Design Criteria For Quantum Dot Based Luminescent Solar Windows

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot Solar Windows Background and Objectives

Quantum dot-based luminescent solar concentrators (LSCs) have emerged as a promising technology at the intersection of renewable energy and architectural innovation. The evolution of this technology can be traced back to the early 2000s when researchers began exploring nanomaterials for solar energy applications. The trajectory has accelerated significantly in the past decade with breakthroughs in quantum dot synthesis, spectral tuning capabilities, and integration methods with conventional building materials.

The fundamental principle behind quantum dot solar windows involves the absorption of sunlight by quantum dots embedded in transparent materials, followed by luminescence and waveguiding of the emitted light to the edges where photovoltaic cells convert it to electricity. This approach offers a unique solution to the architectural-energetic dilemma by maintaining transparency while generating power, unlike traditional opaque solar panels.

Current technological objectives focus on several critical parameters: achieving optimal transparency (70-80%) while maintaining reasonable power conversion efficiency (PCE) of 5-10%; ensuring long-term stability under real-world conditions including UV exposure and temperature fluctuations; and developing cost-effective manufacturing processes compatible with existing window production infrastructure.

The development of quantum dot solar windows aligns with global sustainability initiatives, particularly the drive toward net-zero energy buildings. As regulatory frameworks increasingly mandate energy-efficient construction, building-integrated photovoltaics (BIPV) solutions like quantum dot windows represent a strategic technological response to these evolving requirements.

Recent advancements in quantum dot chemistry have addressed historical limitations, particularly regarding toxicity and stability. The shift from cadmium-based to indium phosphide and perovskite quantum dots represents a significant step toward environmentally compatible materials. Simultaneously, innovations in encapsulation techniques have extended operational lifetimes from months to several years, though further improvements remain necessary for commercial viability.

The technical objectives for quantum dot solar windows extend beyond mere energy generation to include aesthetic considerations, thermal management properties, and integration with smart building systems. The ideal solution would provide dynamic response to changing environmental conditions, optimizing the balance between daylighting, heat gain, and electricity production throughout daily and seasonal cycles.

Achieving these objectives requires interdisciplinary collaboration across materials science, photonics, architectural engineering, and manufacturing technology. The ultimate goal is to develop a transformative building material that seamlessly integrates into the built environment while contributing significantly to distributed renewable energy generation and reduced building energy consumption.

The fundamental principle behind quantum dot solar windows involves the absorption of sunlight by quantum dots embedded in transparent materials, followed by luminescence and waveguiding of the emitted light to the edges where photovoltaic cells convert it to electricity. This approach offers a unique solution to the architectural-energetic dilemma by maintaining transparency while generating power, unlike traditional opaque solar panels.

Current technological objectives focus on several critical parameters: achieving optimal transparency (70-80%) while maintaining reasonable power conversion efficiency (PCE) of 5-10%; ensuring long-term stability under real-world conditions including UV exposure and temperature fluctuations; and developing cost-effective manufacturing processes compatible with existing window production infrastructure.

The development of quantum dot solar windows aligns with global sustainability initiatives, particularly the drive toward net-zero energy buildings. As regulatory frameworks increasingly mandate energy-efficient construction, building-integrated photovoltaics (BIPV) solutions like quantum dot windows represent a strategic technological response to these evolving requirements.

Recent advancements in quantum dot chemistry have addressed historical limitations, particularly regarding toxicity and stability. The shift from cadmium-based to indium phosphide and perovskite quantum dots represents a significant step toward environmentally compatible materials. Simultaneously, innovations in encapsulation techniques have extended operational lifetimes from months to several years, though further improvements remain necessary for commercial viability.

The technical objectives for quantum dot solar windows extend beyond mere energy generation to include aesthetic considerations, thermal management properties, and integration with smart building systems. The ideal solution would provide dynamic response to changing environmental conditions, optimizing the balance between daylighting, heat gain, and electricity production throughout daily and seasonal cycles.

Achieving these objectives requires interdisciplinary collaboration across materials science, photonics, architectural engineering, and manufacturing technology. The ultimate goal is to develop a transformative building material that seamlessly integrates into the built environment while contributing significantly to distributed renewable energy generation and reduced building energy consumption.

Market Analysis for Luminescent Solar Windows

The global market for luminescent solar windows is experiencing significant growth, driven by increasing demand for sustainable building solutions and renewable energy integration in urban environments. Current market valuation stands at approximately 4.5 billion USD in 2023, with projections indicating a compound annual growth rate of 15.7% through 2030, potentially reaching 12.8 billion USD by the end of the decade.

The primary market segments for quantum dot based luminescent solar windows include commercial office buildings, which represent the largest share at 42% of the market, followed by residential applications at 28%, institutional buildings at 18%, and industrial facilities at 12%. Geographically, North America and Europe currently lead adoption rates, accounting for 37% and 33% of the global market respectively, while the Asia-Pacific region shows the fastest growth trajectory at 19.2% annually.

Key market drivers include increasingly stringent building energy efficiency regulations, rising electricity costs, and growing corporate sustainability commitments. The European Union's Energy Performance of Buildings Directive and similar policies in North America have created regulatory tailwinds for technologies that can reduce building energy consumption while generating renewable power. Additionally, the aesthetic appeal of transparent solar windows compared to traditional photovoltaics represents a significant market advantage.

Consumer willingness to pay premiums for sustainable building materials has increased substantially, with surveys indicating that commercial developers are willing to invest 15-20% more for energy-generating windows with payback periods under seven years. This price tolerance creates a viable market entry point despite the currently higher production costs of quantum dot technologies.

Market challenges include competition from alternative technologies such as thin-film photovoltaics, electrochromic smart glass, and conventional building-integrated photovoltaics. Additionally, the relatively long replacement cycles for commercial windows (15-25 years) may slow market penetration rates compared to other renewable technologies.

Distribution channels are primarily dominated by architectural glass manufacturers and building material suppliers, with increasing interest from major construction firms seeking to differentiate their offerings. Strategic partnerships between quantum dot technology developers and established glass manufacturers represent the most promising commercialization pathway, as evidenced by recent joint ventures between materials science startups and global glass producers.

Consumer awareness and education remain significant barriers to wider adoption, with market research indicating that only 23% of building owners and architects fully understand the benefits and applications of luminescent solar window technology. This suggests substantial growth potential as awareness campaigns and demonstration projects increase market visibility.

The primary market segments for quantum dot based luminescent solar windows include commercial office buildings, which represent the largest share at 42% of the market, followed by residential applications at 28%, institutional buildings at 18%, and industrial facilities at 12%. Geographically, North America and Europe currently lead adoption rates, accounting for 37% and 33% of the global market respectively, while the Asia-Pacific region shows the fastest growth trajectory at 19.2% annually.

Key market drivers include increasingly stringent building energy efficiency regulations, rising electricity costs, and growing corporate sustainability commitments. The European Union's Energy Performance of Buildings Directive and similar policies in North America have created regulatory tailwinds for technologies that can reduce building energy consumption while generating renewable power. Additionally, the aesthetic appeal of transparent solar windows compared to traditional photovoltaics represents a significant market advantage.

Consumer willingness to pay premiums for sustainable building materials has increased substantially, with surveys indicating that commercial developers are willing to invest 15-20% more for energy-generating windows with payback periods under seven years. This price tolerance creates a viable market entry point despite the currently higher production costs of quantum dot technologies.

Market challenges include competition from alternative technologies such as thin-film photovoltaics, electrochromic smart glass, and conventional building-integrated photovoltaics. Additionally, the relatively long replacement cycles for commercial windows (15-25 years) may slow market penetration rates compared to other renewable technologies.

Distribution channels are primarily dominated by architectural glass manufacturers and building material suppliers, with increasing interest from major construction firms seeking to differentiate their offerings. Strategic partnerships between quantum dot technology developers and established glass manufacturers represent the most promising commercialization pathway, as evidenced by recent joint ventures between materials science startups and global glass producers.

Consumer awareness and education remain significant barriers to wider adoption, with market research indicating that only 23% of building owners and architects fully understand the benefits and applications of luminescent solar window technology. This suggests substantial growth potential as awareness campaigns and demonstration projects increase market visibility.

Current Quantum Dot Technology Limitations

Despite significant advancements in quantum dot (QD) technology for luminescent solar concentrators (LSCs) in window applications, several critical limitations continue to impede widespread commercial adoption. The primary challenge remains the relatively low power conversion efficiency (PCE) of QD-based solar windows, typically ranging from 2-7% compared to conventional photovoltaics that achieve 15-22%. This efficiency gap stems from multiple technical constraints inherent to the current state of QD technology.

Quantum dot stability presents a major hurdle, particularly in real-world operating conditions. QDs often experience significant degradation when exposed to prolonged UV radiation, oxygen, and moisture - all unavoidable elements in window applications. Most high-performance QDs contain toxic heavy metals like cadmium or lead, which not only raise environmental and regulatory concerns but also limit their integration into consumer-facing building products.

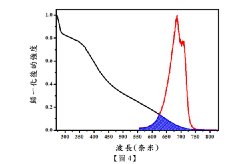

Reabsorption losses constitute another significant limitation. The spectral overlap between QD absorption and emission profiles results in emitted photons being reabsorbed before reaching the solar cell edges, dramatically reducing collection efficiency. This self-absorption phenomenon becomes increasingly problematic as window dimensions increase, creating a scaling challenge for architectural applications.

Current manufacturing processes for high-quality QDs remain complex and costly, involving precise temperature control and inert atmospheres. The integration of QDs into transparent window matrices while maintaining optical clarity and preventing aggregation requires sophisticated encapsulation techniques that have not yet been optimized for mass production.

Light management issues persist in existing QD window designs. The trade-off between transparency (essential for window functionality) and light harvesting capability (necessary for energy generation) has not been adequately resolved. Most current designs sacrifice either aesthetic quality or power output, limiting market acceptance.

The spectral mismatch between QD emission and attached photovoltaic cell absorption represents another efficiency bottleneck. Many QDs emit light at wavelengths that are not optimally matched to the bandgap of standard silicon solar cells, resulting in energy losses during the conversion process.

Lastly, long-term performance consistency remains unproven. Accelerated aging tests suggest significant efficiency degradation over time periods shorter than the expected lifetime of building components. This reliability gap creates uncertainty regarding the return on investment for potential adopters, further hindering commercialization efforts despite the promising theoretical advantages of QD-based luminescent solar windows.

Quantum dot stability presents a major hurdle, particularly in real-world operating conditions. QDs often experience significant degradation when exposed to prolonged UV radiation, oxygen, and moisture - all unavoidable elements in window applications. Most high-performance QDs contain toxic heavy metals like cadmium or lead, which not only raise environmental and regulatory concerns but also limit their integration into consumer-facing building products.

Reabsorption losses constitute another significant limitation. The spectral overlap between QD absorption and emission profiles results in emitted photons being reabsorbed before reaching the solar cell edges, dramatically reducing collection efficiency. This self-absorption phenomenon becomes increasingly problematic as window dimensions increase, creating a scaling challenge for architectural applications.

Current manufacturing processes for high-quality QDs remain complex and costly, involving precise temperature control and inert atmospheres. The integration of QDs into transparent window matrices while maintaining optical clarity and preventing aggregation requires sophisticated encapsulation techniques that have not yet been optimized for mass production.

Light management issues persist in existing QD window designs. The trade-off between transparency (essential for window functionality) and light harvesting capability (necessary for energy generation) has not been adequately resolved. Most current designs sacrifice either aesthetic quality or power output, limiting market acceptance.

The spectral mismatch between QD emission and attached photovoltaic cell absorption represents another efficiency bottleneck. Many QDs emit light at wavelengths that are not optimally matched to the bandgap of standard silicon solar cells, resulting in energy losses during the conversion process.

Lastly, long-term performance consistency remains unproven. Accelerated aging tests suggest significant efficiency degradation over time periods shorter than the expected lifetime of building components. This reliability gap creates uncertainty regarding the return on investment for potential adopters, further hindering commercialization efforts despite the promising theoretical advantages of QD-based luminescent solar windows.

Current Design Solutions for Luminescent Solar Windows

01 Quantum dot composition and structure for solar windows

The composition and structure of quantum dots are critical for luminescent solar windows. Various semiconductor materials like CdSe, CdTe, PbS, and InP can be used to create quantum dots with specific optical properties. The size, shape, and core-shell structure of quantum dots determine their absorption and emission spectra, which directly impacts the efficiency of light harvesting and conversion in solar windows. Proper engineering of quantum dot structures enables tuning of bandgaps to capture specific wavelengths while maintaining transparency in the visible spectrum.- Quantum dot composition and structure for solar windows: Quantum dots with specific compositions and structures are essential for luminescent solar windows. These include semiconductor nanocrystals with tunable bandgaps that can absorb light in specific wavelengths and re-emit it at longer wavelengths. The size, shape, and core-shell structure of quantum dots significantly affect their optical properties, stability, and efficiency in solar window applications. Materials such as CdSe, CdS, PbS, and InP are commonly used, with various surface modifications to enhance their performance.

- Integration of quantum dots in transparent window materials: Effective integration of quantum dots into transparent window materials is crucial for creating functional luminescent solar windows. This involves embedding quantum dots in polymer matrices, glass, or other transparent substrates while maintaining optical clarity and preventing aggregation. Various techniques such as solution processing, in-situ synthesis, and lamination are employed to achieve uniform distribution of quantum dots. The integration method affects light transmission, quantum dot stability, and overall device efficiency.

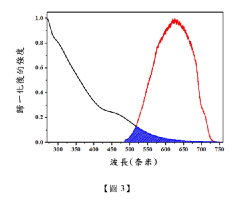

- Spectral management and light harvesting optimization: Optimizing spectral management is critical for quantum dot solar windows to balance transparency and power generation. This involves selecting quantum dots with absorption spectra that capture non-visible light while allowing visible light transmission. Strategic design of quantum dot concentrations, sizes, and distributions enables efficient light harvesting at specific wavelengths. Advanced techniques include using multiple types of quantum dots for broader spectrum utilization and implementing photonic structures to enhance light trapping and directional emission.

- Quantum dot stability and encapsulation methods: Ensuring long-term stability of quantum dots in solar window applications requires effective encapsulation and protection strategies. This includes developing methods to prevent photo-oxidation, thermal degradation, and leaching of quantum dots. Various encapsulation techniques such as silica coating, polymer encapsulation, and multi-layer barrier films are employed to protect quantum dots from environmental factors while maintaining their optical properties. Stability under UV exposure and temperature fluctuations is particularly important for practical window applications.

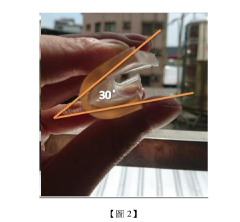

- System design and efficiency enhancement techniques: Overall system design considerations for quantum dot solar windows include optimizing the balance between transparency, aesthetics, and power generation. This involves engineering the complete window structure with appropriate electrodes, wiring, and power extraction systems. Advanced designs incorporate concentrators, reflectors, or waveguide structures to direct luminescent emissions to photovoltaic cells at the edges of windows. Efficiency enhancement techniques also include minimizing reabsorption losses, reducing surface reflections, and optimizing quantum yield of the dots.

02 Integration of quantum dots in transparent substrates

Effective integration of quantum dots into transparent substrates is essential for creating functional luminescent solar windows. Methods include embedding quantum dots in polymer matrices, glass, or as thin films on transparent conductive substrates. The integration technique affects quantum dot stability, optical clarity, and overall device performance. Key considerations include maintaining quantum dot dispersion to prevent aggregation, ensuring compatibility with the host material, and developing processes that allow for uniform distribution across large surface areas while preserving transparency.Expand Specific Solutions03 Spectral management and light guiding techniques

Spectral management involves designing quantum dot systems that selectively absorb ultraviolet and near-infrared light while transmitting visible light, maintaining window transparency. Light guiding techniques direct the re-emitted photons to the edges of the window where solar cells are positioned for energy conversion. This includes total internal reflection principles, specialized coatings, and geometric designs that maximize light collection efficiency. Advanced designs incorporate photonic structures that enhance directional emission toward solar collectors while minimizing losses due to reabsorption or escape cone losses.Expand Specific Solutions04 Efficiency enhancement and energy conversion systems

Various techniques are employed to enhance the efficiency of quantum dot-based luminescent solar windows. These include using multiple quantum dot types with cascading energy levels to capture broader spectrum ranges, incorporating photonic crystals to control light propagation, and optimizing the interface between the luminescent layer and solar cells. The design of the energy conversion system, including the type and placement of solar cells, significantly impacts overall power generation. Advanced systems may include concentrators, wavelength-specific collectors, and hybrid approaches combining luminescent concentration with traditional photovoltaic technologies.Expand Specific Solutions05 Durability and environmental stability considerations

Long-term stability of quantum dots under solar radiation and environmental conditions is crucial for commercial viability of luminescent solar windows. Design criteria include protection against photo-oxidation, thermal degradation, and moisture sensitivity. Encapsulation techniques, surface modifications, and protective coatings are employed to enhance quantum dot durability. Additional considerations include UV stability of the host matrix, thermal management to prevent performance degradation at elevated temperatures, and resistance to weathering effects. Materials and structures must maintain performance over the expected lifetime of building windows while withstanding daily and seasonal environmental variations.Expand Specific Solutions

Leading Companies in Quantum Dot Solar Applications

The quantum dot-based luminescent solar window market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The global market size for building-integrated photovoltaics is projected to reach $36 billion by 2028, with luminescent solar concentrators representing an emerging segment. Technologically, the field remains in development with key challenges in efficiency, transparency, and durability. Leading players include established materials companies like Corning and Avantama AG, which are developing specialized quantum dot formulations, alongside research powerhouses such as MIT, Caltech, and Samsung Display advancing fundamental technologies. Chinese institutions including Tianjin University and Shanghai Jiao Tong University are making significant contributions to efficiency improvements, while companies like SolarWindow Technologies are focused on commercialization pathways for transparent energy-generating surfaces.

SolarWindow Technologies, Inc.

Technical Solution: SolarWindow Technologies has developed proprietary quantum dot-based luminescent solar concentrator (LSC) technology specifically designed for transparent solar windows. Their approach utilizes organic photovoltaic (OPV) coatings containing specially engineered quantum dots that selectively absorb non-visible light wavelengths while maintaining up to 90% visible light transmission. The company's LiquidElectricity™ coatings can be applied to glass surfaces at ambient temperatures, eliminating the need for high-temperature vacuum deposition processes typically required for conventional solar cells. Their quantum dots are tuned to absorb primarily UV and near-infrared light, redirecting it to thin strip solar cells embedded in the window frame, which significantly improves aesthetic appeal while maintaining energy generation capabilities.

Strengths: High transparency (up to 90% visible light transmission) while still generating electricity; room-temperature application process reduces manufacturing costs; can be retrofitted to existing windows. Weaknesses: Lower overall efficiency compared to traditional solar panels; durability and long-term stability of organic materials remains a challenge; commercialization still in progress with limited real-world deployment data.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed advanced quantum dot integration techniques for luminescent solar windows that leverage their extensive expertise in display technologies. Their approach utilizes cadmium-free quantum dots embedded in specialized polymer films that can be laminated between glass layers in standard window manufacturing processes. Samsung's quantum dots feature precisely engineered core-shell structures that optimize both light absorption and emission characteristics while maintaining high transparency in the visible spectrum. The company has pioneered methods to control quantum dot distribution density within the polymer matrix, creating gradient concentrations that maximize edge collection efficiency while minimizing self-absorption losses. Their manufacturing process incorporates roll-to-roll techniques adapted from display production, enabling large-scale, cost-effective fabrication of quantum dot films with consistent performance characteristics across large surface areas.

Strengths: Extensive manufacturing infrastructure and expertise in quantum dot implementation at scale; cadmium-free formulations address environmental and regulatory concerns; established supply chain and quality control systems. Weaknesses: Primary focus on display applications may limit optimization specifically for solar window applications; technology may prioritize aesthetic considerations over maximum energy generation efficiency; relatively new entrant to the solar energy sector.

Key Patents in Quantum Dot Solar Window Technology

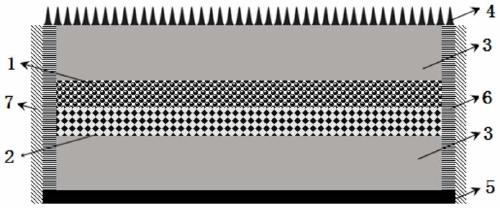

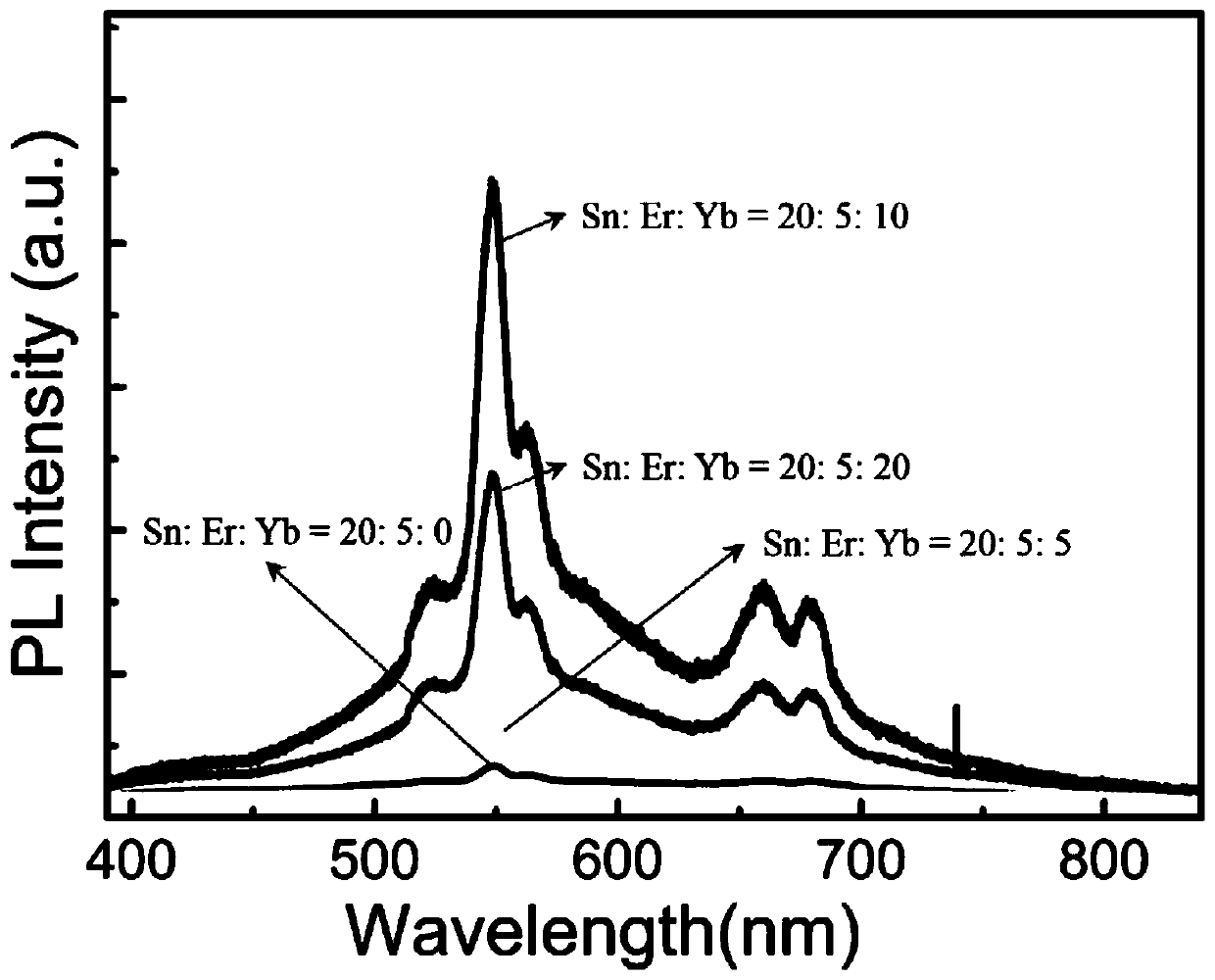

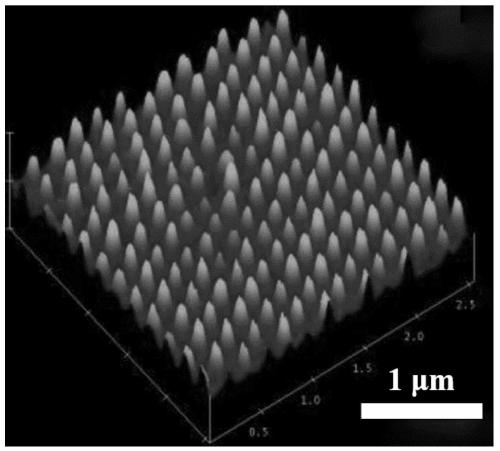

Quantum dots based luminescent solar concentrator based on spectral up-conversion technique, flat concentrating photovoltaic device and preparation method thereof

PatentActiveCN110246922A

Innovation

- A quantum dot fluorescent solar concentrator based on spectral upconversion technology is used to design a solar spectrum upconversion layer, a light trapping layer glass sheet, a top anti-reflection layer and a bottom metal reflection layer, which are improved through the resonance energy transfer of rare earth ions and nanocrystals. The light collection efficiency of low-energy photons is reduced, and the escape rate of photons is reduced through the metal reflective layer.

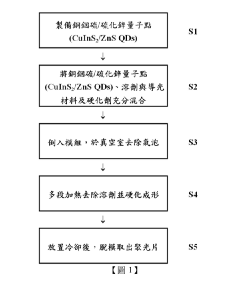

Quantum Dots-containing Flexible Luminescent Solar Concentrators and the preparation method thereof

PatentInactiveTW201806309A

Innovation

- A flexible quantum dot solar concentrating sheet composed of quantum dots and organic polymer materials, specifically using polydimethylsiloxane (PDMS), polyvinyl butyral (PVB), or polyvinyl alcohol (PVA) as light guide materials, with copper indium sulfur/zinc sulfide (CIS/ZnS) quantum dots, and a manufacturing process involving vacuum mixing and controlled heating to create a flexible, durable sheet.

Energy Efficiency and Performance Metrics

The evaluation of quantum dot based luminescent solar windows necessitates comprehensive energy efficiency and performance metrics to quantify their effectiveness in real-world applications. Power conversion efficiency (PCE) stands as the primary metric, typically ranging from 3-8% for current quantum dot solar window technologies, significantly lower than conventional photovoltaic panels but offering the unique advantage of transparency and architectural integration.

Visible light transmission (VLT) represents another critical parameter, measuring the percentage of visible light passing through the window. Commercial quantum dot solar windows currently achieve 30-70% VLT, with the trade-off that higher transparency generally results in lower power generation. This balance between transparency and energy harvesting efficiency constitutes a fundamental design consideration.

Solar heat gain coefficient (SHGC) measures the fraction of incident solar radiation admitted through the window, directly affecting building cooling loads. Quantum dot technologies can be engineered to selectively absorb ultraviolet and near-infrared wavelengths while transmitting visible light, potentially achieving SHGC values between 0.25-0.45, significantly lower than conventional glass.

Spectral response characterizes the window's ability to convert different wavelengths of light into electricity. Ideal quantum dot formulations demonstrate broad absorption in the UV and NIR regions while maintaining transparency in the visible spectrum (approximately 400-700nm). This wavelength-selective behavior enables the dual functionality of energy generation and daylighting.

Operational lifetime and degradation rates must be considered, as quantum dot materials can experience photodegradation and thermal stress over time. Current technologies demonstrate 80% efficiency retention over 3-5 years, though significant research focuses on extending this to match the 20+ year lifespan of conventional windows through encapsulation techniques and material innovations.

Energy payback time (EPBT) and embodied energy calculations reveal the sustainability profile of these technologies. Preliminary assessments indicate EPBT of 1-3 years for quantum dot solar windows in optimal conditions, comparing favorably to traditional photovoltaics while offering additional benefits through reduced building energy consumption for lighting and temperature control.

Cost-performance ratio remains a significant challenge, with current production costs estimated at $150-300 per square meter above conventional glazing. Market viability requires either cost reduction through manufacturing scale or performance improvements that justify the premium through enhanced energy savings.

Visible light transmission (VLT) represents another critical parameter, measuring the percentage of visible light passing through the window. Commercial quantum dot solar windows currently achieve 30-70% VLT, with the trade-off that higher transparency generally results in lower power generation. This balance between transparency and energy harvesting efficiency constitutes a fundamental design consideration.

Solar heat gain coefficient (SHGC) measures the fraction of incident solar radiation admitted through the window, directly affecting building cooling loads. Quantum dot technologies can be engineered to selectively absorb ultraviolet and near-infrared wavelengths while transmitting visible light, potentially achieving SHGC values between 0.25-0.45, significantly lower than conventional glass.

Spectral response characterizes the window's ability to convert different wavelengths of light into electricity. Ideal quantum dot formulations demonstrate broad absorption in the UV and NIR regions while maintaining transparency in the visible spectrum (approximately 400-700nm). This wavelength-selective behavior enables the dual functionality of energy generation and daylighting.

Operational lifetime and degradation rates must be considered, as quantum dot materials can experience photodegradation and thermal stress over time. Current technologies demonstrate 80% efficiency retention over 3-5 years, though significant research focuses on extending this to match the 20+ year lifespan of conventional windows through encapsulation techniques and material innovations.

Energy payback time (EPBT) and embodied energy calculations reveal the sustainability profile of these technologies. Preliminary assessments indicate EPBT of 1-3 years for quantum dot solar windows in optimal conditions, comparing favorably to traditional photovoltaics while offering additional benefits through reduced building energy consumption for lighting and temperature control.

Cost-performance ratio remains a significant challenge, with current production costs estimated at $150-300 per square meter above conventional glazing. Market viability requires either cost reduction through manufacturing scale or performance improvements that justify the premium through enhanced energy savings.

Environmental Impact and Sustainability Considerations

The integration of quantum dot-based luminescent solar windows into the built environment necessitates thorough consideration of their environmental impact and sustainability profile throughout their entire lifecycle. These innovative windows represent a significant advancement in building-integrated photovoltaics, but their environmental implications must be carefully assessed to ensure they deliver genuine sustainability benefits.

Manufacturing processes for quantum dot materials involve potentially hazardous substances, including heavy metals like cadmium, lead, or indium, which pose environmental and health risks if improperly managed. Recent developments have focused on reducing or eliminating these toxic elements through the development of non-toxic alternatives such as carbon dots or silicon quantum dots. These alternatives maintain optical performance while significantly reducing environmental hazards associated with production and disposal.

Energy payback time (EPBT) represents a critical metric for quantum dot solar windows, measuring the time required for the energy generated to offset the energy consumed during manufacturing and installation. Current research indicates that well-designed quantum dot windows can achieve EPBTs of 1-3 years, substantially lower than many conventional photovoltaic systems, particularly when accounting for the dual functionality of these windows as both energy generators and building envelope components.

End-of-life management presents unique challenges due to the composite nature of these windows, which combine glass, polymer interlayers, and quantum dot materials. Developing effective recycling protocols is essential to recover valuable materials and prevent environmental contamination. Emerging techniques such as solvent-based separation methods show promise for isolating quantum dot materials from window components, enabling their recovery and potential reuse.

Water consumption during manufacturing warrants particular attention, as quantum dot synthesis often requires significant water resources. Closed-loop water systems and advanced filtration technologies are being implemented to minimize freshwater requirements and prevent the release of contaminated effluents into natural water systems.

Carbon footprint analysis reveals that quantum dot solar windows can significantly reduce building-related emissions through on-site clean energy generation. Life cycle assessments indicate potential carbon emission reductions of 30-50% compared to conventional windows when accounting for both embodied carbon and operational energy savings over a typical 25-year service life.

Regulatory frameworks worldwide are evolving to address the unique environmental considerations of quantum dot technologies. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions increasingly influence material selection and manufacturing processes, driving innovation toward more environmentally benign quantum dot formulations and production methods.

Manufacturing processes for quantum dot materials involve potentially hazardous substances, including heavy metals like cadmium, lead, or indium, which pose environmental and health risks if improperly managed. Recent developments have focused on reducing or eliminating these toxic elements through the development of non-toxic alternatives such as carbon dots or silicon quantum dots. These alternatives maintain optical performance while significantly reducing environmental hazards associated with production and disposal.

Energy payback time (EPBT) represents a critical metric for quantum dot solar windows, measuring the time required for the energy generated to offset the energy consumed during manufacturing and installation. Current research indicates that well-designed quantum dot windows can achieve EPBTs of 1-3 years, substantially lower than many conventional photovoltaic systems, particularly when accounting for the dual functionality of these windows as both energy generators and building envelope components.

End-of-life management presents unique challenges due to the composite nature of these windows, which combine glass, polymer interlayers, and quantum dot materials. Developing effective recycling protocols is essential to recover valuable materials and prevent environmental contamination. Emerging techniques such as solvent-based separation methods show promise for isolating quantum dot materials from window components, enabling their recovery and potential reuse.

Water consumption during manufacturing warrants particular attention, as quantum dot synthesis often requires significant water resources. Closed-loop water systems and advanced filtration technologies are being implemented to minimize freshwater requirements and prevent the release of contaminated effluents into natural water systems.

Carbon footprint analysis reveals that quantum dot solar windows can significantly reduce building-related emissions through on-site clean energy generation. Life cycle assessments indicate potential carbon emission reductions of 30-50% compared to conventional windows when accounting for both embodied carbon and operational energy savings over a typical 25-year service life.

Regulatory frameworks worldwide are evolving to address the unique environmental considerations of quantum dot technologies. The European Union's Restriction of Hazardous Substances (RoHS) directive and similar regulations in other regions increasingly influence material selection and manufacturing processes, driving innovation toward more environmentally benign quantum dot formulations and production methods.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!