Precise Temperature Monitoring Techniques for Sodium Ion Batteries

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Temp Monitoring Background and Objectives

Temperature monitoring in sodium-ion batteries has become a critical aspect of battery management systems, driven by the increasing demand for safer and more efficient energy storage solutions. The evolution of this technology can be traced back to the early development of lithium-ion batteries, where temperature control was recognized as a key factor in preventing thermal runaway and ensuring optimal performance.

As sodium-ion batteries emerged as a promising alternative to lithium-ion batteries, the need for precise temperature monitoring techniques became even more pronounced. This is due to the unique characteristics of sodium-ion chemistry, which can be more sensitive to temperature fluctuations than its lithium-ion counterparts. The primary objective of temperature monitoring in sodium-ion batteries is to maintain the cells within their optimal operating range, typically between 20°C and 40°C, to ensure safety, longevity, and performance.

The development of temperature monitoring techniques for sodium-ion batteries has been driven by several factors. First, the push for higher energy densities and faster charging capabilities has increased the thermal stress on battery cells, making accurate temperature control crucial. Second, the automotive industry's adoption of electric vehicles has raised the bar for battery safety and reliability, necessitating more sophisticated monitoring systems.

Recent advancements in sensor technology have played a significant role in improving temperature monitoring precision. The integration of miniaturized thermistors and thermocouples directly into battery cells has allowed for more accurate and localized temperature measurements. Additionally, the development of fiber optic sensing technologies has opened up new possibilities for distributed temperature sensing across large battery packs.

The goals of current research in this field are multifaceted. One primary objective is to develop monitoring systems that can provide real-time, high-resolution temperature data across the entire battery pack. This would enable more effective thermal management strategies and early detection of potential issues. Another aim is to create predictive models that can anticipate temperature changes based on usage patterns and environmental conditions, allowing for proactive thermal management.

Furthermore, researchers are working on integrating temperature monitoring with other battery parameters, such as voltage and current, to create comprehensive battery management systems. These systems aim to optimize battery performance, extend lifespan, and enhance safety by considering the complex interplay between various operational factors.

As sodium-ion battery technology continues to mature, the focus on temperature monitoring techniques is expected to intensify. The ultimate goal is to develop robust, cost-effective, and highly accurate monitoring solutions that can be seamlessly integrated into next-generation energy storage systems, paving the way for wider adoption of sodium-ion batteries in various applications.

As sodium-ion batteries emerged as a promising alternative to lithium-ion batteries, the need for precise temperature monitoring techniques became even more pronounced. This is due to the unique characteristics of sodium-ion chemistry, which can be more sensitive to temperature fluctuations than its lithium-ion counterparts. The primary objective of temperature monitoring in sodium-ion batteries is to maintain the cells within their optimal operating range, typically between 20°C and 40°C, to ensure safety, longevity, and performance.

The development of temperature monitoring techniques for sodium-ion batteries has been driven by several factors. First, the push for higher energy densities and faster charging capabilities has increased the thermal stress on battery cells, making accurate temperature control crucial. Second, the automotive industry's adoption of electric vehicles has raised the bar for battery safety and reliability, necessitating more sophisticated monitoring systems.

Recent advancements in sensor technology have played a significant role in improving temperature monitoring precision. The integration of miniaturized thermistors and thermocouples directly into battery cells has allowed for more accurate and localized temperature measurements. Additionally, the development of fiber optic sensing technologies has opened up new possibilities for distributed temperature sensing across large battery packs.

The goals of current research in this field are multifaceted. One primary objective is to develop monitoring systems that can provide real-time, high-resolution temperature data across the entire battery pack. This would enable more effective thermal management strategies and early detection of potential issues. Another aim is to create predictive models that can anticipate temperature changes based on usage patterns and environmental conditions, allowing for proactive thermal management.

Furthermore, researchers are working on integrating temperature monitoring with other battery parameters, such as voltage and current, to create comprehensive battery management systems. These systems aim to optimize battery performance, extend lifespan, and enhance safety by considering the complex interplay between various operational factors.

As sodium-ion battery technology continues to mature, the focus on temperature monitoring techniques is expected to intensify. The ultimate goal is to develop robust, cost-effective, and highly accurate monitoring solutions that can be seamlessly integrated into next-generation energy storage systems, paving the way for wider adoption of sodium-ion batteries in various applications.

Market Demand for Sodium Ion Battery Temp Control

The market demand for precise temperature monitoring techniques in sodium ion batteries is driven by the growing interest in these batteries as a sustainable and cost-effective alternative to lithium-ion batteries. As the electric vehicle (EV) market expands and renewable energy storage solutions become more prevalent, the need for efficient and safe battery technologies has intensified. Sodium ion batteries offer advantages such as abundant raw materials, lower costs, and improved safety profiles, making them attractive for various applications.

Temperature control is crucial for the performance, safety, and longevity of sodium ion batteries. Accurate temperature monitoring enables optimal operating conditions, prevents thermal runaway, and extends battery life. This has created a significant market demand for advanced temperature monitoring techniques specifically tailored to sodium ion battery systems.

The automotive industry is a major driver of this demand, as EV manufacturers seek to improve battery performance and safety. Grid-scale energy storage systems also require precise temperature control to maintain efficiency and reliability. Additionally, consumer electronics and portable devices are potential markets for sodium ion batteries with advanced temperature monitoring capabilities.

Market analysts project substantial growth in the sodium ion battery market over the coming years, with some estimates suggesting a compound annual growth rate (CAGR) of over 20% through 2030. This growth is expected to directly correlate with increased demand for precise temperature monitoring techniques.

The demand for these monitoring systems is further fueled by stringent safety regulations and standards in the battery industry. Regulatory bodies and industry associations are emphasizing the importance of temperature management in battery systems, driving manufacturers to invest in advanced monitoring technologies.

Emerging trends in battery management systems (BMS) also contribute to the market demand. There is a growing focus on intelligent BMS that incorporate real-time temperature monitoring and predictive analytics. These systems not only enhance safety but also optimize battery performance and lifespan, making them highly desirable for end-users across various sectors.

As research and development in sodium ion battery technology progresses, there is an increasing need for more sophisticated and accurate temperature monitoring techniques. This includes the development of sensors capable of withstanding the unique chemical environment of sodium ion batteries and providing high-resolution temperature data across the entire battery pack.

The market is also seeing demand for integrated solutions that combine temperature monitoring with other critical parameters such as voltage and current. This holistic approach to battery management is becoming increasingly important as manufacturers seek to maximize the potential of sodium ion technology.

Temperature control is crucial for the performance, safety, and longevity of sodium ion batteries. Accurate temperature monitoring enables optimal operating conditions, prevents thermal runaway, and extends battery life. This has created a significant market demand for advanced temperature monitoring techniques specifically tailored to sodium ion battery systems.

The automotive industry is a major driver of this demand, as EV manufacturers seek to improve battery performance and safety. Grid-scale energy storage systems also require precise temperature control to maintain efficiency and reliability. Additionally, consumer electronics and portable devices are potential markets for sodium ion batteries with advanced temperature monitoring capabilities.

Market analysts project substantial growth in the sodium ion battery market over the coming years, with some estimates suggesting a compound annual growth rate (CAGR) of over 20% through 2030. This growth is expected to directly correlate with increased demand for precise temperature monitoring techniques.

The demand for these monitoring systems is further fueled by stringent safety regulations and standards in the battery industry. Regulatory bodies and industry associations are emphasizing the importance of temperature management in battery systems, driving manufacturers to invest in advanced monitoring technologies.

Emerging trends in battery management systems (BMS) also contribute to the market demand. There is a growing focus on intelligent BMS that incorporate real-time temperature monitoring and predictive analytics. These systems not only enhance safety but also optimize battery performance and lifespan, making them highly desirable for end-users across various sectors.

As research and development in sodium ion battery technology progresses, there is an increasing need for more sophisticated and accurate temperature monitoring techniques. This includes the development of sensors capable of withstanding the unique chemical environment of sodium ion batteries and providing high-resolution temperature data across the entire battery pack.

The market is also seeing demand for integrated solutions that combine temperature monitoring with other critical parameters such as voltage and current. This holistic approach to battery management is becoming increasingly important as manufacturers seek to maximize the potential of sodium ion technology.

Current Challenges in Na-ion Battery Temp Monitoring

Temperature monitoring in sodium-ion (Na-ion) batteries presents several significant challenges that researchers and engineers are currently grappling with. One of the primary issues is the lack of standardized temperature monitoring techniques specifically tailored for Na-ion batteries. Unlike their lithium-ion counterparts, Na-ion batteries have unique thermal characteristics that require specialized monitoring approaches.

The dynamic nature of Na-ion battery temperature profiles poses another challenge. During charge and discharge cycles, these batteries exhibit complex temperature fluctuations that are difficult to predict and monitor accurately. This variability makes it challenging to develop reliable temperature models and control systems, potentially compromising battery performance and safety.

Sensor placement and integration present additional hurdles. The optimal locations for temperature sensors within Na-ion cells are not yet well-established, and integrating sensors without disrupting battery performance or increasing manufacturing complexity remains a significant challenge. Moreover, the corrosive nature of sodium compounds can potentially damage or degrade conventional temperature sensors over time, necessitating the development of more robust and compatible sensing technologies.

The need for high-resolution temperature data across the entire battery pack adds another layer of complexity. Current monitoring systems often provide limited spatial resolution, making it difficult to detect localized hotspots or temperature gradients that could lead to thermal runaway or uneven aging of battery cells. Developing cost-effective solutions for high-density temperature sensing without significantly increasing the overall battery system cost is a major hurdle.

Real-time data processing and interpretation present further challenges. The vast amount of temperature data generated by a comprehensive monitoring system requires sophisticated algorithms and computing power to analyze and interpret in real-time. Developing efficient data processing techniques that can quickly identify potential thermal issues while minimizing false alarms is an ongoing area of research.

Lastly, the integration of temperature monitoring systems with battery management systems (BMS) poses interoperability challenges. Ensuring seamless communication and coordination between temperature sensors, data processing units, and the BMS is crucial for effective thermal management and overall battery performance optimization. Standardizing communication protocols and interfaces for Na-ion battery temperature monitoring systems remains an important goal for the industry.

The dynamic nature of Na-ion battery temperature profiles poses another challenge. During charge and discharge cycles, these batteries exhibit complex temperature fluctuations that are difficult to predict and monitor accurately. This variability makes it challenging to develop reliable temperature models and control systems, potentially compromising battery performance and safety.

Sensor placement and integration present additional hurdles. The optimal locations for temperature sensors within Na-ion cells are not yet well-established, and integrating sensors without disrupting battery performance or increasing manufacturing complexity remains a significant challenge. Moreover, the corrosive nature of sodium compounds can potentially damage or degrade conventional temperature sensors over time, necessitating the development of more robust and compatible sensing technologies.

The need for high-resolution temperature data across the entire battery pack adds another layer of complexity. Current monitoring systems often provide limited spatial resolution, making it difficult to detect localized hotspots or temperature gradients that could lead to thermal runaway or uneven aging of battery cells. Developing cost-effective solutions for high-density temperature sensing without significantly increasing the overall battery system cost is a major hurdle.

Real-time data processing and interpretation present further challenges. The vast amount of temperature data generated by a comprehensive monitoring system requires sophisticated algorithms and computing power to analyze and interpret in real-time. Developing efficient data processing techniques that can quickly identify potential thermal issues while minimizing false alarms is an ongoing area of research.

Lastly, the integration of temperature monitoring systems with battery management systems (BMS) poses interoperability challenges. Ensuring seamless communication and coordination between temperature sensors, data processing units, and the BMS is crucial for effective thermal management and overall battery performance optimization. Standardizing communication protocols and interfaces for Na-ion battery temperature monitoring systems remains an important goal for the industry.

Existing Temp Monitoring Solutions for Na-ion Batteries

01 Temperature control systems for sodium-ion batteries

Advanced temperature control systems are developed to maintain optimal operating conditions for sodium-ion batteries. These systems help regulate battery temperature during charging, discharging, and storage, improving overall performance and longevity. Techniques may include active cooling, thermal management materials, and intelligent temperature monitoring.- Temperature control systems for sodium-ion batteries: Advanced temperature control systems are developed to maintain optimal operating conditions for sodium-ion batteries. These systems help regulate battery temperature during charging, discharging, and storage, enhancing performance and longevity. They may include cooling mechanisms, thermal management materials, and intelligent temperature monitoring devices.

- High-temperature resistant electrolytes for sodium-ion batteries: Researchers are developing electrolyte formulations that can withstand higher temperatures, improving the thermal stability of sodium-ion batteries. These electrolytes may include additives or novel compounds that maintain their properties and prevent decomposition at elevated temperatures, allowing for safer and more efficient battery operation in various environmental conditions.

- Thermal management materials for sodium-ion battery electrodes: Innovative materials are being incorporated into sodium-ion battery electrodes to enhance thermal conductivity and heat dissipation. These materials help distribute heat evenly throughout the battery, preventing hotspots and improving overall temperature stability. This approach can lead to better performance and increased safety in high-temperature environments.

- Low-temperature performance optimization for sodium-ion batteries: Techniques are being developed to improve the performance of sodium-ion batteries at low temperatures. These may include modifications to electrode materials, electrolyte compositions, or battery designs that facilitate ion transport and electrochemical reactions in cold conditions. Such advancements expand the usability of sodium-ion batteries in diverse climates and applications.

- Temperature-responsive safety mechanisms for sodium-ion batteries: Safety features are being integrated into sodium-ion batteries to respond to temperature fluctuations. These may include smart separators, thermal fuses, or other components that can detect and mitigate temperature-related risks. Such mechanisms help prevent thermal runaway and enhance the overall safety profile of sodium-ion battery systems.

02 High-temperature resistant electrolytes for sodium-ion batteries

Specialized electrolyte formulations are designed to enhance the thermal stability of sodium-ion batteries. These electrolytes maintain their performance and safety at elevated temperatures, allowing for a wider operating temperature range and improved battery reliability in various applications and environments.Expand Specific Solutions03 Thermal management of sodium-ion battery packs

Innovative thermal management solutions are developed for sodium-ion battery packs used in electric vehicles and large-scale energy storage systems. These solutions may include phase change materials, liquid cooling systems, or advanced heat dissipation structures to ensure uniform temperature distribution and prevent thermal runaway.Expand Specific Solutions04 Low-temperature performance optimization of sodium-ion batteries

Techniques are developed to improve the performance of sodium-ion batteries at low temperatures. These may include electrode material modifications, electrolyte additives, or structural design changes that enhance ion mobility and reduce internal resistance at lower temperatures, ensuring reliable operation in cold environments.Expand Specific Solutions05 Temperature-responsive safety mechanisms for sodium-ion batteries

Safety features are integrated into sodium-ion batteries to respond to temperature fluctuations. These may include temperature-sensitive separators, thermal fuses, or smart battery management systems that can detect and mitigate temperature-related issues, enhancing the overall safety and reliability of the battery system.Expand Specific Solutions

Key Players in Na-ion Battery Temp Monitoring Industry

The precise temperature monitoring techniques for sodium ion batteries are in an early development stage, with the market still emerging. The technology's maturity is relatively low, but growing interest from major players indicates potential for rapid advancement. Companies like Robert Bosch GmbH, Toyota Motor Corp., and Samsung SDI Co., Ltd. are investing in research and development, leveraging their expertise in battery technologies. Smaller specialized firms such as Liyang HiNa Battery Technology Co., Ltd. and Alps Green Devices Co., Ltd. are also contributing to innovation in this field. The market size is currently limited but expected to expand as sodium ion batteries gain traction as a cost-effective alternative to lithium-ion batteries in certain applications.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a sophisticated temperature monitoring solution for sodium-ion batteries using a combination of infrared imaging and distributed temperature sensors. The system employs high-resolution thermal cameras to create detailed surface temperature maps, while strategically placed micro-thermocouples provide internal temperature data. Bosch's proprietary software integrates these data streams to create a 3D thermal model of the battery in real-time[7]. The company has also developed smart battery management algorithms that adjust charging and discharging rates based on temperature profiles to optimize performance and longevity[9].

Strengths: High-resolution 3D thermal mapping; integrated battery management; non-invasive monitoring. Weaknesses: Reliance on external imaging may be challenging in some applications; higher cost due to advanced imaging technology.

Toyota Motor Corp.

Technical Solution: Toyota has developed a hybrid approach to temperature monitoring in sodium-ion batteries, combining traditional methods with innovative materials science. The company has integrated temperature-sensitive phosphorescent materials into the battery separator, allowing for direct optical measurement of internal temperatures. This is coupled with a network of thin-film resistance temperature detectors (RTDs) on the cell surface. Toyota's system also incorporates a novel electrolyte additive that changes viscosity with temperature, providing an additional passive safety mechanism[10]. The data from these multiple sources is processed using Toyota's advanced battery management system, which employs predictive modeling to optimize battery performance and safety across various operating conditions[11].

Strengths: Multi-layered temperature monitoring approach; passive safety features; advanced predictive modeling. Weaknesses: Increased complexity in battery manufacturing; potential for optical signal degradation over time.

Core Innovations in Precise Battery Temp Sensing

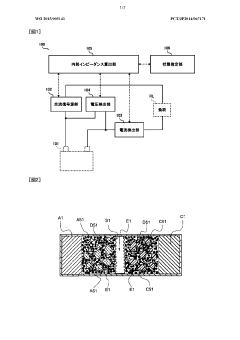

Method and device for estimating state of charge of a battery

PatentPendingEP4283318A1

Innovation

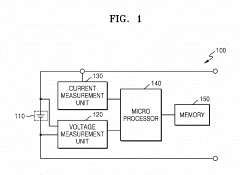

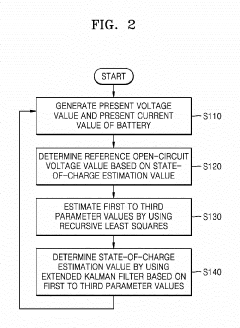

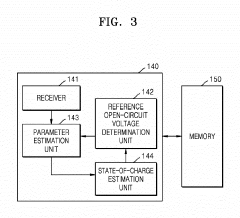

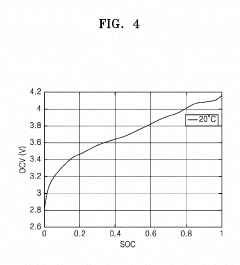

- A method using a battery parametric model that employs recursive least squares (RLS) and an extended Kalman filter (EKF) to estimate SOC, compensating for temperature changes by estimating first to third parameter values from present voltage and current measurements, reducing the need for multiple preliminary temperature experiments.

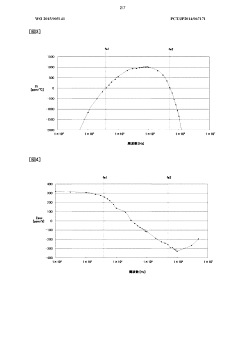

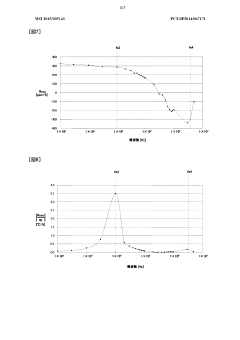

Method for estimating state of electricity storage device

PatentWO2015005141A1

Innovation

- A method that measures the internal impedance at frequencies where it does not change with temperature, allowing for accurate estimation of SOC and SOH without the need for temperature measurement, by offsetting temperature-dependent changes in ionic and electronic conduction-based components, and using specific frequencies to cancel these effects.

Safety Standards for Na-ion Battery Temp Management

Safety standards for sodium-ion battery temperature management are crucial for ensuring the safe operation and widespread adoption of this emerging energy storage technology. These standards encompass a range of requirements and guidelines designed to mitigate thermal risks associated with Na-ion batteries during various operational conditions.

One of the primary focuses of these safety standards is the establishment of acceptable temperature ranges for Na-ion batteries. Typically, these ranges are more stringent than those for lithium-ion batteries due to the unique characteristics of sodium-ion chemistry. The standards often specify maximum and minimum temperature limits for normal operation, charging, and discharging processes. These limits are determined through extensive testing and analysis of Na-ion cell behavior under different thermal conditions.

Temperature monitoring requirements form a significant part of these safety standards. They mandate the implementation of precise and reliable temperature sensing systems within Na-ion battery packs. These systems must be capable of continuously measuring cell temperatures at multiple points, ensuring comprehensive thermal monitoring. The standards often specify the minimum number of temperature sensors required per battery module or pack, as well as their strategic placement to capture potential hotspots.

Safety standards also address thermal management systems for Na-ion batteries. They outline requirements for active and passive cooling mechanisms, including specifications for thermal interface materials, heat dissipation structures, and cooling fluid circulation systems. These standards ensure that the thermal management system can effectively maintain the battery temperature within the prescribed safe range under various operating conditions and ambient temperatures.

Emergency thermal runaway prevention and mitigation measures are another critical aspect covered by these safety standards. They define protocols for detecting rapid temperature increases, triggering emergency shutdown procedures, and implementing thermal isolation techniques to prevent the propagation of thermal events between cells or modules. The standards may also specify requirements for fire-resistant materials and thermal barriers within the battery pack design.

Furthermore, safety standards for Na-ion battery temperature management include guidelines for thermal testing and certification procedures. These tests often involve subjecting battery packs to extreme temperature conditions, thermal cycling, and simulated thermal runaway scenarios to evaluate their safety performance and compliance with the established standards.

Lastly, these safety standards typically incorporate requirements for temperature-related battery management system (BMS) functionalities. This includes specifications for temperature-based charge and discharge current limitations, thermal balancing algorithms, and temperature-dependent state-of-health estimation methods. The BMS must be capable of implementing these functions to ensure safe and optimal operation of Na-ion batteries across their entire operational temperature range.

One of the primary focuses of these safety standards is the establishment of acceptable temperature ranges for Na-ion batteries. Typically, these ranges are more stringent than those for lithium-ion batteries due to the unique characteristics of sodium-ion chemistry. The standards often specify maximum and minimum temperature limits for normal operation, charging, and discharging processes. These limits are determined through extensive testing and analysis of Na-ion cell behavior under different thermal conditions.

Temperature monitoring requirements form a significant part of these safety standards. They mandate the implementation of precise and reliable temperature sensing systems within Na-ion battery packs. These systems must be capable of continuously measuring cell temperatures at multiple points, ensuring comprehensive thermal monitoring. The standards often specify the minimum number of temperature sensors required per battery module or pack, as well as their strategic placement to capture potential hotspots.

Safety standards also address thermal management systems for Na-ion batteries. They outline requirements for active and passive cooling mechanisms, including specifications for thermal interface materials, heat dissipation structures, and cooling fluid circulation systems. These standards ensure that the thermal management system can effectively maintain the battery temperature within the prescribed safe range under various operating conditions and ambient temperatures.

Emergency thermal runaway prevention and mitigation measures are another critical aspect covered by these safety standards. They define protocols for detecting rapid temperature increases, triggering emergency shutdown procedures, and implementing thermal isolation techniques to prevent the propagation of thermal events between cells or modules. The standards may also specify requirements for fire-resistant materials and thermal barriers within the battery pack design.

Furthermore, safety standards for Na-ion battery temperature management include guidelines for thermal testing and certification procedures. These tests often involve subjecting battery packs to extreme temperature conditions, thermal cycling, and simulated thermal runaway scenarios to evaluate their safety performance and compliance with the established standards.

Lastly, these safety standards typically incorporate requirements for temperature-related battery management system (BMS) functionalities. This includes specifications for temperature-based charge and discharge current limitations, thermal balancing algorithms, and temperature-dependent state-of-health estimation methods. The BMS must be capable of implementing these functions to ensure safe and optimal operation of Na-ion batteries across their entire operational temperature range.

Environmental Impact of Na-ion Battery Technologies

The environmental impact of sodium-ion battery technologies is a crucial consideration as these batteries emerge as a potential alternative to lithium-ion batteries. One of the primary advantages of sodium-ion batteries is their reduced environmental footprint compared to their lithium-ion counterparts. This is largely due to the abundance and widespread distribution of sodium resources, which eliminates the need for extensive mining operations associated with lithium extraction.

The production process of sodium-ion batteries generally requires less energy and generates fewer greenhouse gas emissions than lithium-ion battery manufacturing. This is partly because sodium-based materials can be processed at lower temperatures, reducing the overall energy consumption during production. Additionally, the use of more common and less reactive materials in sodium-ion batteries contributes to a safer and more environmentally friendly manufacturing process.

In terms of raw material sourcing, sodium-ion batteries rely on more readily available and less geographically concentrated resources. This reduces the environmental impact associated with long-distance transportation and complex supply chains. Furthermore, the extraction of sodium from seawater or salt deposits has a significantly lower environmental impact compared to lithium mining, which often involves extensive water use and potential habitat disruption.

The end-of-life management of sodium-ion batteries also presents environmental advantages. These batteries are generally easier to recycle due to the less reactive nature of their components. The recycling process for sodium-ion batteries is potentially more straightforward and less energy-intensive than that of lithium-ion batteries, leading to improved resource recovery and reduced waste.

However, it is important to note that the environmental impact of sodium-ion batteries is not entirely negligible. The production of other components, such as electrodes and electrolytes, still requires careful consideration of resource use and potential pollutants. As the technology evolves, ongoing research is focused on developing even more environmentally friendly materials and production processes to further minimize the ecological footprint of sodium-ion batteries.

In the context of grid-scale energy storage, sodium-ion batteries could play a significant role in supporting renewable energy integration. Their potential for large-scale, low-cost energy storage could facilitate greater adoption of intermittent renewable energy sources, indirectly contributing to reduced greenhouse gas emissions from the power sector.

The production process of sodium-ion batteries generally requires less energy and generates fewer greenhouse gas emissions than lithium-ion battery manufacturing. This is partly because sodium-based materials can be processed at lower temperatures, reducing the overall energy consumption during production. Additionally, the use of more common and less reactive materials in sodium-ion batteries contributes to a safer and more environmentally friendly manufacturing process.

In terms of raw material sourcing, sodium-ion batteries rely on more readily available and less geographically concentrated resources. This reduces the environmental impact associated with long-distance transportation and complex supply chains. Furthermore, the extraction of sodium from seawater or salt deposits has a significantly lower environmental impact compared to lithium mining, which often involves extensive water use and potential habitat disruption.

The end-of-life management of sodium-ion batteries also presents environmental advantages. These batteries are generally easier to recycle due to the less reactive nature of their components. The recycling process for sodium-ion batteries is potentially more straightforward and less energy-intensive than that of lithium-ion batteries, leading to improved resource recovery and reduced waste.

However, it is important to note that the environmental impact of sodium-ion batteries is not entirely negligible. The production of other components, such as electrodes and electrolytes, still requires careful consideration of resource use and potential pollutants. As the technology evolves, ongoing research is focused on developing even more environmentally friendly materials and production processes to further minimize the ecological footprint of sodium-ion batteries.

In the context of grid-scale energy storage, sodium-ion batteries could play a significant role in supporting renewable energy integration. Their potential for large-scale, low-cost energy storage could facilitate greater adoption of intermittent renewable energy sources, indirectly contributing to reduced greenhouse gas emissions from the power sector.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!