Sodium Ion Batteries and Thin Film Deposition Techniques

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Evolution and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries, driven by the increasing demand for sustainable and cost-effective energy storage solutions. The evolution of SIBs can be traced back to the 1980s when initial research on sodium-based intercalation compounds began. However, it wasn't until the early 2000s that significant progress was made in developing practical SIB systems.

The technological trajectory of SIBs has been marked by several key milestones. In the early stages, research focused on identifying suitable cathode materials, with layered oxide compounds showing promising results. The discovery of hard carbon as an effective anode material in the mid-2000s represented a major breakthrough, addressing the challenge of sodium ion insertion and extraction.

Recent years have witnessed accelerated development in SIB technology, with improvements in electrode materials, electrolytes, and cell design. The introduction of Prussian blue analogs as cathode materials and the development of sodium superionic conductor (NASICON) electrolytes have significantly enhanced the performance and stability of SIBs.

The primary objectives driving SIB research are multifaceted. Firstly, there is a strong focus on improving energy density to make SIBs competitive with lithium-ion batteries. This involves developing high-capacity electrode materials and optimizing cell architecture. Secondly, enhancing the cycle life and stability of SIBs is crucial for their practical implementation in various applications.

Another key objective is to reduce the overall cost of SIB systems. This includes not only the materials used but also the manufacturing processes. The abundance and wide distribution of sodium resources offer a significant advantage in this regard, potentially leading to more economical and geopolitically stable supply chains.

Safety is also a paramount concern in SIB development. Researchers aim to mitigate potential safety issues associated with sodium's reactivity and develop robust battery management systems. Additionally, there is a growing emphasis on environmental sustainability, with efforts to design SIBs that are easily recyclable and have a minimal ecological footprint.

The integration of thin film deposition techniques in SIB fabrication represents an emerging frontier. These techniques offer the potential for precise control over electrode morphology and composition, potentially leading to enhanced performance and novel form factors for SIBs. The objectives in this area include developing scalable thin film deposition methods suitable for large-scale SIB production and exploring new material combinations enabled by thin film technology.

As research progresses, the ultimate goal is to position SIBs as a viable, large-scale energy storage solution capable of supporting renewable energy integration and electrification of transportation. This ambitious objective requires continued innovation across multiple technological domains and close collaboration between academia and industry.

The technological trajectory of SIBs has been marked by several key milestones. In the early stages, research focused on identifying suitable cathode materials, with layered oxide compounds showing promising results. The discovery of hard carbon as an effective anode material in the mid-2000s represented a major breakthrough, addressing the challenge of sodium ion insertion and extraction.

Recent years have witnessed accelerated development in SIB technology, with improvements in electrode materials, electrolytes, and cell design. The introduction of Prussian blue analogs as cathode materials and the development of sodium superionic conductor (NASICON) electrolytes have significantly enhanced the performance and stability of SIBs.

The primary objectives driving SIB research are multifaceted. Firstly, there is a strong focus on improving energy density to make SIBs competitive with lithium-ion batteries. This involves developing high-capacity electrode materials and optimizing cell architecture. Secondly, enhancing the cycle life and stability of SIBs is crucial for their practical implementation in various applications.

Another key objective is to reduce the overall cost of SIB systems. This includes not only the materials used but also the manufacturing processes. The abundance and wide distribution of sodium resources offer a significant advantage in this regard, potentially leading to more economical and geopolitically stable supply chains.

Safety is also a paramount concern in SIB development. Researchers aim to mitigate potential safety issues associated with sodium's reactivity and develop robust battery management systems. Additionally, there is a growing emphasis on environmental sustainability, with efforts to design SIBs that are easily recyclable and have a minimal ecological footprint.

The integration of thin film deposition techniques in SIB fabrication represents an emerging frontier. These techniques offer the potential for precise control over electrode morphology and composition, potentially leading to enhanced performance and novel form factors for SIBs. The objectives in this area include developing scalable thin film deposition methods suitable for large-scale SIB production and exploring new material combinations enabled by thin film technology.

As research progresses, the ultimate goal is to position SIBs as a viable, large-scale energy storage solution capable of supporting renewable energy integration and electrification of transportation. This ambitious objective requires continued innovation across multiple technological domains and close collaboration between academia and industry.

Market Analysis for Sodium Ion Energy Storage

The sodium-ion energy storage market is experiencing rapid growth and attracting significant attention from both industry players and investors. This emerging technology offers a promising alternative to traditional lithium-ion batteries, addressing concerns about lithium supply chain vulnerabilities and cost fluctuations. The global sodium-ion battery market is projected to expand substantially in the coming years, driven by increasing demand for sustainable energy storage solutions across various sectors.

One of the primary drivers for the sodium-ion battery market is the growing need for large-scale energy storage systems to support renewable energy integration. As countries worldwide push for greater adoption of solar and wind power, the demand for efficient and cost-effective energy storage solutions continues to rise. Sodium-ion batteries are well-positioned to meet this demand, offering advantages such as abundant raw materials, lower production costs, and improved safety compared to lithium-ion batteries.

The electric vehicle (EV) sector represents another significant market opportunity for sodium-ion batteries. While lithium-ion batteries currently dominate the EV market, concerns about long-term lithium supply and pricing volatility have prompted automakers to explore alternative technologies. Sodium-ion batteries could potentially offer a more sustainable and cost-effective solution for certain EV applications, particularly in the low to mid-range vehicle segments.

In the consumer electronics market, sodium-ion batteries are gaining traction as a potential replacement for lithium-ion batteries in devices with less demanding power requirements. This includes applications such as smart home devices, wearables, and portable electronics. The lower cost and improved safety characteristics of sodium-ion batteries make them an attractive option for manufacturers looking to differentiate their products and reduce production costs.

The industrial and grid storage sectors also present significant opportunities for sodium-ion battery adoption. These applications often require large-scale energy storage solutions with long cycle life and high reliability. Sodium-ion batteries' ability to operate efficiently at room temperature and their potential for lower total cost of ownership make them well-suited for these demanding applications.

Geographically, Asia-Pacific is expected to lead the sodium-ion battery market, with China at the forefront of research, development, and commercialization efforts. European countries are also showing strong interest in sodium-ion technology, driven by their commitment to renewable energy and sustainable transportation. North America is anticipated to see growing adoption as well, particularly in grid storage and industrial applications.

Despite the promising outlook, challenges remain for widespread adoption of sodium-ion batteries. These include the need for further improvements in energy density, cycle life, and manufacturing scalability. Ongoing research and development efforts are focused on addressing these challenges, with significant progress being made in areas such as electrode materials and electrolyte formulations.

One of the primary drivers for the sodium-ion battery market is the growing need for large-scale energy storage systems to support renewable energy integration. As countries worldwide push for greater adoption of solar and wind power, the demand for efficient and cost-effective energy storage solutions continues to rise. Sodium-ion batteries are well-positioned to meet this demand, offering advantages such as abundant raw materials, lower production costs, and improved safety compared to lithium-ion batteries.

The electric vehicle (EV) sector represents another significant market opportunity for sodium-ion batteries. While lithium-ion batteries currently dominate the EV market, concerns about long-term lithium supply and pricing volatility have prompted automakers to explore alternative technologies. Sodium-ion batteries could potentially offer a more sustainable and cost-effective solution for certain EV applications, particularly in the low to mid-range vehicle segments.

In the consumer electronics market, sodium-ion batteries are gaining traction as a potential replacement for lithium-ion batteries in devices with less demanding power requirements. This includes applications such as smart home devices, wearables, and portable electronics. The lower cost and improved safety characteristics of sodium-ion batteries make them an attractive option for manufacturers looking to differentiate their products and reduce production costs.

The industrial and grid storage sectors also present significant opportunities for sodium-ion battery adoption. These applications often require large-scale energy storage solutions with long cycle life and high reliability. Sodium-ion batteries' ability to operate efficiently at room temperature and their potential for lower total cost of ownership make them well-suited for these demanding applications.

Geographically, Asia-Pacific is expected to lead the sodium-ion battery market, with China at the forefront of research, development, and commercialization efforts. European countries are also showing strong interest in sodium-ion technology, driven by their commitment to renewable energy and sustainable transportation. North America is anticipated to see growing adoption as well, particularly in grid storage and industrial applications.

Despite the promising outlook, challenges remain for widespread adoption of sodium-ion batteries. These include the need for further improvements in energy density, cycle life, and manufacturing scalability. Ongoing research and development efforts are focused on addressing these challenges, with significant progress being made in areas such as electrode materials and electrolyte formulations.

Current Challenges in Sodium Ion Battery Technology

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries, yet they face several significant challenges that hinder their widespread adoption. One of the primary obstacles is the lower energy density compared to lithium-ion counterparts. This limitation stems from the larger size of sodium ions, which affects the intercalation process and reduces the overall capacity of the battery.

Another critical challenge lies in the development of suitable electrode materials. The anode, in particular, poses difficulties due to the larger size of sodium ions. Graphite, commonly used in lithium-ion batteries, is not effective for sodium intercalation. Researchers are exploring alternative materials such as hard carbons and alloys, but these often suffer from poor cycling stability and capacity retention.

The cathode materials for SIBs also present challenges. While several promising candidates exist, such as layered oxides and polyanionic compounds, they often exhibit lower voltage and specific capacity compared to lithium-based cathodes. This further contributes to the overall lower energy density of sodium-ion batteries.

Electrolyte development is another area of concern. The reactivity of sodium with conventional organic electrolytes can lead to safety issues and reduced battery life. Finding stable electrolytes that are compatible with both the anode and cathode materials while maintaining high ionic conductivity remains a significant challenge.

The solid-electrolyte interphase (SEI) formation in SIBs is also problematic. The SEI layer, crucial for battery stability and performance, tends to be less stable in sodium-ion systems compared to lithium-ion batteries. This instability can lead to continuous electrolyte decomposition and capacity fading over time.

Thin film deposition techniques, while promising for enhancing battery performance, face their own set of challenges when applied to SIBs. The deposition of uniform and stable thin films on electrode surfaces is complicated by the reactivity of sodium and the larger ion size. Achieving precise control over film thickness and composition while maintaining good adhesion to the substrate is essential but technically demanding.

Lastly, the scalability and cost-effectiveness of sodium-ion battery production present significant hurdles. While sodium is more abundant than lithium, the entire battery ecosystem, including manufacturing processes and supply chains, is currently optimized for lithium-ion technology. Transitioning to sodium-ion batteries requires substantial investments in new production facilities and processes, which can be a barrier to rapid commercialization.

Another critical challenge lies in the development of suitable electrode materials. The anode, in particular, poses difficulties due to the larger size of sodium ions. Graphite, commonly used in lithium-ion batteries, is not effective for sodium intercalation. Researchers are exploring alternative materials such as hard carbons and alloys, but these often suffer from poor cycling stability and capacity retention.

The cathode materials for SIBs also present challenges. While several promising candidates exist, such as layered oxides and polyanionic compounds, they often exhibit lower voltage and specific capacity compared to lithium-based cathodes. This further contributes to the overall lower energy density of sodium-ion batteries.

Electrolyte development is another area of concern. The reactivity of sodium with conventional organic electrolytes can lead to safety issues and reduced battery life. Finding stable electrolytes that are compatible with both the anode and cathode materials while maintaining high ionic conductivity remains a significant challenge.

The solid-electrolyte interphase (SEI) formation in SIBs is also problematic. The SEI layer, crucial for battery stability and performance, tends to be less stable in sodium-ion systems compared to lithium-ion batteries. This instability can lead to continuous electrolyte decomposition and capacity fading over time.

Thin film deposition techniques, while promising for enhancing battery performance, face their own set of challenges when applied to SIBs. The deposition of uniform and stable thin films on electrode surfaces is complicated by the reactivity of sodium and the larger ion size. Achieving precise control over film thickness and composition while maintaining good adhesion to the substrate is essential but technically demanding.

Lastly, the scalability and cost-effectiveness of sodium-ion battery production present significant hurdles. While sodium is more abundant than lithium, the entire battery ecosystem, including manufacturing processes and supply chains, is currently optimized for lithium-ion technology. Transitioning to sodium-ion batteries requires substantial investments in new production facilities and processes, which can be a barrier to rapid commercialization.

Thin Film Deposition Techniques for Na-Ion Batteries

01 Thin film deposition techniques for sodium-ion battery electrodes

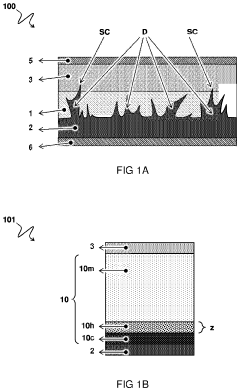

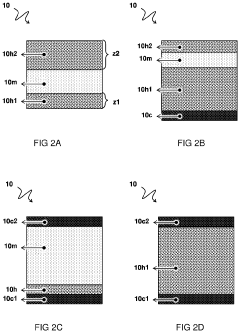

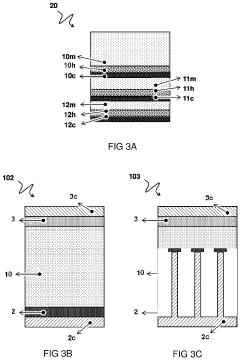

Various thin film deposition techniques are employed to fabricate electrodes for sodium-ion batteries. These methods include physical vapor deposition, chemical vapor deposition, and sputtering. These techniques allow for precise control of film thickness and composition, which is crucial for optimizing battery performance and energy density.- Thin film deposition techniques for sodium-ion battery electrodes: Various thin film deposition techniques are employed to fabricate electrodes for sodium-ion batteries. These methods include physical vapor deposition (PVD), chemical vapor deposition (CVD), and atomic layer deposition (ALD). These techniques allow for precise control over the thickness and composition of the electrode materials, potentially improving battery performance and efficiency.

- Sodium-ion battery electrolyte deposition: Thin film deposition techniques are utilized to create solid electrolyte layers for sodium-ion batteries. These methods enable the formation of uniform and dense electrolyte films, which can enhance ionic conductivity and improve overall battery performance. Techniques such as sputtering and pulsed laser deposition are commonly used for this purpose.

- Nanostructured electrode materials for sodium-ion batteries: Thin film deposition techniques are employed to create nanostructured electrode materials for sodium-ion batteries. These nanostructures, such as nanotubes, nanowires, and nanoparticles, can enhance the battery's capacity, cycling stability, and rate capability. Methods like chemical vapor deposition and electrodeposition are used to fabricate these nanostructured electrodes.

- Interface engineering in sodium-ion batteries: Thin film deposition techniques are used for interface engineering in sodium-ion batteries. This involves depositing thin layers of materials at the electrode-electrolyte interface to improve the stability, conductivity, and overall performance of the battery. Techniques such as atomic layer deposition and magnetron sputtering are commonly employed for this purpose.

- In-situ characterization of thin film deposition for sodium-ion batteries: Advanced in-situ characterization techniques are developed to monitor and analyze the thin film deposition process for sodium-ion battery components. These methods allow for real-time observation of film growth, composition, and structure, enabling better control and optimization of the deposition process. Techniques such as in-situ X-ray diffraction and spectroscopic ellipsometry are used for this purpose.

02 Solid electrolyte thin films for sodium-ion batteries

Thin film deposition techniques are used to create solid electrolyte layers for sodium-ion batteries. These solid electrolytes can enhance battery safety and performance by preventing dendrite formation and improving ion conductivity. Methods such as pulsed laser deposition and atomic layer deposition are utilized to achieve uniform and dense electrolyte films.Expand Specific Solutions03 Nanostructured electrode materials for sodium-ion batteries

Thin film deposition techniques are applied to create nanostructured electrode materials for sodium-ion batteries. These nanostructures, such as nanotubes, nanowires, and nanoparticles, can improve the battery's charge-discharge rates, cycle life, and energy density. Techniques like electrodeposition and plasma-enhanced chemical vapor deposition are used to achieve these nanostructures.Expand Specific Solutions04 Interface engineering in sodium-ion battery thin films

Thin film deposition techniques are utilized for interface engineering in sodium-ion batteries. This involves creating buffer layers or modifying the interface between the electrode and electrolyte to improve ion transport, reduce side reactions, and enhance overall battery performance. Methods such as atomic layer deposition and molecular beam epitaxy are employed for precise interface control.Expand Specific Solutions05 In-situ characterization of thin film sodium-ion battery components

Advanced thin film deposition systems are integrated with in-situ characterization techniques to study the growth and properties of sodium-ion battery components in real-time. This approach allows for a better understanding of the formation mechanisms and optimization of the deposition processes. Techniques such as in-situ X-ray diffraction and spectroscopic ellipsometry are used in conjunction with thin film deposition.Expand Specific Solutions

Key Players in Sodium Ion Battery Industry

The research on sodium ion batteries and thin film deposition techniques is in a nascent stage, with the market showing significant growth potential. The global sodium ion battery market is projected to expand rapidly, driven by increasing demand for sustainable energy storage solutions. Technologically, the field is still evolving, with companies like Contemporary Amperex Technology Co., Ltd. and Beijing Zhongke Haina Technology Co. Ltd. leading the charge in sodium ion battery development. In thin film deposition, established players such as Applied Materials, Inc. and ULVAC, Inc. are leveraging their expertise to advance the technology. The convergence of these technologies presents opportunities for innovation, particularly in improving battery performance and manufacturing processes.

Applied Materials, Inc.

Technical Solution: Applied Materials focuses on advanced thin film deposition techniques crucial for sodium-ion battery development. They have developed high-precision Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) systems specifically tailored for battery electrode and electrolyte fabrication[5]. Their Endura® platform allows for multi-layer deposition of cathode, electrolyte, and anode materials with precise control over thickness and composition. Additionally, they are exploring Atomic Layer Deposition (ALD) for creating ultra-thin protective coatings on electrode materials to enhance cycling stability and battery life[6].

Strengths: Industry-leading expertise in thin film deposition technologies, wide range of deposition techniques available. Weaknesses: Not primarily a battery manufacturer, reliant on partnerships for full battery development.

Sony Group Corp.

Technical Solution: Sony has been researching sodium-ion batteries as a potential alternative to lithium-ion batteries. They have developed a unique hard carbon material for the anode, which allows for higher capacity and better cycle life[3]. Sony is also exploring thin-film deposition techniques, particularly for solid electrolyte layers in all-solid-state batteries. Their approach combines physical vapor deposition (PVD) and chemical vapor deposition (CVD) methods to create uniform, dense electrolyte films with excellent ionic conductivity[4].

Strengths: Expertise in battery technology and manufacturing, potential for high-capacity anodes. Weaknesses: Relatively new to sodium-ion technology, may face competition from more established players in this field.

Innovative Electrode Materials and Electrolytes

Hybrid solid state electrolyte

PatentActiveUS20220052378A1

Innovation

- A solid state electrolyte comprising a polymer matrix with an infiltrated ceramic phase, forming hybrid interface layers to enhance ion conductivity and reduce interface resistance, and optionally using capping layers for improved adhesion and mechanical properties.

Environmental Impact of Sodium Ion Batteries

The environmental impact of sodium-ion batteries is a crucial consideration in their development and adoption. These batteries offer several environmental advantages over traditional lithium-ion batteries, primarily due to the abundance and widespread distribution of sodium resources. This reduces the need for extensive mining operations and long-distance transportation, thereby lowering the overall carbon footprint associated with battery production.

One of the most significant environmental benefits of sodium-ion batteries is their potential to reduce reliance on critical raw materials. Unlike lithium-ion batteries, which depend on scarce elements like cobalt and nickel, sodium-ion batteries can be manufactured using more readily available materials. This shift could alleviate pressure on ecosystems in regions where these rare elements are mined, often under challenging environmental and social conditions.

The production process of sodium-ion batteries also tends to be less energy-intensive compared to lithium-ion batteries. This is partly due to the lower melting point of sodium, which requires less energy during the manufacturing phase. Additionally, the materials used in sodium-ion batteries are generally less reactive, reducing the risk of fires and environmental contamination during production, use, and disposal.

End-of-life management for sodium-ion batteries presents both challenges and opportunities. On the positive side, these batteries contain fewer toxic materials than their lithium-ion counterparts, making them potentially safer and easier to recycle. However, the recycling infrastructure for sodium-ion batteries is still in its infancy, and significant investment will be required to develop efficient recycling processes at scale.

Water usage and management are important considerations in the production of sodium-ion batteries. While the extraction of sodium is generally less water-intensive than lithium extraction, particularly from brine sources, careful water management practices are still necessary to minimize environmental impact, especially in water-stressed regions.

The long-term environmental effects of widespread sodium-ion battery adoption are still being studied. Potential concerns include the impact of increased sodium mining on local ecosystems and the need for responsible disposal of battery components that cannot be recycled. However, ongoing research is focused on developing more environmentally friendly electrolytes and electrode materials, which could further reduce the ecological footprint of these batteries.

In conclusion, while sodium-ion batteries show promise in terms of reduced environmental impact compared to current lithium-ion technology, continued research and development are essential to fully realize their potential as a sustainable energy storage solution. The environmental benefits must be carefully weighed against any potential new challenges to ensure a net positive impact on our planet's ecosystems.

One of the most significant environmental benefits of sodium-ion batteries is their potential to reduce reliance on critical raw materials. Unlike lithium-ion batteries, which depend on scarce elements like cobalt and nickel, sodium-ion batteries can be manufactured using more readily available materials. This shift could alleviate pressure on ecosystems in regions where these rare elements are mined, often under challenging environmental and social conditions.

The production process of sodium-ion batteries also tends to be less energy-intensive compared to lithium-ion batteries. This is partly due to the lower melting point of sodium, which requires less energy during the manufacturing phase. Additionally, the materials used in sodium-ion batteries are generally less reactive, reducing the risk of fires and environmental contamination during production, use, and disposal.

End-of-life management for sodium-ion batteries presents both challenges and opportunities. On the positive side, these batteries contain fewer toxic materials than their lithium-ion counterparts, making them potentially safer and easier to recycle. However, the recycling infrastructure for sodium-ion batteries is still in its infancy, and significant investment will be required to develop efficient recycling processes at scale.

Water usage and management are important considerations in the production of sodium-ion batteries. While the extraction of sodium is generally less water-intensive than lithium extraction, particularly from brine sources, careful water management practices are still necessary to minimize environmental impact, especially in water-stressed regions.

The long-term environmental effects of widespread sodium-ion battery adoption are still being studied. Potential concerns include the impact of increased sodium mining on local ecosystems and the need for responsible disposal of battery components that cannot be recycled. However, ongoing research is focused on developing more environmentally friendly electrolytes and electrode materials, which could further reduce the ecological footprint of these batteries.

In conclusion, while sodium-ion batteries show promise in terms of reduced environmental impact compared to current lithium-ion technology, continued research and development are essential to fully realize their potential as a sustainable energy storage solution. The environmental benefits must be carefully weighed against any potential new challenges to ensure a net positive impact on our planet's ecosystems.

Cost-Effectiveness Analysis of Na-Ion vs Li-Ion

The cost-effectiveness analysis of sodium-ion (Na-ion) batteries compared to lithium-ion (Li-ion) batteries is a crucial factor in determining the future adoption and commercialization of Na-ion technology. While Li-ion batteries have dominated the energy storage market for decades, the rising costs and limited availability of lithium have prompted researchers and industries to explore alternative solutions.

Na-ion batteries offer several cost advantages over their Li-ion counterparts. The primary raw material, sodium, is abundantly available and widely distributed geographically, leading to significantly lower material costs. Sodium is approximately 1000 times more abundant than lithium in the Earth's crust, which translates to a more stable and potentially lower long-term supply cost. Additionally, the extraction and processing of sodium compounds are generally less energy-intensive and environmentally impactful than lithium extraction.

The manufacturing processes for Na-ion batteries can leverage existing Li-ion battery production infrastructure with minimal modifications. This compatibility allows for a smoother transition and reduces the capital expenditure required for large-scale production. The use of aluminum current collectors for both cathode and anode in Na-ion batteries, as opposed to copper for the anode in Li-ion batteries, further contributes to cost reduction.

However, Na-ion batteries currently lag behind Li-ion in terms of energy density and cycle life. This performance gap means that more Na-ion battery material is required to achieve the same energy storage capacity as Li-ion, potentially offsetting some of the raw material cost savings. Ongoing research aims to improve Na-ion battery performance, with recent advancements showing promising results in narrowing this gap.

When considering total cost of ownership, Na-ion batteries may offer advantages in certain applications. Their superior safety characteristics, ability to be fully discharged for transport, and better low-temperature performance can lead to reduced costs in battery management systems, transportation, and operation in extreme environments.

The economic viability of Na-ion batteries also depends on scale. As production volumes increase, economies of scale are expected to further drive down costs. Projections suggest that Na-ion batteries could potentially achieve a 20-30% lower cost per kWh compared to Li-ion batteries at similar production scales.

In conclusion, while Na-ion batteries show promising cost-effectiveness potential, particularly in raw material and manufacturing costs, their overall economic competitiveness will depend on continued improvements in performance and the ability to scale up production efficiently. The cost-effectiveness analysis suggests that Na-ion batteries could become a viable alternative to Li-ion batteries, especially in applications where their unique advantages align with specific use case requirements.

Na-ion batteries offer several cost advantages over their Li-ion counterparts. The primary raw material, sodium, is abundantly available and widely distributed geographically, leading to significantly lower material costs. Sodium is approximately 1000 times more abundant than lithium in the Earth's crust, which translates to a more stable and potentially lower long-term supply cost. Additionally, the extraction and processing of sodium compounds are generally less energy-intensive and environmentally impactful than lithium extraction.

The manufacturing processes for Na-ion batteries can leverage existing Li-ion battery production infrastructure with minimal modifications. This compatibility allows for a smoother transition and reduces the capital expenditure required for large-scale production. The use of aluminum current collectors for both cathode and anode in Na-ion batteries, as opposed to copper for the anode in Li-ion batteries, further contributes to cost reduction.

However, Na-ion batteries currently lag behind Li-ion in terms of energy density and cycle life. This performance gap means that more Na-ion battery material is required to achieve the same energy storage capacity as Li-ion, potentially offsetting some of the raw material cost savings. Ongoing research aims to improve Na-ion battery performance, with recent advancements showing promising results in narrowing this gap.

When considering total cost of ownership, Na-ion batteries may offer advantages in certain applications. Their superior safety characteristics, ability to be fully discharged for transport, and better low-temperature performance can lead to reduced costs in battery management systems, transportation, and operation in extreme environments.

The economic viability of Na-ion batteries also depends on scale. As production volumes increase, economies of scale are expected to further drive down costs. Projections suggest that Na-ion batteries could potentially achieve a 20-30% lower cost per kWh compared to Li-ion batteries at similar production scales.

In conclusion, while Na-ion batteries show promising cost-effectiveness potential, particularly in raw material and manufacturing costs, their overall economic competitiveness will depend on continued improvements in performance and the ability to scale up production efficiently. The cost-effectiveness analysis suggests that Na-ion batteries could become a viable alternative to Li-ion batteries, especially in applications where their unique advantages align with specific use case requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!