Durable QD-Polymer Composites: Photostability Enhancement Methods

AUG 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QD-Polymer Composite Evolution and Objectives

Quantum dot-polymer composites have evolved significantly since their initial development in the early 1990s. The integration of semiconductor nanocrystals (quantum dots) into polymer matrices represented a breakthrough in materials science, combining the unique optical and electronic properties of QDs with the processability and mechanical stability of polymers. Early composites suffered from severe photodegradation issues, with QD luminescence often diminishing rapidly under normal lighting conditions, limiting their practical applications.

The evolution trajectory has been marked by several key advancements. First-generation composites utilized simple physical blending techniques, resulting in poor QD dispersion and minimal protection against environmental factors. Second-generation systems introduced surface modification strategies to improve compatibility between inorganic QDs and organic polymer matrices. The current third-generation composites employ sophisticated encapsulation methods and engineered interfaces to enhance durability while maintaining optical performance.

A critical milestone in this evolution was the development of core-shell QD structures, which provided an initial barrier against oxidation and photodegradation. This was followed by innovations in ligand chemistry that facilitated better integration with various polymer systems while providing additional protection against photochemical reactions.

The primary objective in developing durable QD-polymer composites is to achieve long-term photostability without compromising the exceptional optical properties that make QDs valuable. This includes maintaining high quantum yields, narrow emission bandwidths, and tunable emission wavelengths across extended operational lifetimes under various lighting conditions. Specific technical goals include reducing photobleaching rates by at least an order of magnitude compared to current commercial standards and ensuring stable performance for 10,000+ hours under standard indoor lighting conditions.

Secondary objectives focus on maintaining compatibility with existing manufacturing processes, ensuring environmental sustainability, and reducing production costs to enable widespread commercial adoption. The development of scalable synthesis methods that can produce consistent, high-quality composites remains a significant challenge.

Recent research has increasingly focused on understanding the fundamental photophysical and photochemical processes that lead to degradation, enabling more targeted approaches to stability enhancement. This includes investigating energy transfer mechanisms between polymer matrices and QDs, identifying specific degradation pathways, and developing strategies to mitigate these effects through molecular engineering approaches.

The field is now moving toward predictive design principles that can guide the development of next-generation composites with application-specific durability profiles, ranging from display technologies to solid-state lighting and photovoltaics.

The evolution trajectory has been marked by several key advancements. First-generation composites utilized simple physical blending techniques, resulting in poor QD dispersion and minimal protection against environmental factors. Second-generation systems introduced surface modification strategies to improve compatibility between inorganic QDs and organic polymer matrices. The current third-generation composites employ sophisticated encapsulation methods and engineered interfaces to enhance durability while maintaining optical performance.

A critical milestone in this evolution was the development of core-shell QD structures, which provided an initial barrier against oxidation and photodegradation. This was followed by innovations in ligand chemistry that facilitated better integration with various polymer systems while providing additional protection against photochemical reactions.

The primary objective in developing durable QD-polymer composites is to achieve long-term photostability without compromising the exceptional optical properties that make QDs valuable. This includes maintaining high quantum yields, narrow emission bandwidths, and tunable emission wavelengths across extended operational lifetimes under various lighting conditions. Specific technical goals include reducing photobleaching rates by at least an order of magnitude compared to current commercial standards and ensuring stable performance for 10,000+ hours under standard indoor lighting conditions.

Secondary objectives focus on maintaining compatibility with existing manufacturing processes, ensuring environmental sustainability, and reducing production costs to enable widespread commercial adoption. The development of scalable synthesis methods that can produce consistent, high-quality composites remains a significant challenge.

Recent research has increasingly focused on understanding the fundamental photophysical and photochemical processes that lead to degradation, enabling more targeted approaches to stability enhancement. This includes investigating energy transfer mechanisms between polymer matrices and QDs, identifying specific degradation pathways, and developing strategies to mitigate these effects through molecular engineering approaches.

The field is now moving toward predictive design principles that can guide the development of next-generation composites with application-specific durability profiles, ranging from display technologies to solid-state lighting and photovoltaics.

Market Analysis for Photostable QD-Polymer Applications

The quantum dot (QD)-polymer composite market is experiencing significant growth, driven by increasing demand for advanced display technologies, lighting solutions, and photovoltaic applications. The global market for QD materials reached approximately $4.5 billion in 2022 and is projected to grow at a CAGR of 23.5% through 2028, with QD-polymer composites representing a substantial segment of this expansion.

Display technologies currently dominate the application landscape, accounting for nearly 65% of the QD-polymer composite market. Samsung, LG, and TCL have successfully commercialized QD-enhanced displays, demonstrating the technology's commercial viability. However, photostability concerns have limited broader adoption in premium product segments where extended lifespans are expected.

The lighting sector presents the fastest-growing opportunity for photostable QD-polymer composites, with a projected CAGR of 27% through 2028. This growth is fueled by increasing demand for energy-efficient lighting solutions with superior color rendering capabilities. Manufacturers are particularly interested in QD-enhanced LED products that can maintain consistent spectral output over extended operational periods.

Photovoltaic applications represent another promising market segment, particularly for near-infrared (NIR) QDs incorporated into polymer matrices. The ability to harvest previously unutilized portions of the solar spectrum could potentially increase conversion efficiencies by 10-15%, creating substantial value in both residential and commercial solar installations.

Regional analysis reveals Asia-Pacific as the dominant market for QD-polymer composites, accounting for approximately 58% of global demand. This concentration stems from the region's robust electronics manufacturing infrastructure and growing consumer electronics market. North America follows with 24% market share, driven primarily by early adoption in premium consumer electronics and specialized industrial applications.

Customer segmentation indicates three primary market tiers: premium consumer electronics manufacturers demanding the highest photostability (>50,000 hours operational life), mid-tier industrial applications requiring moderate stability (20,000-40,000 hours), and emerging applications where cost considerations outweigh longevity requirements.

Price sensitivity analysis reveals that manufacturers are willing to pay a premium of 15-20% for QD-polymer composites with demonstrably superior photostability, particularly in applications where replacement costs are high or where brand reputation depends on product longevity.

The regulatory landscape is evolving rapidly, with particular focus on heavy metal content in QDs. Cadmium-free formulations with enhanced photostability command significant market interest, as they address both environmental compliance requirements and performance needs simultaneously.

Display technologies currently dominate the application landscape, accounting for nearly 65% of the QD-polymer composite market. Samsung, LG, and TCL have successfully commercialized QD-enhanced displays, demonstrating the technology's commercial viability. However, photostability concerns have limited broader adoption in premium product segments where extended lifespans are expected.

The lighting sector presents the fastest-growing opportunity for photostable QD-polymer composites, with a projected CAGR of 27% through 2028. This growth is fueled by increasing demand for energy-efficient lighting solutions with superior color rendering capabilities. Manufacturers are particularly interested in QD-enhanced LED products that can maintain consistent spectral output over extended operational periods.

Photovoltaic applications represent another promising market segment, particularly for near-infrared (NIR) QDs incorporated into polymer matrices. The ability to harvest previously unutilized portions of the solar spectrum could potentially increase conversion efficiencies by 10-15%, creating substantial value in both residential and commercial solar installations.

Regional analysis reveals Asia-Pacific as the dominant market for QD-polymer composites, accounting for approximately 58% of global demand. This concentration stems from the region's robust electronics manufacturing infrastructure and growing consumer electronics market. North America follows with 24% market share, driven primarily by early adoption in premium consumer electronics and specialized industrial applications.

Customer segmentation indicates three primary market tiers: premium consumer electronics manufacturers demanding the highest photostability (>50,000 hours operational life), mid-tier industrial applications requiring moderate stability (20,000-40,000 hours), and emerging applications where cost considerations outweigh longevity requirements.

Price sensitivity analysis reveals that manufacturers are willing to pay a premium of 15-20% for QD-polymer composites with demonstrably superior photostability, particularly in applications where replacement costs are high or where brand reputation depends on product longevity.

The regulatory landscape is evolving rapidly, with particular focus on heavy metal content in QDs. Cadmium-free formulations with enhanced photostability command significant market interest, as they address both environmental compliance requirements and performance needs simultaneously.

Photostability Challenges in QD-Polymer Systems

Quantum dots (QDs) integrated into polymer matrices offer exceptional optical properties, but their widespread application is significantly hindered by photostability challenges. When exposed to light, QDs in polymer composites undergo photodegradation processes that diminish their luminescence efficiency and alter their emission characteristics over time. This degradation manifests as photobleaching, spectral shifting, and reduced quantum yield, severely limiting the operational lifetime of QD-polymer devices and materials.

The primary photodegradation mechanisms in QD-polymer systems involve complex photochemical reactions. Photooxidation represents a major challenge, occurring when oxygen molecules penetrate the polymer matrix and react with photoexcited QDs, forming oxide layers on QD surfaces that trap charge carriers and reduce emission efficiency. This process is particularly problematic in air-exposed applications where oxygen diffusion through the polymer matrix is inevitable.

Photoinduced ligand degradation constitutes another critical issue. The organic ligands that stabilize QDs and facilitate their dispersion in polymer matrices can undergo photolysis under UV or high-energy visible light exposure. This degradation compromises the surface passivation of QDs, creating trap states that quench luminescence and accelerate further degradation through a cascading effect.

The polymer matrix itself contributes to photostability challenges through several mechanisms. Polymer chain scission and cross-linking induced by UV exposure can alter the physical environment surrounding QDs, affecting their optical properties. Additionally, reactive species generated within the polymer during photodegradation can migrate to QD surfaces and catalyze further deterioration of the quantum dots.

Environmental factors significantly exacerbate these photostability issues. Temperature fluctuations can accelerate degradation processes and cause differential expansion between QDs and the polymer matrix, potentially creating microcracks that facilitate oxygen penetration. Humidity presents another challenge, as water molecules can penetrate the polymer matrix and interact with QD surfaces, particularly for chalcogenide-based QDs that are susceptible to hydrolysis.

The composition of QDs themselves influences their photostability profile. Core-only QDs typically exhibit poor photostability compared to core-shell architectures. The shell material choice critically affects photostability, with wider bandgap materials generally providing better protection against photodegradation. However, lattice mismatch between core and shell materials can create strain-induced defects that become photodegradation initiation sites.

Quantifying photostability remains challenging due to the lack of standardized testing protocols across the field. Different research groups employ varying light sources, intensities, and environmental conditions, making direct comparisons between reported photostability enhancements difficult. This inconsistency hampers systematic improvement efforts and technology transfer from laboratory to commercial applications.

The primary photodegradation mechanisms in QD-polymer systems involve complex photochemical reactions. Photooxidation represents a major challenge, occurring when oxygen molecules penetrate the polymer matrix and react with photoexcited QDs, forming oxide layers on QD surfaces that trap charge carriers and reduce emission efficiency. This process is particularly problematic in air-exposed applications where oxygen diffusion through the polymer matrix is inevitable.

Photoinduced ligand degradation constitutes another critical issue. The organic ligands that stabilize QDs and facilitate their dispersion in polymer matrices can undergo photolysis under UV or high-energy visible light exposure. This degradation compromises the surface passivation of QDs, creating trap states that quench luminescence and accelerate further degradation through a cascading effect.

The polymer matrix itself contributes to photostability challenges through several mechanisms. Polymer chain scission and cross-linking induced by UV exposure can alter the physical environment surrounding QDs, affecting their optical properties. Additionally, reactive species generated within the polymer during photodegradation can migrate to QD surfaces and catalyze further deterioration of the quantum dots.

Environmental factors significantly exacerbate these photostability issues. Temperature fluctuations can accelerate degradation processes and cause differential expansion between QDs and the polymer matrix, potentially creating microcracks that facilitate oxygen penetration. Humidity presents another challenge, as water molecules can penetrate the polymer matrix and interact with QD surfaces, particularly for chalcogenide-based QDs that are susceptible to hydrolysis.

The composition of QDs themselves influences their photostability profile. Core-only QDs typically exhibit poor photostability compared to core-shell architectures. The shell material choice critically affects photostability, with wider bandgap materials generally providing better protection against photodegradation. However, lattice mismatch between core and shell materials can create strain-induced defects that become photodegradation initiation sites.

Quantifying photostability remains challenging due to the lack of standardized testing protocols across the field. Different research groups employ varying light sources, intensities, and environmental conditions, making direct comparisons between reported photostability enhancements difficult. This inconsistency hampers systematic improvement efforts and technology transfer from laboratory to commercial applications.

Current Photostability Enhancement Methodologies

01 Surface modification of quantum dots for enhanced photostability

Surface modification techniques can significantly enhance the photostability of quantum dot-polymer composites. By applying various ligands, coatings, or encapsulation methods to the quantum dot surface, degradation from UV exposure can be minimized. These modifications create protective barriers that prevent oxidation and photobleaching while maintaining the optical properties of the quantum dots. Surface-modified QDs show improved resistance to photodegradation when incorporated into polymer matrices.- Polymer encapsulation techniques for QD photostability: Encapsulating quantum dots within polymer matrices can significantly enhance their photostability by providing physical barriers against oxygen, moisture, and other environmental factors that cause degradation. Various encapsulation methods include core-shell structures, polymer coating, and embedding QDs in polymer films. These techniques help maintain the optical properties of QDs over extended periods of exposure to light, thereby improving their longevity in applications such as displays and lighting.

- Surface modification of QDs for enhanced stability in polymer composites: Surface modification of quantum dots through ligand exchange or functionalization can improve their compatibility with polymer matrices and enhance photostability. By attaching specific functional groups to the QD surface, the interface between QDs and the polymer matrix can be optimized, reducing aggregation and improving dispersion. This results in more stable QD-polymer composites with better resistance to photo-oxidation and degradation under UV exposure.

- Additives and stabilizers for QD-polymer composite photostability: Incorporating specific additives and stabilizers into QD-polymer composites can significantly improve their photostability. These include antioxidants, UV absorbers, radical scavengers, and hindered amine light stabilizers (HALS). Such additives can neutralize free radicals, absorb harmful UV radiation, or quench excited states that would otherwise lead to degradation of the quantum dots. The strategic selection and concentration of these additives can extend the operational lifetime of QD-polymer composites in various applications.

- Novel polymer matrices for improved QD photostability: Development of specialized polymer matrices with inherent resistance to UV degradation can enhance the photostability of embedded quantum dots. These include fluoropolymers, silicone-based polymers, and cross-linked networks with reduced oxygen permeability. The chemical structure of these polymers can be tailored to minimize energy transfer to QDs, reduce oxygen diffusion, or provide inherent UV absorption capabilities, thereby protecting the quantum dots from photo-induced degradation.

- Processing methods for photostable QD-polymer composites: Specific processing techniques can significantly impact the photostability of QD-polymer composites. Methods such as in-situ polymerization, solvent-free processing, and low-temperature curing can reduce defects and stress in the polymer matrix. Additionally, controlled atmosphere processing and multi-layer structures can minimize exposure to degradation factors. These processing approaches help maintain the quantum confinement properties of QDs and preserve their optical characteristics under prolonged light exposure.

02 Polymer selection and composition for QD photostability

The choice of polymer matrix significantly impacts the photostability of quantum dot composites. Polymers with high UV resistance, such as certain acrylates, polyolefins, and fluoropolymers, can protect embedded quantum dots from photodegradation. Additionally, incorporating antioxidants, UV absorbers, and radical scavengers into the polymer matrix can further enhance the photostability of the composite. The molecular weight, crystallinity, and cross-linking density of the polymer also affect how well it shields quantum dots from photodegradation.Expand Specific Solutions03 Core-shell structures for improved QD-polymer photostability

Core-shell quantum dot structures offer superior photostability when incorporated into polymer matrices. By engineering multilayered QDs with appropriate shell materials (such as ZnS, CdS, or silica), the photoluminescence quantum yield can be maintained even after prolonged UV exposure. These core-shell structures effectively isolate the optically active core from environmental factors that cause degradation. The thickness and composition of the shell layers can be optimized to balance quantum efficiency with photostability in polymer composite applications.Expand Specific Solutions04 Processing methods affecting QD-polymer composite photostability

Manufacturing and processing techniques significantly impact the photostability of quantum dot-polymer composites. Methods such as in-situ polymerization, solution blending, and melt processing affect the dispersion quality and interfacial interactions between QDs and the polymer matrix. Techniques that prevent QD aggregation and ensure uniform distribution throughout the polymer result in composites with enhanced photostability. Post-processing treatments, such as annealing or UV curing, can also be optimized to improve the resistance to photodegradation.Expand Specific Solutions05 Additives and stabilizers for enhanced QD-polymer photostability

Various additives and stabilizers can be incorporated into QD-polymer composites to enhance photostability. These include hindered amine light stabilizers (HALS), UV absorbers, antioxidants, and radical scavengers that protect both the quantum dots and polymer matrix from photodegradation. Synergistic combinations of these additives can provide comprehensive protection against different degradation mechanisms. Additionally, certain metal oxides and nanoparticles can be added to the composite to absorb harmful UV radiation and prevent it from reaching the quantum dots.Expand Specific Solutions

Leading Organizations in QD-Polymer Composite Development

The quantum dot-polymer composite market is in a growth phase, characterized by increasing R&D focus on photostability enhancement methods. The global market is expanding rapidly, driven by applications in displays, lighting, and photovoltaics, with projections reaching several billion dollars by 2028. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include established chemical corporations like Merck Patent GmbH, BASF Corp., and Eastman Chemical, alongside specialized QD developers such as Najing Technology and Qustomdot. Japanese firms (Ricoh, Tokuyama, Nitto Denko) demonstrate strong patent activity, while research institutions like Shanghai Jiao Tong University and KIST contribute fundamental advancements. The industry is witnessing increased collaboration between materials science companies and electronics manufacturers to overcome photostability challenges.

Qustomdot

Technical Solution: Qustomdot has developed a revolutionary approach to QD-polymer composite photostability through their "ShellLock" technology. This proprietary system focuses on creating ultra-thick shell quantum dots with precisely engineered interfaces between the core and shell materials. Their quantum dots feature gradient alloy shells that minimize lattice mismatch stress while maximizing photon absorption and emission efficiency. Qustomdot's technology incorporates specialized ligand exchange processes that replace conventional ligands with custom-designed multifunctional molecules that simultaneously bond to the QD surface and the polymer matrix. Their composites utilize proprietary cross-linking chemistry that creates a three-dimensional network around each quantum dot, physically restricting exposure to oxygen and moisture. Additionally, Qustomdot has developed novel "sacrificial chromophore" additives that preferentially absorb high-energy photons and dissipate the energy harmlessly, preventing direct excitation of QDs by potentially damaging wavelengths. Their most advanced systems incorporate self-regenerating antioxidant networks that can maintain protection levels even after extended exposure to harsh conditions.

Strengths: Qustomdot's specialized focus on quantum dot technology has allowed them to develop highly optimized protection strategies specifically for QD-polymer systems. Their solutions typically maintain higher quantum yields after aging compared to competitors. Weaknesses: As a smaller company, they may have more limited manufacturing capacity and global reach compared to larger chemical corporations.

Merck Patent GmbH

Technical Solution: Merck has developed advanced QD-polymer composite systems with enhanced photostability through multi-layered protection strategies. Their approach includes core-shell quantum dot structures where the semiconductor core is encapsulated with wider bandgap materials (typically ZnS) to prevent oxidation and photodegradation. Merck's proprietary surface ligand engineering replaces traditional organic ligands with more robust alternatives that form stronger bonds with the QD surface, creating better integration with polymer matrices. Additionally, they've implemented radical scavenger additives that neutralize reactive oxygen species generated during photo-excitation. Their QD-polymer composites incorporate UV absorbers strategically distributed throughout the polymer matrix to filter harmful radiation before reaching the quantum dots. Merck has also developed specialized encapsulation techniques using fluorinated polymers that provide exceptional oxygen and moisture barrier properties, extending QD luminescence lifetime by up to 10,000 hours under continuous illumination.

Strengths: Merck's multi-layered protection approach provides comprehensive defense against multiple degradation pathways simultaneously. Their global manufacturing capabilities ensure consistent quality and scalability. Weaknesses: Their solutions often require proprietary materials that increase production costs, and some of their advanced formulations may have limited compatibility with certain polymer systems.

Key Patents in QD Photodegradation Prevention

Quantum dot composite, quantum dot composition comprising same, and electronic device comprising same

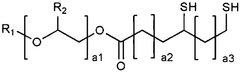

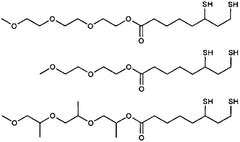

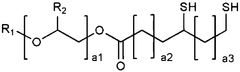

PatentWO2025155080A1

Innovation

- A quantum dot complex is developed with a bidentate ligand containing an ethylene glycol group and a ligand with an acryloyl group, along with a carboxylate group, to enhance photostability by improving ligand binding and dispersibility in solvents.

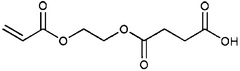

Quantum dot-containing polymer and method for producing the same

PatentPendingUS20230265338A1

Innovation

- A quantum dot-containing polymer is developed where a ligand with reactive substituents, such as an amino or thiol group, is coordinated to the quantum dot surface, and then polymerized with a silicone compound having polymerizable substituents like vinyl or methacrylic groups, enhancing steric hindrance and stability without the need for barrier films.

Environmental Impact Assessment of QD-Polymer Materials

The environmental impact of quantum dot-polymer composites represents a critical consideration in their development and application. These materials, while offering significant technological advantages, also pose potential environmental challenges throughout their lifecycle. The production of QD-polymer composites typically involves heavy metals such as cadmium, lead, or indium, which are known environmental contaminants with potential toxicity to aquatic ecosystems and human health.

Manufacturing processes for these composites often require organic solvents and energy-intensive conditions, contributing to their environmental footprint. The synthesis of quantum dots themselves involves multiple chemical reactions that may generate hazardous waste streams requiring specialized treatment and disposal protocols. Additionally, the polymer matrices used in these composites may derive from petroleum-based sources, further increasing their carbon footprint.

During the use phase, the environmental impact largely depends on the application context and the stability of the QD-polymer system. Photostability enhancement methods, while improving durability, may introduce additional chemical components that could affect end-of-life environmental outcomes. Core-shell structures and surface ligand modifications, commonly employed to enhance photostability, alter the leaching behavior and degradation pathways of these materials in environmental settings.

End-of-life considerations present particular challenges for QD-polymer composites. The persistence of quantum dots in the environment remains inadequately understood, with potential for bioaccumulation in food chains. Current recycling infrastructure is generally ill-equipped to handle these advanced materials, potentially leading to improper disposal and environmental release. The heterogeneous nature of these composites complicates material recovery efforts.

Recent life cycle assessment (LCA) studies indicate that the environmental impact of QD-polymer composites varies significantly based on synthesis methods, stabilization approaches, and end-use applications. Emerging research suggests that green synthesis routes utilizing biopolymers and aqueous processing can substantially reduce environmental impacts. Similarly, designing photostability enhancement methods that avoid persistent additives or toxic components can improve the overall environmental profile.

Regulatory frameworks worldwide are increasingly addressing nanomaterials like quantum dots, with the European Union's REACH regulation and similar initiatives in other regions establishing reporting requirements and usage restrictions. Future development of durable QD-polymer composites will need to balance performance requirements with environmental sustainability considerations, potentially through design-for-environment approaches that consider the entire material lifecycle.

Manufacturing processes for these composites often require organic solvents and energy-intensive conditions, contributing to their environmental footprint. The synthesis of quantum dots themselves involves multiple chemical reactions that may generate hazardous waste streams requiring specialized treatment and disposal protocols. Additionally, the polymer matrices used in these composites may derive from petroleum-based sources, further increasing their carbon footprint.

During the use phase, the environmental impact largely depends on the application context and the stability of the QD-polymer system. Photostability enhancement methods, while improving durability, may introduce additional chemical components that could affect end-of-life environmental outcomes. Core-shell structures and surface ligand modifications, commonly employed to enhance photostability, alter the leaching behavior and degradation pathways of these materials in environmental settings.

End-of-life considerations present particular challenges for QD-polymer composites. The persistence of quantum dots in the environment remains inadequately understood, with potential for bioaccumulation in food chains. Current recycling infrastructure is generally ill-equipped to handle these advanced materials, potentially leading to improper disposal and environmental release. The heterogeneous nature of these composites complicates material recovery efforts.

Recent life cycle assessment (LCA) studies indicate that the environmental impact of QD-polymer composites varies significantly based on synthesis methods, stabilization approaches, and end-use applications. Emerging research suggests that green synthesis routes utilizing biopolymers and aqueous processing can substantially reduce environmental impacts. Similarly, designing photostability enhancement methods that avoid persistent additives or toxic components can improve the overall environmental profile.

Regulatory frameworks worldwide are increasingly addressing nanomaterials like quantum dots, with the European Union's REACH regulation and similar initiatives in other regions establishing reporting requirements and usage restrictions. Future development of durable QD-polymer composites will need to balance performance requirements with environmental sustainability considerations, potentially through design-for-environment approaches that consider the entire material lifecycle.

Scalability and Manufacturing Considerations

The scalability of quantum dot-polymer composite manufacturing represents a critical factor in their commercial viability. Current laboratory-scale synthesis methods for photostable QD-polymer composites often involve complex multi-step processes that are challenging to scale up. The transition from bench-scale to industrial production requires significant process optimization to maintain the enhanced photostability achieved in research settings while enabling cost-effective mass production.

Industrial-scale manufacturing of durable QD-polymer composites faces several key challenges. First, maintaining uniform dispersion of quantum dots within polymer matrices becomes increasingly difficult at larger volumes, potentially leading to aggregation and reduced photostability. Second, the precise control of polymerization conditions necessary for creating protective interfaces between QDs and polymer matrices is harder to maintain in large-scale reactors.

Advanced manufacturing technologies show promise for overcoming these challenges. Microfluidic-based continuous flow synthesis offers superior control over reaction parameters compared to batch processes, potentially enabling consistent production of photostable composites at commercial scales. Additionally, spray-drying and supercritical fluid technologies present alternative routes for achieving uniform QD dispersion in polymer matrices while maintaining the interfacial properties critical for photostability.

Economic considerations significantly impact manufacturing strategy selection. While solution-phase processing methods remain the most cost-effective for many applications, they often provide limited protection against photo-oxidation. More sophisticated encapsulation techniques that enhance durability typically incur higher production costs, creating a trade-off between performance and economic viability that manufacturers must carefully navigate.

Quality control represents another crucial aspect of scalable manufacturing. Implementing real-time monitoring systems for quantum yield, emission wavelength stability, and dispersion homogeneity throughout the production process is essential for ensuring consistent photostability in the final products. Automated optical characterization techniques integrated into production lines can help maintain quality standards during scale-up.

Environmental and regulatory considerations also influence manufacturing approaches. The potential toxicity of certain quantum dot materials necessitates careful containment during production. Additionally, sustainable manufacturing practices, including solvent recovery systems and energy-efficient curing processes, are increasingly important for commercial viability as regulatory frameworks evolve globally.

Collaborative development between materials scientists and process engineers will be essential for successful commercialization. Cross-disciplinary approaches that simultaneously address material design and manufacturing constraints offer the most promising path toward scalable production of photostable QD-polymer composites for applications ranging from display technologies to solar energy conversion systems.

Industrial-scale manufacturing of durable QD-polymer composites faces several key challenges. First, maintaining uniform dispersion of quantum dots within polymer matrices becomes increasingly difficult at larger volumes, potentially leading to aggregation and reduced photostability. Second, the precise control of polymerization conditions necessary for creating protective interfaces between QDs and polymer matrices is harder to maintain in large-scale reactors.

Advanced manufacturing technologies show promise for overcoming these challenges. Microfluidic-based continuous flow synthesis offers superior control over reaction parameters compared to batch processes, potentially enabling consistent production of photostable composites at commercial scales. Additionally, spray-drying and supercritical fluid technologies present alternative routes for achieving uniform QD dispersion in polymer matrices while maintaining the interfacial properties critical for photostability.

Economic considerations significantly impact manufacturing strategy selection. While solution-phase processing methods remain the most cost-effective for many applications, they often provide limited protection against photo-oxidation. More sophisticated encapsulation techniques that enhance durability typically incur higher production costs, creating a trade-off between performance and economic viability that manufacturers must carefully navigate.

Quality control represents another crucial aspect of scalable manufacturing. Implementing real-time monitoring systems for quantum yield, emission wavelength stability, and dispersion homogeneity throughout the production process is essential for ensuring consistent photostability in the final products. Automated optical characterization techniques integrated into production lines can help maintain quality standards during scale-up.

Environmental and regulatory considerations also influence manufacturing approaches. The potential toxicity of certain quantum dot materials necessitates careful containment during production. Additionally, sustainable manufacturing practices, including solvent recovery systems and energy-efficient curing processes, are increasingly important for commercial viability as regulatory frameworks evolve globally.

Collaborative development between materials scientists and process engineers will be essential for successful commercialization. Cross-disciplinary approaches that simultaneously address material design and manufacturing constraints offer the most promising path toward scalable production of photostable QD-polymer composites for applications ranging from display technologies to solar energy conversion systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!