Economic Scale-Up Strategies for Sodium Ion Battery Manufacturing

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Na-Ion Battery Evolution

Sodium-ion batteries have undergone significant evolution since their inception in the 1980s. Initially, research focused on developing suitable cathode materials, with early efforts centered on layered oxide compounds. The 1990s saw a shift towards Prussian blue analogues and polyanionic compounds, which offered improved stability and higher voltage potentials.

A major breakthrough came in the early 2000s with the development of hard carbon anodes, which provided a viable alternative to graphite used in lithium-ion batteries. This innovation addressed the challenge of sodium's larger ionic radius and enabled practical sodium-ion cell designs. Concurrently, advances in electrolyte formulations, particularly the use of sodium hexafluorophosphate (NaPF6) in organic solvents, further enhanced battery performance.

The 2010s marked a period of rapid progress, with researchers exploring a diverse range of cathode materials, including layered oxides (NaxMO2), polyanionic compounds (NaFePO4), and Prussian blue analogues. These efforts led to significant improvements in energy density, cycle life, and rate capability. Notable achievements include the development of high-voltage cathodes and the optimization of electrolyte additives to enhance the solid electrolyte interphase (SEI) formation.

Recent years have seen a focus on scalable manufacturing processes and cost reduction strategies. Researchers have made strides in developing aqueous processing techniques for electrode fabrication, which promise to reduce production costs and environmental impact. Additionally, efforts to utilize earth-abundant materials have intensified, with sodium-based alternatives being explored for various battery components.

The evolution of sodium-ion batteries has also been marked by increasing industrial interest. Several companies have announced plans to commercialize the technology, with pilot production lines established in various countries. This industrial involvement has accelerated the transition from laboratory-scale research to practical, large-format cells suitable for grid storage and electric vehicle applications.

Looking ahead, the sodium-ion battery evolution is expected to continue with a focus on further improving energy density, cycle life, and fast-charging capabilities. Research into advanced electrolytes, including solid-state options, and novel electrode architectures promises to unlock new performance frontiers. As the technology matures, emphasis on sustainable production methods and end-of-life recycling strategies will likely gain prominence, aligning with global efforts towards a circular economy in energy storage solutions.

A major breakthrough came in the early 2000s with the development of hard carbon anodes, which provided a viable alternative to graphite used in lithium-ion batteries. This innovation addressed the challenge of sodium's larger ionic radius and enabled practical sodium-ion cell designs. Concurrently, advances in electrolyte formulations, particularly the use of sodium hexafluorophosphate (NaPF6) in organic solvents, further enhanced battery performance.

The 2010s marked a period of rapid progress, with researchers exploring a diverse range of cathode materials, including layered oxides (NaxMO2), polyanionic compounds (NaFePO4), and Prussian blue analogues. These efforts led to significant improvements in energy density, cycle life, and rate capability. Notable achievements include the development of high-voltage cathodes and the optimization of electrolyte additives to enhance the solid electrolyte interphase (SEI) formation.

Recent years have seen a focus on scalable manufacturing processes and cost reduction strategies. Researchers have made strides in developing aqueous processing techniques for electrode fabrication, which promise to reduce production costs and environmental impact. Additionally, efforts to utilize earth-abundant materials have intensified, with sodium-based alternatives being explored for various battery components.

The evolution of sodium-ion batteries has also been marked by increasing industrial interest. Several companies have announced plans to commercialize the technology, with pilot production lines established in various countries. This industrial involvement has accelerated the transition from laboratory-scale research to practical, large-format cells suitable for grid storage and electric vehicle applications.

Looking ahead, the sodium-ion battery evolution is expected to continue with a focus on further improving energy density, cycle life, and fast-charging capabilities. Research into advanced electrolytes, including solid-state options, and novel electrode architectures promises to unlock new performance frontiers. As the technology matures, emphasis on sustainable production methods and end-of-life recycling strategies will likely gain prominence, aligning with global efforts towards a circular economy in energy storage solutions.

Market Demand Analysis

The market demand for sodium-ion batteries is experiencing significant growth, driven by the increasing need for sustainable and cost-effective energy storage solutions. As the world transitions towards renewable energy sources and electrification of transportation, the demand for large-scale energy storage systems is surging. Sodium-ion batteries are emerging as a promising alternative to lithium-ion batteries, particularly in grid-scale applications and electric vehicles.

The global energy storage market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 20% through 2030. This growth is primarily fueled by the increasing adoption of renewable energy sources, such as solar and wind power, which require efficient energy storage solutions to manage intermittency issues. Sodium-ion batteries are well-positioned to capture a significant portion of this market due to their potential cost advantages and abundant raw material supply.

In the electric vehicle sector, sodium-ion batteries are gaining traction as a potential solution for entry-level and mid-range vehicles. The automotive industry's shift towards electrification is creating a substantial demand for battery technologies that can offer a balance between performance and affordability. Sodium-ion batteries, with their lower cost potential and improved safety characteristics, are attracting interest from automakers looking to diversify their battery supply chains and reduce dependency on lithium-ion technology.

The industrial and residential energy storage markets also present significant opportunities for sodium-ion batteries. As businesses and homeowners increasingly adopt solar panels and seek to reduce their reliance on the grid, the demand for cost-effective and long-lasting energy storage solutions is growing. Sodium-ion batteries' potential for longer cycle life and lower environmental impact make them an attractive option for these applications.

Geographically, the demand for sodium-ion batteries is expected to be particularly strong in regions with ambitious renewable energy targets and limited lithium resources. Countries in Asia, Europe, and North America are likely to be key markets, with China potentially leading the way in terms of production and adoption. The Chinese government's support for sodium-ion battery development and manufacturing is expected to accelerate market growth in the region.

However, it is important to note that the market for sodium-ion batteries is still in its early stages, and significant technological advancements and cost reductions are needed to compete directly with established lithium-ion technology. The success of economic scale-up strategies for sodium-ion battery manufacturing will play a crucial role in determining the technology's market penetration and long-term viability as a mainstream energy storage solution.

The global energy storage market is projected to expand rapidly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 20% through 2030. This growth is primarily fueled by the increasing adoption of renewable energy sources, such as solar and wind power, which require efficient energy storage solutions to manage intermittency issues. Sodium-ion batteries are well-positioned to capture a significant portion of this market due to their potential cost advantages and abundant raw material supply.

In the electric vehicle sector, sodium-ion batteries are gaining traction as a potential solution for entry-level and mid-range vehicles. The automotive industry's shift towards electrification is creating a substantial demand for battery technologies that can offer a balance between performance and affordability. Sodium-ion batteries, with their lower cost potential and improved safety characteristics, are attracting interest from automakers looking to diversify their battery supply chains and reduce dependency on lithium-ion technology.

The industrial and residential energy storage markets also present significant opportunities for sodium-ion batteries. As businesses and homeowners increasingly adopt solar panels and seek to reduce their reliance on the grid, the demand for cost-effective and long-lasting energy storage solutions is growing. Sodium-ion batteries' potential for longer cycle life and lower environmental impact make them an attractive option for these applications.

Geographically, the demand for sodium-ion batteries is expected to be particularly strong in regions with ambitious renewable energy targets and limited lithium resources. Countries in Asia, Europe, and North America are likely to be key markets, with China potentially leading the way in terms of production and adoption. The Chinese government's support for sodium-ion battery development and manufacturing is expected to accelerate market growth in the region.

However, it is important to note that the market for sodium-ion batteries is still in its early stages, and significant technological advancements and cost reductions are needed to compete directly with established lithium-ion technology. The success of economic scale-up strategies for sodium-ion battery manufacturing will play a crucial role in determining the technology's market penetration and long-term viability as a mainstream energy storage solution.

Technical Challenges

The scale-up of sodium-ion battery manufacturing faces several significant technical challenges that need to be addressed for successful commercialization. One of the primary hurdles is the development of high-performance cathode materials that can match or exceed the energy density of lithium-ion batteries. Current sodium-ion cathodes often suffer from lower specific capacity and voltage, limiting the overall energy density of the batteries.

Another critical challenge lies in the anode materials. While hard carbon is commonly used, it exhibits lower capacity and rate capability compared to graphite anodes in lithium-ion batteries. Developing advanced anode materials that can provide higher capacity and better cycling stability is crucial for improving the overall performance of sodium-ion batteries.

The electrolyte formulation also presents a significant challenge. Sodium-ion batteries require electrolytes that are compatible with both the cathode and anode materials while ensuring stable solid-electrolyte interphase (SEI) formation. Finding the right balance of solvents, salts, and additives that can provide high ionic conductivity, wide electrochemical stability window, and long-term cycling stability is essential for the successful scale-up of sodium-ion batteries.

Manufacturing processes for sodium-ion batteries need to be optimized for large-scale production. This includes developing efficient methods for electrode preparation, cell assembly, and quality control that can be scaled up without compromising performance or safety. The hygroscopic nature of many sodium-containing materials adds complexity to the manufacturing process, requiring stringent moisture control throughout the production line.

Cycle life and calendar life of sodium-ion batteries remain inferior to their lithium-ion counterparts. Improving the long-term stability of electrode materials and mitigating degradation mechanisms are crucial for enhancing the overall lifespan of sodium-ion batteries. This requires a deep understanding of the complex electrochemical processes and failure modes specific to sodium-ion systems.

Safety considerations also pose technical challenges in scaling up sodium-ion battery manufacturing. While sodium is generally considered safer than lithium due to its lower reactivity, ensuring the safety of large-format cells and battery packs under various operating conditions is critical. This includes developing robust battery management systems and implementing effective thermal management strategies.

Lastly, the integration of sodium-ion batteries into existing manufacturing infrastructure presents a challenge. Adapting current lithium-ion battery production lines to accommodate the unique requirements of sodium-ion chemistry while maintaining cost-effectiveness is a complex task that requires careful engineering and process optimization.

Another critical challenge lies in the anode materials. While hard carbon is commonly used, it exhibits lower capacity and rate capability compared to graphite anodes in lithium-ion batteries. Developing advanced anode materials that can provide higher capacity and better cycling stability is crucial for improving the overall performance of sodium-ion batteries.

The electrolyte formulation also presents a significant challenge. Sodium-ion batteries require electrolytes that are compatible with both the cathode and anode materials while ensuring stable solid-electrolyte interphase (SEI) formation. Finding the right balance of solvents, salts, and additives that can provide high ionic conductivity, wide electrochemical stability window, and long-term cycling stability is essential for the successful scale-up of sodium-ion batteries.

Manufacturing processes for sodium-ion batteries need to be optimized for large-scale production. This includes developing efficient methods for electrode preparation, cell assembly, and quality control that can be scaled up without compromising performance or safety. The hygroscopic nature of many sodium-containing materials adds complexity to the manufacturing process, requiring stringent moisture control throughout the production line.

Cycle life and calendar life of sodium-ion batteries remain inferior to their lithium-ion counterparts. Improving the long-term stability of electrode materials and mitigating degradation mechanisms are crucial for enhancing the overall lifespan of sodium-ion batteries. This requires a deep understanding of the complex electrochemical processes and failure modes specific to sodium-ion systems.

Safety considerations also pose technical challenges in scaling up sodium-ion battery manufacturing. While sodium is generally considered safer than lithium due to its lower reactivity, ensuring the safety of large-format cells and battery packs under various operating conditions is critical. This includes developing robust battery management systems and implementing effective thermal management strategies.

Lastly, the integration of sodium-ion batteries into existing manufacturing infrastructure presents a challenge. Adapting current lithium-ion battery production lines to accommodate the unique requirements of sodium-ion chemistry while maintaining cost-effectiveness is a complex task that requires careful engineering and process optimization.

Current Manufacturing

01 Manufacturing process optimization

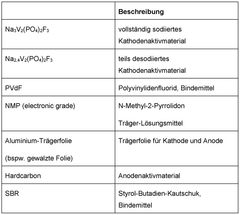

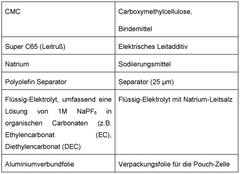

Improving the manufacturing processes for sodium-ion batteries to achieve economic scale-up. This includes developing more efficient production methods, automating assembly lines, and optimizing material usage to reduce costs and increase output. These advancements aim to make sodium-ion batteries more competitive with lithium-ion batteries in terms of production scale and cost-effectiveness.- Electrode material optimization: Improving the performance and cost-effectiveness of sodium-ion batteries through the development of advanced electrode materials. This includes research into novel cathode and anode materials that offer higher energy density, better cycling stability, and lower production costs. Optimized electrode materials are crucial for enhancing the overall efficiency and economic viability of sodium-ion batteries at scale.

- Manufacturing process improvements: Developing and implementing innovative manufacturing techniques to reduce production costs and increase output efficiency. This involves optimizing cell assembly processes, improving material synthesis methods, and adopting automated production lines. These advancements aim to streamline the manufacturing process, reduce labor costs, and enhance the overall economic feasibility of large-scale sodium-ion battery production.

- Electrolyte formulation and optimization: Researching and developing advanced electrolyte formulations to enhance the performance and safety of sodium-ion batteries. This includes investigating novel electrolyte additives, optimizing electrolyte composition, and improving the ionic conductivity. Enhanced electrolyte formulations contribute to better battery performance, longer cycle life, and improved safety characteristics, all of which are crucial for economic scale-up.

- Cell design and packaging innovations: Developing innovative cell designs and packaging solutions to improve energy density, thermal management, and overall battery performance. This includes research into new cell formats, advanced sealing techniques, and efficient heat dissipation methods. Optimized cell design and packaging contribute to better space utilization, improved safety, and enhanced scalability of sodium-ion battery production.

- Supply chain and raw material optimization: Focusing on securing and optimizing the supply chain for raw materials used in sodium-ion battery production. This involves identifying alternative sources for critical materials, developing recycling processes, and improving material utilization efficiency. Optimizing the supply chain and raw material usage is crucial for reducing production costs and ensuring the long-term economic viability of large-scale sodium-ion battery manufacturing.

02 Advanced electrode materials

Developing and utilizing advanced electrode materials to enhance the performance and reduce the cost of sodium-ion batteries. This involves researching and implementing novel cathode and anode materials that offer improved energy density, cycle life, and cost-effectiveness. The focus is on materials that are abundant, sustainable, and suitable for large-scale production.Expand Specific Solutions03 Electrolyte formulation and optimization

Improving electrolyte formulations to enhance the performance and safety of sodium-ion batteries at scale. This includes developing new electrolyte compositions that offer better ionic conductivity, stability, and compatibility with electrode materials. The goal is to create electrolytes that enable faster charging, longer cycle life, and improved safety characteristics for large-scale battery applications.Expand Specific Solutions04 Cell design and packaging innovations

Innovating cell design and packaging techniques to improve the energy density, thermal management, and overall performance of sodium-ion batteries. This involves developing new cell architectures, exploring advanced packaging materials, and optimizing the internal structure of battery cells to enhance their scalability and cost-effectiveness in large-scale energy storage applications.Expand Specific Solutions05 Integration with renewable energy systems

Developing strategies for integrating sodium-ion batteries with renewable energy systems to enhance grid stability and energy storage capabilities. This includes designing battery management systems, creating smart charging algorithms, and optimizing the interface between sodium-ion batteries and various renewable energy sources. The aim is to demonstrate the scalability and economic viability of sodium-ion batteries in large-scale energy storage applications.Expand Specific Solutions

Key Industry Players

The economic scale-up of sodium ion battery manufacturing is in its early stages, with the market still developing. The technology's maturity is progressing rapidly, driven by key players like Faradion, CATL, and Svolt Energy Technology. These companies are advancing sodium ion battery technology, aiming to compete with lithium-ion batteries in terms of performance and cost. The market size is expected to grow significantly as the technology matures and finds applications in electric vehicles and grid storage. However, challenges remain in scaling up production and optimizing battery performance to match established lithium-ion technology.

Faradion Ltd.

Technical Solution: Faradion, now part of Reliance Industries, has developed sodium-ion cells with an energy density of 150-160 Wh/kg[6]. Their economic scale-up strategy focuses on a "drop-in" approach, allowing manufacturers to use existing lithium-ion production equipment with minimal modifications. Faradion's technology uses a hard carbon anode and a layered oxide cathode, both of which can be produced using established manufacturing processes. They have also developed proprietary electrolyte formulations that enhance performance and safety. Faradion's scale-up plan includes licensing their technology to established battery manufacturers, reducing the need for significant capital investment in new production facilities[7].

Strengths: "Drop-in" technology allows for easy adoption by existing manufacturers. Established intellectual property portfolio. Weaknesses: Reliance on licensing model may limit direct control over production scale-up.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a first-generation sodium-ion battery with an energy density of up to 160Wh/kg[1]. Their manufacturing strategy focuses on leveraging existing lithium-ion production lines with minimal modifications, enabling rapid scale-up and cost reduction. CATL's approach includes using hard carbon for the anode and a Prussian white cathode material, which are abundant and low-cost[2]. They have also implemented advanced electrolyte formulations to enhance performance and cycle life. CATL's economic scale-up strategy involves integrating sodium-ion battery production into their existing gigafactories, allowing for shared infrastructure and reduced capital expenditure[3].

Strengths: Leveraging existing lithium-ion production infrastructure reduces initial investment. High energy density for sodium-ion technology. Weaknesses: Still lower energy density compared to lithium-ion batteries, which may limit applications.

Innovative Processes

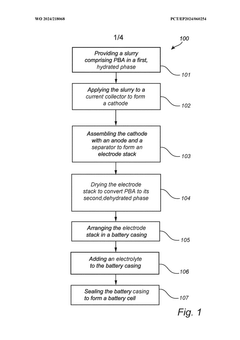

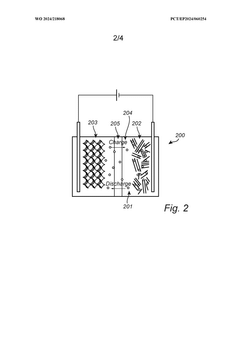

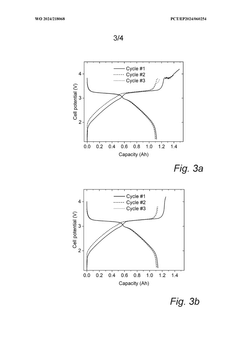

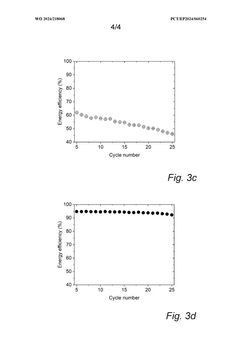

A method for manufacturing a sodium or potassium ion battery cell

PatentWO2024218068A1

Innovation

- A method involving a slurry of Prussian Blue analogue in a hydrated phase applied to a current collector, followed by drying under controlled conditions to achieve a dehydrated phase, with assembly and sealing performed in an atmosphere with a dew point temperature between -40°C to -80°C to prevent moisture reabsorption, allowing for efficient large-scale production.

Sodium ion battery, method for producing a sodium ion battery and use of a sodium ion battery

PatentWO2024260496A1

Innovation

- A sodium ion battery design featuring a partially deodised cathode active material and a pre-sodiated anode active material, allowing the battery to be partially charged during assembly, thus eliminating the need for a pre-charge process and reducing production costs and energy density limitations.

Supply Chain Analysis

The supply chain for sodium-ion battery manufacturing is a critical component in the economic scale-up of this emerging technology. As the demand for sustainable energy storage solutions grows, establishing a robust and efficient supply chain becomes paramount for successful commercialization.

Raw material sourcing plays a crucial role in the sodium-ion battery supply chain. Unlike lithium-ion batteries, sodium-ion technology relies on more abundant and widely distributed materials, such as sodium, iron, and manganese. This geographical diversity of resources can potentially lead to a more stable and cost-effective supply chain, reducing dependence on specific regions or countries.

The production of key components, including cathodes, anodes, and electrolytes, requires specialized manufacturing processes. As the technology is still evolving, there is a need for continuous innovation in materials and production techniques. This presents both challenges and opportunities for suppliers to develop expertise and establish themselves as key players in the sodium-ion battery ecosystem.

Equipment manufacturers also play a vital role in the supply chain. While some existing lithium-ion battery production equipment can be adapted for sodium-ion manufacturing, specialized machinery may be required for certain processes. This creates a potential market for equipment suppliers to develop and provide tailored solutions for sodium-ion battery production.

The logistics and transportation of raw materials, components, and finished products are essential considerations in the supply chain analysis. As production scales up, optimizing transportation routes and storage facilities becomes crucial for maintaining cost-effectiveness and ensuring timely delivery to end-users.

Quality control and testing procedures throughout the supply chain are critical for ensuring the reliability and performance of sodium-ion batteries. Establishing standardized testing protocols and certification processes will be necessary to build consumer confidence and facilitate market adoption.

Recycling and end-of-life management present both challenges and opportunities in the sodium-ion battery supply chain. Developing efficient recycling processes for sodium-ion batteries can contribute to a more sustainable and circular economy, while also potentially reducing reliance on primary raw material sources.

As the sodium-ion battery industry grows, strategic partnerships and collaborations along the supply chain will become increasingly important. Vertical integration or close cooperation between raw material suppliers, component manufacturers, and battery producers can lead to improved efficiency and cost reductions.

Raw material sourcing plays a crucial role in the sodium-ion battery supply chain. Unlike lithium-ion batteries, sodium-ion technology relies on more abundant and widely distributed materials, such as sodium, iron, and manganese. This geographical diversity of resources can potentially lead to a more stable and cost-effective supply chain, reducing dependence on specific regions or countries.

The production of key components, including cathodes, anodes, and electrolytes, requires specialized manufacturing processes. As the technology is still evolving, there is a need for continuous innovation in materials and production techniques. This presents both challenges and opportunities for suppliers to develop expertise and establish themselves as key players in the sodium-ion battery ecosystem.

Equipment manufacturers also play a vital role in the supply chain. While some existing lithium-ion battery production equipment can be adapted for sodium-ion manufacturing, specialized machinery may be required for certain processes. This creates a potential market for equipment suppliers to develop and provide tailored solutions for sodium-ion battery production.

The logistics and transportation of raw materials, components, and finished products are essential considerations in the supply chain analysis. As production scales up, optimizing transportation routes and storage facilities becomes crucial for maintaining cost-effectiveness and ensuring timely delivery to end-users.

Quality control and testing procedures throughout the supply chain are critical for ensuring the reliability and performance of sodium-ion batteries. Establishing standardized testing protocols and certification processes will be necessary to build consumer confidence and facilitate market adoption.

Recycling and end-of-life management present both challenges and opportunities in the sodium-ion battery supply chain. Developing efficient recycling processes for sodium-ion batteries can contribute to a more sustainable and circular economy, while also potentially reducing reliance on primary raw material sources.

As the sodium-ion battery industry grows, strategic partnerships and collaborations along the supply chain will become increasingly important. Vertical integration or close cooperation between raw material suppliers, component manufacturers, and battery producers can lead to improved efficiency and cost reductions.

Environmental Impact

The environmental impact of sodium-ion battery manufacturing is a critical consideration as the industry scales up production. Unlike lithium-ion batteries, sodium-ion batteries utilize more abundant and environmentally friendly materials, potentially reducing the ecological footprint of battery production. The primary raw materials for sodium-ion batteries, such as sodium and iron, are widely available and have less environmental impact during extraction compared to lithium and cobalt used in conventional batteries.

Manufacturing processes for sodium-ion batteries can be designed to be more energy-efficient and less polluting than those for lithium-ion batteries. The lower operating temperatures required for sodium-ion battery production contribute to reduced energy consumption and greenhouse gas emissions during manufacturing. Additionally, the use of water-based electrolytes in sodium-ion batteries eliminates the need for toxic and flammable organic solvents, further reducing environmental risks and disposal concerns.

The recyclability of sodium-ion batteries presents another significant environmental advantage. The materials used in these batteries are generally easier to recycle and recover compared to those in lithium-ion batteries. This characteristic supports the development of a more circular economy in the battery industry, reducing waste and the demand for new raw materials.

However, as production scales up, careful consideration must be given to the potential environmental impacts of large-scale sodium extraction and processing. While sodium is abundant, sustainable extraction methods must be developed to minimize ecosystem disruption. Furthermore, the industry must address the environmental challenges associated with increased mining activities for other battery components, such as iron and manganese.

Water management is another crucial aspect of sodium-ion battery manufacturing that requires attention. The production processes may consume significant amounts of water, and proper treatment and recycling systems must be implemented to minimize water pollution and reduce overall water consumption. This is particularly important in regions where water scarcity is a concern.

As the industry grows, it is essential to conduct comprehensive life cycle assessments to fully understand and mitigate the environmental impacts of sodium-ion battery manufacturing. This includes evaluating the carbon footprint of the entire supply chain, from raw material extraction to end-of-life disposal or recycling. By proactively addressing these environmental considerations, the sodium-ion battery industry can position itself as a more sustainable alternative to current energy storage technologies.

Manufacturing processes for sodium-ion batteries can be designed to be more energy-efficient and less polluting than those for lithium-ion batteries. The lower operating temperatures required for sodium-ion battery production contribute to reduced energy consumption and greenhouse gas emissions during manufacturing. Additionally, the use of water-based electrolytes in sodium-ion batteries eliminates the need for toxic and flammable organic solvents, further reducing environmental risks and disposal concerns.

The recyclability of sodium-ion batteries presents another significant environmental advantage. The materials used in these batteries are generally easier to recycle and recover compared to those in lithium-ion batteries. This characteristic supports the development of a more circular economy in the battery industry, reducing waste and the demand for new raw materials.

However, as production scales up, careful consideration must be given to the potential environmental impacts of large-scale sodium extraction and processing. While sodium is abundant, sustainable extraction methods must be developed to minimize ecosystem disruption. Furthermore, the industry must address the environmental challenges associated with increased mining activities for other battery components, such as iron and manganese.

Water management is another crucial aspect of sodium-ion battery manufacturing that requires attention. The production processes may consume significant amounts of water, and proper treatment and recycling systems must be implemented to minimize water pollution and reduce overall water consumption. This is particularly important in regions where water scarcity is a concern.

As the industry grows, it is essential to conduct comprehensive life cycle assessments to fully understand and mitigate the environmental impacts of sodium-ion battery manufacturing. This includes evaluating the carbon footprint of the entire supply chain, from raw material extraction to end-of-life disposal or recycling. By proactively addressing these environmental considerations, the sodium-ion battery industry can position itself as a more sustainable alternative to current energy storage technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!