IoT Device Implementation Using Sodium Ion Batteries

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

SIB for IoT: Background and Objectives

The implementation of Internet of Things (IoT) devices using Sodium Ion Batteries (SIBs) represents a significant technological advancement in the field of energy storage and sustainable electronics. This emerging technology aims to address the growing demand for more efficient, cost-effective, and environmentally friendly power sources for IoT applications.

The development of SIBs for IoT devices is driven by the limitations of current lithium-ion battery technology, including resource scarcity, high costs, and safety concerns. Sodium, being abundant and widely distributed globally, offers a promising alternative to lithium. The primary objective of this technological shift is to create a new generation of IoT devices that are not only more sustainable but also capable of meeting the increasing power demands of interconnected smart systems.

The evolution of SIB technology can be traced back to the 1980s, but it has gained significant momentum in recent years due to advancements in materials science and the urgent need for alternative energy storage solutions. The current research and development efforts are focused on improving the energy density, cycle life, and overall performance of SIBs to make them competitive with lithium-ion batteries in IoT applications.

One of the key goals in SIB development for IoT is to achieve a balance between energy density and device size. IoT devices often require compact power sources that can deliver sufficient energy for extended periods. This challenge has led to innovative approaches in electrode material design and electrolyte formulations, aiming to maximize the sodium storage capacity while maintaining a small form factor.

Another critical objective is to enhance the safety profile of SIBs, making them suitable for a wide range of IoT applications, including wearable devices and smart home systems. This involves developing new electrolyte compositions and battery management systems that can prevent thermal runaway and ensure stable operation under various environmental conditions.

The integration of SIBs into IoT devices also aims to support the growing trend of energy harvesting and self-powered systems. By combining SIBs with energy harvesting technologies such as solar cells or piezoelectric generators, researchers are working towards creating IoT devices that can operate autonomously for extended periods, reducing the need for frequent battery replacements or recharging.

As the IoT ecosystem continues to expand, the development of SIBs is expected to play a crucial role in enabling the next generation of smart devices. The technology's potential to offer a more sustainable and cost-effective alternative to lithium-ion batteries aligns well with the global push towards greener technologies and circular economy principles.

The development of SIBs for IoT devices is driven by the limitations of current lithium-ion battery technology, including resource scarcity, high costs, and safety concerns. Sodium, being abundant and widely distributed globally, offers a promising alternative to lithium. The primary objective of this technological shift is to create a new generation of IoT devices that are not only more sustainable but also capable of meeting the increasing power demands of interconnected smart systems.

The evolution of SIB technology can be traced back to the 1980s, but it has gained significant momentum in recent years due to advancements in materials science and the urgent need for alternative energy storage solutions. The current research and development efforts are focused on improving the energy density, cycle life, and overall performance of SIBs to make them competitive with lithium-ion batteries in IoT applications.

One of the key goals in SIB development for IoT is to achieve a balance between energy density and device size. IoT devices often require compact power sources that can deliver sufficient energy for extended periods. This challenge has led to innovative approaches in electrode material design and electrolyte formulations, aiming to maximize the sodium storage capacity while maintaining a small form factor.

Another critical objective is to enhance the safety profile of SIBs, making them suitable for a wide range of IoT applications, including wearable devices and smart home systems. This involves developing new electrolyte compositions and battery management systems that can prevent thermal runaway and ensure stable operation under various environmental conditions.

The integration of SIBs into IoT devices also aims to support the growing trend of energy harvesting and self-powered systems. By combining SIBs with energy harvesting technologies such as solar cells or piezoelectric generators, researchers are working towards creating IoT devices that can operate autonomously for extended periods, reducing the need for frequent battery replacements or recharging.

As the IoT ecosystem continues to expand, the development of SIBs is expected to play a crucial role in enabling the next generation of smart devices. The technology's potential to offer a more sustainable and cost-effective alternative to lithium-ion batteries aligns well with the global push towards greener technologies and circular economy principles.

IoT Market Demand Analysis

The Internet of Things (IoT) market has experienced significant growth in recent years, with a surge in demand for connected devices across various sectors. This trend has created a substantial market opportunity for IoT devices powered by sodium-ion batteries. The increasing adoption of IoT solutions in industries such as smart homes, healthcare, agriculture, and industrial automation has driven the need for more sustainable and cost-effective power sources.

In the smart home sector, there is a growing demand for IoT devices that can seamlessly integrate into household environments. Consumers are seeking energy-efficient solutions that can operate for extended periods without frequent battery replacements. Sodium-ion batteries offer a promising alternative to traditional lithium-ion batteries, potentially providing longer-lasting power for smart home devices such as sensors, thermostats, and security systems.

The healthcare industry has also shown a strong interest in IoT devices for remote patient monitoring and wearable medical devices. These applications require reliable, long-lasting power sources that are safe for use in close proximity to the human body. Sodium-ion batteries, with their improved safety profile compared to lithium-ion batteries, are well-positioned to meet this demand.

In the agricultural sector, IoT devices are increasingly used for precision farming, crop monitoring, and livestock tracking. These applications often involve deploying sensors and devices in remote locations where frequent battery replacement is impractical. The potential for sodium-ion batteries to offer extended battery life and improved performance in extreme temperatures makes them particularly attractive for agricultural IoT implementations.

Industrial IoT applications, such as predictive maintenance and asset tracking, require robust power solutions that can withstand harsh environments. Sodium-ion batteries' ability to operate effectively in a wide range of temperatures and their potential for faster charging capabilities align well with the demands of industrial IoT deployments.

The market demand for IoT devices using sodium-ion batteries is further driven by the global push for sustainability and reduced environmental impact. As organizations and consumers become more environmentally conscious, there is a growing preference for power solutions that use more abundant and less environmentally harmful materials compared to traditional lithium-ion batteries.

Additionally, the potential for lower production costs of sodium-ion batteries could lead to more affordable IoT devices, potentially accelerating market adoption across various sectors. This cost advantage could be particularly significant in emerging markets, where price sensitivity is a crucial factor in technology adoption.

As the IoT ecosystem continues to expand and evolve, the demand for innovative power solutions like sodium-ion batteries is expected to grow. The market is likely to see increased investment in research and development to further improve the performance and efficiency of sodium-ion batteries for IoT applications, driving continued innovation in this space.

In the smart home sector, there is a growing demand for IoT devices that can seamlessly integrate into household environments. Consumers are seeking energy-efficient solutions that can operate for extended periods without frequent battery replacements. Sodium-ion batteries offer a promising alternative to traditional lithium-ion batteries, potentially providing longer-lasting power for smart home devices such as sensors, thermostats, and security systems.

The healthcare industry has also shown a strong interest in IoT devices for remote patient monitoring and wearable medical devices. These applications require reliable, long-lasting power sources that are safe for use in close proximity to the human body. Sodium-ion batteries, with their improved safety profile compared to lithium-ion batteries, are well-positioned to meet this demand.

In the agricultural sector, IoT devices are increasingly used for precision farming, crop monitoring, and livestock tracking. These applications often involve deploying sensors and devices in remote locations where frequent battery replacement is impractical. The potential for sodium-ion batteries to offer extended battery life and improved performance in extreme temperatures makes them particularly attractive for agricultural IoT implementations.

Industrial IoT applications, such as predictive maintenance and asset tracking, require robust power solutions that can withstand harsh environments. Sodium-ion batteries' ability to operate effectively in a wide range of temperatures and their potential for faster charging capabilities align well with the demands of industrial IoT deployments.

The market demand for IoT devices using sodium-ion batteries is further driven by the global push for sustainability and reduced environmental impact. As organizations and consumers become more environmentally conscious, there is a growing preference for power solutions that use more abundant and less environmentally harmful materials compared to traditional lithium-ion batteries.

Additionally, the potential for lower production costs of sodium-ion batteries could lead to more affordable IoT devices, potentially accelerating market adoption across various sectors. This cost advantage could be particularly significant in emerging markets, where price sensitivity is a crucial factor in technology adoption.

As the IoT ecosystem continues to expand and evolve, the demand for innovative power solutions like sodium-ion batteries is expected to grow. The market is likely to see increased investment in research and development to further improve the performance and efficiency of sodium-ion batteries for IoT applications, driving continued innovation in this space.

SIB Technology Status and Challenges

Sodium-ion battery (SIB) technology has made significant strides in recent years, positioning itself as a promising alternative to lithium-ion batteries for IoT device implementation. The current status of SIB technology showcases its potential to address the growing demand for sustainable and cost-effective energy storage solutions in the IoT sector.

One of the primary advantages of SIBs is their use of abundant and widely distributed raw materials, particularly sodium, which is significantly more accessible than lithium. This abundance translates to lower production costs and reduced geopolitical risks associated with resource acquisition. Additionally, SIBs exhibit favorable safety characteristics, with a lower risk of thermal runaway and fire compared to their lithium-ion counterparts.

However, several challenges persist in the widespread adoption of SIBs for IoT devices. The energy density of current SIB technologies remains lower than that of lithium-ion batteries, which can limit their application in devices requiring high energy storage capacity in compact form factors. Researchers are actively working on improving cathode and anode materials to enhance energy density and overall performance.

Cycle life and long-term stability present another hurdle for SIB technology. While progress has been made, further improvements are necessary to match the longevity of lithium-ion batteries, especially for IoT applications that demand extended operational lifetimes without frequent maintenance or replacement.

The development of suitable electrolytes for SIBs also poses a significant challenge. Finding electrolyte compositions that ensure stable solid-electrolyte interphase (SEI) formation and prevent unwanted side reactions is crucial for enhancing battery performance and lifespan.

From a manufacturing perspective, adapting existing production lines and processes to accommodate SIB technology presents both opportunities and challenges. While some similarities exist with lithium-ion battery production, specific modifications and optimizations are required to address the unique characteristics of sodium-ion chemistry.

Geographically, research and development efforts in SIB technology are distributed across various regions, with notable contributions from Asia, Europe, and North America. China has emerged as a leader in SIB research and commercialization, with several companies actively pursuing large-scale production. European and North American institutions are also making significant advancements, particularly in materials science and cell design.

As the technology matures, standardization and regulatory frameworks specific to SIBs are being developed. These efforts aim to ensure safety, performance, and interoperability across different manufacturers and applications, which is crucial for widespread adoption in the IoT ecosystem.

One of the primary advantages of SIBs is their use of abundant and widely distributed raw materials, particularly sodium, which is significantly more accessible than lithium. This abundance translates to lower production costs and reduced geopolitical risks associated with resource acquisition. Additionally, SIBs exhibit favorable safety characteristics, with a lower risk of thermal runaway and fire compared to their lithium-ion counterparts.

However, several challenges persist in the widespread adoption of SIBs for IoT devices. The energy density of current SIB technologies remains lower than that of lithium-ion batteries, which can limit their application in devices requiring high energy storage capacity in compact form factors. Researchers are actively working on improving cathode and anode materials to enhance energy density and overall performance.

Cycle life and long-term stability present another hurdle for SIB technology. While progress has been made, further improvements are necessary to match the longevity of lithium-ion batteries, especially for IoT applications that demand extended operational lifetimes without frequent maintenance or replacement.

The development of suitable electrolytes for SIBs also poses a significant challenge. Finding electrolyte compositions that ensure stable solid-electrolyte interphase (SEI) formation and prevent unwanted side reactions is crucial for enhancing battery performance and lifespan.

From a manufacturing perspective, adapting existing production lines and processes to accommodate SIB technology presents both opportunities and challenges. While some similarities exist with lithium-ion battery production, specific modifications and optimizations are required to address the unique characteristics of sodium-ion chemistry.

Geographically, research and development efforts in SIB technology are distributed across various regions, with notable contributions from Asia, Europe, and North America. China has emerged as a leader in SIB research and commercialization, with several companies actively pursuing large-scale production. European and North American institutions are also making significant advancements, particularly in materials science and cell design.

As the technology matures, standardization and regulatory frameworks specific to SIBs are being developed. These efforts aim to ensure safety, performance, and interoperability across different manufacturers and applications, which is crucial for widespread adoption in the IoT ecosystem.

Current SIB Solutions for IoT

01 Electrode materials for sodium-ion batteries

Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. This includes research on cathode and anode materials that offer high capacity, good cycling stability, and improved sodium ion storage capabilities. Researchers are exploring various compounds and nanostructures to enhance the electrochemical properties of these batteries.- Electrode materials for sodium-ion batteries: Development of novel electrode materials is crucial for improving sodium-ion battery performance. This includes research on cathode and anode materials that offer high capacity, good cycling stability, and improved sodium ion storage capabilities. Researchers are exploring various compounds and nanostructures to enhance the electrochemical properties of these batteries.

- Electrolyte formulations for sodium-ion batteries: Optimizing electrolyte compositions is essential for enhancing the performance and safety of sodium-ion batteries. This involves developing new electrolyte formulations that improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system. Research focuses on both liquid and solid electrolytes tailored for sodium-ion chemistry.

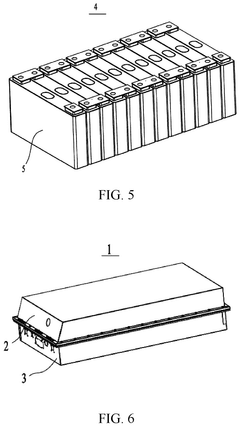

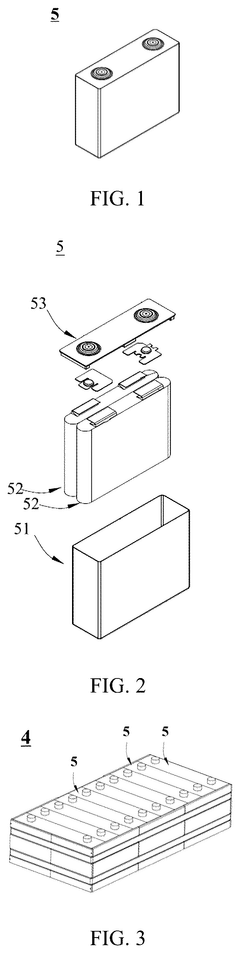

- Battery cell design and manufacturing processes: Innovations in battery cell design and manufacturing processes are key to improving the performance and scalability of sodium-ion batteries. This includes developing new cell architectures, optimizing electrode fabrication techniques, and enhancing assembly methods to increase energy density, reduce costs, and improve production efficiency.

- Sodium-ion battery management systems: Advanced battery management systems are being developed specifically for sodium-ion batteries to optimize their performance and lifespan. These systems focus on monitoring and controlling battery parameters, implementing efficient charging strategies, and ensuring safe operation under various conditions. Innovations in this area aim to enhance the overall reliability and usability of sodium-ion battery systems.

- Integration of sodium-ion batteries in energy storage applications: Research is ongoing to integrate sodium-ion batteries into various energy storage applications, including grid-scale storage, renewable energy systems, and electric vehicles. This involves developing specialized battery packs, addressing scaling challenges, and optimizing battery performance for specific use cases. The focus is on leveraging the advantages of sodium-ion technology, such as lower cost and abundant raw materials, in practical energy storage solutions.

02 Electrolyte formulations for sodium-ion batteries

Optimizing electrolyte compositions is essential for enhancing the performance and safety of sodium-ion batteries. This involves developing new electrolyte formulations that improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system. Research focuses on both liquid and solid electrolytes tailored for sodium-ion chemistry.Expand Specific Solutions03 Battery cell design and manufacturing processes

Innovations in battery cell design and manufacturing processes are key to improving the performance and scalability of sodium-ion batteries. This includes developing new cell architectures, optimizing electrode fabrication techniques, and exploring advanced manufacturing methods to enhance energy density, power output, and production efficiency.Expand Specific Solutions04 Sodium-ion battery management systems

Developing sophisticated battery management systems specifically tailored for sodium-ion batteries is crucial for optimizing their performance and longevity. This involves creating advanced algorithms for state-of-charge estimation, thermal management, and safety controls that account for the unique characteristics of sodium-ion chemistry.Expand Specific Solutions05 Applications and integration of sodium-ion batteries

Exploring various applications and integration strategies for sodium-ion batteries is important for their commercial adoption. This includes research on using these batteries in grid energy storage, electric vehicles, and portable electronics. Efforts are focused on optimizing battery pack designs, addressing integration challenges, and demonstrating the feasibility of sodium-ion technology in different use cases.Expand Specific Solutions

Key Players in SIB and IoT Industries

The IoT device implementation using sodium ion batteries is in an early development stage, with a growing market potential driven by the increasing demand for sustainable energy storage solutions. The technology's maturity is still evolving, with key players like Contemporary Amperex Technology Co., Ltd., BYD Co., Ltd., and Faradion Ltd. leading research and development efforts. These companies are focusing on improving the performance, cost-effectiveness, and scalability of sodium ion batteries for IoT applications. The market is characterized by ongoing innovation and collaboration between battery manufacturers, IoT device makers, and research institutions, as they work to overcome technical challenges and optimize the integration of sodium ion batteries into IoT devices. As the technology advances, it is expected to gain traction in various IoT sectors, potentially offering a more sustainable and cost-effective alternative to traditional lithium-ion batteries.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced sodium-ion batteries for IoT devices, featuring a high energy density of 160Wh/kg and fast charging capability, reaching 80% capacity in 15 minutes[1]. Their proprietary Prussian white cathode material and hard carbon anode enable a longer cycle life of over 3000 cycles[2]. CATL's sodium-ion batteries incorporate a novel electrolyte formulation that enhances low-temperature performance, maintaining 90% capacity at -20°C[3]. For IoT applications, they've designed compact, modular battery packs with integrated battery management systems, optimizing space utilization and enabling easy integration into various IoT devices[4].

Strengths: High energy density, fast charging, long cycle life, and excellent low-temperature performance. The modular design facilitates easy integration into diverse IoT devices. Weaknesses: Sodium-ion technology is still relatively new, potentially leading to higher initial costs and limited production capacity compared to established lithium-ion batteries.

Faradion Ltd.

Technical Solution: Faradion has pioneered sodium-ion technology specifically tailored for IoT devices. Their batteries utilize a proprietary layered oxide cathode and hard carbon anode, achieving an energy density of 140Wh/kg[5]. Faradion's IoT-focused batteries feature a thin-film design, allowing for flexible form factors as thin as 0.5mm, ideal for space-constrained IoT applications[6]. The company has developed a unique electrolyte additive that significantly improves the battery's thermal stability, enhancing safety for wearable IoT devices[7]. Faradion's sodium-ion batteries also incorporate advanced power management circuitry, enabling ultra-low self-discharge rates of less than 2% per month, crucial for long-term IoT deployments[8].

Strengths: Flexible form factor, enhanced safety features, and low self-discharge rates, making them ideal for various IoT applications. Weaknesses: Lower energy density compared to some lithium-ion alternatives, which may limit use in high-power IoT devices.

Core SIB Innovations for IoT

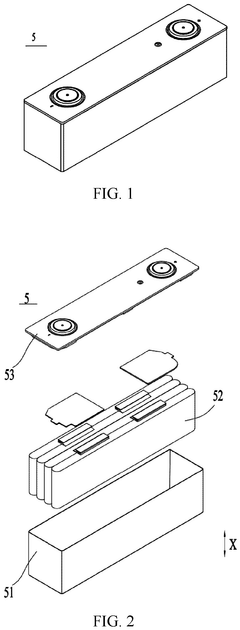

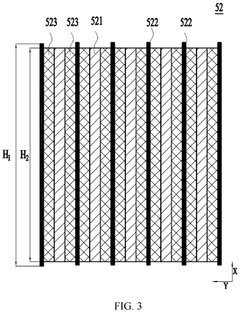

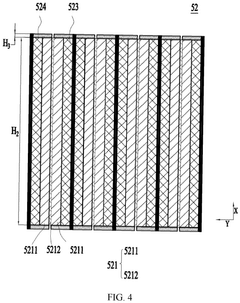

Sodium ion battery, battery and electric device

PatentPendingEP4517993A1

Innovation

- Incorporating an ion conductor with an elastic modulus of 0.10 to 5.00 GPa between the positive and negative electrode plates, which isolates the electrodes and provides conduction paths for sodium ions, reducing the risk of short circuits by allowing the ion conductor to deform and contain the deposited sodium metal.

Sodium-ion battery and electric apparatus containing same

PatentPendingUS20250112242A1

Innovation

- A sodium-ion battery design that omits the negative electrode active material layer, utilizing a carbon nanotube coating on the current collector to suppress sodium dendrite formation by providing a surface for uniform sodium deposition, enhancing cycling performance and energy density.

Environmental Impact of SIB in IoT

The implementation of Sodium Ion Batteries (SIBs) in Internet of Things (IoT) devices presents a significant opportunity to reduce the environmental impact of these increasingly ubiquitous technologies. SIBs offer several environmental advantages over traditional lithium-ion batteries, particularly in terms of resource availability and end-of-life management.

Sodium, the primary material in SIBs, is abundantly available and widely distributed across the globe. This reduces the environmental strain associated with mining and processing rare earth elements often required for lithium-ion batteries. The extraction process for sodium is generally less energy-intensive and has a lower carbon footprint compared to lithium extraction, contributing to a reduced overall environmental impact from the manufacturing stage.

In the context of IoT devices, which are often deployed in large numbers and distributed across wide areas, the use of SIBs can lead to significant reductions in the cumulative environmental impact of battery production. This is particularly relevant as the IoT ecosystem continues to expand rapidly, with billions of devices expected to be in operation in the coming years.

The operational phase of SIB-powered IoT devices also offers environmental benefits. SIBs typically have a longer cycle life compared to many lithium-ion batteries, which means they need to be replaced less frequently. This reduces the overall material consumption and waste generation associated with battery replacements in IoT networks.

End-of-life management is another area where SIBs show promise in reducing environmental impact. The materials used in SIBs are generally less toxic and easier to recycle compared to those in lithium-ion batteries. This facilitates more efficient and environmentally friendly recycling processes, potentially leading to a more circular economy approach in the IoT sector.

Furthermore, the use of SIBs in IoT devices can contribute to reduced electronic waste. As SIBs become more prevalent, standardization of battery sizes and chemistries may follow, simplifying recycling processes and increasing the likelihood of proper disposal and recycling of IoT devices at the end of their life cycle.

However, it's important to note that the environmental impact of SIBs in IoT applications is not uniformly positive. The production of SIBs still requires energy and resources, and the full life-cycle assessment of these batteries in various IoT applications needs further study. Additionally, as SIB technology is still evolving, ongoing research is needed to optimize their performance and environmental profile specifically for IoT use cases.

Sodium, the primary material in SIBs, is abundantly available and widely distributed across the globe. This reduces the environmental strain associated with mining and processing rare earth elements often required for lithium-ion batteries. The extraction process for sodium is generally less energy-intensive and has a lower carbon footprint compared to lithium extraction, contributing to a reduced overall environmental impact from the manufacturing stage.

In the context of IoT devices, which are often deployed in large numbers and distributed across wide areas, the use of SIBs can lead to significant reductions in the cumulative environmental impact of battery production. This is particularly relevant as the IoT ecosystem continues to expand rapidly, with billions of devices expected to be in operation in the coming years.

The operational phase of SIB-powered IoT devices also offers environmental benefits. SIBs typically have a longer cycle life compared to many lithium-ion batteries, which means they need to be replaced less frequently. This reduces the overall material consumption and waste generation associated with battery replacements in IoT networks.

End-of-life management is another area where SIBs show promise in reducing environmental impact. The materials used in SIBs are generally less toxic and easier to recycle compared to those in lithium-ion batteries. This facilitates more efficient and environmentally friendly recycling processes, potentially leading to a more circular economy approach in the IoT sector.

Furthermore, the use of SIBs in IoT devices can contribute to reduced electronic waste. As SIBs become more prevalent, standardization of battery sizes and chemistries may follow, simplifying recycling processes and increasing the likelihood of proper disposal and recycling of IoT devices at the end of their life cycle.

However, it's important to note that the environmental impact of SIBs in IoT applications is not uniformly positive. The production of SIBs still requires energy and resources, and the full life-cycle assessment of these batteries in various IoT applications needs further study. Additionally, as SIB technology is still evolving, ongoing research is needed to optimize their performance and environmental profile specifically for IoT use cases.

SIB Supply Chain for IoT Devices

The supply chain for sodium-ion batteries (SIBs) in IoT devices is a critical component in the successful implementation of this emerging technology. As the demand for sustainable and cost-effective energy storage solutions grows, the SIB supply chain is rapidly evolving to meet the unique requirements of IoT applications.

Raw material sourcing forms the foundation of the SIB supply chain. Unlike lithium-ion batteries, SIBs rely on abundant and widely distributed materials such as sodium, iron, and manganese. This geographical diversity in raw material sources contributes to a more resilient and potentially less expensive supply chain, reducing dependency on specific regions or countries.

The manufacturing process for SIB components involves several specialized steps. Cathode production typically utilizes sodium-based compounds, while anode materials often incorporate hard carbon or other sodium-intercalation materials. Electrolyte formulation for SIBs requires specific attention to compatibility with sodium ions, often utilizing organic solvents or solid-state electrolytes.

Assembly of SIB cells for IoT devices presents unique challenges and opportunities. The lower energy density of SIBs compared to lithium-ion batteries necessitates innovative design approaches to maximize performance within the compact form factors typical of IoT devices. This has led to the development of specialized manufacturing techniques and equipment tailored for SIB production.

Quality control and testing procedures are crucial elements of the SIB supply chain for IoT applications. Given the nascent nature of SIB technology, rigorous testing protocols are essential to ensure reliability, safety, and performance consistency across various IoT use cases and environmental conditions.

Distribution and integration of SIBs into IoT devices require close collaboration between battery manufacturers and device makers. This often involves customized solutions to address specific power requirements, form factors, and operational parameters of different IoT applications.

End-of-life considerations and recycling processes are increasingly important aspects of the SIB supply chain. The relatively simple chemistry of SIBs potentially allows for more straightforward and cost-effective recycling compared to lithium-ion batteries, aligning well with the growing emphasis on circular economy principles in the IoT sector.

As the technology matures, the SIB supply chain for IoT devices is expected to become more streamlined and efficient. Ongoing research and development efforts are focused on improving material performance, optimizing manufacturing processes, and enhancing overall supply chain sustainability to meet the evolving needs of the IoT market.

Raw material sourcing forms the foundation of the SIB supply chain. Unlike lithium-ion batteries, SIBs rely on abundant and widely distributed materials such as sodium, iron, and manganese. This geographical diversity in raw material sources contributes to a more resilient and potentially less expensive supply chain, reducing dependency on specific regions or countries.

The manufacturing process for SIB components involves several specialized steps. Cathode production typically utilizes sodium-based compounds, while anode materials often incorporate hard carbon or other sodium-intercalation materials. Electrolyte formulation for SIBs requires specific attention to compatibility with sodium ions, often utilizing organic solvents or solid-state electrolytes.

Assembly of SIB cells for IoT devices presents unique challenges and opportunities. The lower energy density of SIBs compared to lithium-ion batteries necessitates innovative design approaches to maximize performance within the compact form factors typical of IoT devices. This has led to the development of specialized manufacturing techniques and equipment tailored for SIB production.

Quality control and testing procedures are crucial elements of the SIB supply chain for IoT applications. Given the nascent nature of SIB technology, rigorous testing protocols are essential to ensure reliability, safety, and performance consistency across various IoT use cases and environmental conditions.

Distribution and integration of SIBs into IoT devices require close collaboration between battery manufacturers and device makers. This often involves customized solutions to address specific power requirements, form factors, and operational parameters of different IoT applications.

End-of-life considerations and recycling processes are increasingly important aspects of the SIB supply chain. The relatively simple chemistry of SIBs potentially allows for more straightforward and cost-effective recycling compared to lithium-ion batteries, aligning well with the growing emphasis on circular economy principles in the IoT sector.

As the technology matures, the SIB supply chain for IoT devices is expected to become more streamlined and efficient. Ongoing research and development efforts are focused on improving material performance, optimizing manufacturing processes, and enhancing overall supply chain sustainability to meet the evolving needs of the IoT market.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!