Sodium Ion Batteries in Hybrid Marine Propulsion Systems

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Ion Battery Evolution and Objectives

Sodium-ion batteries have emerged as a promising alternative to lithium-ion batteries in recent years, particularly for large-scale energy storage applications. The evolution of sodium-ion battery technology can be traced back to the 1980s, but significant advancements have been made in the past decade. This renewed interest is driven by the abundance and low cost of sodium resources, as well as the growing demand for sustainable energy storage solutions.

The development of sodium-ion batteries has been marked by several key milestones. Early research focused on identifying suitable electrode materials and electrolytes that could effectively accommodate the larger sodium ions. In the 2010s, breakthroughs in cathode materials, such as layered oxides and polyanionic compounds, significantly improved the energy density and cycling stability of sodium-ion batteries.

More recently, advancements in anode materials, including hard carbons and alloy-based materials, have further enhanced the performance of these batteries. Concurrently, electrolyte formulations have been optimized to improve the overall electrochemical stability and safety of sodium-ion systems.

In the context of hybrid marine propulsion systems, sodium-ion batteries present a compelling opportunity to address the unique challenges of maritime applications. The marine industry is under increasing pressure to reduce emissions and improve energy efficiency, driving the adoption of hybrid and electric propulsion systems. Sodium-ion batteries offer several advantages in this domain, including lower cost, improved safety, and the potential for better performance in harsh marine environments.

The primary objectives of research on sodium-ion batteries for hybrid marine propulsion systems are multifaceted. First, there is a focus on increasing energy density to meet the high power demands of marine vessels while minimizing the battery system's weight and volume. Second, researchers aim to enhance the cycle life and calendar life of sodium-ion batteries to ensure long-term reliability in marine applications.

Another critical objective is to improve the safety and thermal stability of sodium-ion batteries, particularly in the challenging conditions encountered at sea. This includes developing robust battery management systems and exploring new cell designs that can withstand vibration, temperature fluctuations, and potential exposure to saltwater.

Furthermore, research efforts are directed towards optimizing the integration of sodium-ion batteries with other components of hybrid marine propulsion systems, such as diesel engines, fuel cells, and electric motors. This involves developing advanced control strategies and power management algorithms to maximize efficiency and performance across various operating conditions.

As the technology continues to evolve, the ultimate goal is to create sodium-ion battery systems that can compete with or surpass the performance of lithium-ion batteries in marine applications, while offering advantages in terms of cost, sustainability, and safety. This ambitious objective drives ongoing research into novel materials, manufacturing processes, and system-level optimizations for sodium-ion batteries in the marine sector.

The development of sodium-ion batteries has been marked by several key milestones. Early research focused on identifying suitable electrode materials and electrolytes that could effectively accommodate the larger sodium ions. In the 2010s, breakthroughs in cathode materials, such as layered oxides and polyanionic compounds, significantly improved the energy density and cycling stability of sodium-ion batteries.

More recently, advancements in anode materials, including hard carbons and alloy-based materials, have further enhanced the performance of these batteries. Concurrently, electrolyte formulations have been optimized to improve the overall electrochemical stability and safety of sodium-ion systems.

In the context of hybrid marine propulsion systems, sodium-ion batteries present a compelling opportunity to address the unique challenges of maritime applications. The marine industry is under increasing pressure to reduce emissions and improve energy efficiency, driving the adoption of hybrid and electric propulsion systems. Sodium-ion batteries offer several advantages in this domain, including lower cost, improved safety, and the potential for better performance in harsh marine environments.

The primary objectives of research on sodium-ion batteries for hybrid marine propulsion systems are multifaceted. First, there is a focus on increasing energy density to meet the high power demands of marine vessels while minimizing the battery system's weight and volume. Second, researchers aim to enhance the cycle life and calendar life of sodium-ion batteries to ensure long-term reliability in marine applications.

Another critical objective is to improve the safety and thermal stability of sodium-ion batteries, particularly in the challenging conditions encountered at sea. This includes developing robust battery management systems and exploring new cell designs that can withstand vibration, temperature fluctuations, and potential exposure to saltwater.

Furthermore, research efforts are directed towards optimizing the integration of sodium-ion batteries with other components of hybrid marine propulsion systems, such as diesel engines, fuel cells, and electric motors. This involves developing advanced control strategies and power management algorithms to maximize efficiency and performance across various operating conditions.

As the technology continues to evolve, the ultimate goal is to create sodium-ion battery systems that can compete with or surpass the performance of lithium-ion batteries in marine applications, while offering advantages in terms of cost, sustainability, and safety. This ambitious objective drives ongoing research into novel materials, manufacturing processes, and system-level optimizations for sodium-ion batteries in the marine sector.

Marine Propulsion Market Analysis

The marine propulsion market is experiencing significant growth and transformation, driven by increasing global trade, maritime tourism, and the push for more sustainable shipping solutions. This market encompasses various propulsion systems, including diesel engines, gas turbines, electric propulsion, and hybrid systems. The integration of sodium-ion batteries in hybrid marine propulsion systems represents a potential game-changer in this evolving landscape.

Currently, the global marine propulsion market is valued at several billion dollars, with steady growth projected over the next decade. This growth is fueled by the rising demand for energy-efficient and environmentally friendly propulsion systems, particularly in response to stringent emissions regulations imposed by international maritime organizations.

The market for hybrid marine propulsion systems, which combine conventional engines with electric propulsion, is experiencing rapid expansion. This growth is driven by the need for improved fuel efficiency, reduced emissions, and enhanced operational flexibility. Hybrid systems offer advantages such as lower fuel consumption, reduced maintenance costs, and improved maneuverability, making them increasingly attractive to shipowners and operators.

Within the hybrid propulsion segment, battery technologies play a crucial role. While lithium-ion batteries have been the dominant choice, sodium-ion batteries are emerging as a promising alternative. The potential market for sodium-ion batteries in marine applications is substantial, given their advantages in terms of cost, safety, and raw material availability.

The demand for sodium-ion batteries in hybrid marine propulsion systems is expected to grow significantly in the coming years. This growth is driven by several factors, including the increasing adoption of hybrid propulsion systems in various vessel types, from small pleasure crafts to large commercial ships. Additionally, the push for zero-emission vessels and the development of all-electric ships create new opportunities for advanced battery technologies.

Geographically, Asia-Pacific dominates the marine propulsion market, followed by Europe and North America. These regions are also expected to be key markets for sodium-ion battery adoption in marine applications. Developing economies, particularly in Southeast Asia, are showing increased interest in sustainable maritime technologies, presenting significant growth opportunities.

The market for sodium-ion batteries in marine propulsion faces both opportunities and challenges. While the technology offers potential cost advantages and improved safety compared to lithium-ion batteries, it must overcome technical hurdles related to energy density and cycle life. The success of sodium-ion batteries in this market will depend on continued research and development efforts, as well as the ability to scale up production to meet growing demand.

Currently, the global marine propulsion market is valued at several billion dollars, with steady growth projected over the next decade. This growth is fueled by the rising demand for energy-efficient and environmentally friendly propulsion systems, particularly in response to stringent emissions regulations imposed by international maritime organizations.

The market for hybrid marine propulsion systems, which combine conventional engines with electric propulsion, is experiencing rapid expansion. This growth is driven by the need for improved fuel efficiency, reduced emissions, and enhanced operational flexibility. Hybrid systems offer advantages such as lower fuel consumption, reduced maintenance costs, and improved maneuverability, making them increasingly attractive to shipowners and operators.

Within the hybrid propulsion segment, battery technologies play a crucial role. While lithium-ion batteries have been the dominant choice, sodium-ion batteries are emerging as a promising alternative. The potential market for sodium-ion batteries in marine applications is substantial, given their advantages in terms of cost, safety, and raw material availability.

The demand for sodium-ion batteries in hybrid marine propulsion systems is expected to grow significantly in the coming years. This growth is driven by several factors, including the increasing adoption of hybrid propulsion systems in various vessel types, from small pleasure crafts to large commercial ships. Additionally, the push for zero-emission vessels and the development of all-electric ships create new opportunities for advanced battery technologies.

Geographically, Asia-Pacific dominates the marine propulsion market, followed by Europe and North America. These regions are also expected to be key markets for sodium-ion battery adoption in marine applications. Developing economies, particularly in Southeast Asia, are showing increased interest in sustainable maritime technologies, presenting significant growth opportunities.

The market for sodium-ion batteries in marine propulsion faces both opportunities and challenges. While the technology offers potential cost advantages and improved safety compared to lithium-ion batteries, it must overcome technical hurdles related to energy density and cycle life. The success of sodium-ion batteries in this market will depend on continued research and development efforts, as well as the ability to scale up production to meet growing demand.

Sodium Ion Battery Challenges in Marine Applications

The integration of sodium-ion batteries into hybrid marine propulsion systems presents several unique challenges that must be addressed for successful implementation. One of the primary concerns is the battery's performance in the harsh marine environment. Exposure to saltwater, high humidity, and constant vibrations can significantly impact the battery's longevity and reliability. Engineers must develop robust enclosures and protective measures to shield the batteries from these elements while maintaining efficient thermal management.

Another critical challenge is the energy density of sodium-ion batteries compared to their lithium-ion counterparts. While sodium-ion technology has made significant strides, it still lags behind lithium-ion in terms of energy storage capacity per unit volume and weight. This limitation is particularly crucial in marine applications, where space and weight constraints are often stringent. Researchers are actively working on improving electrode materials and cell designs to enhance energy density, but bridging this gap remains a significant hurdle.

The charging and discharging characteristics of sodium-ion batteries in marine conditions also pose challenges. The batteries must be capable of rapid charging during short port stays and provide consistent power output during long voyages. Additionally, the battery management system needs to be optimized for the unique discharge patterns of marine propulsion, which can involve sudden power demands and prolonged periods of low-level operation.

Safety considerations are paramount in marine applications, and sodium-ion batteries must meet rigorous standards. While they generally offer improved safety compared to lithium-ion batteries due to lower reactivity, concerns about thermal runaway and fire risks in the confined spaces of a ship still need to be thoroughly addressed. Developing advanced safety mechanisms and conducting extensive testing under marine-specific conditions are essential steps in overcoming these challenges.

The integration of sodium-ion batteries with existing marine propulsion systems presents another set of challenges. Hybrid systems require sophisticated control algorithms to optimize the interplay between batteries, engines, and other power sources. Developing these algorithms to account for the specific characteristics of sodium-ion batteries, such as their voltage profiles and cycle life, is crucial for maximizing efficiency and performance.

Lastly, the marine industry's conservative nature and stringent regulatory environment pose adoption challenges. Extensive testing, certification processes, and compliance with maritime regulations are necessary before widespread implementation can occur. Demonstrating the long-term reliability and cost-effectiveness of sodium-ion batteries in real-world marine conditions will be critical in overcoming skepticism and gaining industry acceptance.

Another critical challenge is the energy density of sodium-ion batteries compared to their lithium-ion counterparts. While sodium-ion technology has made significant strides, it still lags behind lithium-ion in terms of energy storage capacity per unit volume and weight. This limitation is particularly crucial in marine applications, where space and weight constraints are often stringent. Researchers are actively working on improving electrode materials and cell designs to enhance energy density, but bridging this gap remains a significant hurdle.

The charging and discharging characteristics of sodium-ion batteries in marine conditions also pose challenges. The batteries must be capable of rapid charging during short port stays and provide consistent power output during long voyages. Additionally, the battery management system needs to be optimized for the unique discharge patterns of marine propulsion, which can involve sudden power demands and prolonged periods of low-level operation.

Safety considerations are paramount in marine applications, and sodium-ion batteries must meet rigorous standards. While they generally offer improved safety compared to lithium-ion batteries due to lower reactivity, concerns about thermal runaway and fire risks in the confined spaces of a ship still need to be thoroughly addressed. Developing advanced safety mechanisms and conducting extensive testing under marine-specific conditions are essential steps in overcoming these challenges.

The integration of sodium-ion batteries with existing marine propulsion systems presents another set of challenges. Hybrid systems require sophisticated control algorithms to optimize the interplay between batteries, engines, and other power sources. Developing these algorithms to account for the specific characteristics of sodium-ion batteries, such as their voltage profiles and cycle life, is crucial for maximizing efficiency and performance.

Lastly, the marine industry's conservative nature and stringent regulatory environment pose adoption challenges. Extensive testing, certification processes, and compliance with maritime regulations are necessary before widespread implementation can occur. Demonstrating the long-term reliability and cost-effectiveness of sodium-ion batteries in real-world marine conditions will be critical in overcoming skepticism and gaining industry acceptance.

Current Sodium Ion Battery Solutions for Ships

01 Electrode materials for sodium-ion batteries

Development of novel electrode materials is crucial for improving sodium-ion battery performance. This includes research on cathode and anode materials that offer high capacity, good cycling stability, and improved sodium ion insertion/extraction properties. Materials being explored include various sodium-based compounds, carbon-based materials, and metal oxides.- Electrode materials for sodium-ion batteries: Development of novel electrode materials is crucial for improving the performance of sodium-ion batteries. These materials focus on enhancing energy density, cycling stability, and rate capability. Research includes exploring various compounds, nanostructures, and composites that can effectively store and release sodium ions.

- Electrolyte formulations for sodium-ion batteries: Innovative electrolyte formulations play a key role in sodium-ion battery performance. These formulations aim to improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system. Research focuses on developing new electrolyte compositions, additives, and solvents tailored for sodium-ion chemistry.

- Battery management systems for sodium-ion batteries: Advanced battery management systems are essential for optimizing the performance and safety of sodium-ion batteries. These systems involve sophisticated control algorithms, monitoring techniques, and thermal management strategies. Research aims to develop intelligent systems that can effectively manage charging, discharging, and overall battery health.

- Manufacturing processes for sodium-ion batteries: Efficient and cost-effective manufacturing processes are crucial for the commercialization of sodium-ion batteries. Research focuses on developing scalable production methods, including electrode fabrication techniques, cell assembly processes, and quality control measures. These advancements aim to reduce production costs and improve the consistency of battery performance.

- Sodium-ion battery applications and integration: Exploring various applications and integration strategies for sodium-ion batteries is essential for their widespread adoption. Research focuses on adapting these batteries for use in electric vehicles, grid energy storage, and portable electronics. This includes developing battery pack designs, thermal management systems, and integration solutions tailored to specific application requirements.

02 Electrolyte compositions for sodium-ion batteries

Innovative electrolyte formulations are being developed to enhance the performance and safety of sodium-ion batteries. These may include new salt compositions, solvent mixtures, and additives that improve ionic conductivity, reduce side reactions, and enhance the overall stability of the battery system.Expand Specific Solutions03 Battery cell design and manufacturing processes

Advancements in cell design and manufacturing techniques are being made to optimize sodium-ion battery performance and scalability. This includes innovations in electrode preparation, cell assembly, and packaging to improve energy density, reduce costs, and enhance production efficiency.Expand Specific Solutions04 Battery management systems for sodium-ion batteries

Development of specialized battery management systems tailored for sodium-ion batteries is ongoing. These systems aim to optimize charging/discharging protocols, monitor battery health, and ensure safe operation under various conditions, taking into account the unique characteristics of sodium-ion chemistry.Expand Specific Solutions05 Applications and integration of sodium-ion batteries

Research is being conducted on the integration and application of sodium-ion batteries in various fields, including grid energy storage, electric vehicles, and portable electronics. This involves addressing challenges related to scaling up battery systems, optimizing performance for specific use cases, and developing appropriate interfaces with existing infrastructure.Expand Specific Solutions

Key Players in Marine Battery Industry

The research on sodium-ion batteries in hybrid marine propulsion systems is in an early developmental stage, with the market still emerging. The technology's maturity is progressing, driven by efforts from key players like Contemporary Amperex Technology Co., Ltd. (CATL) and Faradion Ltd. Academic institutions such as Fudan University and Korea Advanced Institute of Science & Technology are contributing significantly to fundamental research. While the market size remains relatively small, there's growing interest due to the potential advantages of sodium-ion batteries in marine applications, including lower costs and improved safety compared to lithium-ion alternatives. The competitive landscape is diverse, with both established battery manufacturers and specialized startups vying for position in this promising sector.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a first-generation sodium-ion battery with an energy density of up to 160Wh/kg[1]. Their innovative AB battery system integrates sodium-ion and lithium-ion cells, leveraging the advantages of both chemistries. For marine applications, CATL's sodium-ion batteries offer fast-charging capability, reaching 80% state of charge in 15 minutes[2]. The company has also focused on improving the low-temperature performance, crucial for marine environments, with their sodium-ion batteries maintaining over 90% capacity retention at -20°C[3]. CATL's approach includes using Prussian white material for the cathode and hard carbon for the anode, enhancing overall battery performance and stability[4].

Strengths: High energy density, fast charging, excellent low-temperature performance, and innovative hybrid battery systems. Weaknesses: Still lower energy density compared to lithium-ion batteries, potential challenges in large-scale production for marine applications.

Faradion Ltd.

Technical Solution: Faradion has pioneered sodium-ion technology specifically tailored for large-scale energy storage applications, including marine propulsion systems. Their patented technology utilizes a layered oxide cathode and hard carbon anode, achieving energy densities comparable to lithium-ion phosphate batteries[5]. For marine applications, Faradion's batteries demonstrate exceptional cycle life, exceeding 1000 cycles at 100% depth of discharge[6]. The company has developed a proprietary electrolyte formulation that enhances the battery's performance in humid marine environments. Faradion's sodium-ion cells have shown impressive power capabilities, delivering up to 130 W/kg, which is crucial for hybrid marine propulsion systems requiring both high energy and power[7].

Strengths: Tailored for large-scale applications, long cycle life, high power capabilities, and resistance to humid environments. Weaknesses: Energy density still lags behind some advanced lithium-ion chemistries, limited commercial-scale production experience in marine sector.

Innovations in Marine Sodium Ion Batteries

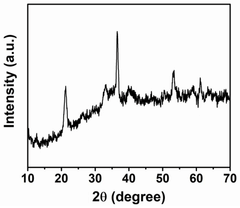

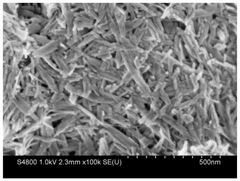

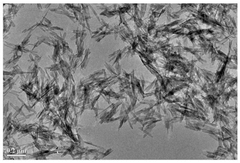

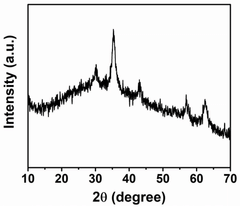

Iron sulfide Fe1-xS-carbon sodium ion battery negative electrode material and preparation method thereof

PatentPendingCN118231662A

Innovation

- Ultra-thin Fe1-xS nanosheets are combined with highly conductive carbon materials, and Fe1-xS@C nanosheets are prepared through hydrothermal and carbonization reduction methods to improve the conductivity and structural stability of the electrode material.

Environmental Impact and Regulations

The integration of sodium-ion batteries in hybrid marine propulsion systems presents significant environmental implications and regulatory considerations. As the maritime industry seeks to reduce its carbon footprint, these innovative energy storage solutions offer a promising alternative to traditional fossil fuel-based systems.

From an environmental perspective, sodium-ion batteries have several advantages over their lithium-ion counterparts. The abundance and widespread availability of sodium resources reduce the environmental impact associated with raw material extraction. Unlike lithium mining, which often involves extensive water usage and potential habitat disruption, sodium extraction methods are generally less invasive and more sustainable.

Moreover, the production process for sodium-ion batteries typically requires less energy and generates fewer greenhouse gas emissions compared to lithium-ion battery manufacturing. This lower carbon footprint aligns well with the maritime industry's goals of reducing overall emissions and meeting increasingly stringent environmental regulations.

The end-of-life management of sodium-ion batteries also presents environmental benefits. These batteries are more easily recyclable than lithium-ion batteries, with simpler and less energy-intensive recycling processes. This characteristic contributes to a more circular economy approach in the marine sector, reducing waste and minimizing the need for new raw materials.

Regulatory frameworks are evolving to address the adoption of sodium-ion batteries in marine applications. The International Maritime Organization (IMO) has set ambitious targets for reducing greenhouse gas emissions from ships, driving the need for cleaner propulsion technologies. While specific regulations for sodium-ion batteries in marine use are still developing, they are likely to fall under broader guidelines for energy storage systems on ships.

Safety regulations are a critical aspect of battery implementation in marine environments. Sodium-ion batteries generally have a lower fire risk compared to lithium-ion batteries, which may lead to more favorable safety classifications and potentially simpler compliance requirements. However, regulatory bodies will need to develop comprehensive safety standards tailored to the unique characteristics of sodium-ion technology in marine applications.

As the technology matures, it is anticipated that regulatory frameworks will adapt to accommodate the specific needs and benefits of sodium-ion batteries. This may include updates to existing maritime codes, such as the International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code), to incorporate provisions for sodium-ion battery systems.

In conclusion, the environmental impact and regulatory landscape surrounding sodium-ion batteries in hybrid marine propulsion systems are generally positive. The technology aligns well with sustainability goals and offers potential advantages in terms of resource utilization, emissions reduction, and end-of-life management. As regulations continue to evolve, they are likely to facilitate the adoption of this promising technology in the maritime sector.

From an environmental perspective, sodium-ion batteries have several advantages over their lithium-ion counterparts. The abundance and widespread availability of sodium resources reduce the environmental impact associated with raw material extraction. Unlike lithium mining, which often involves extensive water usage and potential habitat disruption, sodium extraction methods are generally less invasive and more sustainable.

Moreover, the production process for sodium-ion batteries typically requires less energy and generates fewer greenhouse gas emissions compared to lithium-ion battery manufacturing. This lower carbon footprint aligns well with the maritime industry's goals of reducing overall emissions and meeting increasingly stringent environmental regulations.

The end-of-life management of sodium-ion batteries also presents environmental benefits. These batteries are more easily recyclable than lithium-ion batteries, with simpler and less energy-intensive recycling processes. This characteristic contributes to a more circular economy approach in the marine sector, reducing waste and minimizing the need for new raw materials.

Regulatory frameworks are evolving to address the adoption of sodium-ion batteries in marine applications. The International Maritime Organization (IMO) has set ambitious targets for reducing greenhouse gas emissions from ships, driving the need for cleaner propulsion technologies. While specific regulations for sodium-ion batteries in marine use are still developing, they are likely to fall under broader guidelines for energy storage systems on ships.

Safety regulations are a critical aspect of battery implementation in marine environments. Sodium-ion batteries generally have a lower fire risk compared to lithium-ion batteries, which may lead to more favorable safety classifications and potentially simpler compliance requirements. However, regulatory bodies will need to develop comprehensive safety standards tailored to the unique characteristics of sodium-ion technology in marine applications.

As the technology matures, it is anticipated that regulatory frameworks will adapt to accommodate the specific needs and benefits of sodium-ion batteries. This may include updates to existing maritime codes, such as the International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code), to incorporate provisions for sodium-ion battery systems.

In conclusion, the environmental impact and regulatory landscape surrounding sodium-ion batteries in hybrid marine propulsion systems are generally positive. The technology aligns well with sustainability goals and offers potential advantages in terms of resource utilization, emissions reduction, and end-of-life management. As regulations continue to evolve, they are likely to facilitate the adoption of this promising technology in the maritime sector.

Safety Considerations for Marine Sodium Ion Batteries

Safety considerations for marine sodium-ion batteries are paramount in the development and implementation of hybrid marine propulsion systems. The marine environment presents unique challenges that require careful attention to ensure the safe operation of these batteries.

One of the primary safety concerns is the risk of thermal runaway, which can lead to fires or explosions. To mitigate this risk, advanced thermal management systems must be integrated into the battery design. These systems should include efficient cooling mechanisms and temperature monitoring sensors to prevent overheating and maintain optimal operating conditions.

Electrical safety is another critical aspect that demands thorough consideration. Marine sodium-ion batteries must be equipped with robust insulation and protection against short circuits. Additionally, the integration of sophisticated battery management systems (BMS) is essential to monitor and control voltage, current, and state of charge, ensuring safe operation within specified parameters.

The corrosive nature of the marine environment poses significant challenges to battery safety. Sodium-ion batteries must be designed with corrosion-resistant materials and sealed enclosures to prevent saltwater ingress. This protection is crucial not only for the longevity of the battery but also to prevent potential chemical reactions that could compromise safety.

Mechanical integrity is equally important in marine applications. Batteries must be able to withstand the constant vibrations, shocks, and potential impacts associated with marine operations. Robust structural design and secure mounting systems are necessary to prevent physical damage that could lead to safety hazards.

Emergency response protocols specific to sodium-ion batteries in marine environments must be developed and implemented. This includes training crew members on proper handling procedures, establishing clear evacuation plans, and installing appropriate fire suppression systems designed for battery fires.

The potential for gas evolution during battery operation or in case of failure must also be addressed. Adequate ventilation systems should be in place to prevent the accumulation of potentially hazardous gases, particularly in enclosed spaces within the vessel.

Lastly, regulatory compliance is a crucial aspect of safety considerations. Marine sodium-ion batteries must meet stringent international maritime safety standards and undergo rigorous testing and certification processes to ensure their suitability for use in marine environments.

One of the primary safety concerns is the risk of thermal runaway, which can lead to fires or explosions. To mitigate this risk, advanced thermal management systems must be integrated into the battery design. These systems should include efficient cooling mechanisms and temperature monitoring sensors to prevent overheating and maintain optimal operating conditions.

Electrical safety is another critical aspect that demands thorough consideration. Marine sodium-ion batteries must be equipped with robust insulation and protection against short circuits. Additionally, the integration of sophisticated battery management systems (BMS) is essential to monitor and control voltage, current, and state of charge, ensuring safe operation within specified parameters.

The corrosive nature of the marine environment poses significant challenges to battery safety. Sodium-ion batteries must be designed with corrosion-resistant materials and sealed enclosures to prevent saltwater ingress. This protection is crucial not only for the longevity of the battery but also to prevent potential chemical reactions that could compromise safety.

Mechanical integrity is equally important in marine applications. Batteries must be able to withstand the constant vibrations, shocks, and potential impacts associated with marine operations. Robust structural design and secure mounting systems are necessary to prevent physical damage that could lead to safety hazards.

Emergency response protocols specific to sodium-ion batteries in marine environments must be developed and implemented. This includes training crew members on proper handling procedures, establishing clear evacuation plans, and installing appropriate fire suppression systems designed for battery fires.

The potential for gas evolution during battery operation or in case of failure must also be addressed. Adequate ventilation systems should be in place to prevent the accumulation of potentially hazardous gases, particularly in enclosed spaces within the vessel.

Lastly, regulatory compliance is a crucial aspect of safety considerations. Marine sodium-ion batteries must meet stringent international maritime safety standards and undergo rigorous testing and certification processes to ensure their suitability for use in marine environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!