Role of In-Situ Analysis in Sodium Ion Battery Development

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Na-Ion Battery Evolution

The evolution of sodium-ion batteries (SIBs) represents a significant milestone in the quest for sustainable and cost-effective energy storage solutions. Initially conceived as an alternative to lithium-ion batteries, SIBs have undergone rapid development over the past decade, driven by the abundance and low cost of sodium resources.

The journey of SIB evolution began in the 1980s with early research into sodium-based intercalation compounds. However, it wasn't until the 2010s that SIBs gained renewed interest due to concerns over lithium supply and cost. This resurgence led to intensive research efforts focused on developing high-performance electrode materials and electrolytes specifically tailored for sodium-ion systems.

A key breakthrough in SIB evolution came with the development of hard carbon anodes, which provided a viable alternative to graphite used in lithium-ion batteries. This was followed by significant advancements in cathode materials, including layered oxides, polyanionic compounds, and Prussian blue analogues, each offering unique advantages in terms of capacity, stability, and rate capability.

The evolution of electrolytes has been equally crucial, with researchers exploring various liquid, solid, and hybrid electrolyte systems to enhance the performance and safety of SIBs. Notably, the development of sodium-ion conducting solid electrolytes has opened up possibilities for all-solid-state sodium batteries, potentially addressing safety concerns associated with liquid electrolytes.

In recent years, the focus has shifted towards optimizing the entire cell architecture, including binders, separators, and current collectors, to maximize the performance of SIBs. This holistic approach has led to significant improvements in energy density, cycle life, and rate capability, bringing SIBs closer to commercial viability.

The role of in-situ analysis techniques has been instrumental in accelerating the evolution of SIBs. These techniques, including in-situ X-ray diffraction, Raman spectroscopy, and electron microscopy, have provided unprecedented insights into the structural and chemical changes occurring within SIB components during operation. This real-time information has been crucial in understanding degradation mechanisms, optimizing electrode formulations, and developing strategies to enhance battery performance and longevity.

Looking ahead, the evolution of SIBs is expected to continue at a rapid pace, with emerging trends focusing on novel electrode architectures, advanced electrolyte formulations, and innovative cell designs. The integration of artificial intelligence and machine learning in battery research is also anticipated to play a significant role in accelerating the discovery and optimization of new materials and cell configurations for next-generation SIBs.

The journey of SIB evolution began in the 1980s with early research into sodium-based intercalation compounds. However, it wasn't until the 2010s that SIBs gained renewed interest due to concerns over lithium supply and cost. This resurgence led to intensive research efforts focused on developing high-performance electrode materials and electrolytes specifically tailored for sodium-ion systems.

A key breakthrough in SIB evolution came with the development of hard carbon anodes, which provided a viable alternative to graphite used in lithium-ion batteries. This was followed by significant advancements in cathode materials, including layered oxides, polyanionic compounds, and Prussian blue analogues, each offering unique advantages in terms of capacity, stability, and rate capability.

The evolution of electrolytes has been equally crucial, with researchers exploring various liquid, solid, and hybrid electrolyte systems to enhance the performance and safety of SIBs. Notably, the development of sodium-ion conducting solid electrolytes has opened up possibilities for all-solid-state sodium batteries, potentially addressing safety concerns associated with liquid electrolytes.

In recent years, the focus has shifted towards optimizing the entire cell architecture, including binders, separators, and current collectors, to maximize the performance of SIBs. This holistic approach has led to significant improvements in energy density, cycle life, and rate capability, bringing SIBs closer to commercial viability.

The role of in-situ analysis techniques has been instrumental in accelerating the evolution of SIBs. These techniques, including in-situ X-ray diffraction, Raman spectroscopy, and electron microscopy, have provided unprecedented insights into the structural and chemical changes occurring within SIB components during operation. This real-time information has been crucial in understanding degradation mechanisms, optimizing electrode formulations, and developing strategies to enhance battery performance and longevity.

Looking ahead, the evolution of SIBs is expected to continue at a rapid pace, with emerging trends focusing on novel electrode architectures, advanced electrolyte formulations, and innovative cell designs. The integration of artificial intelligence and machine learning in battery research is also anticipated to play a significant role in accelerating the discovery and optimization of new materials and cell configurations for next-generation SIBs.

Market Demand Analysis

The market demand for in-situ analysis techniques in sodium-ion battery development has been steadily increasing in recent years. This growth is primarily driven by the urgent need for more sustainable and cost-effective energy storage solutions. As the world transitions towards renewable energy sources, the limitations of lithium-ion batteries, such as resource scarcity and high costs, have become more apparent.

Sodium-ion batteries have emerged as a promising alternative, offering abundant raw materials and potentially lower production costs. However, to accelerate their development and commercialization, researchers and manufacturers require advanced analytical tools that can provide real-time insights into battery performance and degradation mechanisms. This is where in-situ analysis plays a crucial role.

The global energy storage market is projected to grow significantly in the coming years, with a particular focus on grid-scale storage and electric vehicles. These applications demand batteries with improved performance, longer lifespans, and enhanced safety profiles. In-situ analysis techniques enable researchers to observe and understand the complex electrochemical processes occurring within sodium-ion batteries during operation, leading to faster optimization and innovation.

Furthermore, the automotive industry's shift towards electrification has created a substantial demand for advanced battery technologies. While lithium-ion batteries currently dominate this sector, sodium-ion batteries are gaining attention due to their potential cost advantages and sustainability. In-situ analysis tools are essential for addressing the specific challenges associated with sodium-ion batteries, such as electrode degradation and electrolyte stability.

The renewable energy sector also presents a significant market opportunity for sodium-ion batteries and, by extension, in-situ analysis techniques. As wind and solar power generation continues to grow, the need for efficient and cost-effective energy storage solutions becomes more pressing. In-situ analysis can help researchers develop sodium-ion batteries tailored for grid storage applications, addressing issues such as cycle life and large-scale scalability.

Additionally, there is a growing demand for in-situ analysis techniques in academic and industrial research settings. Universities, national laboratories, and corporate R&D departments are investing in advanced analytical tools to accelerate battery development cycles and gain a competitive edge in the rapidly evolving energy storage landscape.

The market for in-situ analysis in sodium-ion battery development is also being driven by increasing environmental regulations and sustainability goals. As governments worldwide implement stricter emissions standards and promote clean energy technologies, the pressure to develop more efficient and environmentally friendly battery solutions intensifies. In-situ analysis techniques are crucial for optimizing battery performance and reducing waste throughout the product lifecycle.

Sodium-ion batteries have emerged as a promising alternative, offering abundant raw materials and potentially lower production costs. However, to accelerate their development and commercialization, researchers and manufacturers require advanced analytical tools that can provide real-time insights into battery performance and degradation mechanisms. This is where in-situ analysis plays a crucial role.

The global energy storage market is projected to grow significantly in the coming years, with a particular focus on grid-scale storage and electric vehicles. These applications demand batteries with improved performance, longer lifespans, and enhanced safety profiles. In-situ analysis techniques enable researchers to observe and understand the complex electrochemical processes occurring within sodium-ion batteries during operation, leading to faster optimization and innovation.

Furthermore, the automotive industry's shift towards electrification has created a substantial demand for advanced battery technologies. While lithium-ion batteries currently dominate this sector, sodium-ion batteries are gaining attention due to their potential cost advantages and sustainability. In-situ analysis tools are essential for addressing the specific challenges associated with sodium-ion batteries, such as electrode degradation and electrolyte stability.

The renewable energy sector also presents a significant market opportunity for sodium-ion batteries and, by extension, in-situ analysis techniques. As wind and solar power generation continues to grow, the need for efficient and cost-effective energy storage solutions becomes more pressing. In-situ analysis can help researchers develop sodium-ion batteries tailored for grid storage applications, addressing issues such as cycle life and large-scale scalability.

Additionally, there is a growing demand for in-situ analysis techniques in academic and industrial research settings. Universities, national laboratories, and corporate R&D departments are investing in advanced analytical tools to accelerate battery development cycles and gain a competitive edge in the rapidly evolving energy storage landscape.

The market for in-situ analysis in sodium-ion battery development is also being driven by increasing environmental regulations and sustainability goals. As governments worldwide implement stricter emissions standards and promote clean energy technologies, the pressure to develop more efficient and environmentally friendly battery solutions intensifies. In-situ analysis techniques are crucial for optimizing battery performance and reducing waste throughout the product lifecycle.

In-Situ Analysis Status

In-situ analysis has emerged as a crucial tool in the development of sodium-ion batteries, providing real-time insights into the complex electrochemical processes occurring within these energy storage devices. The current status of in-situ analysis techniques for sodium-ion batteries reflects significant advancements in both methodology and instrumentation.

X-ray-based techniques, such as in-situ X-ray diffraction (XRD) and X-ray absorption spectroscopy (XAS), have become indispensable for studying structural changes and electronic states of electrode materials during battery operation. These methods offer high spatial and temporal resolution, enabling researchers to track phase transitions and elemental oxidation states with unprecedented accuracy.

Electron microscopy-based in-situ techniques have also made substantial progress. Environmental transmission electron microscopy (E-TEM) allows for direct observation of electrode-electrolyte interfaces and the formation of solid-electrolyte interphase (SEI) layers. This technique has been instrumental in understanding the unique challenges posed by sodium-ion systems compared to their lithium-ion counterparts.

Spectroscopic methods, including in-situ Raman and Fourier-transform infrared (FTIR) spectroscopy, have been adapted for sodium-ion battery research. These techniques provide valuable information on the chemical composition and bonding changes occurring during charge-discharge cycles, offering insights into degradation mechanisms and performance limitations.

Electrochemical techniques coupled with in-situ analysis have seen significant refinement. In-situ impedance spectroscopy and differential electrochemical mass spectrometry (DEMS) are now routinely used to study electrode kinetics and gas evolution, respectively. These methods have been crucial in identifying and mitigating safety concerns associated with sodium-ion batteries.

Advanced synchrotron-based techniques have pushed the boundaries of in-situ analysis. Techniques such as operando X-ray tomography and X-ray ptychography now offer three-dimensional visualization of electrode microstructures during cycling, providing unprecedented insights into degradation mechanisms and ion transport pathways.

The integration of multiple in-situ techniques has become increasingly common, allowing for correlative studies that provide a more comprehensive understanding of battery behavior. For instance, combining XRD with XAS and Raman spectroscopy has enabled researchers to link structural changes with electronic and chemical transformations in real-time.

Despite these advancements, challenges remain in the field of in-situ analysis for sodium-ion batteries. The development of specialized cell designs that maintain realistic operating conditions while allowing for in-situ measurements remains an active area of research. Additionally, data analysis and interpretation of complex, multi-modal datasets present ongoing challenges that require advanced computational approaches and machine learning algorithms.

X-ray-based techniques, such as in-situ X-ray diffraction (XRD) and X-ray absorption spectroscopy (XAS), have become indispensable for studying structural changes and electronic states of electrode materials during battery operation. These methods offer high spatial and temporal resolution, enabling researchers to track phase transitions and elemental oxidation states with unprecedented accuracy.

Electron microscopy-based in-situ techniques have also made substantial progress. Environmental transmission electron microscopy (E-TEM) allows for direct observation of electrode-electrolyte interfaces and the formation of solid-electrolyte interphase (SEI) layers. This technique has been instrumental in understanding the unique challenges posed by sodium-ion systems compared to their lithium-ion counterparts.

Spectroscopic methods, including in-situ Raman and Fourier-transform infrared (FTIR) spectroscopy, have been adapted for sodium-ion battery research. These techniques provide valuable information on the chemical composition and bonding changes occurring during charge-discharge cycles, offering insights into degradation mechanisms and performance limitations.

Electrochemical techniques coupled with in-situ analysis have seen significant refinement. In-situ impedance spectroscopy and differential electrochemical mass spectrometry (DEMS) are now routinely used to study electrode kinetics and gas evolution, respectively. These methods have been crucial in identifying and mitigating safety concerns associated with sodium-ion batteries.

Advanced synchrotron-based techniques have pushed the boundaries of in-situ analysis. Techniques such as operando X-ray tomography and X-ray ptychography now offer three-dimensional visualization of electrode microstructures during cycling, providing unprecedented insights into degradation mechanisms and ion transport pathways.

The integration of multiple in-situ techniques has become increasingly common, allowing for correlative studies that provide a more comprehensive understanding of battery behavior. For instance, combining XRD with XAS and Raman spectroscopy has enabled researchers to link structural changes with electronic and chemical transformations in real-time.

Despite these advancements, challenges remain in the field of in-situ analysis for sodium-ion batteries. The development of specialized cell designs that maintain realistic operating conditions while allowing for in-situ measurements remains an active area of research. Additionally, data analysis and interpretation of complex, multi-modal datasets present ongoing challenges that require advanced computational approaches and machine learning algorithms.

Current In-Situ Methods

01 Electrode materials for sodium-ion batteries

Development of novel electrode materials is crucial for improving sodium-ion battery performance. This includes research on cathode and anode materials that offer high capacity, good cycling stability, and improved sodium ion insertion/extraction properties. Materials being explored include various sodium-based compounds, carbon-based materials, and metal oxides.- Electrode materials for sodium-ion batteries: Development of novel electrode materials is crucial for improving sodium-ion battery performance. This includes research on cathode and anode materials that offer high capacity, good cycling stability, and improved sodium ion insertion/extraction properties. Materials being explored include various sodium-based compounds, carbon-based materials, and metal oxides.

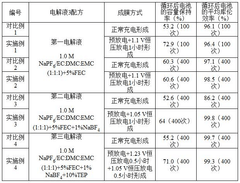

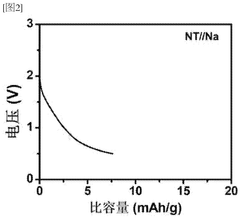

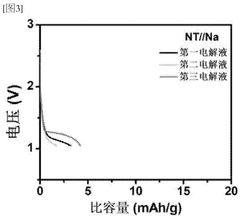

- Electrolyte formulations for sodium-ion batteries: Advancements in electrolyte compositions are essential for enhancing the performance and safety of sodium-ion batteries. This involves developing new electrolyte formulations that provide better ionic conductivity, wider electrochemical stability windows, and improved compatibility with electrode materials. Research focuses on both liquid and solid electrolytes.

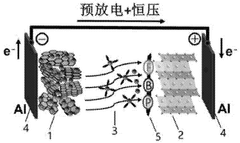

- Battery cell design and manufacturing processes: Innovations in battery cell design and manufacturing processes are key to optimizing sodium-ion battery performance and scalability. This includes developing new cell architectures, improving assembly techniques, and creating more efficient production methods to enhance energy density, reduce costs, and increase manufacturing throughput.

- Battery management systems for sodium-ion batteries: Developing specialized battery management systems is crucial for optimizing the performance and longevity of sodium-ion batteries. This involves creating advanced algorithms for state-of-charge estimation, thermal management, and cell balancing tailored to the unique characteristics of sodium-ion chemistry.

- Integration of sodium-ion batteries in energy storage systems: Research on effectively integrating sodium-ion batteries into various energy storage applications is ongoing. This includes developing hybrid systems that combine sodium-ion batteries with other energy storage technologies, as well as optimizing battery pack designs for specific use cases such as grid storage or electric vehicles.

02 Electrolyte formulations for sodium-ion batteries

Optimizing electrolyte compositions is essential for enhancing the performance and safety of sodium-ion batteries. Research focuses on developing electrolytes with high ionic conductivity, wide electrochemical stability windows, and compatibility with electrode materials. This includes exploring various solvents, salts, and additives to improve battery efficiency and lifespan.Expand Specific Solutions03 Battery cell design and manufacturing processes

Innovations in cell design and manufacturing techniques are being pursued to enhance the overall performance and cost-effectiveness of sodium-ion batteries. This includes optimizing cell components, improving assembly methods, and developing scalable production processes to make sodium-ion batteries more competitive with other battery technologies.Expand Specific Solutions04 Sodium-ion battery management systems

Development of advanced battery management systems specifically tailored for sodium-ion batteries is crucial for optimizing their performance and longevity. This includes designing control algorithms for charge/discharge cycles, thermal management, and state-of-charge estimation to ensure safe and efficient operation of sodium-ion battery packs.Expand Specific Solutions05 Integration of sodium-ion batteries in energy storage systems

Research is being conducted on effectively integrating sodium-ion batteries into various energy storage applications. This includes developing strategies for grid-scale energy storage, renewable energy integration, and electric vehicle applications. The focus is on leveraging the unique characteristics of sodium-ion batteries to create efficient and cost-effective energy storage solutions.Expand Specific Solutions

Key Industry Players

The development of sodium-ion batteries is in its early stages, with the market still emerging and technology rapidly evolving. The competitive landscape is characterized by a mix of established players and innovative startups, reflecting the industry's growth potential. Companies like Samsung Electronics, Hyundai Motor, and Kia are investing in this technology, leveraging their expertise in battery development. Research institutions such as Karlsruher Institut für Technologie and Nankai University are contributing to fundamental advancements. Specialized firms like Shenzhen Capchem Technology and Sion Power are focusing on material innovations. The market size is expanding, driven by the demand for sustainable energy storage solutions, but remains smaller compared to lithium-ion batteries. Technical challenges persist, particularly in improving energy density and cycle life, indicating that sodium-ion battery technology is still maturing.

Karlsruher Institut für Technologie

Technical Solution: KIT has developed a suite of in-situ characterization techniques for sodium-ion batteries, with a focus on operando synchrotron-based X-ray techniques. Their approach includes high-energy X-ray diffraction (HEXRD) for bulk structural analysis and X-ray absorption spectroscopy (XAS) for probing local electronic structures[8]. KIT researchers have also pioneered the use of in-situ 23Na solid-state NMR spectroscopy to directly observe sodium-ion dynamics in battery materials[10]. Additionally, they have implemented in-situ dilatometry to measure volume changes in electrode materials during cycling, which is crucial for understanding mechanical degradation processes[12].

Strengths: Comprehensive suite of complementary in-situ techniques; strong focus on understanding fundamental mechanisms. Weaknesses: Some techniques require access to large-scale facilities like synchrotrons; may have limitations in studying full cell configurations.

Nankai University

Technical Solution: Nankai University has pioneered the use of in-situ transmission electron microscopy (TEM) for sodium-ion battery research. Their approach involves designing specialized TEM holders that allow for real-time observation of electrochemical processes at the nanoscale[2]. This technique has been particularly effective in studying the formation and evolution of solid-electrolyte interphase (SEI) layers on sodium-ion battery anodes. Researchers at Nankai have also developed in-situ Raman spectroscopy methods to investigate the structural changes in cathode materials during sodium insertion and extraction[4]. These techniques are complemented by in-situ X-ray diffraction studies, providing a multi-modal approach to understanding sodium-ion battery mechanisms[6].

Strengths: Nanoscale visualization of electrochemical processes; comprehensive analysis of SEI formation and electrode structural changes. Weaknesses: TEM analysis limited to thin samples, may not fully represent bulk battery behavior; requires highly specialized equipment.

Core In-Situ Innovations

An in-situ synthesis of sodium insertion material-sacrificial salt composite for sodium ion batteries and the material produced thereof

PatentInactiveIN201611018942A

Innovation

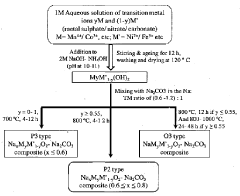

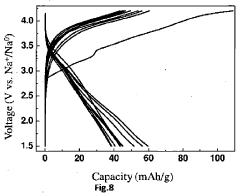

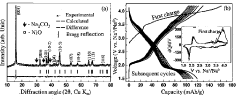

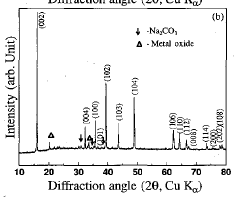

- An in-situ synthesis method involving hydroxide co-precipitation and solid state synthesis with excess sodium carbonate to stabilize the P2 phase at room temperature, using sodium carbonate as a sacrificial salt to reduce first cycle irreversibility and phase decomposition, and extending this method to P3 and O3 types.

Sodium ion battery positive electrode interface film and preparation method therefor, and sodium ion battery

PatentWO2025020932A1

Innovation

- By pre-distributed the assembled sodium ion battery to the restore potential of the electrolyte, constant voltage discharge is performed to restore the electrolyte on the surface of the positive electrode, forming a positive-electrolytic liquid meal with inorganic objects.

Material Characterization

In-situ analysis plays a crucial role in the development of sodium-ion batteries, particularly in material characterization. This advanced technique allows researchers to observe and analyze battery materials in real-time during operation, providing invaluable insights into their behavior and performance.

One of the primary advantages of in-situ analysis is its ability to capture dynamic processes within the battery. Traditional ex-situ methods often fail to capture transient phenomena or intermediate states that occur during cycling. In-situ techniques, however, enable the observation of structural and chemical changes as they happen, offering a more comprehensive understanding of battery materials.

X-ray diffraction (XRD) is a widely used in-situ technique for characterizing sodium-ion battery materials. It allows researchers to monitor structural changes in electrode materials during charge and discharge cycles. This information is crucial for understanding phase transitions, lattice expansions, and contractions that occur during sodium insertion and extraction.

Another powerful in-situ method is X-ray absorption spectroscopy (XAS), which provides detailed information about the local electronic structure and oxidation states of elements within the battery materials. This technique is particularly useful for studying the redox processes in cathode materials and the formation of solid-electrolyte interphase (SEI) layers on anodes.

Transmission electron microscopy (TEM) has also been adapted for in-situ analysis of sodium-ion batteries. In-situ TEM enables direct visualization of morphological changes, particle degradation, and the formation of secondary phases at the nanoscale. This high-resolution imaging technique offers unique insights into the mechanisms of capacity fading and structural instability in battery materials.

Raman spectroscopy is another valuable in-situ tool for characterizing sodium-ion battery materials. It provides information about the vibrational modes of molecules and can detect subtle changes in the local chemical environment. This technique is particularly useful for studying the formation and evolution of SEI layers and identifying the presence of unwanted side products.

The integration of multiple in-situ techniques, known as operando characterization, has become increasingly popular in sodium-ion battery research. This approach combines complementary techniques to provide a more comprehensive understanding of material behavior. For example, combining XRD with XAS can simultaneously reveal structural and electronic changes during battery operation.

In-situ analysis has significantly accelerated the development of sodium-ion battery materials by providing real-time feedback on material performance and degradation mechanisms. This information is invaluable for optimizing electrode compositions, electrolyte formulations, and cell designs. As the field continues to advance, in-situ characterization techniques will undoubtedly play an even more critical role in the development of next-generation sodium-ion batteries.

One of the primary advantages of in-situ analysis is its ability to capture dynamic processes within the battery. Traditional ex-situ methods often fail to capture transient phenomena or intermediate states that occur during cycling. In-situ techniques, however, enable the observation of structural and chemical changes as they happen, offering a more comprehensive understanding of battery materials.

X-ray diffraction (XRD) is a widely used in-situ technique for characterizing sodium-ion battery materials. It allows researchers to monitor structural changes in electrode materials during charge and discharge cycles. This information is crucial for understanding phase transitions, lattice expansions, and contractions that occur during sodium insertion and extraction.

Another powerful in-situ method is X-ray absorption spectroscopy (XAS), which provides detailed information about the local electronic structure and oxidation states of elements within the battery materials. This technique is particularly useful for studying the redox processes in cathode materials and the formation of solid-electrolyte interphase (SEI) layers on anodes.

Transmission electron microscopy (TEM) has also been adapted for in-situ analysis of sodium-ion batteries. In-situ TEM enables direct visualization of morphological changes, particle degradation, and the formation of secondary phases at the nanoscale. This high-resolution imaging technique offers unique insights into the mechanisms of capacity fading and structural instability in battery materials.

Raman spectroscopy is another valuable in-situ tool for characterizing sodium-ion battery materials. It provides information about the vibrational modes of molecules and can detect subtle changes in the local chemical environment. This technique is particularly useful for studying the formation and evolution of SEI layers and identifying the presence of unwanted side products.

The integration of multiple in-situ techniques, known as operando characterization, has become increasingly popular in sodium-ion battery research. This approach combines complementary techniques to provide a more comprehensive understanding of material behavior. For example, combining XRD with XAS can simultaneously reveal structural and electronic changes during battery operation.

In-situ analysis has significantly accelerated the development of sodium-ion battery materials by providing real-time feedback on material performance and degradation mechanisms. This information is invaluable for optimizing electrode compositions, electrolyte formulations, and cell designs. As the field continues to advance, in-situ characterization techniques will undoubtedly play an even more critical role in the development of next-generation sodium-ion batteries.

Safety and Regulations

The development and implementation of sodium-ion batteries (SIBs) require careful consideration of safety aspects and adherence to regulatory standards. As in-situ analysis plays a crucial role in SIB development, it is essential to address the safety concerns and regulatory requirements associated with this technology.

Safety considerations for in-situ analysis of SIBs encompass both the experimental setup and the battery components themselves. The use of sodium in batteries presents unique challenges due to its high reactivity with water and air. Researchers must implement stringent safety protocols to prevent accidental exposure and potential fire hazards. This includes the use of specialized glove boxes, inert atmospheres, and proper handling procedures for sodium-based materials.

Regulatory bodies, such as the International Electrotechnical Commission (IEC) and the United Nations Economic Commission for Europe (UNECE), have established guidelines for the testing and certification of battery systems. While these regulations primarily focus on lithium-ion batteries, they are being adapted to address the specific characteristics of SIBs. In-situ analysis techniques must comply with these evolving standards to ensure the safety and reliability of SIB technology.

The transportation of sodium-ion batteries and their components is subject to strict regulations. The International Air Transport Association (IATA) and the U.S. Department of Transportation (DOT) have specific requirements for the packaging, labeling, and shipping of battery materials. Researchers conducting in-situ analysis must be aware of these regulations to ensure compliance during the transportation of experimental setups and battery samples.

Environmental considerations also play a significant role in the regulatory landscape of SIB development. The European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impact the materials used in battery production. In-situ analysis techniques must be designed to support the development of SIBs that meet these environmental standards.

As the field of sodium-ion batteries continues to evolve, it is crucial for researchers and manufacturers to stay informed about the latest safety guidelines and regulatory updates. Collaboration between industry stakeholders, regulatory bodies, and research institutions is essential to develop comprehensive safety standards that address the unique characteristics of SIBs and the in-situ analysis techniques used in their development.

Safety considerations for in-situ analysis of SIBs encompass both the experimental setup and the battery components themselves. The use of sodium in batteries presents unique challenges due to its high reactivity with water and air. Researchers must implement stringent safety protocols to prevent accidental exposure and potential fire hazards. This includes the use of specialized glove boxes, inert atmospheres, and proper handling procedures for sodium-based materials.

Regulatory bodies, such as the International Electrotechnical Commission (IEC) and the United Nations Economic Commission for Europe (UNECE), have established guidelines for the testing and certification of battery systems. While these regulations primarily focus on lithium-ion batteries, they are being adapted to address the specific characteristics of SIBs. In-situ analysis techniques must comply with these evolving standards to ensure the safety and reliability of SIB technology.

The transportation of sodium-ion batteries and their components is subject to strict regulations. The International Air Transport Association (IATA) and the U.S. Department of Transportation (DOT) have specific requirements for the packaging, labeling, and shipping of battery materials. Researchers conducting in-situ analysis must be aware of these regulations to ensure compliance during the transportation of experimental setups and battery samples.

Environmental considerations also play a significant role in the regulatory landscape of SIB development. The European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impact the materials used in battery production. In-situ analysis techniques must be designed to support the development of SIBs that meet these environmental standards.

As the field of sodium-ion batteries continues to evolve, it is crucial for researchers and manufacturers to stay informed about the latest safety guidelines and regulatory updates. Collaboration between industry stakeholders, regulatory bodies, and research institutions is essential to develop comprehensive safety standards that address the unique characteristics of SIBs and the in-situ analysis techniques used in their development.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!