Sodium Ion Batteries in High-Precision Instrumentation Power Supply

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Evolution and Objectives

Sodium-ion batteries have emerged as a promising alternative to lithium-ion batteries in recent years, particularly for high-precision instrumentation power supply applications. The evolution of sodium-ion battery technology can be traced back to the 1980s, but significant advancements have been made in the past decade. This renewed interest stems from the abundance and low cost of sodium resources, as well as the potential to address some of the limitations associated with lithium-ion batteries.

The development of sodium-ion batteries has been driven by the need for sustainable and cost-effective energy storage solutions. Initially, research focused on understanding the fundamental electrochemistry of sodium-ion systems and identifying suitable electrode materials. Early prototypes faced challenges related to low energy density and poor cycling stability, which limited their practical applications.

In recent years, breakthroughs in electrode materials and electrolyte formulations have led to significant improvements in sodium-ion battery performance. Researchers have explored various cathode materials, including layered oxides, polyanionic compounds, and Prussian blue analogues, each offering unique advantages in terms of capacity, voltage, and stability. Anode materials have also evolved, with hard carbons emerging as a promising option due to their high capacity and good cycling performance.

The objectives of sodium-ion battery research for high-precision instrumentation power supply are multifaceted. Firstly, there is a focus on increasing energy density to match or exceed that of lithium-ion batteries, enabling longer operating times for instrumentation. Secondly, improving the power density is crucial for applications requiring rapid charge and discharge capabilities. Thirdly, enhancing the cycling stability and calendar life of sodium-ion batteries is essential to ensure long-term reliability in precision instruments.

Another key objective is to optimize the performance of sodium-ion batteries under various environmental conditions, particularly at extreme temperatures. This is critical for instrumentation deployed in challenging environments, such as aerospace or deep-sea applications. Additionally, researchers aim to develop sodium-ion batteries with improved safety characteristics, reducing the risk of thermal runaway and enhancing overall system reliability.

The integration of sodium-ion batteries into high-precision instrumentation power supply systems presents unique challenges and opportunities. Researchers are working on miniaturization techniques to create compact battery designs suitable for portable and space-constrained instruments. Furthermore, efforts are being made to develop advanced battery management systems tailored to the specific characteristics of sodium-ion chemistry, ensuring optimal performance and longevity.

As the technology continues to mature, the objectives extend beyond performance metrics to include scalability and manufacturability. Researchers are exploring cost-effective production methods and seeking to establish a robust supply chain for sodium-ion battery components. The ultimate goal is to create a viable and sustainable alternative to lithium-ion batteries, capable of meeting the demanding requirements of high-precision instrumentation while offering economic and environmental advantages.

The development of sodium-ion batteries has been driven by the need for sustainable and cost-effective energy storage solutions. Initially, research focused on understanding the fundamental electrochemistry of sodium-ion systems and identifying suitable electrode materials. Early prototypes faced challenges related to low energy density and poor cycling stability, which limited their practical applications.

In recent years, breakthroughs in electrode materials and electrolyte formulations have led to significant improvements in sodium-ion battery performance. Researchers have explored various cathode materials, including layered oxides, polyanionic compounds, and Prussian blue analogues, each offering unique advantages in terms of capacity, voltage, and stability. Anode materials have also evolved, with hard carbons emerging as a promising option due to their high capacity and good cycling performance.

The objectives of sodium-ion battery research for high-precision instrumentation power supply are multifaceted. Firstly, there is a focus on increasing energy density to match or exceed that of lithium-ion batteries, enabling longer operating times for instrumentation. Secondly, improving the power density is crucial for applications requiring rapid charge and discharge capabilities. Thirdly, enhancing the cycling stability and calendar life of sodium-ion batteries is essential to ensure long-term reliability in precision instruments.

Another key objective is to optimize the performance of sodium-ion batteries under various environmental conditions, particularly at extreme temperatures. This is critical for instrumentation deployed in challenging environments, such as aerospace or deep-sea applications. Additionally, researchers aim to develop sodium-ion batteries with improved safety characteristics, reducing the risk of thermal runaway and enhancing overall system reliability.

The integration of sodium-ion batteries into high-precision instrumentation power supply systems presents unique challenges and opportunities. Researchers are working on miniaturization techniques to create compact battery designs suitable for portable and space-constrained instruments. Furthermore, efforts are being made to develop advanced battery management systems tailored to the specific characteristics of sodium-ion chemistry, ensuring optimal performance and longevity.

As the technology continues to mature, the objectives extend beyond performance metrics to include scalability and manufacturability. Researchers are exploring cost-effective production methods and seeking to establish a robust supply chain for sodium-ion battery components. The ultimate goal is to create a viable and sustainable alternative to lithium-ion batteries, capable of meeting the demanding requirements of high-precision instrumentation while offering economic and environmental advantages.

Market Demand Analysis for Precision Instrument Power

The market demand for precision instrument power supplies utilizing sodium-ion batteries is experiencing significant growth, driven by the increasing need for reliable and sustainable energy storage solutions in high-precision applications. This demand is particularly evident in sectors such as scientific research, aerospace, medical equipment, and advanced manufacturing.

In the scientific research sector, there is a growing requirement for stable and long-lasting power sources for sensitive instruments used in laboratories and field research. Sodium-ion batteries offer a promising alternative to traditional lithium-ion batteries, providing comparable performance with potentially lower costs and improved safety profiles.

The aerospace industry is another key driver of market demand for precision instrument power supplies. As space exploration and satellite technology continue to advance, the need for lightweight, high-performance energy storage solutions becomes more critical. Sodium-ion batteries present an attractive option due to their potential for higher energy density and improved thermal stability compared to current technologies.

In the medical equipment sector, the demand for reliable and precise power supplies is paramount. Diagnostic and therapeutic devices require consistent and accurate power delivery to ensure patient safety and treatment efficacy. Sodium-ion batteries could offer extended operational times and reduced maintenance requirements, making them an appealing choice for medical device manufacturers.

Advanced manufacturing, including robotics and automation systems, represents another significant market for precision instrument power supplies. The integration of sodium-ion batteries in these applications could lead to improved efficiency and reduced downtime, addressing the industry's need for reliable and long-lasting power sources.

The market demand is further bolstered by the global push towards sustainable and environmentally friendly technologies. Sodium-ion batteries, with their use of more abundant and less environmentally impactful materials compared to lithium-ion batteries, align well with these sustainability goals. This factor is likely to drive increased adoption across various industries seeking to reduce their carbon footprint and comply with stricter environmental regulations.

As the technology matures and production scales up, the cost-effectiveness of sodium-ion batteries is expected to improve, potentially leading to wider market penetration. This cost reduction, coupled with performance enhancements, is anticipated to expand the application range of sodium-ion batteries in precision instrument power supplies, further stimulating market demand.

In the scientific research sector, there is a growing requirement for stable and long-lasting power sources for sensitive instruments used in laboratories and field research. Sodium-ion batteries offer a promising alternative to traditional lithium-ion batteries, providing comparable performance with potentially lower costs and improved safety profiles.

The aerospace industry is another key driver of market demand for precision instrument power supplies. As space exploration and satellite technology continue to advance, the need for lightweight, high-performance energy storage solutions becomes more critical. Sodium-ion batteries present an attractive option due to their potential for higher energy density and improved thermal stability compared to current technologies.

In the medical equipment sector, the demand for reliable and precise power supplies is paramount. Diagnostic and therapeutic devices require consistent and accurate power delivery to ensure patient safety and treatment efficacy. Sodium-ion batteries could offer extended operational times and reduced maintenance requirements, making them an appealing choice for medical device manufacturers.

Advanced manufacturing, including robotics and automation systems, represents another significant market for precision instrument power supplies. The integration of sodium-ion batteries in these applications could lead to improved efficiency and reduced downtime, addressing the industry's need for reliable and long-lasting power sources.

The market demand is further bolstered by the global push towards sustainable and environmentally friendly technologies. Sodium-ion batteries, with their use of more abundant and less environmentally impactful materials compared to lithium-ion batteries, align well with these sustainability goals. This factor is likely to drive increased adoption across various industries seeking to reduce their carbon footprint and comply with stricter environmental regulations.

As the technology matures and production scales up, the cost-effectiveness of sodium-ion batteries is expected to improve, potentially leading to wider market penetration. This cost reduction, coupled with performance enhancements, is anticipated to expand the application range of sodium-ion batteries in precision instrument power supplies, further stimulating market demand.

Current Challenges in Sodium Ion Battery Technology

Despite the promising potential of sodium-ion batteries (SIBs) in high-precision instrumentation power supply, several significant challenges currently hinder their widespread adoption and optimal performance. One of the primary obstacles is the lower energy density compared to lithium-ion batteries. This limitation stems from the larger ionic radius of sodium ions, which affects the intercalation process and reduces the overall energy storage capacity.

Another critical challenge lies in the development of suitable electrode materials. While progress has been made in identifying potential cathode and anode materials, many still suffer from poor cycling stability and rapid capacity fading. This issue is particularly pronounced in high-precision applications where consistent and reliable power output is crucial.

The electrolyte formulation presents another hurdle in SIB technology. Current electrolytes often struggle to form stable solid electrolyte interphase (SEI) layers, leading to continuous electrolyte decomposition and reduced battery lifespan. This instability is exacerbated in high-precision instruments that may require frequent charge-discharge cycles.

Sodium's high reactivity with water poses significant safety concerns, necessitating stringent moisture control during manufacturing and operation. This challenge becomes more pronounced in portable high-precision instruments that may be exposed to varying environmental conditions.

The rate capability of SIBs also remains a limiting factor, particularly for applications requiring rapid charge and discharge cycles. The slower diffusion kinetics of sodium ions compared to lithium ions can result in reduced power density, potentially impacting the performance of high-precision instruments during peak power demands.

Temperature sensitivity is another critical challenge for SIBs in instrumentation applications. Many current sodium-ion battery systems exhibit significant performance degradation at extreme temperatures, limiting their usability in diverse environmental conditions often encountered in field instrumentation.

Lastly, the lack of established large-scale production processes for SIBs presents a significant barrier to their commercial viability. The absence of optimized manufacturing techniques leads to higher production costs and inconsistent quality, hindering the integration of SIBs into high-precision instrumentation power supplies on a broader scale.

Addressing these challenges requires concerted efforts in materials science, electrochemistry, and engineering to develop innovative solutions that can unlock the full potential of sodium-ion batteries for high-precision instrumentation applications.

Another critical challenge lies in the development of suitable electrode materials. While progress has been made in identifying potential cathode and anode materials, many still suffer from poor cycling stability and rapid capacity fading. This issue is particularly pronounced in high-precision applications where consistent and reliable power output is crucial.

The electrolyte formulation presents another hurdle in SIB technology. Current electrolytes often struggle to form stable solid electrolyte interphase (SEI) layers, leading to continuous electrolyte decomposition and reduced battery lifespan. This instability is exacerbated in high-precision instruments that may require frequent charge-discharge cycles.

Sodium's high reactivity with water poses significant safety concerns, necessitating stringent moisture control during manufacturing and operation. This challenge becomes more pronounced in portable high-precision instruments that may be exposed to varying environmental conditions.

The rate capability of SIBs also remains a limiting factor, particularly for applications requiring rapid charge and discharge cycles. The slower diffusion kinetics of sodium ions compared to lithium ions can result in reduced power density, potentially impacting the performance of high-precision instruments during peak power demands.

Temperature sensitivity is another critical challenge for SIBs in instrumentation applications. Many current sodium-ion battery systems exhibit significant performance degradation at extreme temperatures, limiting their usability in diverse environmental conditions often encountered in field instrumentation.

Lastly, the lack of established large-scale production processes for SIBs presents a significant barrier to their commercial viability. The absence of optimized manufacturing techniques leads to higher production costs and inconsistent quality, hindering the integration of SIBs into high-precision instrumentation power supplies on a broader scale.

Addressing these challenges requires concerted efforts in materials science, electrochemistry, and engineering to develop innovative solutions that can unlock the full potential of sodium-ion batteries for high-precision instrumentation applications.

Existing Sodium Ion Battery Solutions for Instrumentation

01 Electrode materials for sodium-ion batteries

Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials can include various compounds and composites designed to enhance capacity, cycling stability, and rate capability. Research focuses on optimizing the structure and composition of both anode and cathode materials to facilitate efficient sodium ion insertion and extraction.- Electrode materials for sodium-ion batteries: Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials can include various compounds and composites designed to enhance energy density, cycling stability, and charge/discharge rates. Research focuses on optimizing the structure and composition of both anode and cathode materials to better accommodate sodium ions.

- Electrolyte formulations for sodium-ion batteries: Electrolyte composition plays a vital role in the performance and safety of sodium-ion batteries. Researchers are exploring various electrolyte formulations, including liquid, solid, and gel electrolytes, to improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system. Novel additives and solvents are being investigated to address specific challenges in sodium-ion battery technology.

- Battery cell design and manufacturing processes: Innovations in cell design and manufacturing processes are essential for commercializing sodium-ion batteries. This includes developing efficient methods for electrode preparation, cell assembly, and packaging. Researchers are working on scalable production techniques, optimizing cell components, and improving the overall structure to enhance performance and reduce costs.

- Battery management systems for sodium-ion batteries: Specialized battery management systems are being developed to optimize the performance and longevity of sodium-ion batteries. These systems focus on monitoring and controlling various parameters such as voltage, current, and temperature. Advanced algorithms and sensing technologies are employed to ensure safe operation, efficient charging, and accurate state-of-charge estimation for sodium-ion battery packs.

- Integration of sodium-ion batteries in energy storage systems: Research is ongoing to effectively integrate sodium-ion batteries into various energy storage applications. This includes developing hybrid systems that combine sodium-ion batteries with other energy storage technologies, optimizing battery pack designs for specific use cases, and creating intelligent control strategies for grid-scale energy storage. The focus is on leveraging the unique characteristics of sodium-ion batteries to complement existing energy storage solutions.

02 Electrolyte formulations for sodium-ion batteries

Electrolyte composition plays a vital role in the performance and safety of sodium-ion batteries. Researchers are exploring various electrolyte formulations, including liquid, gel, and solid electrolytes, to improve ionic conductivity, electrochemical stability, and interfacial properties. Additives and solvents are being investigated to enhance the overall battery performance and mitigate issues such as dendrite formation.Expand Specific Solutions03 Battery cell design and manufacturing processes

Innovations in cell design and manufacturing processes are essential for commercializing sodium-ion batteries. This includes developing efficient methods for electrode preparation, cell assembly, and packaging. Researchers are focusing on scalable production techniques, optimizing cell components, and improving the overall energy density and power output of sodium-ion battery cells.Expand Specific Solutions04 Sodium-ion battery management systems

Advanced battery management systems are being developed to optimize the performance and longevity of sodium-ion batteries. These systems include sophisticated algorithms for state-of-charge estimation, thermal management, and safety controls. Researchers are working on integrating smart monitoring and control features to enhance the reliability and efficiency of sodium-ion battery packs in various applications.Expand Specific Solutions05 Recycling and sustainability of sodium-ion batteries

As sodium-ion batteries gain traction, there is increasing focus on developing sustainable production methods and efficient recycling processes. Researchers are exploring environmentally friendly materials and manufacturing techniques, as well as designing batteries with end-of-life considerations. Recycling methods are being developed to recover valuable materials and minimize the environmental impact of spent sodium-ion batteries.Expand Specific Solutions

Key Players in Sodium Ion Battery Industry

The research on sodium-ion batteries for high-precision instrumentation power supply is in an emerging stage, with growing market potential due to increasing demand for sustainable energy storage solutions. The technology is still evolving, with moderate maturity levels compared to established lithium-ion batteries. Key players like Contemporary Amperex Technology Co., Ltd. (CATL) and Faradion Ltd. are driving innovation in this field. Academic institutions such as Nankai University and the Chinese Academy of Sciences Institute of Physics are contributing significant research. Companies like Liyang HiNa Battery Technology Co., Ltd. and Beijing Zhongke Haina Technology Co. Ltd. are focusing on commercialization efforts. The competitive landscape is characterized by a mix of established battery manufacturers and specialized sodium-ion technology startups, indicating a dynamic and rapidly developing market.

Contemporary Amperex Technology Co., Ltd.

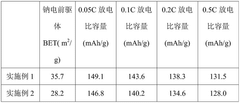

Technical Solution: CATL has developed advanced sodium-ion batteries for high-precision instrumentation power supply. Their technology utilizes a hard carbon anode and a Prussian white cathode, achieving an energy density of 160Wh/kg[1]. The company has implemented a novel electrolyte formulation that enhances the battery's performance at low temperatures, crucial for instrumentation in various environments. CATL's sodium-ion batteries incorporate a unique layered oxide cathode material, which improves the overall stability and cycle life of the cells[2]. They have also developed a proprietary battery management system specifically optimized for sodium-ion chemistry, ensuring precise control and monitoring of the battery's state of charge and health[3].

Strengths: High energy density, improved low-temperature performance, and advanced battery management system. Weaknesses: Relatively new technology with limited long-term performance data in high-precision applications.

Liyang HiNa Battery Technology Co., Ltd.

Technical Solution: HiNa Battery has developed a sodium-ion battery technology specifically tailored for high-precision instrumentation power supply. Their approach focuses on a novel cathode material composition, combining layered oxides with polyanionic compounds to achieve high voltage and stability[4]. The company has implemented a proprietary electrolyte additive that significantly reduces the first-cycle irreversible capacity loss, a common issue in sodium-ion batteries. HiNa's batteries utilize a hard carbon anode with optimized porosity, enhancing sodium ion insertion and extraction kinetics[5]. They have also developed an advanced cell design that improves thermal management, crucial for maintaining consistent performance in precision instruments.

Strengths: Innovative cathode material, reduced first-cycle capacity loss, and improved thermal management. Weaknesses: May have higher production costs due to specialized materials and manufacturing processes.

Core Innovations in Sodium Ion Battery Technology

A high-power density sodium-ion battery

PatentWO2020174496A1

Innovation

- A high-power density sodium-ion battery design featuring a carbon-coated Sodium Vanadium Phosphate cathode and a pre-treated anode with a Solid Electrolyte Interface (SEI) layer, utilizing a specific mass balance and electrolyte composition, along with a convenient pre-alkalization process to prevent initial capacity loss, allowing for charging at higher rates and extended cycle life.

High-rate sodium battery precursor and positive electrode material, and preparation method and use therefor

PatentWO2025111741A1

Innovation

- The sodium-electric precursor material with a porous structure is NixFeyMnzO2, and a rich pore network is formed by calcining nickel ferromanganzine hydroxide, which improves the transmission efficiency of sodium ions, reduces the migration barrier and improves the ion diffusion coefficient.

Environmental Impact of Sodium Ion Batteries

The environmental impact of sodium-ion batteries in high-precision instrumentation power supply applications is a crucial consideration as this technology gains traction. These batteries offer several environmental advantages over traditional lithium-ion batteries, particularly in terms of resource availability and sustainability.

Sodium, the primary material in sodium-ion batteries, is abundant and widely distributed globally, reducing the environmental strain associated with resource extraction. Unlike lithium, which is concentrated in specific regions, sodium can be sourced from seawater or mineral deposits, minimizing the ecological footprint of mining operations. This abundance also translates to reduced geopolitical tensions and more sustainable supply chains.

The production process of sodium-ion batteries generally requires less energy and generates fewer greenhouse gas emissions compared to lithium-ion batteries. This is partly due to the lower processing temperatures needed for sodium-based materials. Additionally, the use of aluminum instead of copper for the current collectors in sodium-ion batteries further reduces the environmental impact, as aluminum production is typically less energy-intensive and more easily recyclable.

In terms of end-of-life management, sodium-ion batteries present fewer challenges for recycling and disposal. The materials used are generally less toxic and easier to handle, reducing the risk of environmental contamination. The recycling process for these batteries is potentially simpler and more cost-effective, encouraging higher recycling rates and promoting a circular economy approach in the battery industry.

However, it's important to note that the environmental benefits of sodium-ion batteries in high-precision instrumentation may be partially offset by their current limitations in energy density. This could lead to a need for larger or more frequent battery replacements, potentially increasing the overall material consumption and waste generation over the lifecycle of the instrumentation.

The use of sodium-ion batteries in high-precision instruments also contributes to reduced environmental impact through improved energy efficiency. These batteries can operate effectively in a wider temperature range compared to some other battery technologies, potentially reducing the energy required for temperature control in sensitive instrumentation environments.

As research and development in sodium-ion battery technology progresses, particularly in the context of high-precision instrumentation, further improvements in environmental performance are anticipated. This includes advancements in material efficiency, battery lifespan, and recycling technologies, all of which will contribute to minimizing the ecological footprint of these power sources in specialized applications.

Sodium, the primary material in sodium-ion batteries, is abundant and widely distributed globally, reducing the environmental strain associated with resource extraction. Unlike lithium, which is concentrated in specific regions, sodium can be sourced from seawater or mineral deposits, minimizing the ecological footprint of mining operations. This abundance also translates to reduced geopolitical tensions and more sustainable supply chains.

The production process of sodium-ion batteries generally requires less energy and generates fewer greenhouse gas emissions compared to lithium-ion batteries. This is partly due to the lower processing temperatures needed for sodium-based materials. Additionally, the use of aluminum instead of copper for the current collectors in sodium-ion batteries further reduces the environmental impact, as aluminum production is typically less energy-intensive and more easily recyclable.

In terms of end-of-life management, sodium-ion batteries present fewer challenges for recycling and disposal. The materials used are generally less toxic and easier to handle, reducing the risk of environmental contamination. The recycling process for these batteries is potentially simpler and more cost-effective, encouraging higher recycling rates and promoting a circular economy approach in the battery industry.

However, it's important to note that the environmental benefits of sodium-ion batteries in high-precision instrumentation may be partially offset by their current limitations in energy density. This could lead to a need for larger or more frequent battery replacements, potentially increasing the overall material consumption and waste generation over the lifecycle of the instrumentation.

The use of sodium-ion batteries in high-precision instruments also contributes to reduced environmental impact through improved energy efficiency. These batteries can operate effectively in a wider temperature range compared to some other battery technologies, potentially reducing the energy required for temperature control in sensitive instrumentation environments.

As research and development in sodium-ion battery technology progresses, particularly in the context of high-precision instrumentation, further improvements in environmental performance are anticipated. This includes advancements in material efficiency, battery lifespan, and recycling technologies, all of which will contribute to minimizing the ecological footprint of these power sources in specialized applications.

Safety Standards for Instrumentation Power Supply

Safety standards for instrumentation power supply in high-precision applications are critical to ensure reliable operation and protect both equipment and personnel. These standards encompass various aspects of power supply design, manufacturing, and implementation, with a particular focus on sodium-ion batteries as an emerging technology.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have established guidelines for power supply safety in instrumentation. These standards address issues such as electrical isolation, electromagnetic compatibility (EMC), and thermal management.

For sodium-ion batteries in high-precision instrumentation, specific safety considerations must be taken into account. These include the potential for thermal runaway, electrolyte stability, and the risk of fire or explosion under certain conditions. As a result, safety standards for sodium-ion batteries in instrumentation power supplies often incorporate stringent requirements for cell design, battery management systems, and protective enclosures.

Voltage regulation and current limiting are essential safety features in instrumentation power supplies. Standards typically specify acceptable voltage fluctuations and current thresholds to prevent damage to sensitive equipment. For sodium-ion batteries, this includes monitoring and controlling individual cell voltages to maintain safe operating conditions.

Environmental factors also play a crucial role in safety standards for instrumentation power supplies. Temperature ranges, humidity levels, and exposure to vibration or shock must be considered when designing and implementing power systems. Sodium-ion batteries may have specific environmental requirements that differ from traditional lithium-ion or lead-acid batteries, necessitating tailored safety measures.

Electrical safety standards for instrumentation power supplies often mandate the use of protective devices such as fuses, circuit breakers, and overvoltage protection circuits. These components help prevent electrical hazards and protect both the power supply and connected equipment from damage due to faults or surges.

As sodium-ion battery technology continues to evolve, safety standards for their use in instrumentation power supplies are likely to undergo regular updates. Manufacturers and researchers must stay informed about the latest safety requirements and best practices to ensure compliance and maintain the highest levels of safety in high-precision applications.

International standards organizations, such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE), have established guidelines for power supply safety in instrumentation. These standards address issues such as electrical isolation, electromagnetic compatibility (EMC), and thermal management.

For sodium-ion batteries in high-precision instrumentation, specific safety considerations must be taken into account. These include the potential for thermal runaway, electrolyte stability, and the risk of fire or explosion under certain conditions. As a result, safety standards for sodium-ion batteries in instrumentation power supplies often incorporate stringent requirements for cell design, battery management systems, and protective enclosures.

Voltage regulation and current limiting are essential safety features in instrumentation power supplies. Standards typically specify acceptable voltage fluctuations and current thresholds to prevent damage to sensitive equipment. For sodium-ion batteries, this includes monitoring and controlling individual cell voltages to maintain safe operating conditions.

Environmental factors also play a crucial role in safety standards for instrumentation power supplies. Temperature ranges, humidity levels, and exposure to vibration or shock must be considered when designing and implementing power systems. Sodium-ion batteries may have specific environmental requirements that differ from traditional lithium-ion or lead-acid batteries, necessitating tailored safety measures.

Electrical safety standards for instrumentation power supplies often mandate the use of protective devices such as fuses, circuit breakers, and overvoltage protection circuits. These components help prevent electrical hazards and protect both the power supply and connected equipment from damage due to faults or surges.

As sodium-ion battery technology continues to evolve, safety standards for their use in instrumentation power supplies are likely to undergo regular updates. Manufacturers and researchers must stay informed about the latest safety requirements and best practices to ensure compliance and maintain the highest levels of safety in high-precision applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!