Sodium Ion Batteries and Next-Gen Material Research

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Evolution and Objectives

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries (LIBs) in recent years, driven by the increasing demand for sustainable and cost-effective energy storage solutions. The evolution of SIBs can be traced back to the 1980s when initial research on sodium-based intercalation compounds began. However, it wasn't until the early 2000s that significant progress was made in developing practical SIB systems.

The primary objective of SIB research is to create a viable energy storage technology that can complement or potentially replace LIBs in certain applications. This goal is motivated by several factors, including the abundance and low cost of sodium resources, the similarity in chemical properties between sodium and lithium, and the potential for improved safety characteristics.

Over the past decade, SIB technology has witnessed remarkable advancements in terms of electrode materials, electrolytes, and overall cell design. Researchers have focused on developing high-performance cathode materials, such as layered oxides, polyanionic compounds, and Prussian blue analogues. Concurrently, efforts have been made to improve anode materials, with hard carbons emerging as a promising option due to their high capacity and good cycling stability.

The evolution of SIBs has been marked by several key milestones. In 2010, the first full-cell SIB with a layered oxide cathode and hard carbon anode was reported, demonstrating the feasibility of room-temperature sodium-ion batteries. Subsequently, rapid progress has been made in improving energy density, cycle life, and rate capability of SIBs.

Looking ahead, the objectives for SIB research are multifaceted. First and foremost is the need to further enhance energy density to make SIBs competitive with LIBs in terms of specific energy and energy density. This involves developing new electrode materials with higher capacities and operating voltages. Another crucial objective is to improve the cycling stability and longevity of SIBs, addressing issues such as electrode degradation and electrolyte decomposition.

Additionally, researchers aim to optimize the performance of SIBs at extreme temperatures, particularly at low temperatures where sodium-ion diffusion can be sluggish. There is also a focus on developing scalable and environmentally friendly manufacturing processes for SIB components, ensuring that the technology can be produced at a commercial scale with minimal environmental impact.

As the field progresses, there is an increasing emphasis on exploring next-generation materials for SIBs. This includes investigating novel cathode and anode materials, such as organic compounds, conversion-type electrodes, and sodium metal anodes. The development of advanced electrolytes, including solid-state electrolytes, is another area of intense research aimed at improving the safety and performance of SIBs.

The primary objective of SIB research is to create a viable energy storage technology that can complement or potentially replace LIBs in certain applications. This goal is motivated by several factors, including the abundance and low cost of sodium resources, the similarity in chemical properties between sodium and lithium, and the potential for improved safety characteristics.

Over the past decade, SIB technology has witnessed remarkable advancements in terms of electrode materials, electrolytes, and overall cell design. Researchers have focused on developing high-performance cathode materials, such as layered oxides, polyanionic compounds, and Prussian blue analogues. Concurrently, efforts have been made to improve anode materials, with hard carbons emerging as a promising option due to their high capacity and good cycling stability.

The evolution of SIBs has been marked by several key milestones. In 2010, the first full-cell SIB with a layered oxide cathode and hard carbon anode was reported, demonstrating the feasibility of room-temperature sodium-ion batteries. Subsequently, rapid progress has been made in improving energy density, cycle life, and rate capability of SIBs.

Looking ahead, the objectives for SIB research are multifaceted. First and foremost is the need to further enhance energy density to make SIBs competitive with LIBs in terms of specific energy and energy density. This involves developing new electrode materials with higher capacities and operating voltages. Another crucial objective is to improve the cycling stability and longevity of SIBs, addressing issues such as electrode degradation and electrolyte decomposition.

Additionally, researchers aim to optimize the performance of SIBs at extreme temperatures, particularly at low temperatures where sodium-ion diffusion can be sluggish. There is also a focus on developing scalable and environmentally friendly manufacturing processes for SIB components, ensuring that the technology can be produced at a commercial scale with minimal environmental impact.

As the field progresses, there is an increasing emphasis on exploring next-generation materials for SIBs. This includes investigating novel cathode and anode materials, such as organic compounds, conversion-type electrodes, and sodium metal anodes. The development of advanced electrolytes, including solid-state electrolytes, is another area of intense research aimed at improving the safety and performance of SIBs.

Market Analysis for Sodium Ion Energy Storage

The sodium-ion battery market is experiencing rapid growth and attracting significant attention from both industry players and investors. This emerging technology is poised to complement and potentially compete with lithium-ion batteries in various energy storage applications. The global market for sodium-ion batteries is projected to expand substantially over the next decade, driven by increasing demand for sustainable and cost-effective energy storage solutions.

One of the primary factors fueling market growth is the rising need for grid-scale energy storage systems. As renewable energy sources like solar and wind power become more prevalent, the demand for efficient and large-scale energy storage solutions continues to increase. Sodium-ion batteries offer a promising alternative to lithium-ion batteries for grid storage applications due to their lower cost, abundant raw materials, and improved safety characteristics.

The electric vehicle (EV) sector represents another significant market opportunity for sodium-ion batteries. While lithium-ion batteries currently dominate the EV market, concerns over the long-term availability and cost of lithium have prompted manufacturers to explore alternative technologies. Sodium-ion batteries could potentially address these concerns, offering a more sustainable and cost-effective solution for certain EV applications, particularly in the low to mid-range vehicle segments.

Consumer electronics is another area where sodium-ion batteries are expected to gain traction. The technology's safety advantages and potential for lower production costs make it an attractive option for portable devices, wearables, and other consumer electronic products. As the technology matures and energy density improves, sodium-ion batteries could capture a significant share of this market.

Geographically, Asia-Pacific is expected to lead the sodium-ion battery market, with China at the forefront of development and commercialization efforts. Several Chinese companies have already announced plans to mass-produce sodium-ion batteries, indicating strong market potential in the region. Europe and North America are also showing increasing interest in the technology, with research institutions and companies actively working on advancing sodium-ion battery technology.

The market for sodium-ion energy storage is characterized by intense research and development activities, with numerous companies and academic institutions working to improve the technology's performance and scalability. Key areas of focus include enhancing energy density, improving cycle life, and developing more efficient manufacturing processes. As these advancements continue, the market is expected to see the introduction of new products and applications, further driving growth and adoption.

One of the primary factors fueling market growth is the rising need for grid-scale energy storage systems. As renewable energy sources like solar and wind power become more prevalent, the demand for efficient and large-scale energy storage solutions continues to increase. Sodium-ion batteries offer a promising alternative to lithium-ion batteries for grid storage applications due to their lower cost, abundant raw materials, and improved safety characteristics.

The electric vehicle (EV) sector represents another significant market opportunity for sodium-ion batteries. While lithium-ion batteries currently dominate the EV market, concerns over the long-term availability and cost of lithium have prompted manufacturers to explore alternative technologies. Sodium-ion batteries could potentially address these concerns, offering a more sustainable and cost-effective solution for certain EV applications, particularly in the low to mid-range vehicle segments.

Consumer electronics is another area where sodium-ion batteries are expected to gain traction. The technology's safety advantages and potential for lower production costs make it an attractive option for portable devices, wearables, and other consumer electronic products. As the technology matures and energy density improves, sodium-ion batteries could capture a significant share of this market.

Geographically, Asia-Pacific is expected to lead the sodium-ion battery market, with China at the forefront of development and commercialization efforts. Several Chinese companies have already announced plans to mass-produce sodium-ion batteries, indicating strong market potential in the region. Europe and North America are also showing increasing interest in the technology, with research institutions and companies actively working on advancing sodium-ion battery technology.

The market for sodium-ion energy storage is characterized by intense research and development activities, with numerous companies and academic institutions working to improve the technology's performance and scalability. Key areas of focus include enhancing energy density, improving cycle life, and developing more efficient manufacturing processes. As these advancements continue, the market is expected to see the introduction of new products and applications, further driving growth and adoption.

Technical Challenges in Sodium Ion Battery Development

The development of sodium-ion batteries faces several significant technical challenges that researchers and engineers are actively working to overcome. One of the primary obstacles is the lower energy density compared to lithium-ion batteries. This limitation stems from the larger size of sodium ions, which affects the battery's capacity and overall performance. Researchers are exploring novel electrode materials and optimizing cell designs to address this issue and improve energy density.

Another critical challenge lies in the development of suitable cathode materials. While several promising candidates have been identified, such as layered oxides and polyanionic compounds, they often suffer from structural instability during cycling. This instability can lead to capacity fading and reduced battery lifespan. Scientists are investigating various strategies, including doping and surface modification, to enhance the structural stability of cathode materials and improve their long-term performance.

The anode material selection also presents significant hurdles. Traditional graphite anodes used in lithium-ion batteries are not suitable for sodium-ion systems due to the larger size of sodium ions. Hard carbon has emerged as a potential alternative, but it still faces challenges in terms of capacity and rate capability. Researchers are exploring other anode materials, such as alloys and metal oxides, to overcome these limitations and enhance the overall battery performance.

Electrolyte development is another crucial area of focus. Sodium-ion batteries require electrolytes that are compatible with both the cathode and anode materials while ensuring stable operation over a wide temperature range. Finding the right balance between conductivity, stability, and safety remains a significant challenge. Researchers are investigating various electrolyte formulations, including both liquid and solid-state options, to address these requirements.

The interface between the electrode and electrolyte, known as the solid-electrolyte interphase (SEI), poses additional challenges. The formation and stability of the SEI layer are critical for battery performance and longevity. In sodium-ion systems, the SEI tends to be less stable compared to lithium-ion batteries, leading to increased side reactions and capacity loss. Developing strategies to control and optimize the SEI formation is an active area of research.

Scaling up sodium-ion battery technology from laboratory prototypes to commercial production presents its own set of challenges. Issues such as material availability, manufacturing processes, and cost-effectiveness need to be addressed to make sodium-ion batteries a viable alternative to lithium-ion technology. Researchers and industry partners are working on optimizing production methods and exploring sustainable sourcing of raw materials to overcome these hurdles.

Another critical challenge lies in the development of suitable cathode materials. While several promising candidates have been identified, such as layered oxides and polyanionic compounds, they often suffer from structural instability during cycling. This instability can lead to capacity fading and reduced battery lifespan. Scientists are investigating various strategies, including doping and surface modification, to enhance the structural stability of cathode materials and improve their long-term performance.

The anode material selection also presents significant hurdles. Traditional graphite anodes used in lithium-ion batteries are not suitable for sodium-ion systems due to the larger size of sodium ions. Hard carbon has emerged as a potential alternative, but it still faces challenges in terms of capacity and rate capability. Researchers are exploring other anode materials, such as alloys and metal oxides, to overcome these limitations and enhance the overall battery performance.

Electrolyte development is another crucial area of focus. Sodium-ion batteries require electrolytes that are compatible with both the cathode and anode materials while ensuring stable operation over a wide temperature range. Finding the right balance between conductivity, stability, and safety remains a significant challenge. Researchers are investigating various electrolyte formulations, including both liquid and solid-state options, to address these requirements.

The interface between the electrode and electrolyte, known as the solid-electrolyte interphase (SEI), poses additional challenges. The formation and stability of the SEI layer are critical for battery performance and longevity. In sodium-ion systems, the SEI tends to be less stable compared to lithium-ion batteries, leading to increased side reactions and capacity loss. Developing strategies to control and optimize the SEI formation is an active area of research.

Scaling up sodium-ion battery technology from laboratory prototypes to commercial production presents its own set of challenges. Issues such as material availability, manufacturing processes, and cost-effectiveness need to be addressed to make sodium-ion batteries a viable alternative to lithium-ion technology. Researchers and industry partners are working on optimizing production methods and exploring sustainable sourcing of raw materials to overcome these hurdles.

Current Sodium Ion Battery Material Solutions

01 Electrode materials for sodium-ion batteries

Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials focus on enhancing energy density, cycling stability, and rate capability. Research includes exploring various compounds and nanostructures to optimize sodium ion storage and transport.- Electrode materials for sodium-ion batteries: Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials can include various compounds and composites designed to enhance energy density, cycling stability, and charge/discharge rates. Research focuses on optimizing the structure and composition of both anode and cathode materials to better accommodate sodium ions.

- Electrolyte formulations for sodium-ion batteries: Electrolyte composition plays a vital role in the performance and safety of sodium-ion batteries. Researchers are exploring various electrolyte formulations, including liquid, solid, and gel electrolytes, to improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system. Novel additives and solvents are being investigated to address specific challenges in sodium-ion battery technology.

- Battery cell design and manufacturing processes: Innovations in battery cell design and manufacturing processes are essential for scaling up sodium-ion battery production. This includes developing new cell architectures, improving assembly techniques, and optimizing the integration of components. Advanced manufacturing methods are being explored to enhance the consistency, reliability, and cost-effectiveness of sodium-ion battery production.

- Battery management systems for sodium-ion batteries: Specialized battery management systems are being developed to optimize the performance and longevity of sodium-ion batteries. These systems focus on monitoring and controlling various parameters such as voltage, current, and temperature to ensure safe and efficient operation. Advanced algorithms and sensing technologies are being implemented to address the unique characteristics of sodium-ion chemistry.

- Applications and integration of sodium-ion batteries: Research is ongoing to explore and expand the potential applications of sodium-ion batteries. This includes their integration into various energy storage systems, from small-scale portable devices to large-scale grid storage. Studies are being conducted on how to effectively combine sodium-ion batteries with other energy technologies and optimize their performance in different use cases and environmental conditions.

02 Electrolyte compositions for sodium-ion batteries

Innovative electrolyte formulations are being developed to enhance the performance and safety of sodium-ion batteries. These may include new solvents, additives, or solid electrolytes that improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system.Expand Specific Solutions03 Battery management and control systems

Advanced battery management systems are being designed specifically for sodium-ion batteries to optimize their performance, longevity, and safety. These systems may include sophisticated monitoring, thermal management, and charge/discharge control algorithms tailored to the unique characteristics of sodium-ion chemistry.Expand Specific Solutions04 Manufacturing processes for sodium-ion batteries

Innovative manufacturing techniques are being developed to produce sodium-ion batteries more efficiently and cost-effectively. These may include new methods for electrode fabrication, cell assembly, and quality control processes that are optimized for the specific requirements of sodium-ion technology.Expand Specific Solutions05 Integration of sodium-ion batteries in energy storage systems

Research is focused on optimizing the integration of sodium-ion batteries into various energy storage applications. This includes developing specialized battery pack designs, power electronics, and system architectures that leverage the unique advantages of sodium-ion technology for grid storage, renewable energy integration, and other large-scale applications.Expand Specific Solutions

Key Players in Sodium Ion Battery Industry

The research on sodium-ion batteries and next-generation materials is in an early development stage, with a growing market potential due to the increasing demand for sustainable energy storage solutions. The technology is still maturing, with various companies and research institutions actively involved in advancing its capabilities. Key players like Faradion, CATL (through subsidiaries Guangdong and Hunan Bangpu), and Beijing Zhongke Haina are leading commercial efforts, while academic institutions such as Nankai University, KAIST, and the Chinese Academy of Sciences are contributing significant research. The competitive landscape is diverse, with both established battery manufacturers and startups vying for market share in this emerging field.

Faradion Ltd.

Technical Solution: Faradion has developed a proprietary sodium-ion technology that offers significant advantages over lithium-ion batteries. Their approach focuses on layered oxide cathodes and hard carbon anodes, optimized for high energy density and long cycle life. The company has achieved energy densities of up to 150 Wh/kg [1], which is competitive with some lithium-ion chemistries. Faradion's batteries utilize abundant, low-cost materials and can be manufactured using existing lithium-ion production facilities, reducing barriers to commercialization. They have also developed electrolyte formulations that enhance the stability and performance of their sodium-ion cells [2].

Strengths: Cost-effective, uses abundant materials, compatible with existing manufacturing. Weaknesses: Lower energy density compared to advanced lithium-ion, less mature technology ecosystem.

Nankai University

Technical Solution: Researchers at Nankai University have made significant strides in sodium-ion battery technology, particularly in electrode materials. They have developed a novel Prussian blue analogue cathode material with a high specific capacity of 170 mAh/g and excellent rate capability [3]. The team has also explored the use of hard carbon materials derived from biomass for high-performance anodes, achieving reversible capacities of over 300 mAh/g [4]. Additionally, they have investigated novel electrolyte systems, including concentrated electrolytes and ionic liquid-based electrolytes, to improve the stability and safety of sodium-ion batteries [5].

Strengths: Innovative electrode materials, focus on sustainable precursors, comprehensive research approach. Weaknesses: Primarily academic research, may face challenges in scaling up for commercial production.

Innovative Electrode Materials for Sodium Ion Batteries

Sodium ion cathode active materials for batteries

PatentWO2025132336A1

Innovation

- A sodium-ion cathode active material with a chemical composition of Na, M, and O, where M consists of Fe, Mn, and X (with X being at least one element selected from B, Si, K, Co, Ga, Rb, Rh, Cs, Re, Tl, and Pb), is developed. This composition is optimized to improve structural and air stability, reducing transition metal dissolution.

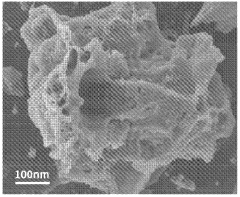

Preparation method for porous sodium ion battery positive electrode material sodium iron phosphate

PatentActiveGB2616234A

Innovation

- A method involving the co-precipitation of silver and iron compounds, followed by sintering with sodium dihydrogen phosphate and sodium iodide, which enhances conductivity and prevents the formation of impurities, resulting in a porous sodium iron phosphate material with improved ion infiltration and deintercalation performance.

Environmental Impact of Sodium Ion Battery Production

The production of sodium-ion batteries presents both environmental challenges and opportunities compared to traditional lithium-ion batteries. While sodium is more abundant and widely distributed than lithium, reducing the environmental impact of resource extraction, the manufacturing process still requires careful consideration of its ecological footprint.

One significant advantage of sodium-ion battery production is the reduced pressure on lithium resources, which are often concentrated in environmentally sensitive areas. This shift can help mitigate the environmental degradation associated with lithium mining, including water pollution and habitat destruction. Additionally, the more even global distribution of sodium resources can lead to shorter transportation routes, potentially reducing carbon emissions in the supply chain.

However, the production of sodium-ion batteries still involves energy-intensive processes and the use of various materials that can have environmental implications. The extraction and processing of other key components, such as hard carbon for anodes and transition metal oxides for cathodes, require careful management to minimize ecological impact. The manufacturing process itself consumes significant energy, contributing to greenhouse gas emissions if not powered by renewable sources.

Water usage is another critical factor in sodium-ion battery production. While potentially less water-intensive than lithium extraction, the manufacturing process still requires substantial amounts of water for cooling, cleaning, and material processing. Proper water management and recycling systems are essential to reduce the strain on local water resources and prevent pollution.

The end-of-life management of sodium-ion batteries also plays a crucial role in their overall environmental impact. Developing efficient recycling processes for these batteries is vital to recover valuable materials and prevent hazardous waste from entering landfills. The potential for easier recycling of sodium-ion batteries compared to lithium-ion counterparts could lead to a more circular economy in the battery industry.

As the technology matures, there is a growing focus on developing more environmentally friendly production methods for sodium-ion batteries. This includes research into green synthesis techniques, the use of bio-derived materials, and the optimization of manufacturing processes to reduce energy consumption and waste generation. These advancements could significantly improve the environmental profile of sodium-ion battery production in the coming years.

One significant advantage of sodium-ion battery production is the reduced pressure on lithium resources, which are often concentrated in environmentally sensitive areas. This shift can help mitigate the environmental degradation associated with lithium mining, including water pollution and habitat destruction. Additionally, the more even global distribution of sodium resources can lead to shorter transportation routes, potentially reducing carbon emissions in the supply chain.

However, the production of sodium-ion batteries still involves energy-intensive processes and the use of various materials that can have environmental implications. The extraction and processing of other key components, such as hard carbon for anodes and transition metal oxides for cathodes, require careful management to minimize ecological impact. The manufacturing process itself consumes significant energy, contributing to greenhouse gas emissions if not powered by renewable sources.

Water usage is another critical factor in sodium-ion battery production. While potentially less water-intensive than lithium extraction, the manufacturing process still requires substantial amounts of water for cooling, cleaning, and material processing. Proper water management and recycling systems are essential to reduce the strain on local water resources and prevent pollution.

The end-of-life management of sodium-ion batteries also plays a crucial role in their overall environmental impact. Developing efficient recycling processes for these batteries is vital to recover valuable materials and prevent hazardous waste from entering landfills. The potential for easier recycling of sodium-ion batteries compared to lithium-ion counterparts could lead to a more circular economy in the battery industry.

As the technology matures, there is a growing focus on developing more environmentally friendly production methods for sodium-ion batteries. This includes research into green synthesis techniques, the use of bio-derived materials, and the optimization of manufacturing processes to reduce energy consumption and waste generation. These advancements could significantly improve the environmental profile of sodium-ion battery production in the coming years.

Sodium Ion Battery Performance Benchmarking

Sodium-ion batteries (SIBs) have emerged as a promising alternative to lithium-ion batteries, particularly for large-scale energy storage applications. To assess their viability and potential for widespread adoption, it is crucial to conduct comprehensive performance benchmarking against existing battery technologies.

In terms of energy density, current state-of-the-art SIBs typically achieve 90-120 Wh/kg at the cell level, which is lower than the 200-300 Wh/kg range of commercial lithium-ion batteries. However, recent advancements in cathode and anode materials have shown potential to narrow this gap significantly. For instance, layered oxide cathodes coupled with hard carbon anodes have demonstrated energy densities approaching 160 Wh/kg in laboratory settings.

Cycle life is another critical performance metric where SIBs have shown promising results. Many sodium-ion chemistries exhibit excellent cycling stability, with some configurations maintaining over 80% capacity retention after 2000-3000 cycles. This longevity is comparable to, and in some cases surpasses, that of lithium-ion batteries, particularly in applications that require frequent cycling.

Power density is an area where SIBs have demonstrated competitive performance. The larger ionic radius of sodium compared to lithium was initially thought to be a limitation. However, optimized electrode structures and electrolyte formulations have enabled high-rate capabilities in SIBs. Some prototypes have achieved charge/discharge rates of up to 10C while retaining 70-80% of their capacity, rivaling the performance of high-power lithium-ion cells.

Safety characteristics of SIBs are generally favorable when compared to lithium-ion batteries. The lower reactivity of sodium with organic electrolytes and the higher melting point of sodium metal contribute to reduced risks of thermal runaway and fire hazards. This inherent safety advantage could be particularly beneficial in large-scale stationary storage applications.

Cost considerations are a significant driver for SIB development. The abundance and wide geographical distribution of sodium resources offer potential for lower raw material costs compared to lithium. Current estimates suggest that SIBs could achieve 10-30% lower costs per kWh than lithium-ion batteries at scale, although this advantage is heavily dependent on the specific materials and manufacturing processes used.

Temperature performance is an area where SIBs have shown both strengths and limitations. Many sodium-ion chemistries exhibit good low-temperature performance, maintaining higher capacity retention at sub-zero temperatures compared to some lithium-ion counterparts. However, high-temperature stability remains a challenge, with some SIB configurations showing accelerated capacity fade above 50°C.

In conclusion, while sodium-ion batteries currently lag behind lithium-ion technologies in some performance aspects, particularly energy density, they demonstrate competitive or superior characteristics in areas such as cycle life, safety, and potentially cost. Ongoing research and development efforts are rapidly improving SIB performance, suggesting that these batteries could become a viable complement or alternative to lithium-ion batteries in certain applications, especially where cost and long-term stability are prioritized over maximum energy density.

In terms of energy density, current state-of-the-art SIBs typically achieve 90-120 Wh/kg at the cell level, which is lower than the 200-300 Wh/kg range of commercial lithium-ion batteries. However, recent advancements in cathode and anode materials have shown potential to narrow this gap significantly. For instance, layered oxide cathodes coupled with hard carbon anodes have demonstrated energy densities approaching 160 Wh/kg in laboratory settings.

Cycle life is another critical performance metric where SIBs have shown promising results. Many sodium-ion chemistries exhibit excellent cycling stability, with some configurations maintaining over 80% capacity retention after 2000-3000 cycles. This longevity is comparable to, and in some cases surpasses, that of lithium-ion batteries, particularly in applications that require frequent cycling.

Power density is an area where SIBs have demonstrated competitive performance. The larger ionic radius of sodium compared to lithium was initially thought to be a limitation. However, optimized electrode structures and electrolyte formulations have enabled high-rate capabilities in SIBs. Some prototypes have achieved charge/discharge rates of up to 10C while retaining 70-80% of their capacity, rivaling the performance of high-power lithium-ion cells.

Safety characteristics of SIBs are generally favorable when compared to lithium-ion batteries. The lower reactivity of sodium with organic electrolytes and the higher melting point of sodium metal contribute to reduced risks of thermal runaway and fire hazards. This inherent safety advantage could be particularly beneficial in large-scale stationary storage applications.

Cost considerations are a significant driver for SIB development. The abundance and wide geographical distribution of sodium resources offer potential for lower raw material costs compared to lithium. Current estimates suggest that SIBs could achieve 10-30% lower costs per kWh than lithium-ion batteries at scale, although this advantage is heavily dependent on the specific materials and manufacturing processes used.

Temperature performance is an area where SIBs have shown both strengths and limitations. Many sodium-ion chemistries exhibit good low-temperature performance, maintaining higher capacity retention at sub-zero temperatures compared to some lithium-ion counterparts. However, high-temperature stability remains a challenge, with some SIB configurations showing accelerated capacity fade above 50°C.

In conclusion, while sodium-ion batteries currently lag behind lithium-ion technologies in some performance aspects, particularly energy density, they demonstrate competitive or superior characteristics in areas such as cycle life, safety, and potentially cost. Ongoing research and development efforts are rapidly improving SIB performance, suggesting that these batteries could become a viable complement or alternative to lithium-ion batteries in certain applications, especially where cost and long-term stability are prioritized over maximum energy density.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!