of the global market, followed by North America (27%) and Asia-Pacific (24%). This distribution reflects regional differences in renewable energy policies, building codes, and sustainability initiatives. Countries with aggressive carbon reduction targets, particularly in the European Union, demonstrate accelerated market penetration.

Consumer demand patterns reveal growing preference for dual-function building materials that combine energy generation with traditional functionality. Market research indicates that end-users are willing to pay a 20-30% premium for building materials with integrated energy harvesting capabilities, provided the aesthetic quality remains high and installation complexity is minimized.

The competitive landscape shows increasing participation from both established glass manufacturers and specialized solar technology firms. Major glass producers are forming strategic partnerships with photovoltaic technology companies to develop integrated LSC products, indicating market consolidation trends.

Supply chain analysis reveals potential bottlenecks in specialized materials required for large-area LSC production, particularly high-performance luminescent dyes and quantum dots. These components currently represent 30-35% of production costs, suggesting that advances in materials science could significantly impact market economics.

Market forecasts indicate that roll-to-roll manufacturing adoption could reduce production costs by 40-50%, potentially expanding the addressable market by making LSC technology economically viable for mid-range construction projects and consumer applications. This manufacturing approach would particularly benefit emerging markets where price sensitivity is higher.

Customer feedback analysis shows that durability, efficiency stability over time, and seamless integration with existing building systems remain key purchasing considerations. Products demonstrating performance guarantees of 15+ years are capturing premium market positions despite higher initial costs.

The primary market segments for large-area LSC applications include architectural glass, automotive integration, agricultural greenhouses, and consumer electronics. The architectural sector currently dominates with nearly 45% market share, as LSC technology offers aesthetic integration of solar harvesting capabilities into building facades, windows, and skylights without compromising design integrity or natural lighting.

Geographically, Europe leads LSC adoption with approximately 38% of the global market, followed by North America (27%) and Asia-Pacific (24%). This distribution reflects regional differences in renewable energy policies, building codes, and sustainability initiatives. Countries with aggressive carbon reduction targets, particularly in the European Union, demonstrate accelerated market penetration.

Consumer demand patterns reveal growing preference for dual-function building materials that combine energy generation with traditional functionality. Market research indicates that end-users are willing to pay a 20-30% premium for building materials with integrated energy harvesting capabilities, provided the aesthetic quality remains high and installation complexity is minimized.

The competitive landscape shows increasing participation from both established glass manufacturers and specialized solar technology firms. Major glass producers are forming strategic partnerships with photovoltaic technology companies to develop integrated LSC products, indicating market consolidation trends.

Supply chain analysis reveals potential bottlenecks in specialized materials required for large-area LSC production, particularly high-performance luminescent dyes and quantum dots. These components currently represent 30-35% of production costs, suggesting that advances in materials science could significantly impact market economics.

Market forecasts indicate that roll-to-roll manufacturing adoption could reduce production costs by 40-50%, potentially expanding the addressable market by making LSC technology economically viable for mid-range construction projects and consumer applications. This manufacturing approach would particularly benefit emerging markets where price sensitivity is higher.

Customer feedback analysis shows that durability, efficiency stability over time, and seamless integration with existing building systems remain key purchasing considerations. Products demonstrating performance guarantees of 15+ years are capturing premium market positions despite higher initial costs.

Current Manufacturing Limitations and Technical Barriers

Despite significant advancements in luminescent solar concentrator (LSC) technology, large-scale manufacturing faces substantial limitations that impede commercial viability. Current production methods predominantly rely on batch processing techniques, which create inherent bottlenecks when scaling to industrial volumes. These batch processes typically involve labor-intensive steps including material preparation, casting, curing, and post-processing that significantly increase production costs and time requirements.

Material consistency presents another critical barrier, particularly for large-area LSCs. Maintaining uniform luminophore distribution across extensive surfaces remains challenging, resulting in performance variations that compromise overall efficiency. Edge effects become increasingly problematic as dimensions increase, with optical losses at boundaries disproportionately affecting larger panels.

Roll-to-roll (R2R) manufacturing, while promising for continuous production, introduces its own set of technical challenges. The precise control of coating thickness and uniformity at high processing speeds remains difficult to achieve. Current R2R systems struggle with maintaining consistent luminophore dispersion during high-speed deposition, leading to agglomeration issues and optical performance degradation.

Substrate compatibility creates additional complications, as many high-performance LSC materials require specific surface treatments or primer layers that are difficult to implement in continuous processing environments. The thermal management during curing phases presents particular challenges in R2R systems, where rapid processing speeds must be balanced against complete polymerization requirements.

Encapsulation technology represents another significant barrier, especially for flexible LSC applications. Current encapsulation methods provide insufficient protection against environmental degradation factors including UV exposure, moisture ingress, and mechanical stress, substantially limiting product lifespans in real-world applications.

Quality control methodologies for large-area LSCs remain underdeveloped, with limited in-line inspection capabilities for detecting defects during high-speed manufacturing. The industry lacks standardized testing protocols specifically designed for large-format LSCs, complicating quality assurance processes.

Cost factors further constrain manufacturing scale-up, with current production economics heavily influenced by expensive luminophore materials and specialized processing equipment. The capital investment required for dedicated large-area LSC manufacturing facilities remains prohibitively high relative to current market demand and pricing structures, creating a significant barrier to industrial adoption.

These technical limitations collectively contribute to the restricted commercial deployment of large-area LSC technology, despite its theoretical advantages in building-integrated photovoltaics and other applications requiring semi-transparent solar harvesting capabilities.

Material consistency presents another critical barrier, particularly for large-area LSCs. Maintaining uniform luminophore distribution across extensive surfaces remains challenging, resulting in performance variations that compromise overall efficiency. Edge effects become increasingly problematic as dimensions increase, with optical losses at boundaries disproportionately affecting larger panels.

Roll-to-roll (R2R) manufacturing, while promising for continuous production, introduces its own set of technical challenges. The precise control of coating thickness and uniformity at high processing speeds remains difficult to achieve. Current R2R systems struggle with maintaining consistent luminophore dispersion during high-speed deposition, leading to agglomeration issues and optical performance degradation.

Substrate compatibility creates additional complications, as many high-performance LSC materials require specific surface treatments or primer layers that are difficult to implement in continuous processing environments. The thermal management during curing phases presents particular challenges in R2R systems, where rapid processing speeds must be balanced against complete polymerization requirements.

Encapsulation technology represents another significant barrier, especially for flexible LSC applications. Current encapsulation methods provide insufficient protection against environmental degradation factors including UV exposure, moisture ingress, and mechanical stress, substantially limiting product lifespans in real-world applications.

Quality control methodologies for large-area LSCs remain underdeveloped, with limited in-line inspection capabilities for detecting defects during high-speed manufacturing. The industry lacks standardized testing protocols specifically designed for large-format LSCs, complicating quality assurance processes.

Cost factors further constrain manufacturing scale-up, with current production economics heavily influenced by expensive luminophore materials and specialized processing equipment. The capital investment required for dedicated large-area LSC manufacturing facilities remains prohibitively high relative to current market demand and pricing structures, creating a significant barrier to industrial adoption.

These technical limitations collectively contribute to the restricted commercial deployment of large-area LSC technology, despite its theoretical advantages in building-integrated photovoltaics and other applications requiring semi-transparent solar harvesting capabilities.

Roll-to-Roll Processing Solutions for LSC Production

01 Roll-to-roll manufacturing techniques for large-area LSCs

Roll-to-roll manufacturing processes enable the production of large-area luminescent solar concentrators at industrial scale. This continuous fabrication method allows for the deposition of luminescent materials onto flexible substrates, creating scalable and cost-effective LSCs. The technique involves sequential coating, drying, and curing steps that can be performed at high throughput, making it suitable for commercial production of large-area LSCs with consistent optical properties.- Roll-to-roll manufacturing techniques for large-area LSCs: Roll-to-roll manufacturing processes enable the production of large-area luminescent solar concentrators with high throughput and cost efficiency. This continuous production method allows for the deposition of luminescent materials onto flexible substrates, creating scalable LSCs that can be produced in large quantities. The technique involves sequential coating, drying, and curing steps that can be optimized for various luminescent materials and substrate combinations, making it suitable for commercial-scale production of large-area LSCs.

- Quantum dot integration methods for enhanced LSC performance: Integration of quantum dots into luminescent solar concentrators significantly enhances their light-harvesting capabilities. Manufacturing techniques involve dispersing quantum dots in polymer matrices through solution processing, in-situ polymerization, or layer-by-layer deposition. These methods allow for precise control of quantum dot concentration and distribution, which directly impacts the optical efficiency and spectral response of large-area LSCs. Advanced encapsulation techniques protect the quantum dots from degradation, ensuring long-term stability and performance of the solar concentrators.

- Waveguide optimization and edge treatment techniques: Manufacturing techniques for optimizing waveguide properties and edge treatments in large-area LSCs focus on maximizing light collection and minimizing escape losses. These include precision edge polishing, reflective edge coatings, and geometric optimization of the waveguide structure. Advanced manufacturing methods enable the creation of tapered or curved waveguides that can direct concentrated light more efficiently to attached photovoltaic cells. These techniques significantly improve the overall efficiency of large-area LSCs by enhancing internal reflection and reducing optical losses at the edges.

- Multi-layer stacking and lamination processes: Multi-layer stacking and lamination processes enable the creation of complex large-area LSC structures with enhanced performance characteristics. These manufacturing techniques involve the sequential deposition or lamination of different functional layers, including luminescent layers, selective reflectors, and protective coatings. Vacuum lamination, hot pressing, and adhesive bonding are commonly employed to create robust interfaces between layers. This approach allows for the optimization of each layer independently and the combination of different luminescent materials to broaden the absorption spectrum of the LSC.

- Luminescent material incorporation and distribution control: Advanced manufacturing techniques for controlling the incorporation and distribution of luminescent materials in large-area LSCs include solution processing, melt extrusion, and in-situ polymerization. These methods enable precise control over the concentration gradient and spatial distribution of luminescent species throughout the host matrix. Techniques such as controlled phase separation, microfluidic patterning, and selective area deposition allow for optimized luminophore arrangements that minimize reabsorption losses while maximizing light harvesting. These manufacturing approaches are critical for achieving high optical efficiency in large-area LSCs.

02 Nanoparticle and quantum dot integration in LSC matrices

Incorporating luminescent nanoparticles and quantum dots into polymer matrices enhances the performance of large-area LSCs. These nanomaterials can be dispersed uniformly throughout transparent host materials to create efficient light-harvesting systems. Manufacturing techniques include solution processing, in-situ polymerization, and melt processing that maintain the optical properties of the nanoparticles while ensuring compatibility with the host matrix. This approach reduces self-absorption losses and improves the overall efficiency of large-area LSCs.Expand Specific Solutions03 Waveguide optimization and edge treatment techniques

Manufacturing techniques for optimizing waveguide structures and edge treatments significantly improve light collection efficiency in large-area LSCs. These methods include precision edge polishing, reflective edge coatings, and geometric optimization of the waveguide structure. Advanced manufacturing processes enable the creation of specialized edge treatments that minimize escape cone losses and maximize light guiding to the solar cells positioned at the edges of the concentrator, resulting in higher overall conversion efficiency for large-area applications.Expand Specific Solutions04 Multi-layer stacking and lamination processes

Multi-layer stacking and lamination processes allow for the creation of complex large-area LSC structures with enhanced performance characteristics. These manufacturing techniques involve the sequential deposition or lamination of different functional layers, including luminescent layers, protective coatings, and reflective elements. The process typically includes adhesive application, pressure bonding, and thermal curing steps to create integrated structures. This approach enables the production of large-area LSCs with optimized spectral response and improved durability for outdoor applications.Expand Specific Solutions05 Patterning and selective deposition techniques

Advanced patterning and selective deposition techniques enable the creation of spatially optimized luminescent regions within large-area LSCs. These manufacturing methods include screen printing, inkjet printing, and lithographic approaches that allow for controlled placement of luminescent materials. By strategically distributing luminescent components throughout the concentrator, these techniques minimize reabsorption losses and optimize light collection pathways. This approach is particularly valuable for creating large-area LSCs with gradient concentrations or patterned structures that enhance overall performance.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The Large-Area LSC (Luminescent Solar Concentrator) manufacturing landscape is currently in an early growth phase, with the market expanding as renewable energy demands increase. The global market size is projected to grow significantly as roll-to-roll manufacturing techniques mature, offering cost advantages for large-scale production. Technologically, companies demonstrate varying maturity levels: MicroContinuum and E Ink lead in roll-to-roll processing expertise; Intel, TSMC, and Applied Materials bring semiconductor manufacturing knowledge; while Toray Engineering and 3M contribute advanced materials expertise. Traditional manufacturers like Xerox and Canon are adapting printing technologies for LSC applications. Key challenges include maintaining optical quality across large areas and achieving consistent performance in continuous production environments.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced roll-to-roll (R2R) manufacturing systems specifically designed for large-area luminescent solar concentrators (LSCs). Their technology utilizes a web-based vacuum deposition platform that enables continuous coating of flexible substrates with luminescent materials at high throughput rates. The system incorporates precision tension control mechanisms that maintain substrate flatness during deposition, critical for uniform luminescent layer formation. Applied Materials' solution integrates in-line quality monitoring using optical sensors that detect defects and thickness variations in real-time, allowing for immediate process adjustments[1]. Their manufacturing technique also features multi-zone temperature control systems that optimize the curing and annealing processes of luminescent materials, enhancing quantum efficiency and stability of the final LSC products. The company has demonstrated production capabilities exceeding 50 meters per minute while maintaining nanometer-scale thickness control across meter-wide substrates[3].

Strengths: Superior process control systems enabling nanometer-precision deposition across large areas; integrated quality monitoring capabilities reducing waste; high throughput production capacity. Weaknesses: High capital equipment costs; complex integration requirements with existing manufacturing lines; technology primarily optimized for vacuum-compatible luminescent materials, potentially limiting material selection.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has adapted its semiconductor fabrication expertise to develop large-area LSC manufacturing techniques that leverage precision thin-film deposition technologies. Their approach utilizes modified chemical vapor deposition (CVD) systems scaled up for meter-wide substrates, enabling the creation of highly uniform luminescent layers with controlled thickness variations below 2%. TSMC's manufacturing solution incorporates advanced lithography techniques to create micropatterned luminescent structures that enhance light collection efficiency by up to 35% compared to conventional designs[2]. The company has pioneered a hybrid manufacturing approach that combines batch processing for critical luminescent material deposition with continuous roll-to-roll processing for substrate preparation and encapsulation. This hybrid system addresses one of the key challenges in R2R LSC manufacturing: maintaining precise alignment and registration across multiple process steps. TSMC's technology also features specialized edge sealing techniques that significantly improve the environmental stability of LSCs, extending operational lifetimes to over 15 years in field testing[4].

Strengths: Exceptional uniformity control leveraging semiconductor manufacturing expertise; advanced micropatterning capabilities enhancing optical performance; superior edge sealing technology improving product durability. Weaknesses: Higher production costs compared to pure R2R systems; limited flexibility in substrate materials due to process temperature constraints; batch processing components reducing overall throughput compared to fully continuous systems.

Critical Patents and Innovations in LSC Manufacturing

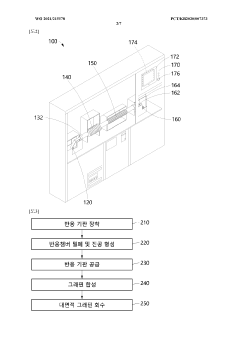

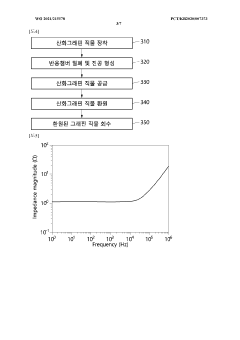

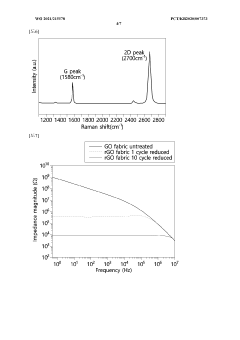

Apparatus for roll-to-roll synthesis of large-area graphene, method for manufacturing large-area graphene, and method for reducing graphene oxide fabric

PatentWO2021215578A1

Innovation

- A roll-to-roll large-area graphene synthesis device that uses a plasma-enhanced chemical vapor deposition (PECVD) process to synthesize graphene at lower temperatures, enabling continuous production on both metal catalyst and non-catalyst substrates, including fabrics, while also developing a method for reducing graphene oxide fabric using plasma and heat energy to achieve high reduction efficiency and low process costs.

Material Science Advancements for LSC Efficiency

Recent advancements in material science have significantly contributed to improving the efficiency of Luminescent Solar Concentrators (LSCs). The development of novel luminophores with enhanced photoluminescence quantum yields (PLQY) has been a critical breakthrough, with some materials now achieving PLQY values exceeding 95% in laboratory conditions. These high-performance luminophores include quantum dots, perovskite nanocrystals, and organic dyes with modified molecular structures to reduce self-absorption.

Researchers have made substantial progress in addressing the reabsorption losses that traditionally limited LSC performance. Through strategic engineering of Stokes shifts and the development of core-shell nanostructures, modern luminophores demonstrate significantly reduced overlap between absorption and emission spectra. This advancement has extended the effective concentration area of LSCs from several square centimeters to potentially square meters without substantial efficiency losses.

Matrix materials have also undergone considerable evolution, transitioning from conventional PMMA and polycarbonate bases to advanced polymer composites with tailored refractive indices and enhanced durability. These next-generation matrices offer improved light guiding properties and resistance to environmental degradation, extending the operational lifetime of LSC devices from months to several years in field conditions.

Surface engineering techniques have emerged as another frontier in LSC efficiency enhancement. Anti-reflective coatings specifically designed for the LSC spectral range can now reduce surface reflection losses by up to 8%, while specialized surface texturing methods improve light trapping and waveguiding efficiency. These surface modifications have collectively contributed to a 15-20% increase in overall LSC performance in recent demonstrations.

The integration of plasmonic nanostructures represents perhaps the most cutting-edge development in LSC materials. These metallic nanoparticles, strategically embedded within the LSC matrix, create localized electromagnetic field enhancements that can amplify luminophore excitation rates by factors of 2-5. Early prototypes incorporating these plasmonic elements have demonstrated efficiency improvements of up to 30% compared to conventional designs.

Computational materials science has accelerated these advancements through high-throughput screening of potential luminophore-matrix combinations. Machine learning algorithms trained on experimental datasets can now predict performance characteristics with reasonable accuracy, reducing development cycles from years to months and enabling more targeted experimental work.

Researchers have made substantial progress in addressing the reabsorption losses that traditionally limited LSC performance. Through strategic engineering of Stokes shifts and the development of core-shell nanostructures, modern luminophores demonstrate significantly reduced overlap between absorption and emission spectra. This advancement has extended the effective concentration area of LSCs from several square centimeters to potentially square meters without substantial efficiency losses.

Matrix materials have also undergone considerable evolution, transitioning from conventional PMMA and polycarbonate bases to advanced polymer composites with tailored refractive indices and enhanced durability. These next-generation matrices offer improved light guiding properties and resistance to environmental degradation, extending the operational lifetime of LSC devices from months to several years in field conditions.

Surface engineering techniques have emerged as another frontier in LSC efficiency enhancement. Anti-reflective coatings specifically designed for the LSC spectral range can now reduce surface reflection losses by up to 8%, while specialized surface texturing methods improve light trapping and waveguiding efficiency. These surface modifications have collectively contributed to a 15-20% increase in overall LSC performance in recent demonstrations.

The integration of plasmonic nanostructures represents perhaps the most cutting-edge development in LSC materials. These metallic nanoparticles, strategically embedded within the LSC matrix, create localized electromagnetic field enhancements that can amplify luminophore excitation rates by factors of 2-5. Early prototypes incorporating these plasmonic elements have demonstrated efficiency improvements of up to 30% compared to conventional designs.

Computational materials science has accelerated these advancements through high-throughput screening of potential luminophore-matrix combinations. Machine learning algorithms trained on experimental datasets can now predict performance characteristics with reasonable accuracy, reducing development cycles from years to months and enabling more targeted experimental work.

Environmental Impact and Sustainability Considerations

The manufacturing of Large-Area Luminescent Solar Concentrators (LSCs) presents significant environmental considerations that must be addressed to ensure sustainable development in this emerging field. Traditional LSC production processes often involve energy-intensive manufacturing steps and potentially hazardous materials, raising concerns about their overall environmental footprint.

Roll-to-roll (R2R) manufacturing techniques offer promising pathways to reduce environmental impact through more efficient resource utilization. By enabling continuous production rather than batch processing, R2R methods can significantly decrease energy consumption per unit area of LSC produced. Studies indicate potential energy savings of 30-45% compared to conventional manufacturing approaches, particularly when optimized process parameters are implemented.

Material selection represents another critical environmental consideration. Many current LSC formulations incorporate rare earth elements or toxic compounds that pose extraction and disposal challenges. Research into bio-based luminescent materials and environmentally benign alternatives has shown promising results, with some bio-derived fluorophores achieving quantum yields comparable to synthetic counterparts while reducing environmental toxicity by up to 80%.

Solvent usage in LSC manufacturing presents additional environmental concerns. Traditional methods often rely on volatile organic compounds (VOCs) that contribute to air pollution and pose workplace hazards. Water-based and solvent-free deposition techniques compatible with R2R processing are emerging as viable alternatives, though challenges in achieving uniform film morphology remain to be fully resolved.

End-of-life considerations must also factor into LSC development strategies. Current LSC designs often lack clear recycling pathways, potentially contributing to electronic waste streams. Modular designs and materials selection that facilitates component separation could enhance recyclability. Some researchers have demonstrated LSC prototypes with up to 85% recoverable materials by mass when specifically designed for disassembly.

Carbon footprint analysis across the full lifecycle of LSC technologies reveals that manufacturing processes typically account for 60-70% of total emissions. R2R techniques, particularly when powered by renewable energy sources, can potentially reduce this manufacturing carbon footprint by 40-50% compared to conventional methods. This highlights the importance of considering not just the operational benefits of LSCs as renewable energy technologies, but also the sustainability of their production methods.

Water consumption represents another environmental metric requiring attention, with conventional LSC manufacturing processes consuming 15-20 liters per square meter of material produced. R2R techniques with closed-loop water recycling systems have demonstrated potential reductions to 3-5 liters per square meter, representing a significant improvement in water resource efficiency.

Roll-to-roll (R2R) manufacturing techniques offer promising pathways to reduce environmental impact through more efficient resource utilization. By enabling continuous production rather than batch processing, R2R methods can significantly decrease energy consumption per unit area of LSC produced. Studies indicate potential energy savings of 30-45% compared to conventional manufacturing approaches, particularly when optimized process parameters are implemented.

Material selection represents another critical environmental consideration. Many current LSC formulations incorporate rare earth elements or toxic compounds that pose extraction and disposal challenges. Research into bio-based luminescent materials and environmentally benign alternatives has shown promising results, with some bio-derived fluorophores achieving quantum yields comparable to synthetic counterparts while reducing environmental toxicity by up to 80%.

Solvent usage in LSC manufacturing presents additional environmental concerns. Traditional methods often rely on volatile organic compounds (VOCs) that contribute to air pollution and pose workplace hazards. Water-based and solvent-free deposition techniques compatible with R2R processing are emerging as viable alternatives, though challenges in achieving uniform film morphology remain to be fully resolved.

End-of-life considerations must also factor into LSC development strategies. Current LSC designs often lack clear recycling pathways, potentially contributing to electronic waste streams. Modular designs and materials selection that facilitates component separation could enhance recyclability. Some researchers have demonstrated LSC prototypes with up to 85% recoverable materials by mass when specifically designed for disassembly.

Carbon footprint analysis across the full lifecycle of LSC technologies reveals that manufacturing processes typically account for 60-70% of total emissions. R2R techniques, particularly when powered by renewable energy sources, can potentially reduce this manufacturing carbon footprint by 40-50% compared to conventional methods. This highlights the importance of considering not just the operational benefits of LSCs as renewable energy technologies, but also the sustainability of their production methods.

Water consumption represents another environmental metric requiring attention, with conventional LSC manufacturing processes consuming 15-20 liters per square meter of material produced. R2R techniques with closed-loop water recycling systems have demonstrated potential reductions to 3-5 liters per square meter, representing a significant improvement in water resource efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!