Edge Cell Technology Comparison: Thin-Film PV Versus Crystalline Cells For LSCs

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Edge Cell Technology Background and Objectives

Edge Cell Technology has evolved significantly over the past decades, transitioning from basic photovoltaic applications to sophisticated energy harvesting solutions. The development trajectory began with conventional silicon-based solar cells in the 1950s, followed by the emergence of thin-film technologies in the 1970s. More recently, Luminescent Solar Concentrators (LSCs) have gained attention as a promising approach for enhancing solar energy collection, particularly in edge applications where traditional photovoltaic installations face limitations.

The evolution of edge cell technology has been driven by the increasing demand for renewable energy solutions in diverse settings, including building-integrated photovoltaics, portable electronics, and IoT devices. This progression reflects broader trends in the photovoltaic industry toward higher efficiency, lower costs, and greater versatility in application scenarios.

Current technological trends indicate a growing interest in comparing and optimizing different photovoltaic technologies for specific use cases. Thin-film photovoltaics offer advantages in flexibility, weight, and potentially lower manufacturing costs, while crystalline cells typically provide higher efficiency rates. When applied specifically to Luminescent Solar Concentrators, these technologies present different performance characteristics that warrant systematic evaluation.

The primary objective of this technical research is to conduct a comprehensive comparison between thin-film photovoltaic cells and crystalline cells specifically in the context of Luminescent Solar Concentrator applications. This comparison aims to identify the optimal technology choice based on multiple parameters including energy conversion efficiency, cost-effectiveness, durability, and integration capabilities.

Secondary objectives include quantifying the performance differences between these technologies under various operating conditions, identifying key technical challenges for each approach, and developing a framework for technology selection based on specific application requirements. Additionally, this research seeks to forecast future developments in both thin-film and crystalline technologies that may influence their suitability for LSC applications.

The expected outcomes of this research include establishing clear performance benchmarks for both technologies in LSC implementations, identifying specific scenarios where each technology excels, and providing actionable insights for manufacturers and researchers developing next-generation edge cell solutions. This comprehensive understanding will support strategic decision-making regarding technology investment and development pathways in the evolving landscape of solar energy harvesting.

The evolution of edge cell technology has been driven by the increasing demand for renewable energy solutions in diverse settings, including building-integrated photovoltaics, portable electronics, and IoT devices. This progression reflects broader trends in the photovoltaic industry toward higher efficiency, lower costs, and greater versatility in application scenarios.

Current technological trends indicate a growing interest in comparing and optimizing different photovoltaic technologies for specific use cases. Thin-film photovoltaics offer advantages in flexibility, weight, and potentially lower manufacturing costs, while crystalline cells typically provide higher efficiency rates. When applied specifically to Luminescent Solar Concentrators, these technologies present different performance characteristics that warrant systematic evaluation.

The primary objective of this technical research is to conduct a comprehensive comparison between thin-film photovoltaic cells and crystalline cells specifically in the context of Luminescent Solar Concentrator applications. This comparison aims to identify the optimal technology choice based on multiple parameters including energy conversion efficiency, cost-effectiveness, durability, and integration capabilities.

Secondary objectives include quantifying the performance differences between these technologies under various operating conditions, identifying key technical challenges for each approach, and developing a framework for technology selection based on specific application requirements. Additionally, this research seeks to forecast future developments in both thin-film and crystalline technologies that may influence their suitability for LSC applications.

The expected outcomes of this research include establishing clear performance benchmarks for both technologies in LSC implementations, identifying specific scenarios where each technology excels, and providing actionable insights for manufacturers and researchers developing next-generation edge cell solutions. This comprehensive understanding will support strategic decision-making regarding technology investment and development pathways in the evolving landscape of solar energy harvesting.

Market Analysis for LSC-Integrated PV Systems

The global market for Luminescent Solar Concentrator (LSC) integrated photovoltaic systems is experiencing significant growth, driven by increasing demand for renewable energy solutions and building-integrated photovoltaics (BIPV). Current market valuation stands at approximately 1.2 billion USD, with projections indicating a compound annual growth rate of 15.7% through 2030.

The primary market segments for LSC-integrated PV systems include architectural applications, consumer electronics, transportation, and off-grid power solutions. Within the architectural sector, which represents the largest market share at 42%, there is particularly strong demand for aesthetically pleasing solar solutions that can be integrated into building facades, windows, and skylights. The thin-film PV technology paired with LSCs has gained substantial traction in this segment due to its flexibility and design versatility.

Consumer electronics manufacturers are increasingly incorporating LSC-PV systems into portable devices, creating a rapidly expanding market segment with 27% annual growth. Transportation applications, particularly in electric vehicles and public transit infrastructure, constitute another emerging market with significant potential, currently valued at 310 million USD.

Regional analysis reveals that Europe leads the market adoption with 38% market share, driven by stringent renewable energy targets and favorable regulatory frameworks. North America follows at 29%, with Asia-Pacific showing the fastest growth rate at 22.3% annually, primarily led by developments in China, Japan, and South Korea.

Key market drivers include decreasing manufacturing costs, which have fallen by 32% over the past five years, improved energy conversion efficiencies, and increasing government incentives for renewable energy adoption. The integration of thin-film PV with LSC technology has reduced production costs by approximately 18% compared to traditional crystalline silicon systems in certain applications.

Market challenges include competition from conventional PV technologies, which still maintain higher overall efficiency rates, and limited consumer awareness about LSC benefits. Additionally, supply chain constraints for specialized materials used in advanced LSC formulations have impacted market expansion in certain regions.

Customer demand analysis indicates strong preference for LSC-integrated systems that offer dual functionality – energy generation combined with aesthetic or functional benefits such as colored windows or light-filtering properties. This preference is reflected in premium pricing, with customers willing to pay 15-25% more for LSC-integrated solutions compared to standard PV systems with similar power ratings.

Future market projections suggest that thin-film PV technologies paired with advanced LSC systems will capture an increasing market share, potentially reaching 23% of the total solar market by 2035, particularly as efficiency improvements continue and manufacturing scales up to meet growing demand.

The primary market segments for LSC-integrated PV systems include architectural applications, consumer electronics, transportation, and off-grid power solutions. Within the architectural sector, which represents the largest market share at 42%, there is particularly strong demand for aesthetically pleasing solar solutions that can be integrated into building facades, windows, and skylights. The thin-film PV technology paired with LSCs has gained substantial traction in this segment due to its flexibility and design versatility.

Consumer electronics manufacturers are increasingly incorporating LSC-PV systems into portable devices, creating a rapidly expanding market segment with 27% annual growth. Transportation applications, particularly in electric vehicles and public transit infrastructure, constitute another emerging market with significant potential, currently valued at 310 million USD.

Regional analysis reveals that Europe leads the market adoption with 38% market share, driven by stringent renewable energy targets and favorable regulatory frameworks. North America follows at 29%, with Asia-Pacific showing the fastest growth rate at 22.3% annually, primarily led by developments in China, Japan, and South Korea.

Key market drivers include decreasing manufacturing costs, which have fallen by 32% over the past five years, improved energy conversion efficiencies, and increasing government incentives for renewable energy adoption. The integration of thin-film PV with LSC technology has reduced production costs by approximately 18% compared to traditional crystalline silicon systems in certain applications.

Market challenges include competition from conventional PV technologies, which still maintain higher overall efficiency rates, and limited consumer awareness about LSC benefits. Additionally, supply chain constraints for specialized materials used in advanced LSC formulations have impacted market expansion in certain regions.

Customer demand analysis indicates strong preference for LSC-integrated systems that offer dual functionality – energy generation combined with aesthetic or functional benefits such as colored windows or light-filtering properties. This preference is reflected in premium pricing, with customers willing to pay 15-25% more for LSC-integrated solutions compared to standard PV systems with similar power ratings.

Future market projections suggest that thin-film PV technologies paired with advanced LSC systems will capture an increasing market share, potentially reaching 23% of the total solar market by 2035, particularly as efficiency improvements continue and manufacturing scales up to meet growing demand.

Current Challenges in Edge Cell Technologies

Edge cell technologies for Luminescent Solar Concentrators (LSCs) face several significant challenges that impede their widespread adoption and commercial viability. The fundamental efficiency limitations remain a primary concern, with both thin-film photovoltaic (PV) and crystalline cell technologies struggling to achieve optimal performance at the edges of LSC panels. Thin-film technologies, while offering flexibility and potentially lower manufacturing costs, suffer from lower conversion efficiencies compared to their crystalline counterparts, particularly in the specific wavelength ranges required for LSC applications.

The spectral mismatch between luminescent materials and edge cells presents another critical challenge. Most luminophores in LSCs emit light in specific wavelength bands, but current edge cell technologies are not optimized to match these emission spectra. Crystalline silicon cells, which dominate the market, have peak efficiency in wavelength ranges that often do not align with common luminophore emissions, resulting in significant energy losses at the conversion interface.

Thermal management issues also plague edge cell performance in LSC systems. The concentrated light at the edges creates localized heating that can significantly reduce cell efficiency and accelerate degradation. Thin-film technologies typically show greater temperature sensitivity than crystalline cells, with performance degrading more rapidly as temperatures rise, though they may offer advantages in thermal expansion compatibility with LSC substrates.

Durability and lifetime concerns differ markedly between the two technologies. Crystalline cells generally demonstrate superior long-term stability but may suffer from mechanical stress when integrated into LSC edges. Thin-film technologies often experience faster degradation rates, particularly when exposed to the concentrated light conditions typical in LSC applications, though their mechanical flexibility can be advantageous for certain LSC designs.

Manufacturing integration presents unique challenges for both technologies. The physical integration of edge cells with LSC panels requires precise alignment and robust electrical connections. Thin-film technologies offer potential advantages in terms of direct deposition onto LSC edges, but struggle with uniformity and quality control at the required scales. Crystalline cells provide higher efficiency but demand more complex mounting solutions and connection interfaces.

Cost-performance balance remains perhaps the most significant barrier to commercial adoption. While thin-film technologies generally offer lower production costs, their reduced efficiency often results in a higher cost per watt when integrated into LSC systems. Crystalline cells deliver superior performance but at significantly higher manufacturing and integration costs, creating a difficult economic equation for LSC developers seeking market viability.

The spectral mismatch between luminescent materials and edge cells presents another critical challenge. Most luminophores in LSCs emit light in specific wavelength bands, but current edge cell technologies are not optimized to match these emission spectra. Crystalline silicon cells, which dominate the market, have peak efficiency in wavelength ranges that often do not align with common luminophore emissions, resulting in significant energy losses at the conversion interface.

Thermal management issues also plague edge cell performance in LSC systems. The concentrated light at the edges creates localized heating that can significantly reduce cell efficiency and accelerate degradation. Thin-film technologies typically show greater temperature sensitivity than crystalline cells, with performance degrading more rapidly as temperatures rise, though they may offer advantages in thermal expansion compatibility with LSC substrates.

Durability and lifetime concerns differ markedly between the two technologies. Crystalline cells generally demonstrate superior long-term stability but may suffer from mechanical stress when integrated into LSC edges. Thin-film technologies often experience faster degradation rates, particularly when exposed to the concentrated light conditions typical in LSC applications, though their mechanical flexibility can be advantageous for certain LSC designs.

Manufacturing integration presents unique challenges for both technologies. The physical integration of edge cells with LSC panels requires precise alignment and robust electrical connections. Thin-film technologies offer potential advantages in terms of direct deposition onto LSC edges, but struggle with uniformity and quality control at the required scales. Crystalline cells provide higher efficiency but demand more complex mounting solutions and connection interfaces.

Cost-performance balance remains perhaps the most significant barrier to commercial adoption. While thin-film technologies generally offer lower production costs, their reduced efficiency often results in a higher cost per watt when integrated into LSC systems. Crystalline cells deliver superior performance but at significantly higher manufacturing and integration costs, creating a difficult economic equation for LSC developers seeking market viability.

Technical Comparison of Thin-Film vs Crystalline Edge Cells

01 Edge isolation techniques for photovoltaic cells

Edge isolation techniques are crucial for preventing electrical shorts in photovoltaic cells. These methods involve creating a physical or electrical separation between the front and back contacts at the cell edges. Various approaches include laser scribing, chemical etching, or mechanical isolation to remove conductive material from the cell edges, thereby improving efficiency and reliability of both thin-film and crystalline solar cells.- Edge isolation techniques for photovoltaic cells: Edge isolation techniques are crucial for preventing electrical shorts and improving efficiency in photovoltaic cells. These methods involve creating a physical or electrical separation between the active area of the cell and its edges. Various approaches include laser scribing, chemical etching, or mechanical methods to remove conductive material from the edges, thereby reducing recombination losses and increasing overall cell performance.

- Thin-film photovoltaic cell structures and manufacturing: Thin-film photovoltaic technologies offer advantages in material usage, flexibility, and manufacturing costs compared to traditional crystalline cells. These structures typically consist of semiconductor materials deposited in thin layers on various substrates. Manufacturing processes include vapor deposition, sputtering, and solution-based methods, with special attention to edge treatment to prevent delamination and moisture ingress, which are critical for long-term stability and performance.

- Integration of crystalline and thin-film technologies: Hybrid approaches combining crystalline silicon and thin-film technologies leverage the advantages of both systems. These integrated designs may feature crystalline cells with thin-film edge treatments or tandem structures with different materials optimized for capturing different portions of the solar spectrum. Edge connection technologies are particularly important in these hybrid systems to ensure proper electrical contact between different materials and cell types.

- Edge busbar and interconnection technologies: Advanced edge busbar designs and interconnection technologies improve current collection and reduce resistive losses in solar cells. These include specialized metallization patterns, multi-busbar configurations, and smart wire connection technologies that minimize shading while maximizing electrical conductivity. Edge-specific interconnection methods address the unique challenges of connecting cells at their periphery, which is particularly important in module assembly and for managing thermal expansion stresses.

- Edge passivation and encapsulation methods: Edge passivation and encapsulation techniques protect solar cells from environmental degradation and electrical losses at the periphery. These methods include applying dielectric materials, specialized polymers, or protective coatings to cell edges. Effective edge passivation reduces surface recombination velocity and prevents moisture ingress, while proper encapsulation protects against mechanical damage and electrical isolation failures, ultimately extending the operational lifetime of the photovoltaic device.

02 Thin-film photovoltaic cell structure and manufacturing

Thin-film photovoltaic cells utilize semiconductor materials deposited in thin layers on substrates. These cells feature unique edge configurations to manage current collection and prevent shunting. Manufacturing processes include deposition techniques like sputtering, chemical vapor deposition, and printing methods that allow for flexible or rigid cell designs. The edge structure is particularly important for maintaining electrical isolation and enhancing overall cell performance.Expand Specific Solutions03 Crystalline silicon cell edge technology

Crystalline silicon solar cells require specialized edge treatments to minimize recombination losses and increase efficiency. Edge technologies include passivation layers, selective doping profiles, and edge isolation structures. These techniques address the unique challenges of crystalline cells, where edge defects can significantly impact performance. Advanced edge treatments help manage the transition between the active cell area and the physical edge of the silicon wafer.Expand Specific Solutions04 Interconnection systems for edge cell technology

Interconnection systems for edge cells involve specialized techniques for connecting adjacent cells while maintaining electrical isolation at the edges. These systems include bus bar designs, conductive adhesives, and soldering techniques optimized for both thin-film and crystalline technologies. Edge-specific interconnection methods address challenges related to mechanical stress, thermal cycling, and long-term reliability while maximizing the active area of the photovoltaic module.Expand Specific Solutions05 Edge sealing and encapsulation methods

Edge sealing and encapsulation methods protect photovoltaic cells from environmental factors while maintaining electrical isolation. These techniques include specialized edge sealants, moisture barriers, and encapsulation materials designed to prevent degradation at cell boundaries. Proper edge sealing extends the operational lifetime of both thin-film and crystalline photovoltaic modules by preventing moisture ingress and corrosion at vulnerable edge regions.Expand Specific Solutions

Key Industry Players in LSC and Edge Cell Development

Edge cell technology for Luminescent Solar Concentrators (LSCs) is evolving rapidly, with thin-film PV and crystalline cells representing competing approaches in an emerging market. The industry is in early growth phase, with increasing commercial interest driven by applications in building-integrated photovoltaics and portable electronics. Companies like Shangyue Optoelectronics, Applied Materials, and First Solar lead thin-film development, while BYD, DuPont, and Kaneka advance crystalline cell technologies. Research institutions including National University of Singapore and Interuniversitair Micro-Electronica Centrum are driving innovation in both technologies. Thin-film offers advantages in flexibility and cost, while crystalline cells provide higher efficiency, with both approaches progressing toward commercial viability through improved manufacturing processes and materials science breakthroughs.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed comprehensive manufacturing solutions for both thin-film and crystalline silicon solar cells optimized for LSC edge applications. Their SmartFactory platform enables precision manufacturing of specialized edge cells with tightly controlled dimensions and electrical characteristics. For thin-film applications, Applied Materials' rotary cathode magnetron sputtering technology produces highly uniform CIGS and CdTe films with precisely engineered bandgaps (1.0-1.7 eV) to match LSC output spectra. Their crystalline silicon solution incorporates advanced texturing processes that create asymmetric light-trapping structures specifically designed for the angular distribution of light exiting LSC waveguides. Applied Materials' PECVD systems enable deposition of specialized passivation layers that reduce surface recombination under concentrated light conditions, critical for maintaining efficiency at LSC edges. Their PVD systems produce specialized anti-reflective coatings with angular acceptance angles exceeding 60 degrees, compared to conventional 40-degree coatings. Recent innovations include automated edge-cell placement systems that achieve optical coupling with less than 2% reflection loss between LSC and cell surfaces, significantly improving overall system efficiency.

Strengths: Comprehensive manufacturing capabilities spanning both thin-film and crystalline technologies; advanced process control enabling tight performance specifications; economies of scale reducing production costs for specialized edge cells. Weaknesses: Primarily focused on manufacturing equipment rather than direct cell production; requires partnerships with cell manufacturers for complete solutions; higher capital investment requirements compared to specialized cell producers.

Kaneka Corp.

Technical Solution: Kaneka has developed a hybrid thin-film/crystalline technology specifically for LSC edge applications. Their approach combines heterojunction technology (HJT) with thin-film amorphous silicon layers on crystalline silicon substrates, creating cells particularly suited for LSC edge mounting. Kaneka's edge cells feature specialized light-trapping textures and anti-reflective coatings optimized for the angular distribution of light exiting LSC waveguides. Their proprietary "SmartWire" connection technology reduces shading losses at LSC edges while improving current collection from concentrated light. The company has achieved 24.37% conversion efficiency in their HJT cells, with specialized edge variants maintaining over 22% efficiency under LSC concentration conditions. Kaneka's manufacturing process incorporates low-temperature deposition techniques (below 200°C) that enable the use of thinner wafers (down to 80μm) while maintaining structural integrity, critical for edge mounting applications. Their cells demonstrate excellent low-light performance, maintaining efficiency even with the spectral modifications that occur in LSC waveguides.

Strengths: Superior temperature stability compared to conventional crystalline cells (temperature coefficient of -0.25%/°C); excellent bifacial factor allowing capture of light from multiple directions in LSC systems; proven long-term reliability with less than 0.5% annual degradation. Weaknesses: Higher manufacturing complexity and cost compared to standard crystalline cells; requires specialized mounting solutions for LSC edge integration; limited production scale compared to mainstream PV manufacturers.

Critical Patents and Research in LSC Edge Cell Integration

Luminescent solar concentrators

PatentInactiveUS8324497B2

Innovation

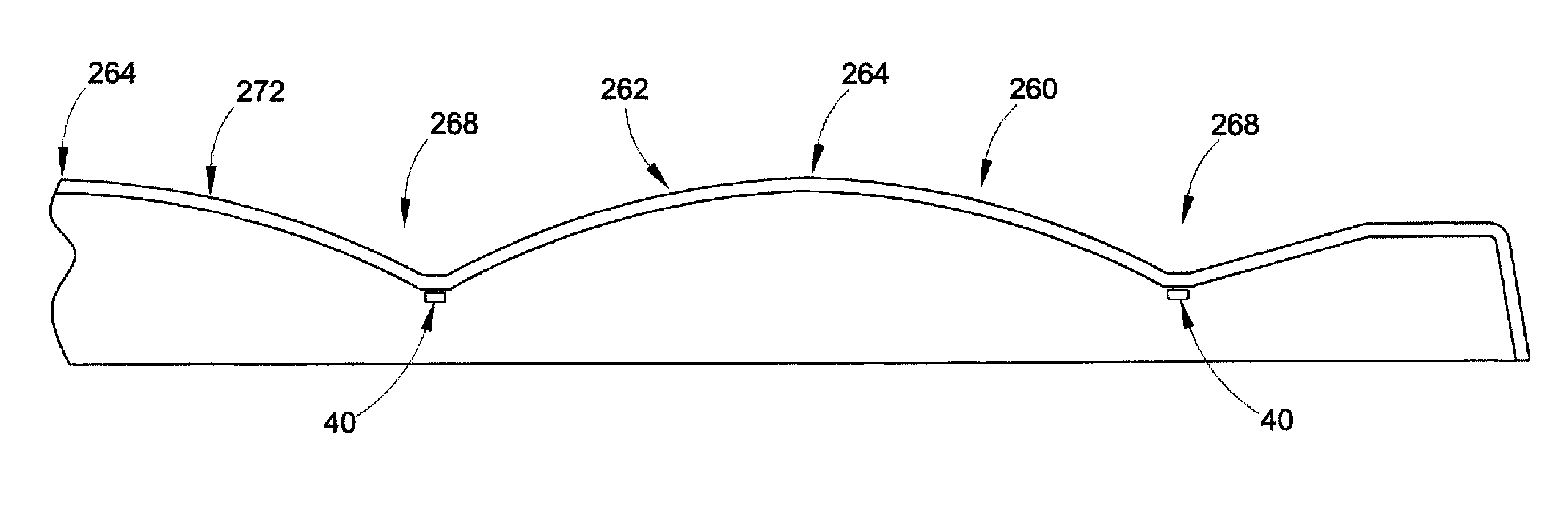

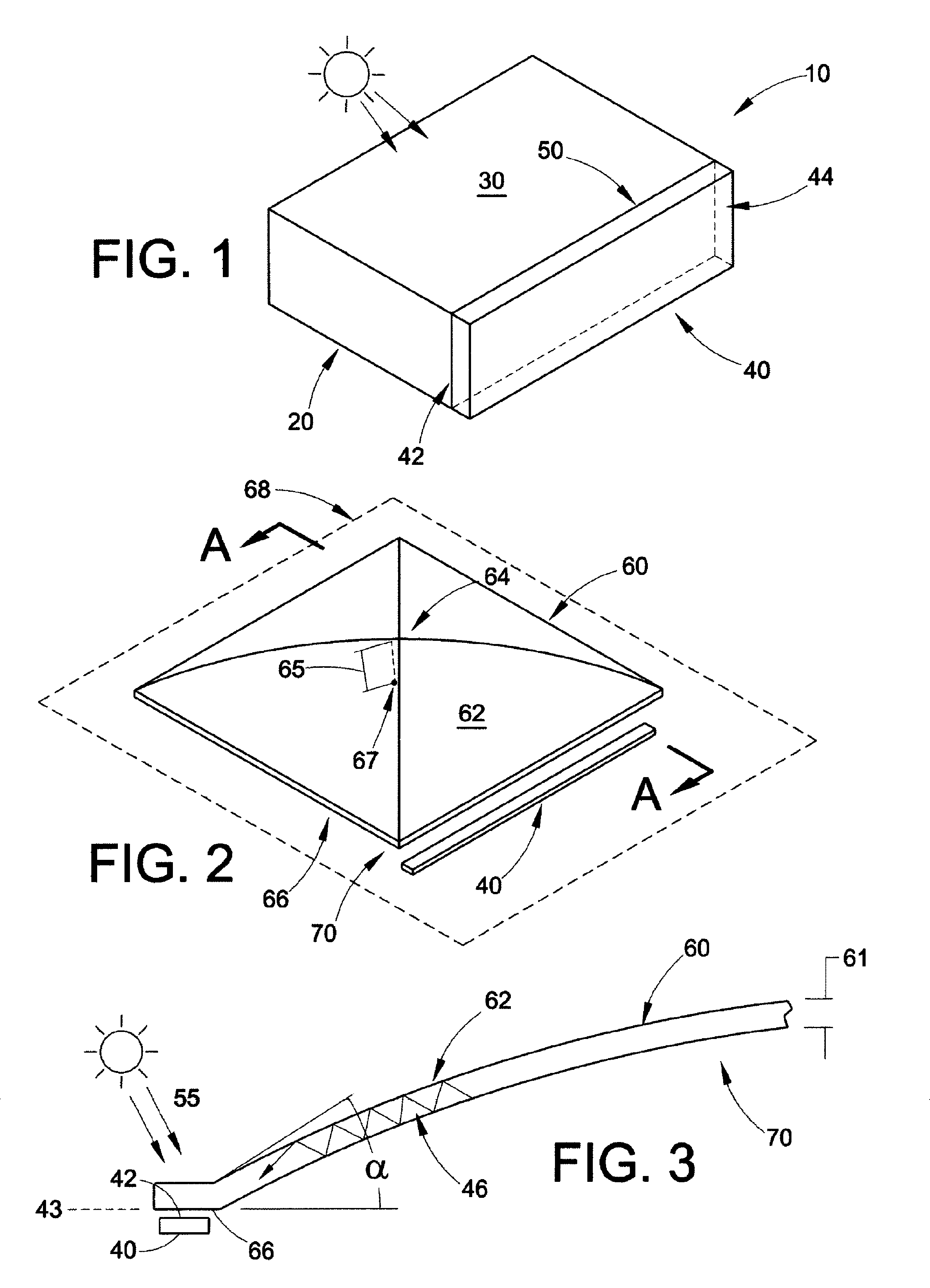

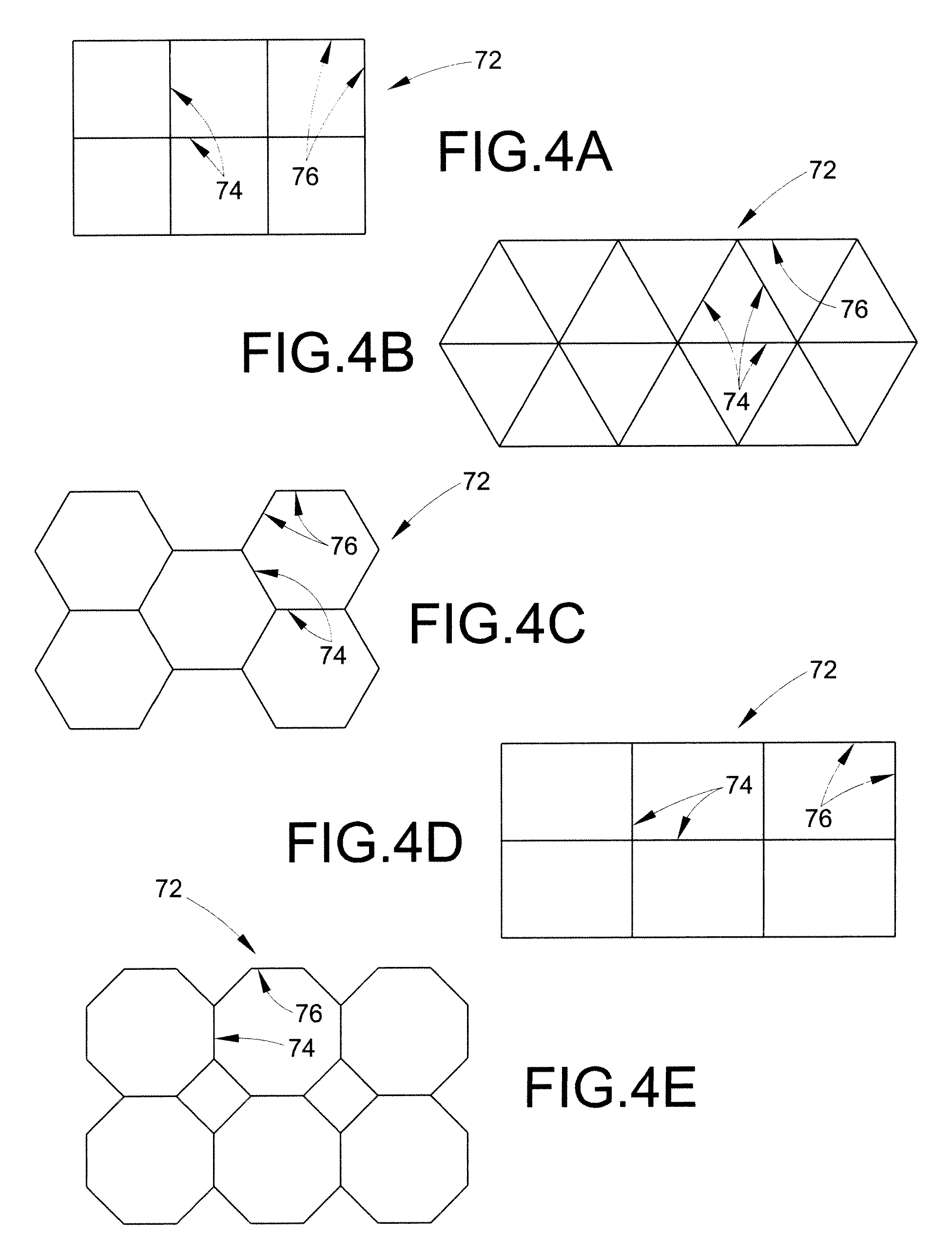

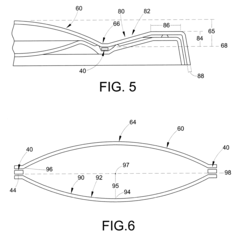

- The design incorporates a luminescent solar concentrator unit with a convex primary waveguide and photovoltaic cells, where the perimeter shape can be a polygon with multiple edges, and a secondary waveguide, along with a structural back sheet to maintain spatial relationships and reflect light, optimizing the placement and efficiency of photovoltaic cells for improved mechanical stability and energy collection.

Environmental Impact and Sustainability Assessment

The environmental footprint of edge cell technologies represents a critical dimension in evaluating their long-term viability and alignment with global sustainability goals. When comparing thin-film photovoltaic (PV) cells with crystalline cells for Luminescent Solar Concentrators (LSCs), several environmental factors emerge as significant differentiators.

Thin-film PV technologies generally require substantially less raw material than their crystalline counterparts, with semiconductor layers often measuring just a few micrometers thick compared to the 200-300 micrometers typical of crystalline silicon cells. This material efficiency translates to reduced resource extraction impacts and lower embodied energy. Life cycle assessments indicate that thin-film technologies like amorphous silicon, CdTe, and CIGS typically achieve energy payback periods of 0.5-1.5 years, compared to 1.5-2.5 years for crystalline silicon in comparable deployment scenarios.

The manufacturing processes for these technologies present distinct environmental considerations. Crystalline cell production involves energy-intensive purification and crystallization processes, contributing to higher carbon emissions during manufacturing. Conversely, thin-film deposition techniques generally operate at lower temperatures and consume less energy, though they may involve toxic materials such as cadmium in CdTe cells or selenium in CIGS formulations, necessitating robust end-of-life management protocols.

When integrated into LSC applications specifically, the environmental calculus shifts further. The enhanced light-harvesting capabilities of LSCs potentially reduce the total semiconductor material required for equivalent energy generation, particularly beneficial for crystalline technologies. However, thin-film cells may offer superior performance in the specific spectral ranges utilized by LSC systems, potentially improving overall system efficiency and sustainability metrics.

End-of-life considerations reveal additional distinctions. The established recycling infrastructure for crystalline silicon offers recovery rates exceeding 90% for silicon and other valuable materials. Thin-film recycling technologies, while developing rapidly, currently demonstrate more variable recovery efficiencies ranging from 60-95% depending on the specific technology and recycling method employed.

Carbon footprint analyses indicate that thin-film PV edge cells in LSC applications typically generate 10-25g CO2-equivalent per kWh over their lifecycle, compared to 30-45g for crystalline alternatives—both substantially lower than fossil fuel generation at 400-1000g CO2-eq/kWh. Water consumption metrics similarly favor thin-film technologies, with manufacturing processes requiring approximately 40-60% less water than crystalline production.

The sustainability assessment must also consider land use efficiency, where LSC applications with either technology offer advantages through building integration capabilities, potentially eliminating additional land requirements entirely when deployed on existing structures.

Thin-film PV technologies generally require substantially less raw material than their crystalline counterparts, with semiconductor layers often measuring just a few micrometers thick compared to the 200-300 micrometers typical of crystalline silicon cells. This material efficiency translates to reduced resource extraction impacts and lower embodied energy. Life cycle assessments indicate that thin-film technologies like amorphous silicon, CdTe, and CIGS typically achieve energy payback periods of 0.5-1.5 years, compared to 1.5-2.5 years for crystalline silicon in comparable deployment scenarios.

The manufacturing processes for these technologies present distinct environmental considerations. Crystalline cell production involves energy-intensive purification and crystallization processes, contributing to higher carbon emissions during manufacturing. Conversely, thin-film deposition techniques generally operate at lower temperatures and consume less energy, though they may involve toxic materials such as cadmium in CdTe cells or selenium in CIGS formulations, necessitating robust end-of-life management protocols.

When integrated into LSC applications specifically, the environmental calculus shifts further. The enhanced light-harvesting capabilities of LSCs potentially reduce the total semiconductor material required for equivalent energy generation, particularly beneficial for crystalline technologies. However, thin-film cells may offer superior performance in the specific spectral ranges utilized by LSC systems, potentially improving overall system efficiency and sustainability metrics.

End-of-life considerations reveal additional distinctions. The established recycling infrastructure for crystalline silicon offers recovery rates exceeding 90% for silicon and other valuable materials. Thin-film recycling technologies, while developing rapidly, currently demonstrate more variable recovery efficiencies ranging from 60-95% depending on the specific technology and recycling method employed.

Carbon footprint analyses indicate that thin-film PV edge cells in LSC applications typically generate 10-25g CO2-equivalent per kWh over their lifecycle, compared to 30-45g for crystalline alternatives—both substantially lower than fossil fuel generation at 400-1000g CO2-eq/kWh. Water consumption metrics similarly favor thin-film technologies, with manufacturing processes requiring approximately 40-60% less water than crystalline production.

The sustainability assessment must also consider land use efficiency, where LSC applications with either technology offer advantages through building integration capabilities, potentially eliminating additional land requirements entirely when deployed on existing structures.

Cost-Benefit Analysis of Edge Cell Manufacturing Technologies

When evaluating the economic viability of edge cell technologies for Luminescent Solar Concentrators (LSCs), manufacturing costs represent a critical factor in determining market adoption. Thin-film photovoltaic (PV) edge cells offer significant cost advantages in terms of raw materials, with material costs typically 30-45% lower than their crystalline counterparts. This reduction stems primarily from the substantially reduced semiconductor material requirements, as thin-film technologies utilize layers measuring only a few micrometers compared to the 150-200 micrometers needed for crystalline silicon cells.

Manufacturing processes for thin-film edge cells also demonstrate economic advantages through simplified production workflows. Thin-film deposition techniques such as sputtering, chemical vapor deposition, or solution-based coating methods enable continuous roll-to-roll processing, reducing labor costs by approximately 25-35% compared to batch processing required for crystalline cells. Additionally, thin-film manufacturing requires approximately 40% less energy input, translating to lower operational expenses and reduced carbon footprint.

However, crystalline edge cells maintain distinct advantages in performance metrics that impact long-term economic returns. Their higher conversion efficiencies—typically 18-25% compared to 10-15% for most commercial thin-film technologies—result in greater power output per unit area. This efficiency advantage translates to improved performance when paired with LSC systems, potentially generating 20-30% more electricity over the system lifetime despite higher initial costs.

Durability considerations further complicate the cost-benefit equation. Crystalline silicon edge cells generally demonstrate superior longevity, with degradation rates of 0.5-0.7% annually versus 1.0-2.5% for various thin-film technologies. This durability difference significantly impacts the total cost of ownership, as crystalline systems typically maintain functional operation for 25-30 years compared to 15-20 years for many thin-film implementations.

Scale economies also factor prominently in the analysis. Crystalline silicon benefits from massive production infrastructure developed over decades, with global manufacturing capacity exceeding 150 GW annually. Thin-film technologies, while growing, represent only about 5-7% of global PV production. This disparity creates pricing advantages for crystalline technologies in current markets, though thin-film manufacturing costs continue to decline at approximately 15% annually as production volumes increase.

For LSC-specific applications, the form factor flexibility of thin-film edge cells provides additional economic benefits through reduced installation and integration costs. Their lightweight, flexible nature enables simplified mounting solutions that can reduce balance-of-system costs by 15-25% compared to rigid crystalline alternatives, particularly in specialized architectural implementations where LSCs serve dual purposes as building elements and energy generators.

Manufacturing processes for thin-film edge cells also demonstrate economic advantages through simplified production workflows. Thin-film deposition techniques such as sputtering, chemical vapor deposition, or solution-based coating methods enable continuous roll-to-roll processing, reducing labor costs by approximately 25-35% compared to batch processing required for crystalline cells. Additionally, thin-film manufacturing requires approximately 40% less energy input, translating to lower operational expenses and reduced carbon footprint.

However, crystalline edge cells maintain distinct advantages in performance metrics that impact long-term economic returns. Their higher conversion efficiencies—typically 18-25% compared to 10-15% for most commercial thin-film technologies—result in greater power output per unit area. This efficiency advantage translates to improved performance when paired with LSC systems, potentially generating 20-30% more electricity over the system lifetime despite higher initial costs.

Durability considerations further complicate the cost-benefit equation. Crystalline silicon edge cells generally demonstrate superior longevity, with degradation rates of 0.5-0.7% annually versus 1.0-2.5% for various thin-film technologies. This durability difference significantly impacts the total cost of ownership, as crystalline systems typically maintain functional operation for 25-30 years compared to 15-20 years for many thin-film implementations.

Scale economies also factor prominently in the analysis. Crystalline silicon benefits from massive production infrastructure developed over decades, with global manufacturing capacity exceeding 150 GW annually. Thin-film technologies, while growing, represent only about 5-7% of global PV production. This disparity creates pricing advantages for crystalline technologies in current markets, though thin-film manufacturing costs continue to decline at approximately 15% annually as production volumes increase.

For LSC-specific applications, the form factor flexibility of thin-film edge cells provides additional economic benefits through reduced installation and integration costs. Their lightweight, flexible nature enables simplified mounting solutions that can reduce balance-of-system costs by 15-25% compared to rigid crystalline alternatives, particularly in specialized architectural implementations where LSCs serve dual purposes as building elements and energy generators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!