Impact of Sodium Ion Batteries in Fast-Track Energy Technology Adoption

AUG 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Evolution and Objectives

Sodium-ion batteries have emerged as a promising alternative to lithium-ion batteries, marking a significant evolution in energy storage technology. The development of sodium-ion batteries can be traced back to the 1980s, but it has gained substantial momentum in recent years due to the increasing demand for sustainable and cost-effective energy storage solutions.

The evolution of sodium-ion batteries has been driven by the need to address the limitations of lithium-ion technology, particularly in terms of resource availability and cost. Sodium, being abundant and widely distributed, offers a more sustainable option compared to lithium. This has led to intensified research and development efforts aimed at improving the performance and stability of sodium-ion batteries.

Key milestones in the evolution of sodium-ion batteries include the development of novel electrode materials, electrolytes, and cell designs. Early research focused on layered oxide cathodes and hard carbon anodes, which laid the foundation for further advancements. Recent breakthroughs in materials science have resulted in the creation of high-performance cathode materials, such as Prussian blue analogs and polyanionic compounds, which have significantly enhanced the energy density and cycle life of sodium-ion batteries.

The objectives of sodium-ion battery technology are multifaceted and aligned with the broader goals of sustainable energy adoption. Primarily, the aim is to develop a cost-effective and environmentally friendly alternative to lithium-ion batteries for large-scale energy storage applications. This includes grid-scale storage, electric vehicles, and renewable energy integration.

Specific technical objectives include improving energy density to match or exceed that of lithium-ion batteries, enhancing cycle life and stability, and developing manufacturing processes that can be easily scaled up for mass production. Additionally, there is a focus on optimizing the battery management systems to address the unique characteristics of sodium-ion chemistry.

From an environmental perspective, the objective is to reduce the carbon footprint associated with battery production and recycling. Sodium-ion batteries have the potential to achieve this through the use of more abundant and less environmentally impactful materials. This aligns with global efforts to transition towards a more sustainable energy ecosystem.

In the context of fast-track energy technology adoption, sodium-ion batteries aim to accelerate the deployment of renewable energy sources by providing a reliable and cost-effective storage solution. The technology seeks to address the intermittency issues associated with solar and wind power, enabling a more stable and resilient energy grid.

As the technology continues to evolve, the overarching goal is to position sodium-ion batteries as a viable and complementary technology to lithium-ion batteries, catering to diverse energy storage needs across various sectors. This evolution is expected to play a crucial role in shaping the future of energy storage and contributing to the global transition towards clean and sustainable energy systems.

The evolution of sodium-ion batteries has been driven by the need to address the limitations of lithium-ion technology, particularly in terms of resource availability and cost. Sodium, being abundant and widely distributed, offers a more sustainable option compared to lithium. This has led to intensified research and development efforts aimed at improving the performance and stability of sodium-ion batteries.

Key milestones in the evolution of sodium-ion batteries include the development of novel electrode materials, electrolytes, and cell designs. Early research focused on layered oxide cathodes and hard carbon anodes, which laid the foundation for further advancements. Recent breakthroughs in materials science have resulted in the creation of high-performance cathode materials, such as Prussian blue analogs and polyanionic compounds, which have significantly enhanced the energy density and cycle life of sodium-ion batteries.

The objectives of sodium-ion battery technology are multifaceted and aligned with the broader goals of sustainable energy adoption. Primarily, the aim is to develop a cost-effective and environmentally friendly alternative to lithium-ion batteries for large-scale energy storage applications. This includes grid-scale storage, electric vehicles, and renewable energy integration.

Specific technical objectives include improving energy density to match or exceed that of lithium-ion batteries, enhancing cycle life and stability, and developing manufacturing processes that can be easily scaled up for mass production. Additionally, there is a focus on optimizing the battery management systems to address the unique characteristics of sodium-ion chemistry.

From an environmental perspective, the objective is to reduce the carbon footprint associated with battery production and recycling. Sodium-ion batteries have the potential to achieve this through the use of more abundant and less environmentally impactful materials. This aligns with global efforts to transition towards a more sustainable energy ecosystem.

In the context of fast-track energy technology adoption, sodium-ion batteries aim to accelerate the deployment of renewable energy sources by providing a reliable and cost-effective storage solution. The technology seeks to address the intermittency issues associated with solar and wind power, enabling a more stable and resilient energy grid.

As the technology continues to evolve, the overarching goal is to position sodium-ion batteries as a viable and complementary technology to lithium-ion batteries, catering to diverse energy storage needs across various sectors. This evolution is expected to play a crucial role in shaping the future of energy storage and contributing to the global transition towards clean and sustainable energy systems.

Market Demand Analysis for Sodium Ion Batteries

The market demand for sodium-ion batteries is experiencing a significant upswing, driven by the global push for sustainable energy solutions and the increasing need for cost-effective energy storage technologies. As the world transitions towards renewable energy sources, the demand for efficient and affordable energy storage systems has become paramount. Sodium-ion batteries are emerging as a promising alternative to lithium-ion batteries, particularly in grid-scale energy storage applications.

The primary market drivers for sodium-ion batteries include the growing renewable energy sector, the need for grid stabilization, and the increasing adoption of electric vehicles. The renewable energy market, which includes solar and wind power, requires large-scale energy storage solutions to manage intermittency issues. Sodium-ion batteries offer a viable option for this application due to their potential for lower costs and abundant raw materials.

In the electric vehicle sector, while lithium-ion batteries currently dominate, sodium-ion batteries are gaining attention as a potential complementary technology, especially for short-range and urban mobility solutions. The lower cost and improved safety characteristics of sodium-ion batteries make them attractive for certain segments of the EV market.

The grid energy storage market presents a substantial opportunity for sodium-ion batteries. As power grids worldwide integrate more renewable energy sources, the demand for large-scale energy storage solutions is escalating. Sodium-ion batteries could play a crucial role in grid stabilization, peak shaving, and load leveling applications.

Geographically, the market demand for sodium-ion batteries is expected to be particularly strong in regions with ambitious renewable energy targets and those lacking domestic lithium resources. Countries in Asia, Europe, and North America are likely to be key markets, with China potentially leading in both production and adoption due to its strong manufacturing base and commitment to renewable energy.

The market size for sodium-ion batteries is projected to grow significantly over the next decade. While current market penetration is limited, industry analysts predict rapid growth as the technology matures and production scales up. The potential for cost reduction through economies of scale and the use of abundant, low-cost materials is a key factor driving market optimism.

However, the market demand analysis must also consider potential challenges. These include competition from established lithium-ion technology, the need for further improvements in energy density and cycle life, and the time required to establish large-scale manufacturing capabilities. Despite these challenges, the overall market trajectory for sodium-ion batteries appears positive, with increasing investment in research and development and growing interest from both established battery manufacturers and new entrants in the energy storage space.

The primary market drivers for sodium-ion batteries include the growing renewable energy sector, the need for grid stabilization, and the increasing adoption of electric vehicles. The renewable energy market, which includes solar and wind power, requires large-scale energy storage solutions to manage intermittency issues. Sodium-ion batteries offer a viable option for this application due to their potential for lower costs and abundant raw materials.

In the electric vehicle sector, while lithium-ion batteries currently dominate, sodium-ion batteries are gaining attention as a potential complementary technology, especially for short-range and urban mobility solutions. The lower cost and improved safety characteristics of sodium-ion batteries make them attractive for certain segments of the EV market.

The grid energy storage market presents a substantial opportunity for sodium-ion batteries. As power grids worldwide integrate more renewable energy sources, the demand for large-scale energy storage solutions is escalating. Sodium-ion batteries could play a crucial role in grid stabilization, peak shaving, and load leveling applications.

Geographically, the market demand for sodium-ion batteries is expected to be particularly strong in regions with ambitious renewable energy targets and those lacking domestic lithium resources. Countries in Asia, Europe, and North America are likely to be key markets, with China potentially leading in both production and adoption due to its strong manufacturing base and commitment to renewable energy.

The market size for sodium-ion batteries is projected to grow significantly over the next decade. While current market penetration is limited, industry analysts predict rapid growth as the technology matures and production scales up. The potential for cost reduction through economies of scale and the use of abundant, low-cost materials is a key factor driving market optimism.

However, the market demand analysis must also consider potential challenges. These include competition from established lithium-ion technology, the need for further improvements in energy density and cycle life, and the time required to establish large-scale manufacturing capabilities. Despite these challenges, the overall market trajectory for sodium-ion batteries appears positive, with increasing investment in research and development and growing interest from both established battery manufacturers and new entrants in the energy storage space.

Current Challenges in Sodium Ion Battery Technology

Despite the promising potential of sodium-ion batteries (SIBs) in fast-track energy technology adoption, several significant challenges currently hinder their widespread implementation and commercialization. One of the primary obstacles is the lower energy density compared to lithium-ion batteries (LIBs). SIBs typically achieve only 50-60% of the energy density of LIBs, limiting their application in scenarios where high energy storage capacity is crucial, such as electric vehicles and grid-scale energy storage systems.

Another major challenge lies in the development of suitable electrode materials. While sodium is abundant and cost-effective, finding electrode materials that can efficiently intercalate sodium ions without significant structural degradation remains a complex task. Current cathode materials often suffer from capacity fading and poor cycle life, limiting the long-term performance of SIBs.

The larger ionic radius of sodium compared to lithium also presents difficulties in terms of electrode kinetics and ion transport. This characteristic leads to slower charge-discharge rates and reduced power density, potentially limiting the applicability of SIBs in high-power applications. Additionally, the larger size of sodium ions can cause more significant volume changes in electrode materials during cycling, leading to mechanical stress and potential structural failure.

Electrolyte development poses another significant challenge. Conventional organic electrolytes used in LIBs are not always compatible with sodium-ion systems, necessitating the development of new electrolyte formulations. These must not only facilitate efficient sodium ion transport but also ensure long-term stability and safety, particularly in terms of minimizing unwanted side reactions and dendrite formation.

The issue of sodium plating and dendrite growth during charging is a critical safety concern that requires addressing. Dendrite formation can lead to short circuits and potential thermal runaway, posing significant safety risks. Developing strategies to mitigate this issue, such as advanced electrolyte additives or engineered separators, is crucial for the widespread adoption of SIBs.

Furthermore, the lack of established manufacturing processes and supply chains specifically tailored for SIB production presents a considerable challenge. While some similarities exist with LIB manufacturing, the unique requirements of SIB components necessitate the development of new production techniques and quality control measures. This challenge extends to the entire lifecycle of SIBs, including recycling and disposal processes, which are still in their infancy compared to those for LIBs.

Lastly, the relative immaturity of SIB technology compared to LIBs means that there is a significant knowledge gap in terms of long-term performance, reliability, and degradation mechanisms. Extensive research and real-world testing are still required to fully understand and optimize SIB systems for various applications and operating conditions.

Another major challenge lies in the development of suitable electrode materials. While sodium is abundant and cost-effective, finding electrode materials that can efficiently intercalate sodium ions without significant structural degradation remains a complex task. Current cathode materials often suffer from capacity fading and poor cycle life, limiting the long-term performance of SIBs.

The larger ionic radius of sodium compared to lithium also presents difficulties in terms of electrode kinetics and ion transport. This characteristic leads to slower charge-discharge rates and reduced power density, potentially limiting the applicability of SIBs in high-power applications. Additionally, the larger size of sodium ions can cause more significant volume changes in electrode materials during cycling, leading to mechanical stress and potential structural failure.

Electrolyte development poses another significant challenge. Conventional organic electrolytes used in LIBs are not always compatible with sodium-ion systems, necessitating the development of new electrolyte formulations. These must not only facilitate efficient sodium ion transport but also ensure long-term stability and safety, particularly in terms of minimizing unwanted side reactions and dendrite formation.

The issue of sodium plating and dendrite growth during charging is a critical safety concern that requires addressing. Dendrite formation can lead to short circuits and potential thermal runaway, posing significant safety risks. Developing strategies to mitigate this issue, such as advanced electrolyte additives or engineered separators, is crucial for the widespread adoption of SIBs.

Furthermore, the lack of established manufacturing processes and supply chains specifically tailored for SIB production presents a considerable challenge. While some similarities exist with LIB manufacturing, the unique requirements of SIB components necessitate the development of new production techniques and quality control measures. This challenge extends to the entire lifecycle of SIBs, including recycling and disposal processes, which are still in their infancy compared to those for LIBs.

Lastly, the relative immaturity of SIB technology compared to LIBs means that there is a significant knowledge gap in terms of long-term performance, reliability, and degradation mechanisms. Extensive research and real-world testing are still required to fully understand and optimize SIB systems for various applications and operating conditions.

Existing Sodium Ion Battery Solutions

01 Electrode materials for sodium-ion batteries

Development of advanced electrode materials is crucial for improving the performance of sodium-ion batteries. These materials include novel cathode and anode compositions that enhance energy density, cycling stability, and rate capability. Researchers are focusing on materials such as layered oxides, polyanionic compounds, and carbon-based anodes to optimize battery performance.- Electrode materials for sodium-ion batteries: Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials include advanced cathodes and anodes that offer higher energy density, better cycling stability, and improved rate capability. Researchers are exploring various compounds and nanostructures to enhance the electrochemical properties of sodium-ion batteries.

- Electrolyte innovations for sodium-ion batteries: Advancements in electrolyte formulations play a significant role in enhancing the safety and performance of sodium-ion batteries. Novel electrolytes are being developed to improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system. These innovations contribute to faster charging capabilities and longer cycle life.

- Manufacturing processes for sodium-ion batteries: Efficient and cost-effective manufacturing processes are essential for the large-scale production of sodium-ion batteries. Innovations in manufacturing techniques, including electrode preparation, cell assembly, and quality control, are being developed to streamline production and reduce costs. These advancements are crucial for the widespread adoption of sodium-ion battery technology.

- Battery management systems for sodium-ion batteries: Advanced battery management systems are being developed specifically for sodium-ion batteries to optimize their performance and lifespan. These systems include sophisticated monitoring and control algorithms that manage charging, discharging, and thermal management. Improved battery management contributes to the overall efficiency and reliability of sodium-ion battery systems.

- Integration of sodium-ion batteries in energy storage systems: Research is focused on integrating sodium-ion batteries into various energy storage applications, including grid-scale storage and renewable energy systems. This involves developing scalable battery designs, optimizing system architectures, and creating efficient power conversion and control systems. The integration of sodium-ion batteries in these applications is key to accelerating their adoption in the energy sector.

02 Electrolyte innovations for sodium-ion batteries

Advancements in electrolyte formulations are key to enhancing the safety and efficiency of sodium-ion batteries. Research is focused on developing new electrolyte compositions, including solid-state electrolytes, that improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system.Expand Specific Solutions03 Battery management systems for sodium-ion technology

Sophisticated battery management systems are being developed to optimize the performance and lifespan of sodium-ion batteries. These systems include advanced monitoring, control, and thermal management technologies that ensure efficient operation, prevent degradation, and enhance safety in various applications.Expand Specific Solutions04 Manufacturing processes for sodium-ion batteries

Innovative manufacturing techniques are being developed to scale up production and reduce costs of sodium-ion batteries. These processes focus on improving electrode fabrication, cell assembly, and quality control measures to enhance the commercial viability of sodium-ion technology.Expand Specific Solutions05 Integration of sodium-ion batteries in energy storage systems

Research is ongoing to effectively integrate sodium-ion batteries into various energy storage applications. This includes developing hybrid systems that combine sodium-ion batteries with other energy storage technologies, as well as optimizing battery pack designs for specific use cases such as grid storage and electric vehicles.Expand Specific Solutions

Key Players in Sodium Ion Battery Industry

The sodium-ion battery market is in an early growth stage, with increasing interest due to potential advantages over lithium-ion batteries. The market size is expanding, driven by demand for sustainable energy storage solutions. Technologically, sodium-ion batteries are progressing rapidly but still maturing. Key players like Contemporary Amperex Technology Co., Ltd. (CATL) and Faradion Ltd. are leading development efforts, with CATL announcing mass production plans. Other companies such as Northvolt AB and BYD Co., Ltd. are also investing in this technology. Research institutions like Nanjing University and Indian Institute of Technology Bombay are contributing to advancements. While challenges remain, the competitive landscape is evolving as more companies enter the field, recognizing the potential of sodium-ion batteries in the energy transition.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a first-generation sodium-ion battery with an energy density of up to 160Wh/kg[1]. Their innovative Prussian white cathode material and hard carbon anode material enable high-power density and excellent low-temperature performance. CATL's AB battery pack solution integrates sodium-ion cells with lithium-ion cells, compensating for the current energy density limitations of sodium-ion technology. This hybrid approach allows for the advantages of both chemistries to be leveraged, potentially accelerating the adoption of sodium-ion batteries in various applications[2].

Strengths: High power density, excellent low-temperature performance, and innovative hybrid battery pack solution. Weaknesses: Energy density still lower than advanced lithium-ion batteries, potentially limiting use in long-range electric vehicles.

Faradion Ltd.

Technical Solution: Faradion has pioneered a proprietary sodium-ion technology that offers a cost-effective and sustainable alternative to lithium-ion batteries. Their patented "Faradion Na-ion Technology" utilizes earth-abundant materials, reducing dependency on critical raw materials like lithium and cobalt. The company's batteries demonstrate high energy density for a sodium-ion system, with reported values exceeding 140 Wh/kg[3]. Faradion's technology also boasts rapid charging capabilities and enhanced safety features, including non-flammability and stability at high temperatures[4].

Strengths: Cost-effective, sustainable materials, rapid charging, and enhanced safety. Weaknesses: Lower energy density compared to state-of-the-art lithium-ion batteries, which may limit applications in certain sectors.

Core Innovations in Sodium Ion Battery Technology

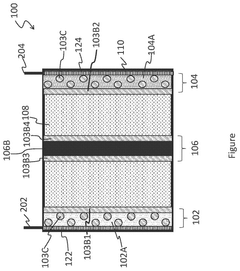

Sodium ion batteries and methods of manufacture thereof

PatentPendingUS20250105341A1

Innovation

- Incorporating a zeolite layer on the anode, cathode, or separator in sodium ion batteries, which undergoes a sodium ion exchange process to eliminate undesirable cations, enhancing electrolyte wettability, capturing trace water and transition metal ions, and acting as a scavenger for hydrofluoric acid to protect the cathode from corrosion.

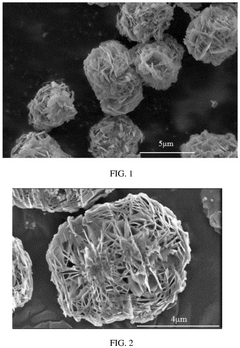

Positive electrode material precursor and positive electrode material and preparation methods therefor, and sodium-ion battery

PatentPendingEP4455092A1

Innovation

- A positive electrode material precursor with a heterogeneous structure of an O3-phase core and a P2-phase shell is developed, where the core and shell are composed of flaky primary particles, allowing for improved sodium ion diffusion and stability, achieved through a controlled co-precipitation process and calcination method suitable for large-scale production.

Environmental Impact of Sodium Ion Batteries

The environmental impact of sodium-ion batteries is a crucial consideration in their potential widespread adoption as an alternative to lithium-ion batteries. These batteries offer several environmental advantages that could contribute to more sustainable energy storage solutions.

One of the primary environmental benefits of sodium-ion batteries is the abundance and accessibility of sodium as a raw material. Unlike lithium, which is concentrated in specific geographical locations, sodium is widely available and can be extracted from seawater. This reduces the environmental impact associated with mining and transportation of raw materials, potentially lowering the carbon footprint of battery production.

The production process of sodium-ion batteries also presents environmental advantages. The materials used in these batteries, such as sodium and iron, are generally less toxic and easier to handle than those used in lithium-ion batteries. This can lead to reduced environmental risks during manufacturing and easier recycling processes at the end of the battery's life cycle.

In terms of performance, sodium-ion batteries have shown promising results in terms of energy density and cycle life. While they may not yet match the energy density of lithium-ion batteries, their potential for rapid charging and discharging could lead to more efficient energy storage systems. This efficiency could translate to reduced energy waste and lower overall environmental impact in various applications, particularly in grid storage and electric vehicles.

The recyclability of sodium-ion batteries is another significant environmental consideration. The materials used in these batteries are generally easier to recycle than those in lithium-ion batteries, potentially leading to a more circular economy in battery production. This could significantly reduce the amount of battery waste entering landfills and minimize the need for new raw material extraction.

However, it's important to note that the environmental impact of sodium-ion batteries is not entirely positive. The production of these batteries still requires energy and resources, and the long-term effects of large-scale sodium extraction from seawater are not yet fully understood. Additionally, while sodium is less reactive than lithium, safety concerns still exist, particularly in terms of fire risk and potential environmental contamination in case of battery failure.

As research and development in sodium-ion battery technology continue, it's likely that their environmental performance will improve further. Ongoing studies are focusing on enhancing the energy density, cycle life, and safety of these batteries, which could lead to even greater environmental benefits in the future. The potential for sodium-ion batteries to contribute to a more sustainable energy storage landscape is significant, but careful consideration of their full life-cycle impact will be crucial as the technology matures and approaches widespread adoption.

One of the primary environmental benefits of sodium-ion batteries is the abundance and accessibility of sodium as a raw material. Unlike lithium, which is concentrated in specific geographical locations, sodium is widely available and can be extracted from seawater. This reduces the environmental impact associated with mining and transportation of raw materials, potentially lowering the carbon footprint of battery production.

The production process of sodium-ion batteries also presents environmental advantages. The materials used in these batteries, such as sodium and iron, are generally less toxic and easier to handle than those used in lithium-ion batteries. This can lead to reduced environmental risks during manufacturing and easier recycling processes at the end of the battery's life cycle.

In terms of performance, sodium-ion batteries have shown promising results in terms of energy density and cycle life. While they may not yet match the energy density of lithium-ion batteries, their potential for rapid charging and discharging could lead to more efficient energy storage systems. This efficiency could translate to reduced energy waste and lower overall environmental impact in various applications, particularly in grid storage and electric vehicles.

The recyclability of sodium-ion batteries is another significant environmental consideration. The materials used in these batteries are generally easier to recycle than those in lithium-ion batteries, potentially leading to a more circular economy in battery production. This could significantly reduce the amount of battery waste entering landfills and minimize the need for new raw material extraction.

However, it's important to note that the environmental impact of sodium-ion batteries is not entirely positive. The production of these batteries still requires energy and resources, and the long-term effects of large-scale sodium extraction from seawater are not yet fully understood. Additionally, while sodium is less reactive than lithium, safety concerns still exist, particularly in terms of fire risk and potential environmental contamination in case of battery failure.

As research and development in sodium-ion battery technology continue, it's likely that their environmental performance will improve further. Ongoing studies are focusing on enhancing the energy density, cycle life, and safety of these batteries, which could lead to even greater environmental benefits in the future. The potential for sodium-ion batteries to contribute to a more sustainable energy storage landscape is significant, but careful consideration of their full life-cycle impact will be crucial as the technology matures and approaches widespread adoption.

Regulatory Framework for Sodium Ion Battery Adoption

The regulatory framework for sodium ion battery adoption is a critical aspect that will significantly influence the widespread implementation of this emerging energy storage technology. As sodium ion batteries gain traction in the fast-track energy technology landscape, governments and regulatory bodies worldwide are working to establish comprehensive guidelines and standards to ensure their safe and efficient deployment.

One of the primary focuses of the regulatory framework is safety standards. Regulatory agencies are developing stringent safety protocols for the manufacturing, transportation, and disposal of sodium ion batteries. These standards aim to address potential risks associated with thermal runaway, electrolyte leakage, and other safety concerns specific to sodium ion chemistry. Manufacturers will be required to comply with these safety regulations to obtain necessary certifications for market entry.

Environmental regulations play a crucial role in shaping the adoption of sodium ion batteries. Regulatory bodies are implementing guidelines for sustainable sourcing of raw materials, emphasizing the use of abundant and environmentally friendly elements like sodium. Additionally, regulations are being established to promote the recyclability and proper disposal of sodium ion batteries, aligning with circular economy principles and reducing the environmental impact of battery production and end-of-life management.

Performance standards are another key component of the regulatory framework. Agencies are developing benchmarks for energy density, cycle life, and charging efficiency to ensure that sodium ion batteries meet minimum performance requirements for various applications. These standards will help build consumer confidence and facilitate the integration of sodium ion batteries into existing energy systems.

Regulatory bodies are also addressing the interoperability and compatibility of sodium ion batteries with existing infrastructure. Standards are being developed to ensure that these batteries can seamlessly integrate with current charging networks, grid systems, and energy management platforms. This approach aims to minimize barriers to adoption and promote a smooth transition to sodium ion technology.

Financial incentives and support mechanisms are being incorporated into the regulatory framework to accelerate the adoption of sodium ion batteries. Governments are implementing tax credits, subsidies, and grants to encourage research, development, and commercialization efforts. These financial instruments are designed to reduce the initial cost barriers and stimulate investment in sodium ion battery technology.

Lastly, the regulatory framework includes provisions for continuous monitoring and assessment of sodium ion battery performance in real-world applications. Regulatory agencies are establishing protocols for data collection, analysis, and reporting to track the long-term safety, reliability, and environmental impact of these batteries. This ongoing evaluation will inform future regulatory updates and ensure that the framework remains responsive to technological advancements and emerging challenges in the field of sodium ion battery adoption.

One of the primary focuses of the regulatory framework is safety standards. Regulatory agencies are developing stringent safety protocols for the manufacturing, transportation, and disposal of sodium ion batteries. These standards aim to address potential risks associated with thermal runaway, electrolyte leakage, and other safety concerns specific to sodium ion chemistry. Manufacturers will be required to comply with these safety regulations to obtain necessary certifications for market entry.

Environmental regulations play a crucial role in shaping the adoption of sodium ion batteries. Regulatory bodies are implementing guidelines for sustainable sourcing of raw materials, emphasizing the use of abundant and environmentally friendly elements like sodium. Additionally, regulations are being established to promote the recyclability and proper disposal of sodium ion batteries, aligning with circular economy principles and reducing the environmental impact of battery production and end-of-life management.

Performance standards are another key component of the regulatory framework. Agencies are developing benchmarks for energy density, cycle life, and charging efficiency to ensure that sodium ion batteries meet minimum performance requirements for various applications. These standards will help build consumer confidence and facilitate the integration of sodium ion batteries into existing energy systems.

Regulatory bodies are also addressing the interoperability and compatibility of sodium ion batteries with existing infrastructure. Standards are being developed to ensure that these batteries can seamlessly integrate with current charging networks, grid systems, and energy management platforms. This approach aims to minimize barriers to adoption and promote a smooth transition to sodium ion technology.

Financial incentives and support mechanisms are being incorporated into the regulatory framework to accelerate the adoption of sodium ion batteries. Governments are implementing tax credits, subsidies, and grants to encourage research, development, and commercialization efforts. These financial instruments are designed to reduce the initial cost barriers and stimulate investment in sodium ion battery technology.

Lastly, the regulatory framework includes provisions for continuous monitoring and assessment of sodium ion battery performance in real-world applications. Regulatory agencies are establishing protocols for data collection, analysis, and reporting to track the long-term safety, reliability, and environmental impact of these batteries. This ongoing evaluation will inform future regulatory updates and ensure that the framework remains responsive to technological advancements and emerging challenges in the field of sodium ion battery adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!