Sodium Ion Batteries in Global Energy Distribution Networks

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Evolution and Objectives

Sodium-ion batteries have emerged as a promising alternative to lithium-ion batteries in recent years, particularly in the context of global energy distribution networks. The evolution of this technology can be traced back to the 1980s when initial research on sodium-based intercalation materials began. However, it wasn't until the early 2000s that significant progress was made in developing practical sodium-ion battery systems.

The primary driving force behind the development of sodium-ion batteries has been the need for more sustainable and cost-effective energy storage solutions. As global demand for energy storage continues to grow, concerns about the long-term availability and cost of lithium have intensified. Sodium, being abundant and widely distributed geographically, offers a potential solution to these challenges.

Over the past decade, research efforts have focused on improving the performance and stability of sodium-ion batteries. Key areas of development have included the optimization of cathode and anode materials, electrolyte formulations, and cell designs. Notable milestones include the development of high-capacity hard carbon anodes, the discovery of layered oxide cathodes with improved cycling stability, and the introduction of novel electrolyte additives to enhance battery life.

The current technological trajectory suggests that sodium-ion batteries are poised to play a significant role in large-scale energy storage applications, particularly in stationary systems for grid stabilization and renewable energy integration. While they may not yet match the energy density of lithium-ion batteries for portable electronics or electric vehicles, their potential for cost-effective, large-scale deployment is driving continued research and development.

Looking ahead, the objectives for sodium-ion battery technology in global energy distribution networks are multifaceted. Researchers aim to further improve energy density, cycling stability, and rate capability to make sodium-ion batteries competitive with lithium-ion batteries in a broader range of applications. Additionally, there is a focus on developing scalable manufacturing processes and establishing robust supply chains to support widespread adoption.

Another critical objective is to enhance the safety and environmental profile of sodium-ion batteries. This includes developing non-flammable electrolytes, improving thermal management systems, and designing batteries with minimal environmental impact throughout their lifecycle. As global energy networks increasingly rely on distributed storage solutions, ensuring the safety and sustainability of sodium-ion batteries becomes paramount.

In conclusion, the evolution of sodium-ion batteries represents a significant technological trend with the potential to reshape global energy distribution networks. By addressing the limitations of current energy storage technologies and leveraging abundant resources, sodium-ion batteries are poised to contribute to a more sustainable and resilient energy future.

The primary driving force behind the development of sodium-ion batteries has been the need for more sustainable and cost-effective energy storage solutions. As global demand for energy storage continues to grow, concerns about the long-term availability and cost of lithium have intensified. Sodium, being abundant and widely distributed geographically, offers a potential solution to these challenges.

Over the past decade, research efforts have focused on improving the performance and stability of sodium-ion batteries. Key areas of development have included the optimization of cathode and anode materials, electrolyte formulations, and cell designs. Notable milestones include the development of high-capacity hard carbon anodes, the discovery of layered oxide cathodes with improved cycling stability, and the introduction of novel electrolyte additives to enhance battery life.

The current technological trajectory suggests that sodium-ion batteries are poised to play a significant role in large-scale energy storage applications, particularly in stationary systems for grid stabilization and renewable energy integration. While they may not yet match the energy density of lithium-ion batteries for portable electronics or electric vehicles, their potential for cost-effective, large-scale deployment is driving continued research and development.

Looking ahead, the objectives for sodium-ion battery technology in global energy distribution networks are multifaceted. Researchers aim to further improve energy density, cycling stability, and rate capability to make sodium-ion batteries competitive with lithium-ion batteries in a broader range of applications. Additionally, there is a focus on developing scalable manufacturing processes and establishing robust supply chains to support widespread adoption.

Another critical objective is to enhance the safety and environmental profile of sodium-ion batteries. This includes developing non-flammable electrolytes, improving thermal management systems, and designing batteries with minimal environmental impact throughout their lifecycle. As global energy networks increasingly rely on distributed storage solutions, ensuring the safety and sustainability of sodium-ion batteries becomes paramount.

In conclusion, the evolution of sodium-ion batteries represents a significant technological trend with the potential to reshape global energy distribution networks. By addressing the limitations of current energy storage technologies and leveraging abundant resources, sodium-ion batteries are poised to contribute to a more sustainable and resilient energy future.

Market Analysis for Grid Energy Storage

The global energy storage market for grid applications is experiencing rapid growth, driven by the increasing integration of renewable energy sources and the need for grid stability. Sodium-ion batteries are emerging as a promising technology in this sector, offering several advantages over traditional lithium-ion batteries. The market for grid energy storage is expected to expand significantly in the coming years, with sodium-ion batteries poised to capture a substantial share.

The demand for grid energy storage solutions is primarily fueled by the growing adoption of intermittent renewable energy sources such as solar and wind power. As these sources become more prevalent in the global energy mix, the need for efficient and cost-effective energy storage systems becomes critical to ensure grid reliability and stability. Sodium-ion batteries are well-positioned to meet this demand due to their potential for lower costs, improved safety, and abundant raw materials.

In terms of market size, the grid energy storage sector is projected to grow substantially. This growth is attributed to factors such as increasing investments in renewable energy infrastructure, government initiatives to promote clean energy, and the declining costs of energy storage technologies. Sodium-ion batteries are expected to play a significant role in this expansion, particularly in large-scale stationary storage applications.

Geographically, the market for grid energy storage, including sodium-ion batteries, shows varying levels of development and adoption. Developed economies such as the United States, European Union countries, and Japan are currently leading in terms of installed capacity and technological advancements. However, emerging markets, particularly in Asia-Pacific and Latin America, are showing rapid growth potential due to their increasing energy demands and commitments to renewable energy targets.

The competitive landscape of the grid energy storage market is diverse, with both established players and new entrants vying for market share. While lithium-ion batteries currently dominate the market, sodium-ion technology is gaining traction. Several companies and research institutions are actively developing and commercializing sodium-ion batteries for grid applications, recognizing their potential to address the limitations of lithium-ion technology.

Key drivers for the adoption of sodium-ion batteries in grid energy storage include their potential for lower costs due to the abundance of sodium resources, improved safety characteristics, and the ability to operate effectively in a wide range of temperatures. These factors make sodium-ion batteries particularly attractive for large-scale, stationary energy storage applications in various climatic conditions.

The demand for grid energy storage solutions is primarily fueled by the growing adoption of intermittent renewable energy sources such as solar and wind power. As these sources become more prevalent in the global energy mix, the need for efficient and cost-effective energy storage systems becomes critical to ensure grid reliability and stability. Sodium-ion batteries are well-positioned to meet this demand due to their potential for lower costs, improved safety, and abundant raw materials.

In terms of market size, the grid energy storage sector is projected to grow substantially. This growth is attributed to factors such as increasing investments in renewable energy infrastructure, government initiatives to promote clean energy, and the declining costs of energy storage technologies. Sodium-ion batteries are expected to play a significant role in this expansion, particularly in large-scale stationary storage applications.

Geographically, the market for grid energy storage, including sodium-ion batteries, shows varying levels of development and adoption. Developed economies such as the United States, European Union countries, and Japan are currently leading in terms of installed capacity and technological advancements. However, emerging markets, particularly in Asia-Pacific and Latin America, are showing rapid growth potential due to their increasing energy demands and commitments to renewable energy targets.

The competitive landscape of the grid energy storage market is diverse, with both established players and new entrants vying for market share. While lithium-ion batteries currently dominate the market, sodium-ion technology is gaining traction. Several companies and research institutions are actively developing and commercializing sodium-ion batteries for grid applications, recognizing their potential to address the limitations of lithium-ion technology.

Key drivers for the adoption of sodium-ion batteries in grid energy storage include their potential for lower costs due to the abundance of sodium resources, improved safety characteristics, and the ability to operate effectively in a wide range of temperatures. These factors make sodium-ion batteries particularly attractive for large-scale, stationary energy storage applications in various climatic conditions.

Technical Challenges in Sodium Ion Battery Development

The development of sodium-ion batteries faces several significant technical challenges that researchers and engineers are actively working to overcome. One of the primary obstacles is the lower energy density compared to lithium-ion batteries. This limitation stems from the larger size of sodium ions, which affects the battery's capacity and overall performance. Researchers are exploring novel electrode materials and optimizing cell designs to address this issue and improve energy density.

Another critical challenge lies in the development of suitable cathode materials. While several promising candidates have been identified, such as layered oxides and polyanionic compounds, they often suffer from structural instability during cycling. This instability can lead to capacity fading and reduced battery lifespan. Scientists are investigating various strategies, including doping and surface modification, to enhance the structural stability of cathode materials and improve their long-term performance.

The anode material selection also presents significant challenges. Graphite, commonly used in lithium-ion batteries, is not suitable for sodium-ion batteries due to the larger size of sodium ions. Alternative anode materials, such as hard carbons and alloys, are being explored. However, these materials often face issues related to low initial Coulombic efficiency and large volume changes during cycling, which can lead to capacity loss and safety concerns.

Electrolyte development is another crucial area of focus. Conventional organic electrolytes used in lithium-ion batteries may not be optimal for sodium-ion systems due to differences in ion transport and interfacial reactions. Researchers are working on developing new electrolyte formulations that can provide stable solid-electrolyte interphase (SEI) formation, enhance ion conductivity, and improve overall battery performance and safety.

The cycling stability of sodium-ion batteries remains a significant challenge. The repeated insertion and extraction of larger sodium ions can cause structural degradation in electrode materials, leading to capacity fade over time. Addressing this issue requires innovative approaches in material design and engineering, as well as the development of advanced electrolyte systems that can mitigate side reactions and maintain electrode integrity.

Safety concerns also pose challenges in sodium-ion battery development. While sodium is generally considered safer than lithium due to its lower reactivity, issues such as dendrite formation and thermal runaway still need to be addressed. Researchers are exploring various strategies, including the use of solid-state electrolytes and advanced battery management systems, to enhance the safety profile of sodium-ion batteries.

Scaling up production and reducing costs present additional technical challenges. The transition from laboratory-scale research to large-scale manufacturing requires overcoming issues related to material synthesis, electrode fabrication, and cell assembly. Developing cost-effective and scalable production methods is crucial for the commercial viability of sodium-ion batteries in global energy distribution networks.

Another critical challenge lies in the development of suitable cathode materials. While several promising candidates have been identified, such as layered oxides and polyanionic compounds, they often suffer from structural instability during cycling. This instability can lead to capacity fading and reduced battery lifespan. Scientists are investigating various strategies, including doping and surface modification, to enhance the structural stability of cathode materials and improve their long-term performance.

The anode material selection also presents significant challenges. Graphite, commonly used in lithium-ion batteries, is not suitable for sodium-ion batteries due to the larger size of sodium ions. Alternative anode materials, such as hard carbons and alloys, are being explored. However, these materials often face issues related to low initial Coulombic efficiency and large volume changes during cycling, which can lead to capacity loss and safety concerns.

Electrolyte development is another crucial area of focus. Conventional organic electrolytes used in lithium-ion batteries may not be optimal for sodium-ion systems due to differences in ion transport and interfacial reactions. Researchers are working on developing new electrolyte formulations that can provide stable solid-electrolyte interphase (SEI) formation, enhance ion conductivity, and improve overall battery performance and safety.

The cycling stability of sodium-ion batteries remains a significant challenge. The repeated insertion and extraction of larger sodium ions can cause structural degradation in electrode materials, leading to capacity fade over time. Addressing this issue requires innovative approaches in material design and engineering, as well as the development of advanced electrolyte systems that can mitigate side reactions and maintain electrode integrity.

Safety concerns also pose challenges in sodium-ion battery development. While sodium is generally considered safer than lithium due to its lower reactivity, issues such as dendrite formation and thermal runaway still need to be addressed. Researchers are exploring various strategies, including the use of solid-state electrolytes and advanced battery management systems, to enhance the safety profile of sodium-ion batteries.

Scaling up production and reducing costs present additional technical challenges. The transition from laboratory-scale research to large-scale manufacturing requires overcoming issues related to material synthesis, electrode fabrication, and cell assembly. Developing cost-effective and scalable production methods is crucial for the commercial viability of sodium-ion batteries in global energy distribution networks.

Current Sodium Ion Battery Solutions for Grid Storage

01 Electrode materials for sodium-ion batteries

Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials focus on enhancing energy density, cycling stability, and rate capability. Research includes exploring various compounds, nanostructures, and composites to optimize sodium storage and transport properties.- Electrode materials for sodium-ion batteries: Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials can include various compounds and composites designed to enhance energy density, cycling stability, and rate capability. Researchers are exploring different structures and compositions to optimize the electrochemical properties of both cathode and anode materials.

- Electrolyte formulations for sodium-ion batteries: Electrolyte composition plays a vital role in the performance and safety of sodium-ion batteries. Researchers are developing new electrolyte formulations, including both liquid and solid electrolytes, to improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system. These advancements aim to increase the energy density and cycle life of sodium-ion batteries.

- Battery cell design and manufacturing processes: Innovations in battery cell design and manufacturing processes are essential for the commercialization of sodium-ion batteries. This includes developing new cell architectures, optimizing electrode fabrication techniques, and improving assembly methods to enhance performance and reduce production costs. Advanced manufacturing processes can lead to better quality control and increased energy density of the final battery product.

- Battery management systems for sodium-ion batteries: Specialized battery management systems are being developed to optimize the performance and longevity of sodium-ion batteries. These systems monitor and control various parameters such as voltage, current, and temperature to ensure safe and efficient operation. Advanced algorithms and sensing technologies are employed to maximize the battery's capacity utilization and prevent degradation.

- Integration of sodium-ion batteries in energy storage systems: Research is focused on integrating sodium-ion batteries into various energy storage applications, including grid-scale storage and electric vehicles. This involves developing scalable battery pack designs, thermal management systems, and power electronics tailored for sodium-ion technology. The goal is to create efficient and cost-effective energy storage solutions that can compete with or complement existing lithium-ion battery systems.

02 Electrolyte formulations for sodium-ion batteries

Innovative electrolyte formulations play a key role in sodium-ion battery performance. These formulations aim to improve ionic conductivity, electrochemical stability, and safety. Research focuses on developing new electrolyte compositions, additives, and solid electrolytes to enhance battery efficiency and lifespan.Expand Specific Solutions03 Battery management systems for sodium-ion batteries

Advanced battery management systems are essential for optimizing the performance and safety of sodium-ion batteries. These systems involve sophisticated control algorithms, monitoring techniques, and thermal management strategies to enhance battery efficiency, longevity, and reliability in various applications.Expand Specific Solutions04 Manufacturing processes for sodium-ion batteries

Innovative manufacturing techniques are being developed to improve the production efficiency and quality of sodium-ion batteries. These processes focus on scalable methods for electrode fabrication, cell assembly, and quality control, aiming to reduce costs and enhance the commercial viability of sodium-ion technology.Expand Specific Solutions05 Integration of sodium-ion batteries in energy storage systems

Research is ongoing to effectively integrate sodium-ion batteries into various energy storage applications. This includes developing hybrid systems, grid-scale storage solutions, and adapting sodium-ion technology for electric vehicles and portable electronics. The focus is on leveraging the unique advantages of sodium-ion batteries in different use cases.Expand Specific Solutions

Key Players in Sodium Ion Battery Industry

The research on sodium-ion batteries in global energy distribution networks is in an emerging stage, with the market showing significant growth potential. The technology is still evolving, with various companies and research institutions actively developing and refining sodium-ion battery solutions. Key players like Contemporary Amperex Technology Co., Ltd., Faradion Ltd., and Northvolt AB are driving innovation in this field. The market size is expanding as the demand for sustainable energy storage solutions increases. While the technology is not yet as mature as lithium-ion batteries, rapid advancements are being made, particularly in improving energy density, cycle life, and cost-effectiveness. The competitive landscape is diverse, with both established battery manufacturers and specialized startups vying for market share in this promising sector.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a first-generation sodium-ion battery with an energy density of up to 160Wh/kg[1]. Their innovative AB battery pack solution integrates sodium-ion and lithium-ion cells, leveraging the advantages of both chemistries. The company's sodium-ion batteries feature a hard carbon anode, a cathode material with a higher specific capacity, and an advanced electrolyte with high-efficiency ion transport properties[2]. CATL has also implemented large-scale production techniques to enhance the stability and long cycle life of these batteries, aiming to achieve energy densities exceeding 200Wh/kg in future iterations[3].

Strengths: High energy density for sodium-ion technology, innovative hybrid battery solutions, and established large-scale production capabilities. Weaknesses: Still lower energy density compared to lithium-ion batteries, and potential challenges in raw material supply chain for large-scale production.

Faradion Ltd.

Technical Solution: Faradion has pioneered a proprietary sodium-ion technology that offers a cost-effective and sustainable alternative to lithium-ion batteries. Their batteries utilize a layered oxide cathode and hard carbon anode, achieving energy densities comparable to lithium-ion phosphate batteries[4]. Faradion's technology boasts a wide operating temperature range (-30°C to +60°C) and improved safety characteristics due to the absence of lithium[5]. The company has developed scalable manufacturing processes and has demonstrated the feasibility of their technology in various applications, including electric vehicles and grid storage systems[6].

Strengths: Cost-effective technology, wide operating temperature range, and improved safety profile. Weaknesses: Lower energy density compared to advanced lithium-ion chemistries, and potential challenges in scaling up production to compete with established lithium-ion manufacturers.

Innovations in Sodium Ion Battery Materials

Sodium ion battery

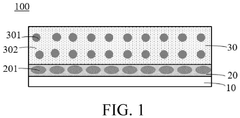

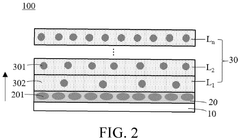

PatentInactiveIN6852CHENP2011A

Innovation

- A sodium ion battery design using an aluminum or aluminum alloy negative electrode current collector with a carbonaceous material capable of being doped and dedoped with sodium ions, along with a sodium inorganic compound positive electrode active material, to enhance cycle life and reduce costs.

Positive electrode sheet for sodium ion battery, sodium ion battery, and device

PatentPendingEP4579787A2

Innovation

- A positive electrode sheet for sodium ion batteries is designed with a sodium-rich transition metal oxide and a sacrificial positive electrode sodium replenishment agent arranged in specific layers to optimize sodium replenishment efficiency, reducing gas production and impedance, and improving energy density and discharge capacity.

Environmental Impact of Sodium Ion Batteries

The environmental impact of sodium-ion batteries in global energy distribution networks is a critical consideration as these batteries gain traction as a potential alternative to lithium-ion batteries. One of the primary advantages of sodium-ion batteries is their reduced environmental footprint compared to their lithium-ion counterparts. The abundance of sodium in the Earth's crust and oceans means that the extraction process for this raw material is less environmentally damaging than lithium mining, which often involves extensive water use and potential habitat disruption.

In the manufacturing phase, sodium-ion batteries require less energy-intensive processes, contributing to a lower carbon footprint. The production of cathode materials for sodium-ion batteries typically involves lower temperatures and less complex synthesis methods, reducing overall energy consumption and greenhouse gas emissions. Additionally, the use of more common and less toxic materials in sodium-ion batteries minimizes the risk of environmental contamination during production and disposal.

The integration of sodium-ion batteries into global energy distribution networks can potentially lead to significant environmental benefits. These batteries can facilitate the increased adoption of renewable energy sources by providing efficient and cost-effective energy storage solutions. This capability is crucial for managing the intermittent nature of solar and wind power, thereby reducing reliance on fossil fuel-based power generation and decreasing overall carbon emissions from the energy sector.

End-of-life considerations for sodium-ion batteries also present environmental advantages. The materials used in these batteries are generally more recyclable and less hazardous than those in lithium-ion batteries. This characteristic simplifies the recycling process and reduces the environmental impact of battery disposal. Furthermore, the potential for second-life applications of sodium-ion batteries in less demanding roles, such as stationary energy storage, can extend their useful life and delay the need for recycling or disposal.

However, it is important to note that the large-scale deployment of sodium-ion batteries is not without environmental challenges. The increased demand for sodium and other raw materials could lead to intensified mining activities, potentially causing localized environmental impacts. Additionally, the energy and resources required for the mass production and distribution of these batteries must be carefully managed to ensure a net positive environmental outcome.

As research and development in sodium-ion battery technology continue, efforts are being made to further enhance their environmental performance. This includes improving energy density to reduce material requirements, developing more efficient recycling processes, and exploring the use of sustainable and bio-based materials in battery components. These advancements will be crucial in maximizing the positive environmental impact of sodium-ion batteries in global energy distribution networks.

In the manufacturing phase, sodium-ion batteries require less energy-intensive processes, contributing to a lower carbon footprint. The production of cathode materials for sodium-ion batteries typically involves lower temperatures and less complex synthesis methods, reducing overall energy consumption and greenhouse gas emissions. Additionally, the use of more common and less toxic materials in sodium-ion batteries minimizes the risk of environmental contamination during production and disposal.

The integration of sodium-ion batteries into global energy distribution networks can potentially lead to significant environmental benefits. These batteries can facilitate the increased adoption of renewable energy sources by providing efficient and cost-effective energy storage solutions. This capability is crucial for managing the intermittent nature of solar and wind power, thereby reducing reliance on fossil fuel-based power generation and decreasing overall carbon emissions from the energy sector.

End-of-life considerations for sodium-ion batteries also present environmental advantages. The materials used in these batteries are generally more recyclable and less hazardous than those in lithium-ion batteries. This characteristic simplifies the recycling process and reduces the environmental impact of battery disposal. Furthermore, the potential for second-life applications of sodium-ion batteries in less demanding roles, such as stationary energy storage, can extend their useful life and delay the need for recycling or disposal.

However, it is important to note that the large-scale deployment of sodium-ion batteries is not without environmental challenges. The increased demand for sodium and other raw materials could lead to intensified mining activities, potentially causing localized environmental impacts. Additionally, the energy and resources required for the mass production and distribution of these batteries must be carefully managed to ensure a net positive environmental outcome.

As research and development in sodium-ion battery technology continue, efforts are being made to further enhance their environmental performance. This includes improving energy density to reduce material requirements, developing more efficient recycling processes, and exploring the use of sustainable and bio-based materials in battery components. These advancements will be crucial in maximizing the positive environmental impact of sodium-ion batteries in global energy distribution networks.

Regulatory Framework for Grid Energy Storage Technologies

The regulatory framework for grid energy storage technologies, particularly in the context of sodium-ion batteries in global energy distribution networks, is a complex and evolving landscape. As these technologies gain prominence in the energy sector, governments and regulatory bodies worldwide are adapting their policies to accommodate and promote their integration.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are developing standards for energy storage systems, including those based on sodium-ion technology. These standards aim to ensure safety, reliability, and interoperability across different markets and applications.

In the United States, the Federal Energy Regulatory Commission (FERC) has taken significant steps to facilitate the integration of energy storage into the grid. Order 841, issued in 2018, requires regional transmission organizations and independent system operators to establish market rules that recognize the physical and operational characteristics of electric storage resources.

The European Union has also been proactive in developing a regulatory framework for energy storage. The Clean Energy Package, adopted in 2019, includes provisions that recognize energy storage as a distinct asset class and prohibit network operators from owning or operating storage facilities, with some exceptions.

In Asia, countries like China and South Korea have implemented supportive policies for energy storage development. China's National Energy Administration has set targets for energy storage deployment and provides subsidies for certain projects. South Korea has introduced a Renewable Energy Certificate (REC) multiplier for energy storage systems connected to renewable energy sources.

Specific to sodium-ion batteries, regulatory bodies are beginning to recognize their potential as a more sustainable and cost-effective alternative to lithium-ion batteries. However, the regulatory framework is still in its early stages. Safety standards and disposal regulations are being developed, drawing on experience from lithium-ion battery regulations while accounting for the unique properties of sodium-ion technology.

Environmental regulations are also shaping the landscape for sodium-ion batteries. Their lower environmental impact compared to lithium-ion batteries, particularly in terms of raw material sourcing and end-of-life disposal, is likely to be reflected in future regulatory frameworks. This could include preferential treatment in carbon accounting schemes or recycling regulations.

As the technology matures, regulators will need to address specific challenges related to sodium-ion batteries in grid applications. These may include guidelines for large-scale deployment, integration with existing grid infrastructure, and performance standards for grid services such as frequency regulation and peak shaving.

At the international level, organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE) are developing standards for energy storage systems, including those based on sodium-ion technology. These standards aim to ensure safety, reliability, and interoperability across different markets and applications.

In the United States, the Federal Energy Regulatory Commission (FERC) has taken significant steps to facilitate the integration of energy storage into the grid. Order 841, issued in 2018, requires regional transmission organizations and independent system operators to establish market rules that recognize the physical and operational characteristics of electric storage resources.

The European Union has also been proactive in developing a regulatory framework for energy storage. The Clean Energy Package, adopted in 2019, includes provisions that recognize energy storage as a distinct asset class and prohibit network operators from owning or operating storage facilities, with some exceptions.

In Asia, countries like China and South Korea have implemented supportive policies for energy storage development. China's National Energy Administration has set targets for energy storage deployment and provides subsidies for certain projects. South Korea has introduced a Renewable Energy Certificate (REC) multiplier for energy storage systems connected to renewable energy sources.

Specific to sodium-ion batteries, regulatory bodies are beginning to recognize their potential as a more sustainable and cost-effective alternative to lithium-ion batteries. However, the regulatory framework is still in its early stages. Safety standards and disposal regulations are being developed, drawing on experience from lithium-ion battery regulations while accounting for the unique properties of sodium-ion technology.

Environmental regulations are also shaping the landscape for sodium-ion batteries. Their lower environmental impact compared to lithium-ion batteries, particularly in terms of raw material sourcing and end-of-life disposal, is likely to be reflected in future regulatory frameworks. This could include preferential treatment in carbon accounting schemes or recycling regulations.

As the technology matures, regulators will need to address specific challenges related to sodium-ion batteries in grid applications. These may include guidelines for large-scale deployment, integration with existing grid infrastructure, and performance standards for grid services such as frequency regulation and peak shaving.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!