Standardized Test Methods For Reporting LSC Window Efficiency

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LSC Window Technology Background and Objectives

Luminescent Solar Concentrators (LSCs) represent a transformative technology in the field of building-integrated photovoltaics, with window applications emerging as one of the most promising implementation areas. The concept of LSC windows dates back to the late 1970s, when researchers first explored the potential of fluorescent dyes embedded in transparent materials to capture and redirect solar energy. Over the subsequent decades, this technology has evolved from theoretical concepts to practical prototypes, driven by advancements in materials science, photonics, and renewable energy demands.

The fundamental principle behind LSC windows involves the absorption of incident sunlight by luminescent molecules or particles embedded within a transparent host material. These luminescent species re-emit the absorbed light at longer wavelengths, which is then guided by total internal reflection to the edges of the panel where photovoltaic cells convert the concentrated light into electricity. This elegant approach allows for the creation of visually appealing, semi-transparent windows that simultaneously generate electricity and provide daylighting functionality.

The technological evolution of LSC windows has been marked by several significant breakthroughs, including the development of quantum dots with tunable optical properties, the introduction of novel luminophores with reduced self-absorption, and the engineering of advanced waveguide materials with enhanced optical efficiency. Recent innovations have also focused on addressing the historical limitations of LSC technology, such as limited power conversion efficiency, color distortion, and long-term stability under real-world conditions.

The primary technical objectives for LSC window development center around optimizing the balance between transparency, power generation, and aesthetic appeal. Researchers aim to achieve power conversion efficiencies exceeding 5% while maintaining visible transmittance above 50% and color rendering indices suitable for architectural applications. Additional goals include extending operational lifetimes beyond 20 years, reducing manufacturing costs to competitive levels, and developing scalable production methods compatible with existing window manufacturing infrastructure.

Current research trends indicate a growing emphasis on standardization of testing protocols and performance metrics for LSC windows. This standardization is crucial for enabling meaningful comparisons between different technologies, facilitating industry adoption, and providing consumers with reliable performance data. The development of internationally recognized test methods for reporting LSC window efficiency represents a critical step toward commercialization and widespread implementation of this promising technology in sustainable building design.

As global initiatives for carbon-neutral buildings gain momentum, LSC windows stand at the intersection of architectural design and renewable energy generation, offering a unique pathway to transform passive building elements into active energy producers without compromising aesthetic or functional requirements.

The fundamental principle behind LSC windows involves the absorption of incident sunlight by luminescent molecules or particles embedded within a transparent host material. These luminescent species re-emit the absorbed light at longer wavelengths, which is then guided by total internal reflection to the edges of the panel where photovoltaic cells convert the concentrated light into electricity. This elegant approach allows for the creation of visually appealing, semi-transparent windows that simultaneously generate electricity and provide daylighting functionality.

The technological evolution of LSC windows has been marked by several significant breakthroughs, including the development of quantum dots with tunable optical properties, the introduction of novel luminophores with reduced self-absorption, and the engineering of advanced waveguide materials with enhanced optical efficiency. Recent innovations have also focused on addressing the historical limitations of LSC technology, such as limited power conversion efficiency, color distortion, and long-term stability under real-world conditions.

The primary technical objectives for LSC window development center around optimizing the balance between transparency, power generation, and aesthetic appeal. Researchers aim to achieve power conversion efficiencies exceeding 5% while maintaining visible transmittance above 50% and color rendering indices suitable for architectural applications. Additional goals include extending operational lifetimes beyond 20 years, reducing manufacturing costs to competitive levels, and developing scalable production methods compatible with existing window manufacturing infrastructure.

Current research trends indicate a growing emphasis on standardization of testing protocols and performance metrics for LSC windows. This standardization is crucial for enabling meaningful comparisons between different technologies, facilitating industry adoption, and providing consumers with reliable performance data. The development of internationally recognized test methods for reporting LSC window efficiency represents a critical step toward commercialization and widespread implementation of this promising technology in sustainable building design.

As global initiatives for carbon-neutral buildings gain momentum, LSC windows stand at the intersection of architectural design and renewable energy generation, offering a unique pathway to transform passive building elements into active energy producers without compromising aesthetic or functional requirements.

Market Analysis for LSC Window Applications

The global market for Luminescent Solar Concentrator (LSC) windows is experiencing significant growth as the building industry increasingly prioritizes energy efficiency and sustainability. Current market analysis indicates that the building-integrated photovoltaics (BIPV) sector, which includes LSC windows, is projected to reach $4.3 billion by 2025, with a compound annual growth rate of 16.7% from 2020. LSC windows represent an emerging segment within this market, offering dual functionality as both architectural elements and renewable energy generators.

Commercial buildings represent the largest potential market for LSC window applications, particularly in regions with high solar irradiance and stringent energy efficiency regulations. North America and Europe currently lead adoption rates, with Asia-Pacific markets showing the fastest growth trajectory due to rapid urbanization and increasing environmental regulations in countries like China, Japan, and South Korea.

Market penetration for LSC windows remains relatively low compared to conventional photovoltaic installations, primarily due to efficiency limitations and standardization challenges. The absence of universally accepted test methods for reporting LSC window efficiency has created market fragmentation and consumer uncertainty, significantly impeding wider adoption despite the technology's aesthetic and functional advantages.

Consumer demand analysis reveals three primary market drivers: energy cost reduction, compliance with increasingly stringent building energy codes, and corporate sustainability initiatives. Commercial property developers particularly value the potential for LSC windows to contribute to LEED, BREEAM, and other green building certification points, creating premium value propositions beyond direct energy generation.

Price sensitivity remains a critical market factor, with current LSC window solutions commanding a 30-40% premium over standard energy-efficient glazing. Market research indicates that achieving price parity with high-end architectural glass would significantly accelerate adoption, with payback periods under seven years representing a key psychological threshold for commercial building investors.

Distribution channels for LSC windows are currently dominated by specialty architectural product suppliers rather than mainstream building material distributors, limiting market reach. Strategic partnerships between LSC technology developers and major glass manufacturers represent a significant opportunity to expand market access and reduce production costs through economies of scale.

Market forecasts suggest that standardized testing methods would catalyze market growth by enabling meaningful product comparisons, reducing perceived investment risk, and facilitating regulatory inclusion in building energy codes. Industry analysts predict that establishing internationally recognized efficiency reporting standards could potentially double the market growth rate for LSC windows within three years of implementation.

Commercial buildings represent the largest potential market for LSC window applications, particularly in regions with high solar irradiance and stringent energy efficiency regulations. North America and Europe currently lead adoption rates, with Asia-Pacific markets showing the fastest growth trajectory due to rapid urbanization and increasing environmental regulations in countries like China, Japan, and South Korea.

Market penetration for LSC windows remains relatively low compared to conventional photovoltaic installations, primarily due to efficiency limitations and standardization challenges. The absence of universally accepted test methods for reporting LSC window efficiency has created market fragmentation and consumer uncertainty, significantly impeding wider adoption despite the technology's aesthetic and functional advantages.

Consumer demand analysis reveals three primary market drivers: energy cost reduction, compliance with increasingly stringent building energy codes, and corporate sustainability initiatives. Commercial property developers particularly value the potential for LSC windows to contribute to LEED, BREEAM, and other green building certification points, creating premium value propositions beyond direct energy generation.

Price sensitivity remains a critical market factor, with current LSC window solutions commanding a 30-40% premium over standard energy-efficient glazing. Market research indicates that achieving price parity with high-end architectural glass would significantly accelerate adoption, with payback periods under seven years representing a key psychological threshold for commercial building investors.

Distribution channels for LSC windows are currently dominated by specialty architectural product suppliers rather than mainstream building material distributors, limiting market reach. Strategic partnerships between LSC technology developers and major glass manufacturers represent a significant opportunity to expand market access and reduce production costs through economies of scale.

Market forecasts suggest that standardized testing methods would catalyze market growth by enabling meaningful product comparisons, reducing perceived investment risk, and facilitating regulatory inclusion in building energy codes. Industry analysts predict that establishing internationally recognized efficiency reporting standards could potentially double the market growth rate for LSC windows within three years of implementation.

Current Standardization Challenges in LSC Efficiency Reporting

Despite significant advancements in Luminescent Solar Concentrator (LSC) window technology, the field currently lacks standardized testing methodologies for reporting efficiency metrics. This absence of uniformity creates substantial challenges for researchers, manufacturers, and end-users when comparing different LSC window solutions. The primary issue stems from the multifaceted nature of LSC performance, which encompasses optical efficiency, power conversion efficiency, and aesthetic considerations that are unique to building-integrated photovoltaics.

Researchers currently employ diverse measurement protocols, equipment setups, and reporting conventions, making direct comparisons between studies nearly impossible. For instance, some laboratories report only optical efficiency while others focus on overall power conversion, creating an incomplete picture of performance. Additionally, testing conditions vary widely—from controlled laboratory environments with artificial light sources to outdoor real-world conditions with fluctuating solar spectra.

The geometric complexity of LSC windows further complicates standardization efforts. Unlike conventional solar panels, LSC performance is highly dependent on form factor, edge treatments, and integration methods with photovoltaic cells. Current testing approaches fail to adequately account for these variables, resulting in efficiency values that may not translate to real-world applications.

Another significant challenge is the lack of consensus regarding appropriate reference conditions. While traditional photovoltaics have established standard test conditions (STC), LSC windows require consideration of additional parameters such as incident angle dependence, diffuse light performance, and seasonal variations—factors particularly relevant for vertical building installations.

The absence of standardized aging and durability testing protocols represents another critical gap. LSC windows must maintain both efficiency and transparency over decades of building integration, yet accelerated aging tests vary widely across research groups, making lifetime performance predictions unreliable.

Industry stakeholders have attempted to address these issues through various working groups and technical committees, but progress remains fragmented. Organizations such as the International Electrotechnical Commission (IEC) and ASTM International have begun preliminary discussions, but no comprehensive standards have emerged. This standardization vacuum impedes market adoption as investors and building developers lack reliable metrics to evaluate technology readiness and economic viability.

The path toward standardization is further complicated by the rapid evolution of LSC materials and designs. As new luminophores, waveguide materials, and architectural integration approaches emerge, testing protocols must remain adaptable while still providing meaningful comparative metrics. Balancing these competing needs—standardization versus flexibility for innovation—represents perhaps the most fundamental challenge facing the LSC community today.

Researchers currently employ diverse measurement protocols, equipment setups, and reporting conventions, making direct comparisons between studies nearly impossible. For instance, some laboratories report only optical efficiency while others focus on overall power conversion, creating an incomplete picture of performance. Additionally, testing conditions vary widely—from controlled laboratory environments with artificial light sources to outdoor real-world conditions with fluctuating solar spectra.

The geometric complexity of LSC windows further complicates standardization efforts. Unlike conventional solar panels, LSC performance is highly dependent on form factor, edge treatments, and integration methods with photovoltaic cells. Current testing approaches fail to adequately account for these variables, resulting in efficiency values that may not translate to real-world applications.

Another significant challenge is the lack of consensus regarding appropriate reference conditions. While traditional photovoltaics have established standard test conditions (STC), LSC windows require consideration of additional parameters such as incident angle dependence, diffuse light performance, and seasonal variations—factors particularly relevant for vertical building installations.

The absence of standardized aging and durability testing protocols represents another critical gap. LSC windows must maintain both efficiency and transparency over decades of building integration, yet accelerated aging tests vary widely across research groups, making lifetime performance predictions unreliable.

Industry stakeholders have attempted to address these issues through various working groups and technical committees, but progress remains fragmented. Organizations such as the International Electrotechnical Commission (IEC) and ASTM International have begun preliminary discussions, but no comprehensive standards have emerged. This standardization vacuum impedes market adoption as investors and building developers lack reliable metrics to evaluate technology readiness and economic viability.

The path toward standardization is further complicated by the rapid evolution of LSC materials and designs. As new luminophores, waveguide materials, and architectural integration approaches emerge, testing protocols must remain adaptable while still providing meaningful comparative metrics. Balancing these competing needs—standardization versus flexibility for innovation—represents perhaps the most fundamental challenge facing the LSC community today.

Existing Test Protocols for LSC Window Efficiency

01 Luminescent materials for improved LSC efficiency

Various luminescent materials can be incorporated into LSC windows to improve their efficiency. These materials include quantum dots, fluorescent dyes, and phosphorescent compounds that absorb light at specific wavelengths and re-emit it at longer wavelengths. The selection of appropriate luminescent materials with high quantum yields and minimal self-absorption is crucial for maximizing the efficiency of LSC windows. Advanced materials with reduced overlap between absorption and emission spectra can significantly enhance light collection and concentration.- Luminescent materials for improved LSC efficiency: Various luminescent materials can be incorporated into LSC windows to improve their efficiency. These materials include quantum dots, fluorescent dyes, and phosphors that absorb light at specific wavelengths and re-emit it at longer wavelengths. The selection of appropriate luminescent materials with high quantum yield, broad absorption spectrum, and minimal self-absorption is crucial for enhancing the overall efficiency of LSC windows.

- Waveguide design and light management techniques: The design of the waveguide structure in LSC windows significantly impacts their efficiency. Advanced waveguide designs incorporate specific geometries, refractive index matching, and surface treatments to maximize total internal reflection and minimize escape cone losses. Light management techniques such as photonic structures, mirrors, and reflective coatings can be integrated to redirect light toward the edges where solar cells are typically placed, thereby increasing the concentration factor and overall efficiency.

- Integration of solar cells with LSC windows: The efficiency of LSC windows is heavily dependent on how solar cells are integrated with the luminescent concentrator. Positioning solar cells at the edges of the waveguide, using thin-film solar cells, or incorporating semi-transparent solar cells within the window structure can optimize energy harvesting. The selection of appropriate solar cell technology that matches the emission spectrum of the luminescent materials is essential for maximizing conversion efficiency.

- Multi-layer and tandem LSC configurations: Multi-layer and tandem configurations can significantly enhance LSC window efficiency. These designs stack multiple luminescent layers with complementary absorption and emission spectra to capture a broader range of the solar spectrum. Each layer can be optimized for specific wavelength ranges, and the arrangement can minimize reabsorption losses. Tandem structures may also incorporate different types of luminescent materials or waveguide designs to maximize overall energy conversion.

- Surface treatments and anti-reflection coatings: Surface treatments and anti-reflection coatings play a crucial role in improving LSC window efficiency. These treatments reduce reflection losses at interfaces, enhance light coupling into the waveguide, and minimize escape cone losses. Techniques include texturing the surface, applying gradient-index coatings, and using photonic structures. Additionally, selective filters can be applied to reflect non-absorbed light back into the waveguide, increasing the probability of absorption by luminescent materials.

02 Waveguide design and optimization

The design and optimization of the waveguide component in LSC windows significantly impacts their efficiency. This includes considerations of waveguide geometry, thickness, and refractive index to maximize total internal reflection and minimize escape cone losses. Advanced waveguide designs incorporate structured surfaces, multilayer configurations, or gradient-index materials to improve light trapping and guiding to the edges where photovoltaic cells are located. Optimized waveguide designs can substantially increase the concentration factor and overall efficiency of LSC windows.Expand Specific Solutions03 Integration with photovoltaic cells

The integration of photovoltaic cells with LSC windows plays a crucial role in determining overall system efficiency. This includes the selection of appropriate PV cell types that match the emission spectrum of the luminescent materials, as well as the optimization of cell placement along the edges of the LSC panel. Advanced integration techniques involve using spectrally selective PV cells, tandem cell configurations, or distributed cell arrangements to maximize power conversion. The interface between the waveguide and PV cells is also optimized to minimize coupling losses.Expand Specific Solutions04 Reduction of optical losses

Various strategies are employed to reduce optical losses in LSC windows, thereby improving their efficiency. These include the application of anti-reflection coatings on the front surface to minimize reflection losses, the use of selective mirrors or photonic structures to recycle escaped luminescence, and the incorporation of scattering centers to enhance light absorption. Advanced designs also address self-absorption losses through strategic placement of luminescent materials or the use of Stokes-shift engineered compounds that minimize reabsorption of emitted light.Expand Specific Solutions05 Novel LSC window architectures

Innovative architectural designs for LSC windows can significantly enhance their efficiency. These include tandem or stacked LSC configurations that capture different portions of the solar spectrum, hybrid designs that combine LSC technology with other solar harvesting approaches, and smart LSC windows with tunable optical properties. Some advanced architectures incorporate micro-structured or nano-structured elements to manipulate light propagation, or employ luminescent solar concentrator arrays with optimized geometric arrangements to maximize energy harvesting while maintaining transparency for building applications.Expand Specific Solutions

Leading Organizations in LSC Window Standardization

The standardized test methods for reporting LSC window efficiency market is in its early growth phase, characterized by increasing research activity but limited commercial deployment. The market size is expanding as energy efficiency regulations drive adoption, though still relatively niche compared to conventional window technologies. From a technical maturity perspective, the field shows varying levels of development across key players. Research institutions like Fraunhofer-Gesellschaft, Carnegie Mellon University, and Zhejiang University lead academic innovation, while companies such as Corning, 3M Innovative Properties, and ASML Netherlands are advancing commercial applications through material science and manufacturing expertise. Testing organizations like Shanghai Institute of Quality Inspection and Korea Institute of Construction Technology are establishing standardization frameworks essential for market growth.

Corning, Inc.

Technical Solution: Corning has developed standardized test methods for evaluating Luminescent Solar Concentrator (LSC) window efficiency that incorporate both optical and thermal performance metrics. Their approach utilizes a comprehensive measurement system that quantifies solar-to-electrical conversion efficiency while maintaining transparency requirements for architectural applications. The methodology includes spectral response characterization across different wavelengths, quantum efficiency measurements, and angular dependence testing to account for varying sun positions. Corning's test protocol establishes clear parameters for measuring optical concentration factors, fluorescence quantum yields, and waveguiding efficiency - all critical components for accurate LSC window performance reporting. Their system also incorporates accelerated weathering tests to predict long-term performance degradation under real-world conditions, allowing for standardized lifetime efficiency reporting.

Strengths: Corning's extensive expertise in glass manufacturing provides them with unique insights into optical material properties critical for LSC windows. Their established quality control infrastructure enables highly reproducible testing methodologies. Weaknesses: Their test methods may be optimized for their proprietary glass formulations, potentially limiting applicability across diverse LSC technologies developed by competitors.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has pioneered standardized test protocols for LSC window efficiency that integrate both indoor laboratory measurements and outdoor field testing validation. Their methodology establishes a multi-parameter assessment framework that evaluates optical efficiency, power conversion efficiency, and architectural performance metrics simultaneously. The Fraunhofer approach incorporates spectrally-resolved measurements using calibrated solar simulators with AM1.5G reference spectra, combined with specialized integrating sphere setups to accurately quantify edge emission and optical losses. Their test protocol standardizes reporting of key performance indicators including concentration factor, optical efficiency, and effective transparency. Particularly innovative is their development of a "Figure of Merit" calculation that weights different performance aspects according to application requirements, allowing meaningful comparison between different LSC window technologies. Fraunhofer's methodology also includes standardized accelerated aging protocols to predict long-term efficiency stability under various environmental conditions.

Strengths: Fraunhofer's interdisciplinary approach combines expertise from multiple institutes, enabling comprehensive testing that addresses both photovoltaic and architectural requirements. Their methods are designed to be technology-agnostic, allowing fair comparison across different LSC implementations. Weaknesses: Their sophisticated testing protocols may require specialized equipment not readily available in all testing facilities, potentially limiting widespread adoption of their standards.

Key Technical Parameters in LSC Window Performance Evaluation

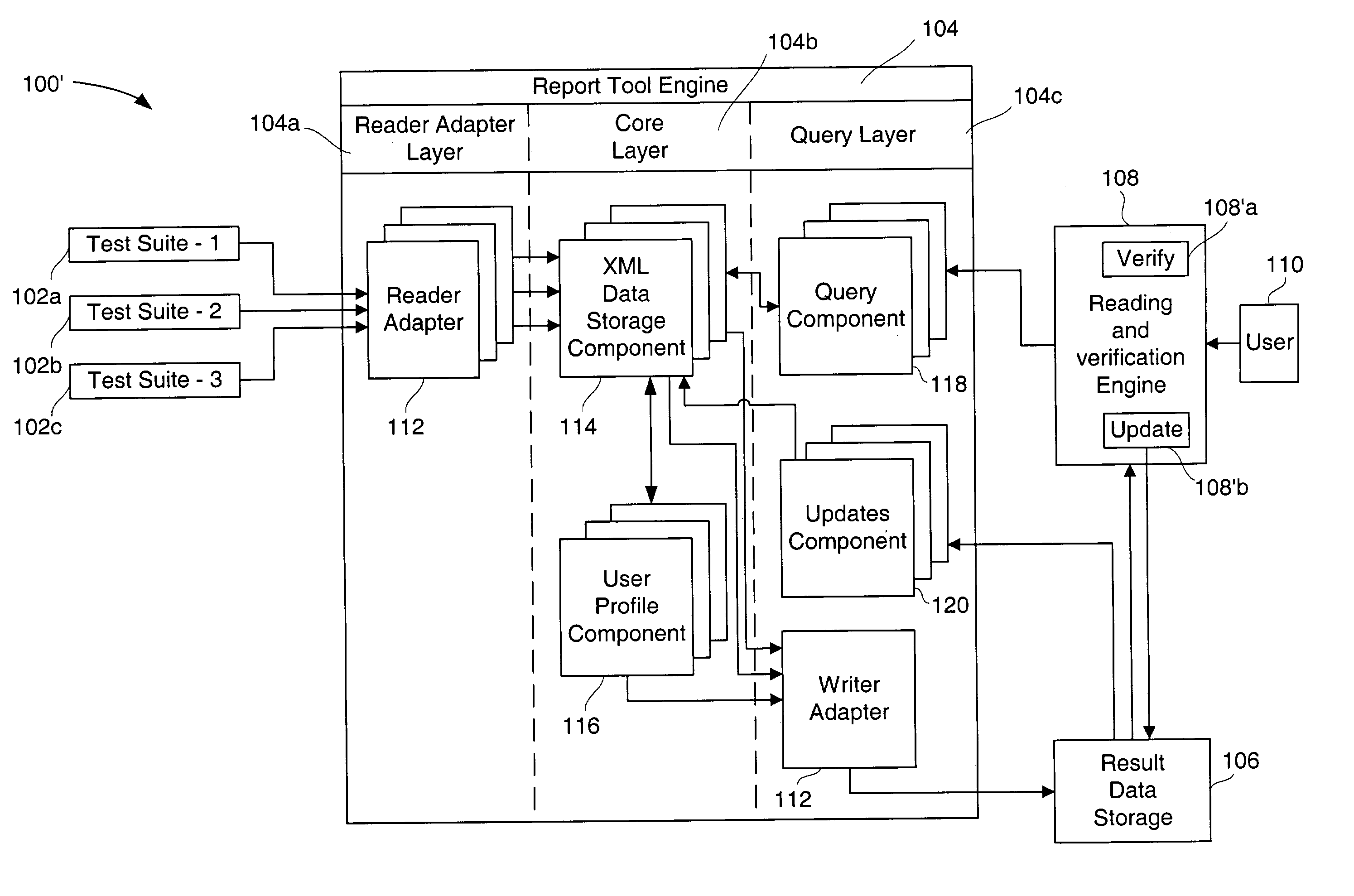

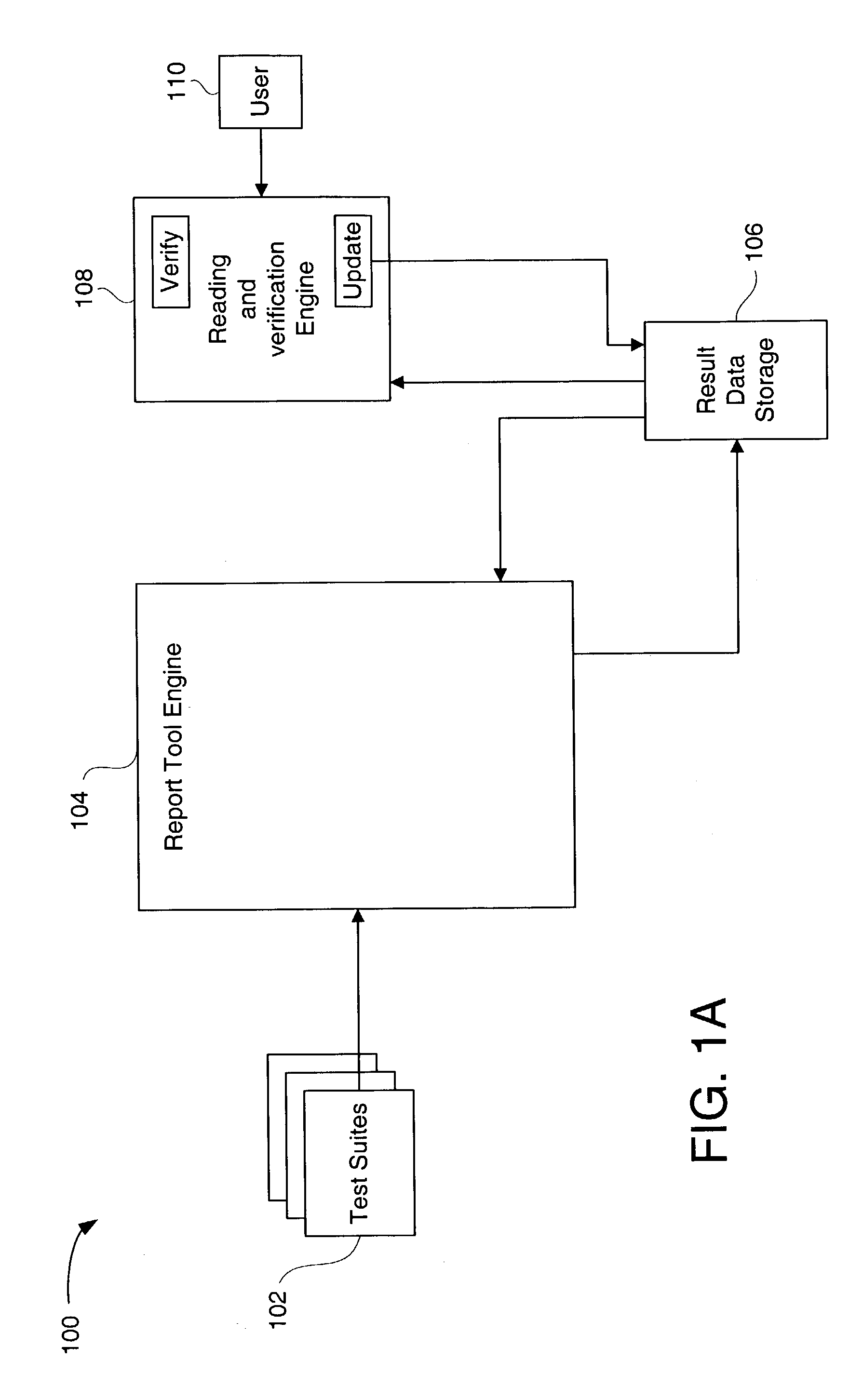

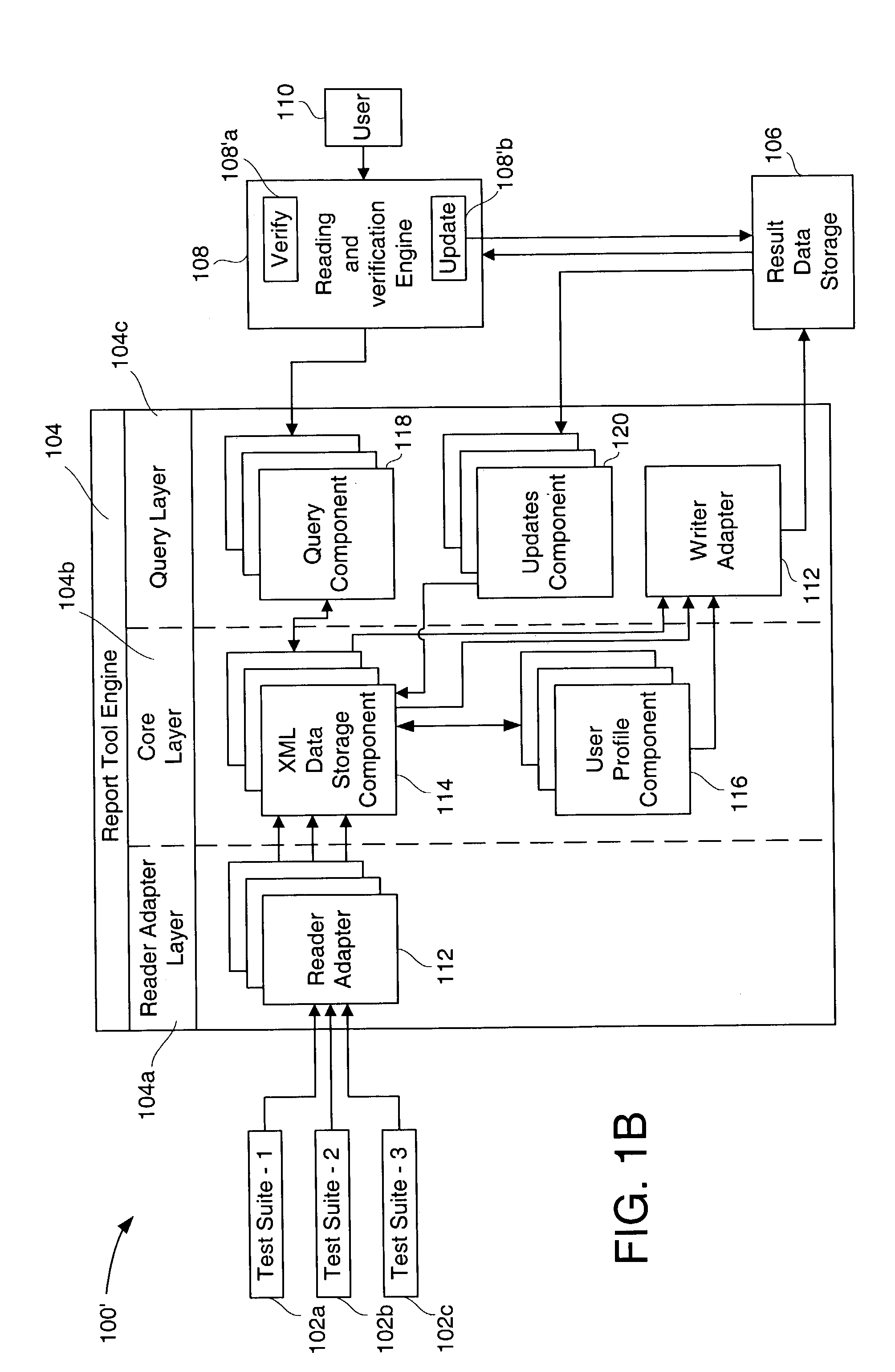

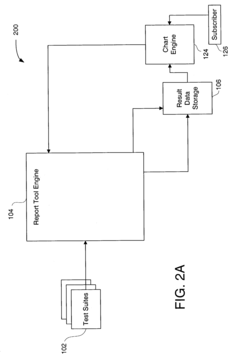

Method and system for reporting standardized and verified data

PatentInactiveUS7054881B2

Innovation

- A report tool standardizes test execution results into a uniform format, allowing users to view verified data customized to their requirements, using a system with a report tool engine that transforms test suite output files into standardized files and stores them for user-specific access.

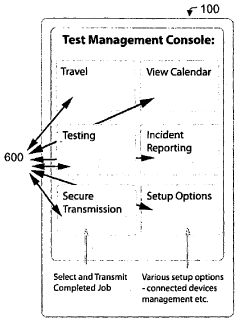

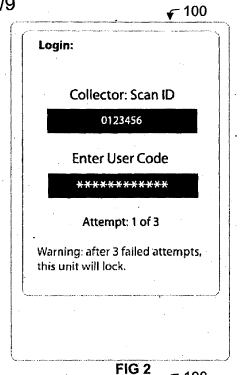

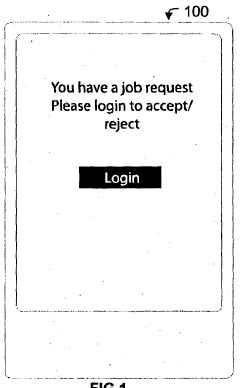

System and method for test management and reporting

PatentActiveAU2012325666B2

Innovation

- A computer-implemented method for managing tests through pre-recording service requirements, transmitting notifications, receiving and analyzing encrypted data, and locking access to test data on a collector electronic terminal, ensuring secure and automated test execution and processing, with features like real-time activation of test procedures and chain of custody documentation.

International Regulatory Framework for Building-Integrated Photovoltaics

The international regulatory landscape for Building-Integrated Photovoltaics (BIPV) significantly impacts the development and adoption of Luminescent Solar Concentrator (LSC) window technologies. Currently, there is no unified global standard specifically addressing LSC window efficiency reporting, creating challenges for market penetration and cross-border certification.

The European Union leads with the most comprehensive framework through its Energy Performance of Buildings Directive (EPBD) and Construction Products Regulation (CPR), which together establish requirements for energy-generating building components. The EU's IEC 61215 and IEC 61730 standards, while primarily designed for conventional photovoltaics, have been adapted by some manufacturers for LSC window certification, though with acknowledged limitations regarding spectral response and light concentration metrics.

In North America, regulatory approaches vary significantly. The United States relies on a combination of ASTM standards and building codes, with the International Building Code (IBC) and ASHRAE 90.1 providing general frameworks for energy-generating windows. However, these standards lack specific provisions for the unique optical properties of LSC technologies. Canada's National Building Code similarly requires adaptation when applied to LSC windows.

The Asia-Pacific region presents a fragmented regulatory environment. Japan's JIS standards and China's GB standards have begun incorporating provisions for advanced photovoltaic windows, though explicit LSC testing protocols remain underdeveloped. Australia's Building Code has recently updated its energy efficiency provisions but still lacks specific guidance for LSC technology evaluation.

International harmonization efforts are emerging through organizations like the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO). The IEC Technical Committee 82 has established a working group focused on developing standardized testing methods for next-generation photovoltaic technologies, including LSC windows. This initiative aims to create globally recognized metrics for quantum efficiency, light harvesting capability, and power conversion under various lighting conditions.

The lack of standardized test methods specifically for LSC windows creates market barriers, as manufacturers must navigate multiple certification processes across different jurisdictions. This regulatory fragmentation increases compliance costs and slows market adoption, highlighting the urgent need for internationally recognized standards that address the unique characteristics of LSC window technology while ensuring safety, reliability, and performance comparability across global markets.

The European Union leads with the most comprehensive framework through its Energy Performance of Buildings Directive (EPBD) and Construction Products Regulation (CPR), which together establish requirements for energy-generating building components. The EU's IEC 61215 and IEC 61730 standards, while primarily designed for conventional photovoltaics, have been adapted by some manufacturers for LSC window certification, though with acknowledged limitations regarding spectral response and light concentration metrics.

In North America, regulatory approaches vary significantly. The United States relies on a combination of ASTM standards and building codes, with the International Building Code (IBC) and ASHRAE 90.1 providing general frameworks for energy-generating windows. However, these standards lack specific provisions for the unique optical properties of LSC technologies. Canada's National Building Code similarly requires adaptation when applied to LSC windows.

The Asia-Pacific region presents a fragmented regulatory environment. Japan's JIS standards and China's GB standards have begun incorporating provisions for advanced photovoltaic windows, though explicit LSC testing protocols remain underdeveloped. Australia's Building Code has recently updated its energy efficiency provisions but still lacks specific guidance for LSC technology evaluation.

International harmonization efforts are emerging through organizations like the International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO). The IEC Technical Committee 82 has established a working group focused on developing standardized testing methods for next-generation photovoltaic technologies, including LSC windows. This initiative aims to create globally recognized metrics for quantum efficiency, light harvesting capability, and power conversion under various lighting conditions.

The lack of standardized test methods specifically for LSC windows creates market barriers, as manufacturers must navigate multiple certification processes across different jurisdictions. This regulatory fragmentation increases compliance costs and slows market adoption, highlighting the urgent need for internationally recognized standards that address the unique characteristics of LSC window technology while ensuring safety, reliability, and performance comparability across global markets.

Environmental Impact Assessment of LSC Window Technologies

The environmental impact assessment of LSC (Luminescent Solar Concentrator) window technologies reveals significant potential for reducing carbon footprints in the built environment. When evaluating these technologies through standardized test methods, it becomes evident that LSC windows offer dual benefits of energy generation and reduced HVAC demands, resulting in lower overall environmental impact compared to conventional glazing systems.

Life cycle assessment (LCA) studies indicate that LSC windows can achieve carbon payback periods of 1-3 years depending on installation location and specific technology implementation. This favorable environmental profile stems from their ability to generate clean electricity while simultaneously reducing building cooling loads by filtering specific wavelengths of incoming solar radiation.

Material composition analysis of current LSC window technologies shows varying environmental impacts. Silicon-based quantum dot LSCs demonstrate lower manufacturing-phase environmental impacts compared to those utilizing rare earth phosphors or organic dyes. However, end-of-life considerations remain challenging, as separation of luminescent materials from glass substrates presents recycling difficulties that standardized testing must address.

Water usage metrics during manufacturing processes reveal that LSC production typically requires 30-45% less water compared to photovoltaic panel production with equivalent power generation capacity. This advantage should be quantified in standardized efficiency reporting to provide a comprehensive environmental assessment.

Embodied energy calculations demonstrate that LSC windows generally contain 20-35% less embodied energy than traditional PV systems when normalized for equivalent power output. This metric becomes particularly relevant when evaluating the total environmental impact of building-integrated photovoltaic solutions.

Indoor environmental quality impacts must also be considered in standardized testing protocols. Research indicates that specific LSC formulations can reduce harmful UV radiation by up to 99% while maintaining healthy levels of visible light transmission, contributing positively to occupant health without increasing artificial lighting requirements.

Regional environmental impact variations are significant, with LSC windows showing greater net environmental benefits in regions with high cooling loads and abundant solar resources. Standardized test methods should incorporate geographic adjustment factors to accurately reflect these regional differences in environmental performance reporting.

Life cycle assessment (LCA) studies indicate that LSC windows can achieve carbon payback periods of 1-3 years depending on installation location and specific technology implementation. This favorable environmental profile stems from their ability to generate clean electricity while simultaneously reducing building cooling loads by filtering specific wavelengths of incoming solar radiation.

Material composition analysis of current LSC window technologies shows varying environmental impacts. Silicon-based quantum dot LSCs demonstrate lower manufacturing-phase environmental impacts compared to those utilizing rare earth phosphors or organic dyes. However, end-of-life considerations remain challenging, as separation of luminescent materials from glass substrates presents recycling difficulties that standardized testing must address.

Water usage metrics during manufacturing processes reveal that LSC production typically requires 30-45% less water compared to photovoltaic panel production with equivalent power generation capacity. This advantage should be quantified in standardized efficiency reporting to provide a comprehensive environmental assessment.

Embodied energy calculations demonstrate that LSC windows generally contain 20-35% less embodied energy than traditional PV systems when normalized for equivalent power output. This metric becomes particularly relevant when evaluating the total environmental impact of building-integrated photovoltaic solutions.

Indoor environmental quality impacts must also be considered in standardized testing protocols. Research indicates that specific LSC formulations can reduce harmful UV radiation by up to 99% while maintaining healthy levels of visible light transmission, contributing positively to occupant health without increasing artificial lighting requirements.

Regional environmental impact variations are significant, with LSC windows showing greater net environmental benefits in regions with high cooling loads and abundant solar resources. Standardized test methods should incorporate geographic adjustment factors to accurately reflect these regional differences in environmental performance reporting.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!