Sodium Ion Battery Pack Design for Modular Applications

AUG 7, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Evolution and Objectives

Sodium-ion batteries have emerged as a promising alternative to lithium-ion batteries, driven by the increasing demand for sustainable and cost-effective energy storage solutions. The evolution of sodium-ion battery technology can be traced back to the 1980s, but significant advancements have been made in recent years, particularly in the realm of materials science and electrochemistry.

The development of sodium-ion batteries has been motivated by several factors, including the abundance and low cost of sodium resources, as well as the potential for improved safety compared to lithium-ion batteries. Early research focused on identifying suitable electrode materials and electrolytes that could efficiently store and release sodium ions. Over time, researchers have made substantial progress in developing high-performance cathode and anode materials, as well as stable electrolytes that enable long-term cycling stability.

One of the key milestones in sodium-ion battery evolution was the development of layered oxide cathode materials, which demonstrated improved energy density and cycling performance. Concurrently, advancements in anode materials, such as hard carbons and alloy-based materials, have contributed to enhanced capacity and rate capability.

The objectives of sodium-ion battery pack design for modular applications are multifaceted and ambitious. Primarily, the goal is to create a versatile and scalable energy storage solution that can be easily integrated into various applications, ranging from grid-scale storage to electric vehicles and portable electronics. This modular approach aims to provide flexibility in terms of capacity, voltage, and form factor, allowing for customization based on specific application requirements.

Another critical objective is to achieve performance metrics comparable to or surpassing those of lithium-ion batteries, particularly in terms of energy density, power density, and cycle life. This involves optimizing cell chemistry, electrode design, and battery management systems to maximize the inherent advantages of sodium-ion technology.

Cost-effectiveness is a paramount objective in sodium-ion battery pack design. By leveraging abundant and inexpensive raw materials, coupled with simplified manufacturing processes, the aim is to significantly reduce the overall cost of energy storage systems. This cost reduction is crucial for widespread adoption and commercialization of sodium-ion technology.

Safety and sustainability are also key objectives in the development of sodium-ion battery packs. The inherent safety advantages of sodium-ion chemistry, such as lower reactivity and reduced fire risk, are being further enhanced through careful cell and pack design. Additionally, the use of environmentally friendly materials and the potential for easier recycling align with the growing emphasis on sustainable energy solutions.

As the technology continues to evolve, researchers and engineers are focusing on addressing remaining challenges, such as improving the energy density at the pack level, enhancing low-temperature performance, and developing advanced battery management systems tailored to the unique characteristics of sodium-ion cells. These ongoing efforts are aimed at realizing the full potential of sodium-ion batteries and establishing them as a viable and competitive alternative in the energy storage landscape.

The development of sodium-ion batteries has been motivated by several factors, including the abundance and low cost of sodium resources, as well as the potential for improved safety compared to lithium-ion batteries. Early research focused on identifying suitable electrode materials and electrolytes that could efficiently store and release sodium ions. Over time, researchers have made substantial progress in developing high-performance cathode and anode materials, as well as stable electrolytes that enable long-term cycling stability.

One of the key milestones in sodium-ion battery evolution was the development of layered oxide cathode materials, which demonstrated improved energy density and cycling performance. Concurrently, advancements in anode materials, such as hard carbons and alloy-based materials, have contributed to enhanced capacity and rate capability.

The objectives of sodium-ion battery pack design for modular applications are multifaceted and ambitious. Primarily, the goal is to create a versatile and scalable energy storage solution that can be easily integrated into various applications, ranging from grid-scale storage to electric vehicles and portable electronics. This modular approach aims to provide flexibility in terms of capacity, voltage, and form factor, allowing for customization based on specific application requirements.

Another critical objective is to achieve performance metrics comparable to or surpassing those of lithium-ion batteries, particularly in terms of energy density, power density, and cycle life. This involves optimizing cell chemistry, electrode design, and battery management systems to maximize the inherent advantages of sodium-ion technology.

Cost-effectiveness is a paramount objective in sodium-ion battery pack design. By leveraging abundant and inexpensive raw materials, coupled with simplified manufacturing processes, the aim is to significantly reduce the overall cost of energy storage systems. This cost reduction is crucial for widespread adoption and commercialization of sodium-ion technology.

Safety and sustainability are also key objectives in the development of sodium-ion battery packs. The inherent safety advantages of sodium-ion chemistry, such as lower reactivity and reduced fire risk, are being further enhanced through careful cell and pack design. Additionally, the use of environmentally friendly materials and the potential for easier recycling align with the growing emphasis on sustainable energy solutions.

As the technology continues to evolve, researchers and engineers are focusing on addressing remaining challenges, such as improving the energy density at the pack level, enhancing low-temperature performance, and developing advanced battery management systems tailored to the unique characteristics of sodium-ion cells. These ongoing efforts are aimed at realizing the full potential of sodium-ion batteries and establishing them as a viable and competitive alternative in the energy storage landscape.

Market Demand for Modular Energy Storage

The market demand for modular energy storage solutions has been experiencing significant growth in recent years, driven by the increasing need for flexible and scalable power systems across various industries. This trend is particularly evident in the context of sodium-ion battery pack design for modular applications, which offers a promising alternative to traditional lithium-ion batteries.

The modular energy storage market is primarily fueled by the rapid expansion of renewable energy sources, such as solar and wind power. These intermittent energy sources require efficient storage solutions to ensure a stable and reliable power supply. Modular sodium-ion battery packs are well-positioned to meet this demand due to their scalability, cost-effectiveness, and environmental friendliness.

In the electric vehicle (EV) sector, there is a growing interest in modular battery designs that can be easily swapped or upgraded. This approach allows for more flexible vehicle configurations and potentially longer lifespans for EVs. Sodium-ion battery packs, with their modular design capabilities, are attracting attention from automotive manufacturers looking to diversify their battery technologies and reduce dependency on lithium-ion batteries.

The telecommunications industry is another key driver of demand for modular energy storage. As 5G networks continue to expand, there is an increasing need for reliable backup power solutions that can be easily deployed and scaled. Modular sodium-ion battery packs offer an attractive option for telecom companies seeking to enhance their infrastructure resilience while minimizing operational costs.

In the residential and commercial building sectors, the concept of smart grids and distributed energy resources is gaining traction. Modular energy storage systems, including those based on sodium-ion technology, are becoming essential components of these advanced energy management solutions. They enable better integration of renewable energy sources, peak shaving, and improved grid stability.

The industrial sector is also showing strong interest in modular energy storage solutions. Manufacturing facilities, data centers, and other energy-intensive operations are exploring ways to optimize their power consumption and reduce reliance on the grid. Modular sodium-ion battery packs offer the flexibility to scale storage capacity as needed, making them an attractive option for industrial applications.

Emerging markets, particularly in regions with less developed power infrastructure, represent a significant opportunity for modular energy storage solutions. These areas often require off-grid or micro-grid systems that can be easily transported and installed. The modularity and relative abundance of sodium compared to lithium make sodium-ion battery packs a compelling choice for these markets.

As the global focus on sustainability and circular economy principles intensifies, the demand for recyclable and environmentally friendly energy storage solutions is expected to grow. Sodium-ion batteries, with their potential for easier recycling and reduced environmental impact compared to lithium-ion batteries, are well-positioned to capitalize on this trend in the modular energy storage market.

The modular energy storage market is primarily fueled by the rapid expansion of renewable energy sources, such as solar and wind power. These intermittent energy sources require efficient storage solutions to ensure a stable and reliable power supply. Modular sodium-ion battery packs are well-positioned to meet this demand due to their scalability, cost-effectiveness, and environmental friendliness.

In the electric vehicle (EV) sector, there is a growing interest in modular battery designs that can be easily swapped or upgraded. This approach allows for more flexible vehicle configurations and potentially longer lifespans for EVs. Sodium-ion battery packs, with their modular design capabilities, are attracting attention from automotive manufacturers looking to diversify their battery technologies and reduce dependency on lithium-ion batteries.

The telecommunications industry is another key driver of demand for modular energy storage. As 5G networks continue to expand, there is an increasing need for reliable backup power solutions that can be easily deployed and scaled. Modular sodium-ion battery packs offer an attractive option for telecom companies seeking to enhance their infrastructure resilience while minimizing operational costs.

In the residential and commercial building sectors, the concept of smart grids and distributed energy resources is gaining traction. Modular energy storage systems, including those based on sodium-ion technology, are becoming essential components of these advanced energy management solutions. They enable better integration of renewable energy sources, peak shaving, and improved grid stability.

The industrial sector is also showing strong interest in modular energy storage solutions. Manufacturing facilities, data centers, and other energy-intensive operations are exploring ways to optimize their power consumption and reduce reliance on the grid. Modular sodium-ion battery packs offer the flexibility to scale storage capacity as needed, making them an attractive option for industrial applications.

Emerging markets, particularly in regions with less developed power infrastructure, represent a significant opportunity for modular energy storage solutions. These areas often require off-grid or micro-grid systems that can be easily transported and installed. The modularity and relative abundance of sodium compared to lithium make sodium-ion battery packs a compelling choice for these markets.

As the global focus on sustainability and circular economy principles intensifies, the demand for recyclable and environmentally friendly energy storage solutions is expected to grow. Sodium-ion batteries, with their potential for easier recycling and reduced environmental impact compared to lithium-ion batteries, are well-positioned to capitalize on this trend in the modular energy storage market.

Current Challenges in Sodium Ion Battery Pack Design

The development of sodium-ion battery pack design for modular applications faces several significant challenges that need to be addressed to ensure widespread adoption and commercial viability. One of the primary obstacles is the lower energy density of sodium-ion batteries compared to their lithium-ion counterparts. This limitation necessitates larger battery packs to achieve equivalent energy storage, potentially compromising the modularity and flexibility of the design.

Another critical challenge lies in the thermal management of sodium-ion battery packs. These batteries tend to generate more heat during operation, requiring more sophisticated cooling systems. This increased thermal output complicates the design of compact, modular battery packs and may impact the overall efficiency and lifespan of the batteries.

The stability and longevity of sodium-ion batteries also present hurdles in pack design. Current sodium-ion chemistries often exhibit faster capacity fade and shorter cycle life compared to established lithium-ion technologies. This degradation pattern necessitates careful consideration in the pack design to ensure consistent performance and longevity across all modules, potentially requiring more frequent replacements or maintenance.

Balancing and management systems for sodium-ion battery packs pose another significant challenge. The unique characteristics of sodium-ion cells, including their voltage profiles and state-of-charge indicators, require specialized battery management systems (BMS). Developing BMS solutions that can accurately monitor and control sodium-ion cells while maintaining modularity and scalability is a complex task.

The integration of sodium-ion battery packs into existing infrastructure and applications designed for lithium-ion batteries presents additional challenges. Differences in voltage ranges, charging protocols, and safety considerations necessitate adaptations in both hardware and software interfaces. This compatibility issue can hinder the seamless adoption of sodium-ion technology in modular applications.

Safety concerns also play a crucial role in sodium-ion battery pack design. While generally considered safer than lithium-ion batteries due to lower reactivity, sodium-ion batteries still require robust safety measures. Designing modular packs that maintain safety integrity across various configurations and use cases is essential for widespread acceptance.

Lastly, the manufacturing and supply chain for sodium-ion battery components are less mature compared to the established lithium-ion industry. This immaturity can lead to challenges in sourcing consistent, high-quality materials and components for modular pack designs, potentially affecting production scalability and cost-effectiveness.

Another critical challenge lies in the thermal management of sodium-ion battery packs. These batteries tend to generate more heat during operation, requiring more sophisticated cooling systems. This increased thermal output complicates the design of compact, modular battery packs and may impact the overall efficiency and lifespan of the batteries.

The stability and longevity of sodium-ion batteries also present hurdles in pack design. Current sodium-ion chemistries often exhibit faster capacity fade and shorter cycle life compared to established lithium-ion technologies. This degradation pattern necessitates careful consideration in the pack design to ensure consistent performance and longevity across all modules, potentially requiring more frequent replacements or maintenance.

Balancing and management systems for sodium-ion battery packs pose another significant challenge. The unique characteristics of sodium-ion cells, including their voltage profiles and state-of-charge indicators, require specialized battery management systems (BMS). Developing BMS solutions that can accurately monitor and control sodium-ion cells while maintaining modularity and scalability is a complex task.

The integration of sodium-ion battery packs into existing infrastructure and applications designed for lithium-ion batteries presents additional challenges. Differences in voltage ranges, charging protocols, and safety considerations necessitate adaptations in both hardware and software interfaces. This compatibility issue can hinder the seamless adoption of sodium-ion technology in modular applications.

Safety concerns also play a crucial role in sodium-ion battery pack design. While generally considered safer than lithium-ion batteries due to lower reactivity, sodium-ion batteries still require robust safety measures. Designing modular packs that maintain safety integrity across various configurations and use cases is essential for widespread acceptance.

Lastly, the manufacturing and supply chain for sodium-ion battery components are less mature compared to the established lithium-ion industry. This immaturity can lead to challenges in sourcing consistent, high-quality materials and components for modular pack designs, potentially affecting production scalability and cost-effectiveness.

Existing Modular Battery Pack Solutions

01 Modular design for sodium-ion battery packs

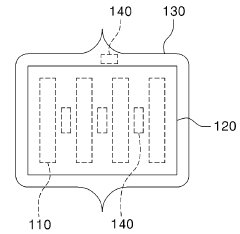

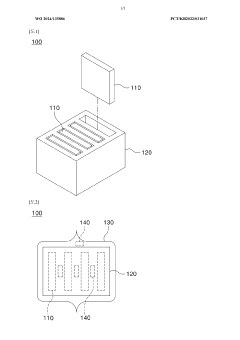

Modular designs for sodium-ion battery packs allow for flexible configuration and easy maintenance. These designs typically involve standardized battery modules that can be easily assembled, replaced, or scaled up to meet different energy storage requirements. This approach enhances the versatility and serviceability of sodium-ion battery systems.- Modular battery pack design: Sodium-ion battery packs are designed with a modular structure, allowing for easy assembly, disassembly, and replacement of individual modules. This approach enhances flexibility in battery pack configuration, simplifies maintenance, and enables scalability for different energy storage requirements.

- Thermal management systems: Innovative thermal management solutions are integrated into sodium-ion battery pack modules to maintain optimal operating temperatures. These systems may include advanced cooling mechanisms, heat dissipation materials, or thermal regulation controls to enhance battery performance and longevity.

- Battery management system integration: Modular sodium-ion battery packs incorporate sophisticated battery management systems (BMS) to monitor and control individual cells and modules. The BMS ensures balanced charging, discharging, and overall pack health, contributing to improved efficiency and safety of the battery system.

- Interconnection and wiring optimization: Advanced interconnection techniques and optimized wiring layouts are employed in modular sodium-ion battery packs. These improvements reduce internal resistance, enhance current distribution, and facilitate easier module replacement or reconfiguration of the battery pack.

- Structural design for improved safety: Modular sodium-ion battery packs feature enhanced structural designs to improve overall safety. This includes reinforced casings, impact-resistant materials, and innovative cell arrangement patterns to minimize the risk of thermal runaway and contain potential failures within individual modules.

02 Thermal management in modular sodium-ion battery packs

Effective thermal management is crucial for the performance and safety of modular sodium-ion battery packs. This involves designing cooling systems that can efficiently dissipate heat from individual modules and maintain optimal operating temperatures across the entire pack. Advanced thermal management solutions may include liquid cooling, phase change materials, or intelligent temperature control systems.Expand Specific Solutions03 Battery management systems for modular sodium-ion packs

Sophisticated battery management systems (BMS) are essential for modular sodium-ion battery packs. These systems monitor and control individual modules, ensuring balanced charging, discharging, and overall pack health. Advanced BMS may incorporate machine learning algorithms for predictive maintenance and optimization of pack performance.Expand Specific Solutions04 Interconnection and scalability of sodium-ion battery modules

Innovative interconnection methods for sodium-ion battery modules enable seamless scalability and flexibility in pack design. This includes standardized electrical and mechanical interfaces that allow for easy module addition or replacement. Advanced interconnection technologies may also incorporate features for rapid assembly, improved current distribution, and enhanced safety.Expand Specific Solutions05 Safety features in modular sodium-ion battery packs

Safety is a critical aspect of modular sodium-ion battery pack design. This includes implementing features such as isolation mechanisms between modules, robust enclosures, and integrated fire suppression systems. Advanced safety designs may also incorporate smart sensors for early detection of potential issues and automatic shutdown capabilities at the module level.Expand Specific Solutions

Key Players in Sodium Ion Battery Industry

The sodium-ion battery pack design for modular applications is in an early development stage, with a growing market potential due to increasing demand for sustainable energy storage solutions. The technology's maturity is still evolving, with key players like Contemporary Amperex Technology Co., Ltd., Faradion Ltd., and Samsung SDI Co., Ltd. leading research and development efforts. These companies are focusing on improving energy density, cycle life, and cost-effectiveness of sodium-ion batteries. The competitive landscape is characterized by a mix of established battery manufacturers and innovative startups, each striving to overcome technical challenges and scale up production. As the technology progresses, we can expect increased competition and potential collaborations to accelerate commercialization and market adoption.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a first-generation sodium-ion battery with an energy density of up to 160Wh/kg[1]. Their modular battery pack design incorporates both sodium-ion and lithium-ion cells in a single pack, leveraging the AB battery system[2]. This system allows for the complementary advantages of both battery types, with sodium-ion cells providing high power and fast charging capabilities, while lithium-ion cells offer high energy density. The modular design enables flexible configuration and easy scaling for various applications, from electric vehicles to large-scale energy storage systems[3]. CATL's sodium-ion batteries use Prussian white material for the cathode and hard carbon for the anode, with optimized electrolyte systems to improve overall performance[4].

Strengths: High power density, fast charging capability, low-temperature performance, and cost-effectiveness. Weaknesses: Lower energy density compared to lithium-ion batteries, which may limit range in some applications.

Faradion Ltd.

Technical Solution: Faradion has pioneered a proprietary sodium-ion technology that focuses on high energy density and long cycle life. Their modular battery pack design utilizes pouch cells with a layered oxide cathode and hard carbon anode[5]. The company has developed a unique electrolyte formulation that enhances the stability of the electrode-electrolyte interface, leading to improved cycle life and performance[6]. Faradion's modular approach allows for scalable solutions, ranging from small portable devices to large-scale grid storage systems. Their battery management system (BMS) is specifically optimized for sodium-ion chemistry, ensuring efficient operation and longevity of the battery packs[7]. The company has also focused on developing sodium-ion batteries that can operate effectively in extreme temperatures, making them suitable for a wide range of applications[8].

Strengths: Wide operating temperature range, potentially lower cost due to abundant raw materials, and scalability. Weaknesses: Lower volumetric energy density compared to some lithium-ion technologies, which may impact space efficiency in certain applications.

Core Innovations in Sodium Ion Cell Chemistry

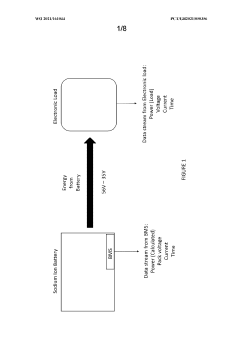

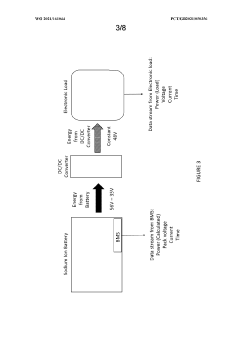

Sodium-ion battery pack

PatentWO2021161044A1

Innovation

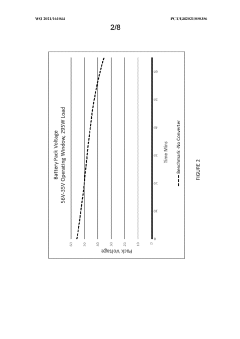

- Incorporating voltage converters, specifically DC/DC converters, within the sodium-ion battery pack to align the output voltage with electronic components' requirements, allowing sodium-ion cells to operate within a wider voltage range and increasing the usable energy density and specific energy of the battery pack.

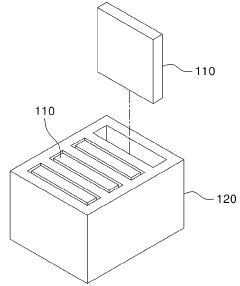

Battery module including cartridges for flexible batteries

PatentWO2024135886A1

Innovation

- A battery module design featuring flexible sodium battery cells housed in cartridges mounted on a rack with non-conductive, moisture-absorbing packaging made of flexible materials like polyolefin or PVC, and silica gel to prevent moisture ingress and electrolyte leakage.

Safety and Performance Standards for Na-ion Batteries

The development of safety and performance standards for sodium-ion (Na-ion) batteries is crucial for their widespread adoption in modular applications. These standards ensure the reliability, safety, and consistent performance of Na-ion battery packs across various use cases.

Safety standards for Na-ion batteries focus on thermal stability, electrical safety, and mechanical integrity. Thermal runaway prevention is a key consideration, with standards specifying temperature limits and heat dissipation requirements. Electrical safety standards address issues such as short circuit protection, overcharge prevention, and voltage regulation. Mechanical integrity standards ensure the battery pack can withstand physical stress, vibration, and impact.

Performance standards for Na-ion batteries encompass energy density, power output, cycle life, and charge/discharge rates. These metrics are essential for comparing Na-ion technology with existing lithium-ion solutions and determining their suitability for specific applications. Standards also define testing protocols for capacity retention, self-discharge rates, and performance under various environmental conditions.

Interoperability standards are particularly important for modular applications. These standards define common interfaces, connectors, and communication protocols, enabling seamless integration of Na-ion battery packs into diverse systems. Standardization of form factors and electrical characteristics facilitates the development of modular, scalable energy storage solutions.

Environmental and sustainability standards are emerging as critical components of Na-ion battery regulations. These include guidelines for recyclability, material sourcing, and end-of-life management. As Na-ion technology gains traction, standards are being developed to minimize environmental impact and promote circular economy principles in battery production and disposal.

Certification processes and compliance testing procedures are being established to ensure adherence to these standards. Third-party testing and validation protocols are crucial for building trust in Na-ion technology and facilitating its adoption across industries. These processes verify that battery packs meet the required safety and performance criteria before market entry.

As Na-ion technology evolves, standards must remain flexible and adaptable. Regular reviews and updates to safety and performance standards are necessary to keep pace with technological advancements and emerging applications. Collaboration between industry stakeholders, research institutions, and regulatory bodies is essential for developing comprehensive and effective standards that support the growth of Na-ion battery technology in modular applications.

Safety standards for Na-ion batteries focus on thermal stability, electrical safety, and mechanical integrity. Thermal runaway prevention is a key consideration, with standards specifying temperature limits and heat dissipation requirements. Electrical safety standards address issues such as short circuit protection, overcharge prevention, and voltage regulation. Mechanical integrity standards ensure the battery pack can withstand physical stress, vibration, and impact.

Performance standards for Na-ion batteries encompass energy density, power output, cycle life, and charge/discharge rates. These metrics are essential for comparing Na-ion technology with existing lithium-ion solutions and determining their suitability for specific applications. Standards also define testing protocols for capacity retention, self-discharge rates, and performance under various environmental conditions.

Interoperability standards are particularly important for modular applications. These standards define common interfaces, connectors, and communication protocols, enabling seamless integration of Na-ion battery packs into diverse systems. Standardization of form factors and electrical characteristics facilitates the development of modular, scalable energy storage solutions.

Environmental and sustainability standards are emerging as critical components of Na-ion battery regulations. These include guidelines for recyclability, material sourcing, and end-of-life management. As Na-ion technology gains traction, standards are being developed to minimize environmental impact and promote circular economy principles in battery production and disposal.

Certification processes and compliance testing procedures are being established to ensure adherence to these standards. Third-party testing and validation protocols are crucial for building trust in Na-ion technology and facilitating its adoption across industries. These processes verify that battery packs meet the required safety and performance criteria before market entry.

As Na-ion technology evolves, standards must remain flexible and adaptable. Regular reviews and updates to safety and performance standards are necessary to keep pace with technological advancements and emerging applications. Collaboration between industry stakeholders, research institutions, and regulatory bodies is essential for developing comprehensive and effective standards that support the growth of Na-ion battery technology in modular applications.

Environmental Impact of Sodium Ion Battery Production

The environmental impact of sodium-ion battery production is a crucial consideration in the development and adoption of this emerging energy storage technology. Compared to traditional lithium-ion batteries, sodium-ion batteries offer several potential environmental advantages, primarily due to the abundance and widespread distribution of sodium resources.

Sodium is the sixth most abundant element in the Earth's crust, making it significantly more accessible and less geographically concentrated than lithium. This abundance translates to reduced environmental stress associated with resource extraction. Mining operations for sodium are generally less invasive and require less energy input compared to lithium extraction, particularly when considering the water-intensive processes used in lithium brine extraction.

The production of sodium-ion batteries also has a lower carbon footprint compared to lithium-ion batteries. The energy-intensive processes required for lithium extraction and refinement contribute significantly to the overall environmental impact of lithium-ion battery production. In contrast, sodium compounds used in battery production can be sourced from more environmentally friendly processes, such as the chlor-alkali process, which is already widely used in various industries.

Another environmental benefit of sodium-ion battery production is the reduced reliance on critical and rare earth materials. While lithium-ion batteries often require cobalt and nickel, which are associated with significant environmental and social concerns in their extraction, sodium-ion batteries can be manufactured using more abundant and less problematic materials such as iron and manganese.

The end-of-life management of sodium-ion batteries also presents potential environmental advantages. The materials used in these batteries are generally less toxic and easier to recycle compared to those in lithium-ion batteries. This characteristic could lead to more efficient and less environmentally harmful recycling processes, contributing to a more circular economy in the battery industry.

However, it is important to note that the environmental impact of sodium-ion battery production is not entirely benign. The manufacturing process still requires energy and resources, and the large-scale production of these batteries would necessitate the development of new supply chains and production facilities. Additionally, the long-term environmental effects of widespread sodium-ion battery use and disposal are not yet fully understood, as the technology is still in its early stages of commercialization.

As research and development in sodium-ion battery technology continue, it is crucial to maintain a focus on minimizing environmental impacts throughout the entire life cycle of these batteries. This includes optimizing production processes, developing efficient recycling methods, and ensuring responsible sourcing of raw materials. By addressing these aspects, the sodium-ion battery industry can position itself as a more sustainable alternative to current energy storage technologies, aligning with global efforts to reduce carbon emissions and promote environmental stewardship.

Sodium is the sixth most abundant element in the Earth's crust, making it significantly more accessible and less geographically concentrated than lithium. This abundance translates to reduced environmental stress associated with resource extraction. Mining operations for sodium are generally less invasive and require less energy input compared to lithium extraction, particularly when considering the water-intensive processes used in lithium brine extraction.

The production of sodium-ion batteries also has a lower carbon footprint compared to lithium-ion batteries. The energy-intensive processes required for lithium extraction and refinement contribute significantly to the overall environmental impact of lithium-ion battery production. In contrast, sodium compounds used in battery production can be sourced from more environmentally friendly processes, such as the chlor-alkali process, which is already widely used in various industries.

Another environmental benefit of sodium-ion battery production is the reduced reliance on critical and rare earth materials. While lithium-ion batteries often require cobalt and nickel, which are associated with significant environmental and social concerns in their extraction, sodium-ion batteries can be manufactured using more abundant and less problematic materials such as iron and manganese.

The end-of-life management of sodium-ion batteries also presents potential environmental advantages. The materials used in these batteries are generally less toxic and easier to recycle compared to those in lithium-ion batteries. This characteristic could lead to more efficient and less environmentally harmful recycling processes, contributing to a more circular economy in the battery industry.

However, it is important to note that the environmental impact of sodium-ion battery production is not entirely benign. The manufacturing process still requires energy and resources, and the large-scale production of these batteries would necessitate the development of new supply chains and production facilities. Additionally, the long-term environmental effects of widespread sodium-ion battery use and disposal are not yet fully understood, as the technology is still in its early stages of commercialization.

As research and development in sodium-ion battery technology continue, it is crucial to maintain a focus on minimizing environmental impacts throughout the entire life cycle of these batteries. This includes optimizing production processes, developing efficient recycling methods, and ensuring responsible sourcing of raw materials. By addressing these aspects, the sodium-ion battery industry can position itself as a more sustainable alternative to current energy storage technologies, aligning with global efforts to reduce carbon emissions and promote environmental stewardship.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!