Environmental And Health Risk Assessment For QD Based LSCs

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Quantum Dot LSC Technology Background and Objectives

Quantum Dot Luminescent Solar Concentrators (QD-LSCs) represent a significant advancement in solar energy harvesting technology, emerging from decades of research into photovoltaic efficiency enhancement. The concept of LSCs was first introduced in the 1970s, but the integration of quantum dots as luminophores has revolutionized this field over the past two decades. These nanoscale semiconductor particles exhibit exceptional optical properties, including size-tunable absorption and emission spectra, high quantum yields, and broad absorption bands, making them ideal candidates for solar concentration applications.

The evolution of QD-LSC technology has been marked by continuous improvements in quantum dot synthesis methods, from hot-injection techniques to more environmentally benign approaches. Parallel advancements in surface chemistry and core-shell architectures have significantly enhanced quantum dot stability and optical performance, addressing historical limitations of photobleaching and self-absorption that plagued earlier LSC designs.

Current technological trajectories indicate a growing emphasis on developing QD-LSCs with reduced environmental and health impacts while maintaining or improving performance metrics. This includes exploration of heavy metal-free quantum dots, such as carbon dots, silicon quantum dots, and perovskite nanocrystals, which aim to eliminate the reliance on toxic elements like cadmium and lead that are common in conventional quantum dot formulations.

The primary technical objective of this research is to conduct a comprehensive environmental and health risk assessment of quantum dot materials used in LSC applications across their entire lifecycle. This includes evaluation of potential exposure pathways during manufacturing, installation, operation, and end-of-life disposal or recycling. The assessment aims to identify and quantify potential hazards associated with different quantum dot compositions, with particular attention to leaching behavior, nanoparticle release mechanisms, and bioaccumulation potential.

Secondary objectives include establishing standardized testing protocols for QD-LSC environmental safety evaluation, developing comparative risk profiles for different quantum dot chemistries, and proposing design guidelines for environmentally benign QD-LSC systems. These objectives align with broader industry trends toward sustainable photovoltaic technologies and increasing regulatory scrutiny of nanomaterials in consumer and industrial applications.

The technological goal is to establish a framework that balances the promising energy efficiency benefits of QD-LSCs against their potential environmental and health implications, ultimately informing the development of next-generation solar concentration systems that minimize ecological footprint while maximizing energy harvesting capabilities. This research responds to the growing recognition that technological advancement must be coupled with responsible environmental stewardship to achieve truly sustainable energy solutions.

The evolution of QD-LSC technology has been marked by continuous improvements in quantum dot synthesis methods, from hot-injection techniques to more environmentally benign approaches. Parallel advancements in surface chemistry and core-shell architectures have significantly enhanced quantum dot stability and optical performance, addressing historical limitations of photobleaching and self-absorption that plagued earlier LSC designs.

Current technological trajectories indicate a growing emphasis on developing QD-LSCs with reduced environmental and health impacts while maintaining or improving performance metrics. This includes exploration of heavy metal-free quantum dots, such as carbon dots, silicon quantum dots, and perovskite nanocrystals, which aim to eliminate the reliance on toxic elements like cadmium and lead that are common in conventional quantum dot formulations.

The primary technical objective of this research is to conduct a comprehensive environmental and health risk assessment of quantum dot materials used in LSC applications across their entire lifecycle. This includes evaluation of potential exposure pathways during manufacturing, installation, operation, and end-of-life disposal or recycling. The assessment aims to identify and quantify potential hazards associated with different quantum dot compositions, with particular attention to leaching behavior, nanoparticle release mechanisms, and bioaccumulation potential.

Secondary objectives include establishing standardized testing protocols for QD-LSC environmental safety evaluation, developing comparative risk profiles for different quantum dot chemistries, and proposing design guidelines for environmentally benign QD-LSC systems. These objectives align with broader industry trends toward sustainable photovoltaic technologies and increasing regulatory scrutiny of nanomaterials in consumer and industrial applications.

The technological goal is to establish a framework that balances the promising energy efficiency benefits of QD-LSCs against their potential environmental and health implications, ultimately informing the development of next-generation solar concentration systems that minimize ecological footprint while maximizing energy harvesting capabilities. This research responds to the growing recognition that technological advancement must be coupled with responsible environmental stewardship to achieve truly sustainable energy solutions.

Market Analysis for Quantum Dot Solar Applications

The quantum dot solar application market is experiencing significant growth, driven by increasing demand for renewable energy solutions and advancements in nanotechnology. The global market for quantum dot solar applications was valued at approximately $2.5 billion in 2022 and is projected to reach $7.1 billion by 2028, representing a compound annual growth rate (CAGR) of 19.2%. This growth trajectory is supported by substantial investments in research and development, as well as increasing government initiatives promoting clean energy technologies.

North America currently dominates the market with a 38% share, followed by Europe (27%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and South Korea, is expected to witness the fastest growth due to aggressive renewable energy targets and supportive government policies. The market segmentation reveals that thin-film solar cells incorporating quantum dots hold the largest market share at 45%, followed by luminescent solar concentrators at 30%.

Key market drivers include the superior optical properties of quantum dots, which enable higher efficiency in solar energy conversion compared to traditional photovoltaic technologies. Quantum dot-based luminescent solar concentrators (QD-LSCs) specifically offer advantages such as tunable absorption spectra, reduced manufacturing costs, and potential for integration into building materials, creating new market opportunities in building-integrated photovoltaics (BIPV).

Consumer demand for aesthetically pleasing solar solutions is also fueling market growth, as QD-LSCs can be manufactured in various colors and transparencies, making them suitable for architectural applications. The automotive sector represents an emerging market segment, with quantum dot solar films being developed for integration into vehicle surfaces to power auxiliary systems.

Despite positive growth indicators, market challenges persist. High production costs and technical barriers related to quantum dot stability and toxicity concerns are limiting widespread commercial adoption. The environmental and health risks associated with certain quantum dot materials, particularly those containing cadmium and lead, have prompted regulatory scrutiny in major markets, potentially impacting future growth trajectories.

Market forecasts suggest that cadmium-free quantum dots will gain significant market share, growing at 24% annually, as manufacturers respond to environmental concerns and regulatory pressures. Strategic partnerships between quantum dot manufacturers and solar panel producers are becoming increasingly common, accelerating commercialization efforts and market penetration of quantum dot solar technologies.

North America currently dominates the market with a 38% share, followed by Europe (27%) and Asia-Pacific (25%). The Asia-Pacific region, particularly China and South Korea, is expected to witness the fastest growth due to aggressive renewable energy targets and supportive government policies. The market segmentation reveals that thin-film solar cells incorporating quantum dots hold the largest market share at 45%, followed by luminescent solar concentrators at 30%.

Key market drivers include the superior optical properties of quantum dots, which enable higher efficiency in solar energy conversion compared to traditional photovoltaic technologies. Quantum dot-based luminescent solar concentrators (QD-LSCs) specifically offer advantages such as tunable absorption spectra, reduced manufacturing costs, and potential for integration into building materials, creating new market opportunities in building-integrated photovoltaics (BIPV).

Consumer demand for aesthetically pleasing solar solutions is also fueling market growth, as QD-LSCs can be manufactured in various colors and transparencies, making them suitable for architectural applications. The automotive sector represents an emerging market segment, with quantum dot solar films being developed for integration into vehicle surfaces to power auxiliary systems.

Despite positive growth indicators, market challenges persist. High production costs and technical barriers related to quantum dot stability and toxicity concerns are limiting widespread commercial adoption. The environmental and health risks associated with certain quantum dot materials, particularly those containing cadmium and lead, have prompted regulatory scrutiny in major markets, potentially impacting future growth trajectories.

Market forecasts suggest that cadmium-free quantum dots will gain significant market share, growing at 24% annually, as manufacturers respond to environmental concerns and regulatory pressures. Strategic partnerships between quantum dot manufacturers and solar panel producers are becoming increasingly common, accelerating commercialization efforts and market penetration of quantum dot solar technologies.

Current Challenges in QD LSC Development

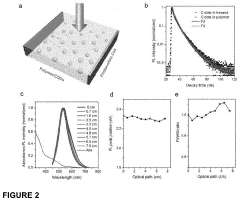

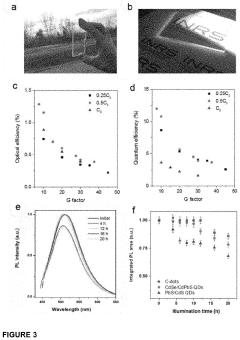

Despite significant advancements in Quantum Dot Luminescent Solar Concentrator (QD LSC) technology, several critical challenges continue to impede widespread commercial adoption. The primary obstacle remains the relatively low optical efficiency of current QD LSC systems, with most devices achieving only 5-7% efficiency under optimal laboratory conditions. This falls significantly short of the 10-15% threshold generally considered necessary for commercial viability in solar energy applications.

Quantum yield limitations represent another substantial hurdle. While laboratory-synthesized QDs can achieve internal quantum yields exceeding 90%, these values typically decrease to 60-70% when incorporated into polymer matrices for LSC applications. This reduction stems from surface defects, aggregation phenomena, and interactions between QDs and the host material that quench luminescence.

Stability concerns pose persistent challenges for QD LSC development. Environmental factors including UV exposure, temperature fluctuations, and humidity significantly accelerate QD degradation. Current generation QD LSCs typically demonstrate performance degradation of 15-25% after just 1000 hours of outdoor exposure, falling well short of the 20+ year lifespan expected for commercial solar technologies.

Reabsorption losses constitute a fundamental limitation in QD LSC performance. The spectral overlap between absorption and emission profiles in most QD systems results in significant photon losses during transport to the edges. This self-absorption phenomenon becomes increasingly problematic as device dimensions increase, creating a scaling barrier for larger applications.

Manufacturing complexities further hinder commercialization efforts. Current QD synthesis methods often involve toxic precursors and energy-intensive processes that are difficult to scale. Additionally, achieving uniform QD dispersion within polymer matrices remains challenging at industrial scales, leading to inconsistent performance across larger panels.

Cost factors present substantial barriers to market entry. Current production costs for high-quality QDs suitable for LSC applications range from $2,000-10,000 per gram, translating to prohibitively high costs for large-scale deployment. While economies of scale could potentially reduce these figures, the specialized materials and precise manufacturing conditions required maintain significant cost pressures.

Regulatory uncertainties surrounding nanomaterials, particularly those containing heavy metals like cadmium or lead commonly found in high-performance QDs, create additional market barriers. Evolving environmental regulations in key markets may restrict certain QD compositions, necessitating the development of alternative, potentially less efficient formulations.

Quantum yield limitations represent another substantial hurdle. While laboratory-synthesized QDs can achieve internal quantum yields exceeding 90%, these values typically decrease to 60-70% when incorporated into polymer matrices for LSC applications. This reduction stems from surface defects, aggregation phenomena, and interactions between QDs and the host material that quench luminescence.

Stability concerns pose persistent challenges for QD LSC development. Environmental factors including UV exposure, temperature fluctuations, and humidity significantly accelerate QD degradation. Current generation QD LSCs typically demonstrate performance degradation of 15-25% after just 1000 hours of outdoor exposure, falling well short of the 20+ year lifespan expected for commercial solar technologies.

Reabsorption losses constitute a fundamental limitation in QD LSC performance. The spectral overlap between absorption and emission profiles in most QD systems results in significant photon losses during transport to the edges. This self-absorption phenomenon becomes increasingly problematic as device dimensions increase, creating a scaling barrier for larger applications.

Manufacturing complexities further hinder commercialization efforts. Current QD synthesis methods often involve toxic precursors and energy-intensive processes that are difficult to scale. Additionally, achieving uniform QD dispersion within polymer matrices remains challenging at industrial scales, leading to inconsistent performance across larger panels.

Cost factors present substantial barriers to market entry. Current production costs for high-quality QDs suitable for LSC applications range from $2,000-10,000 per gram, translating to prohibitively high costs for large-scale deployment. While economies of scale could potentially reduce these figures, the specialized materials and precise manufacturing conditions required maintain significant cost pressures.

Regulatory uncertainties surrounding nanomaterials, particularly those containing heavy metals like cadmium or lead commonly found in high-performance QDs, create additional market barriers. Evolving environmental regulations in key markets may restrict certain QD compositions, necessitating the development of alternative, potentially less efficient formulations.

Current Environmental Risk Mitigation Approaches

01 Toxicity and environmental impact of quantum dot materials

Quantum dots used in luminescent solar concentrators (LSCs) often contain heavy metals like cadmium, lead, or other potentially toxic elements that pose environmental and health risks. These materials can leach into the environment during manufacturing, use, or disposal, potentially contaminating soil and water systems. Research focuses on assessing the bioaccumulation potential and long-term ecological impacts of these nanomaterials, as well as developing methods to mitigate their release into the environment.- Toxicity and environmental impact of quantum dot materials: Quantum dots used in luminescent solar concentrators (LSCs) often contain toxic heavy metals like cadmium, lead, or selenium that pose environmental and health risks. These materials can leach into the environment during manufacturing, use, or disposal, potentially contaminating soil and water systems. Research indicates concerns about bioaccumulation in living organisms and potential long-term ecological damage from improper disposal of QD-containing devices.

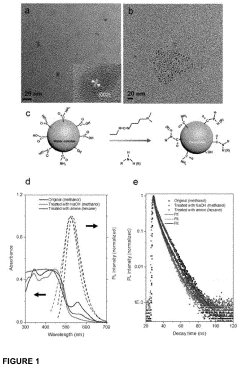

- Encapsulation and containment strategies for QD safety: Various encapsulation methods have been developed to mitigate the health and environmental risks of quantum dots in LSCs. These include core-shell structures, polymer encapsulation, and glass sealing techniques that prevent leaching of toxic components. Effective containment strategies can significantly reduce exposure risks during the product lifecycle while maintaining the optical performance of the QD-LSCs. These approaches focus on creating physical barriers between the quantum dots and the environment.

- Alternative non-toxic quantum dot compositions: Research has focused on developing less toxic or non-toxic alternatives to traditional heavy metal-based quantum dots for LSC applications. These include carbon-based quantum dots, silicon quantum dots, and other semiconductor nanoparticles made from more environmentally benign materials. These alternative compositions aim to maintain the optical efficiency and spectral tunability of conventional quantum dots while eliminating or reducing associated health and environmental hazards.

- Life cycle assessment and regulatory considerations: Life cycle assessments of QD-LSCs evaluate environmental impacts from raw material extraction through manufacturing, use, and end-of-life disposal. Regulatory frameworks in various countries impose restrictions on hazardous substances in electronic and photovoltaic devices, affecting QD-LSC development and commercialization. Compliance with regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) presents challenges for QD-LSC manufacturers and influences material selection and design approaches.

- Occupational exposure and safety protocols: Manufacturing processes for QD-LSCs present potential occupational health risks through inhalation, ingestion, or dermal contact with quantum dot materials. Safety protocols include specialized handling procedures, personal protective equipment requirements, and controlled manufacturing environments to minimize worker exposure. Research into the biological interactions of quantum dots with human tissues informs these safety measures, with particular attention to nanoparticle penetration through skin and respiratory pathways.

02 Development of non-toxic quantum dot alternatives

To address health and environmental concerns, researchers are developing alternative quantum dot materials that eliminate or reduce toxic heavy metals. These include carbon-based quantum dots, silicon quantum dots, and other environmentally benign semiconductor nanocrystals. These alternatives aim to maintain the optical efficiency and stability required for LSC applications while minimizing potential harm to human health and ecosystems during production, use, and end-of-life disposal.Expand Specific Solutions03 Encapsulation and containment strategies

Encapsulation technologies are being developed to physically contain quantum dots within LSC devices, preventing their release into the environment. These include robust polymer matrices, glass encapsulation, and multi-layer barrier films that can withstand weathering and degradation over the intended lifetime of solar concentrators. Such containment strategies aim to minimize exposure risks during normal operation and potential accidental breakage, while maintaining the optical performance of the quantum dots.Expand Specific Solutions04 Life cycle assessment and end-of-life management

Comprehensive life cycle assessments are being conducted to evaluate the environmental footprint of QD-LSCs from raw material extraction through manufacturing, use, and disposal. Research focuses on developing recycling and safe disposal protocols specifically for quantum dot-containing solar technologies. These assessments consider energy payback time, carbon footprint, and potential environmental contamination risks, helping to guide sustainable development of QD-LSC technologies.Expand Specific Solutions05 Regulatory frameworks and safety standards

Emerging regulatory frameworks and safety standards are being developed to govern the production, use, and disposal of quantum dot-based solar technologies. These include exposure limits for manufacturing workers, product safety certifications, and disposal regulations. Research is ongoing to establish standardized testing protocols for assessing potential leaching of quantum dots from LSCs under various environmental conditions, and to develop industry best practices that balance technological advancement with environmental protection.Expand Specific Solutions

Leading Organizations in Quantum Dot Solar Research

The quantum dot-based luminescent solar concentrator (QD-LSC) market is in an early growth phase, characterized by intensive research and development rather than widespread commercial deployment. The global market size remains relatively small but is expected to expand significantly as technology matures. Leading research institutions including California Institute of Technology, University of California, and Shanghai Jiao Tong University are advancing fundamental science in this field, while companies like Eni SpA and Eastman Kodak are exploring commercial applications. The technology maturity is currently transitioning from laboratory to pilot scale, with key players focusing on addressing environmental and health concerns through risk assessment frameworks. Research collaborations between academic institutions and industry partners are accelerating development, with particular emphasis on improving quantum yield efficiency and reducing potential toxicity issues.

The Regents of the University of California

Technical Solution: The University of California system has established a multi-campus research initiative focused on environmental and health risk assessment for quantum dot technologies in solar applications. Their approach emphasizes the development of safer-by-design QD formulations for luminescent solar concentrators that minimize potential environmental and health impacts. UC researchers have created standardized testing protocols to evaluate quantum dot toxicity across different environmental compartments (air, water, soil) and biological systems. Their work includes detailed investigations of quantum dot degradation mechanisms under environmental stressors such as UV radiation, temperature fluctuations, and microbial activity, with particular attention to how these processes affect toxicity profiles over time. The UC system has also pioneered research on cadmium-free quantum dot alternatives specifically designed for LSC applications, evaluating their performance characteristics alongside comprehensive toxicological profiles. Their risk assessment framework incorporates exposure modeling across the entire life cycle of QD-LSCs, from raw material extraction through manufacturing, use phase, and end-of-life scenarios.

Strengths: Extensive research network across multiple campuses allows for diverse expertise and collaborative approaches to complex risk assessment challenges. Strong focus on safer-by-design alternatives demonstrates practical application of risk findings. Weaknesses: Research sometimes emphasizes academic outcomes over commercial implementation guidance, potentially limiting direct industry adoption of findings.

Eastman Kodak Co.

Technical Solution: Eastman Kodak has leveraged its extensive experience in thin film technologies and chemical manufacturing to develop specialized risk assessment protocols for quantum dot luminescent solar concentrators. Their approach focuses particularly on manufacturing process safety and occupational exposure assessment, drawing on decades of experience handling photosensitive materials. Kodak has created detailed chemical fate models that track potential quantum dot migration through various environmental media, with particular attention to photodegradation pathways that may be relevant to outdoor solar installations. Their risk assessment framework incorporates specialized analytical techniques for detecting and quantifying ultra-low concentrations of quantum dots and their degradation products in environmental samples. Kodak researchers have also developed standardized leaching tests specifically designed to evaluate the stability of encapsulated quantum dots in LSC applications under various environmental conditions, including acid rain exposure, freeze-thaw cycles, and high-humidity environments. Their comprehensive approach includes evaluation of potential recycling and disposal pathways, assessing environmental risks associated with end-of-life management of QD-LSC technologies.

Strengths: Extensive industrial experience in chemical manufacturing provides practical insights into scaling risk assessment from laboratory to commercial production. Well-established analytical capabilities enable precise quantification of potential exposures. Weaknesses: Their assessment methodologies may be more focused on traditional chemical risks rather than the unique properties of nanomaterials, potentially overlooking some quantum dot-specific hazards.

Key Toxicological Studies on Quantum Dot Materials

Quantum dot-containing compositions having superior resistance to degradation from exposure to environmental contaminants while maintaining their light generating capabilities

PatentWO2018200946A1

Innovation

- Incorporating desiccants and/or oxygen scavengers into the quantum dot-containing compositions, specifically in the curable matrix, to enhance resistance to degradation, with tailored types, loading, and particle sizes for effective edge protection.

Luminescent solar concentrator using a metal-free emitter

PatentInactiveUS20200235254A1

Innovation

- The development of a metal-free luminescent solar concentrator using colloidal carbon quantum dots (C-dots) with surface modification, which are non-toxic, stable, and can be synthesized at low cost, reducing reabsorption losses and enhancing photostability by embedding them in a polymer matrix or coating on a substrate.

Regulatory Framework for Nanomaterials in Solar Energy

The regulatory landscape governing nanomaterials in solar energy applications, particularly quantum dot-based luminescent solar concentrators (QD-LSCs), is evolving rapidly as these technologies advance toward commercialization. Currently, regulatory frameworks vary significantly across regions, creating challenges for global deployment of QD-LSC technologies.

In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials primarily through the Toxic Substances Control Act (TSCA), which requires manufacturers to submit premanufacture notices for new chemical substances, including engineered nanomaterials. The EPA has established specific reporting rules for nanomaterials under the TSCA Section 8(a), requiring companies to report production volume, manufacturing methods, exposure information, and available health and safety data.

The European Union implements a more precautionary approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which requires registration of substances manufactured or imported in quantities over one ton per year. Additionally, the EU's Nano Observatory tracks nanomaterials in commercial products, providing transparency for consumers and researchers regarding potential environmental exposure pathways.

In Asia, regulatory approaches differ substantially. Japan has established voluntary reporting schemes through its Ministry of Economy, Trade and Industry, while China has incorporated nanomaterial regulations into its broader chemical management framework under the Measures for Environmental Management of New Chemical Substances.

International organizations have also developed guidelines that influence regulatory decisions. The Organization for Economic Cooperation and Development (OECD) Working Party on Manufactured Nanomaterials has established standardized testing protocols specifically for nanomaterials, which are increasingly being adopted by national regulatory bodies to assess quantum dot toxicity and environmental fate.

For QD-LSCs specifically, regulatory gaps remain concerning end-of-life management and recycling requirements. Most current frameworks fail to adequately address the unique challenges posed by quantum dots embedded in polymer matrices, particularly regarding leaching potential during disposal or recycling processes.

Recent regulatory trends indicate movement toward lifecycle-based approaches that consider nanomaterial risks throughout the product lifecycle. The International Organization for Standardization (ISO) has developed standards (ISO/TS 12901-2:2014) for risk management approaches to engineered nanomaterials in occupational settings, which manufacturers of QD-LSCs increasingly reference for compliance documentation.

Regulatory compliance costs represent a significant consideration for commercialization of QD-LSC technologies. Testing requirements for novel nanomaterials can exceed $1 million per substance, creating barriers to market entry for smaller manufacturers and potentially limiting innovation in this promising solar energy application.

In the United States, the Environmental Protection Agency (EPA) regulates nanomaterials primarily through the Toxic Substances Control Act (TSCA), which requires manufacturers to submit premanufacture notices for new chemical substances, including engineered nanomaterials. The EPA has established specific reporting rules for nanomaterials under the TSCA Section 8(a), requiring companies to report production volume, manufacturing methods, exposure information, and available health and safety data.

The European Union implements a more precautionary approach through the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which requires registration of substances manufactured or imported in quantities over one ton per year. Additionally, the EU's Nano Observatory tracks nanomaterials in commercial products, providing transparency for consumers and researchers regarding potential environmental exposure pathways.

In Asia, regulatory approaches differ substantially. Japan has established voluntary reporting schemes through its Ministry of Economy, Trade and Industry, while China has incorporated nanomaterial regulations into its broader chemical management framework under the Measures for Environmental Management of New Chemical Substances.

International organizations have also developed guidelines that influence regulatory decisions. The Organization for Economic Cooperation and Development (OECD) Working Party on Manufactured Nanomaterials has established standardized testing protocols specifically for nanomaterials, which are increasingly being adopted by national regulatory bodies to assess quantum dot toxicity and environmental fate.

For QD-LSCs specifically, regulatory gaps remain concerning end-of-life management and recycling requirements. Most current frameworks fail to adequately address the unique challenges posed by quantum dots embedded in polymer matrices, particularly regarding leaching potential during disposal or recycling processes.

Recent regulatory trends indicate movement toward lifecycle-based approaches that consider nanomaterial risks throughout the product lifecycle. The International Organization for Standardization (ISO) has developed standards (ISO/TS 12901-2:2014) for risk management approaches to engineered nanomaterials in occupational settings, which manufacturers of QD-LSCs increasingly reference for compliance documentation.

Regulatory compliance costs represent a significant consideration for commercialization of QD-LSC technologies. Testing requirements for novel nanomaterials can exceed $1 million per substance, creating barriers to market entry for smaller manufacturers and potentially limiting innovation in this promising solar energy application.

Life Cycle Assessment of QD-based Solar Technologies

Life Cycle Assessment (LCA) of quantum dot-based solar technologies provides a comprehensive framework for evaluating environmental impacts throughout the entire product lifecycle. This assessment begins with raw material extraction, where the environmental footprint of mining rare earth elements and semiconductor materials for quantum dot synthesis is quantified. These processes often involve energy-intensive operations and potential release of hazardous substances, requiring careful environmental monitoring.

The manufacturing phase represents a critical stage in the LCA, encompassing quantum dot synthesis, purification, and integration into luminescent solar concentrator (LSC) devices. Current manufacturing methods typically employ solution-based processes that may utilize toxic precursors such as cadmium, lead, or selenium compounds. The environmental implications of these processes include energy consumption, chemical waste generation, and potential worker exposure to hazardous materials.

Transportation and installation phases contribute additional environmental impacts through fuel consumption and associated emissions. While these impacts are generally less significant compared to manufacturing, they remain important considerations in the overall assessment, particularly for large-scale deployment scenarios.

The operational phase of QD-based solar technologies demonstrates their primary environmental benefit through renewable electricity generation. This phase typically spans 20-30 years, during which these technologies offset conventional electricity production and associated greenhouse gas emissions. Recent studies indicate that QD-LSC systems can achieve energy payback periods of 1-3 years depending on geographical location and system configuration, representing a significant improvement over earlier generations.

End-of-life management presents unique challenges due to the potential toxicity of certain quantum dot materials. Current recycling technologies for QD-containing devices remain limited, with concerns regarding the potential release of hazardous substances during disposal or improper recycling. Research into environmentally benign recovery methods and circular economy approaches is ongoing but requires further development.

Comparative LCA studies have demonstrated that QD-based solar technologies generally exhibit lower global warming potential compared to conventional silicon photovoltaics when normalized by electricity output. However, they may score higher in categories such as ecotoxicity and resource depletion, depending on the specific quantum dot composition and manufacturing processes employed.

Recent innovations in "green" synthesis routes and non-toxic quantum dot formulations show promise for reducing environmental impacts. These include aqueous synthesis methods, heavy metal-free compositions, and manufacturing processes with reduced solvent usage and energy requirements, potentially addressing many of the environmental concerns identified in comprehensive lifecycle assessments.

The manufacturing phase represents a critical stage in the LCA, encompassing quantum dot synthesis, purification, and integration into luminescent solar concentrator (LSC) devices. Current manufacturing methods typically employ solution-based processes that may utilize toxic precursors such as cadmium, lead, or selenium compounds. The environmental implications of these processes include energy consumption, chemical waste generation, and potential worker exposure to hazardous materials.

Transportation and installation phases contribute additional environmental impacts through fuel consumption and associated emissions. While these impacts are generally less significant compared to manufacturing, they remain important considerations in the overall assessment, particularly for large-scale deployment scenarios.

The operational phase of QD-based solar technologies demonstrates their primary environmental benefit through renewable electricity generation. This phase typically spans 20-30 years, during which these technologies offset conventional electricity production and associated greenhouse gas emissions. Recent studies indicate that QD-LSC systems can achieve energy payback periods of 1-3 years depending on geographical location and system configuration, representing a significant improvement over earlier generations.

End-of-life management presents unique challenges due to the potential toxicity of certain quantum dot materials. Current recycling technologies for QD-containing devices remain limited, with concerns regarding the potential release of hazardous substances during disposal or improper recycling. Research into environmentally benign recovery methods and circular economy approaches is ongoing but requires further development.

Comparative LCA studies have demonstrated that QD-based solar technologies generally exhibit lower global warming potential compared to conventional silicon photovoltaics when normalized by electricity output. However, they may score higher in categories such as ecotoxicity and resource depletion, depending on the specific quantum dot composition and manufacturing processes employed.

Recent innovations in "green" synthesis routes and non-toxic quantum dot formulations show promise for reducing environmental impacts. These include aqueous synthesis methods, heavy metal-free compositions, and manufacturing processes with reduced solvent usage and energy requirements, potentially addressing many of the environmental concerns identified in comprehensive lifecycle assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!