Perspectives on Sodium Ion Battery Lifecycle Management

AUG 7, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Na-ion Battery Evolution

Sodium-ion batteries have undergone significant evolution since their inception, driven by the need for sustainable and cost-effective energy storage solutions. The journey of Na-ion batteries began in the 1970s, paralleling the development of lithium-ion batteries. However, initial progress was slower due to the focus on lithium-based systems.

The early 2000s marked a resurgence in Na-ion battery research, prompted by concerns over lithium resource scarcity and cost. This period saw intensive efforts to develop suitable electrode materials and electrolytes, laying the groundwork for future advancements. The discovery of hard carbon as an anode material in 2000 was a crucial milestone, offering a viable alternative to graphite used in Li-ion batteries.

By the mid-2010s, Na-ion technology had made substantial strides. Researchers successfully developed high-performance cathode materials, such as layered oxides and polyanionic compounds, significantly improving energy density and cycle life. Concurrently, electrolyte formulations were optimized to enhance stability and conductivity, addressing key challenges in Na-ion systems.

The late 2010s witnessed the emergence of practical Na-ion battery prototypes, with several companies and research institutions demonstrating their potential in real-world applications. This period also saw increased focus on scalability and manufacturing processes, paving the way for commercial viability.

Recent years have seen accelerated progress in Na-ion technology. Breakthroughs in electrode materials, such as Prussian blue analogs and organic compounds, have pushed the boundaries of performance and sustainability. Advanced engineering techniques, including nanostructuring and composite materials, have further enhanced battery characteristics.

The current state of Na-ion batteries represents a convergence of scientific innovation and practical implementation. While still lagging behind Li-ion batteries in some aspects, Na-ion technology has reached a point where it offers a compelling alternative for certain applications, particularly in stationary energy storage and low-cost portable electronics.

Looking ahead, the evolution of Na-ion batteries is expected to continue at a rapid pace. Research efforts are focused on further improving energy density, cycle life, and rate capability. Additionally, there is growing emphasis on developing environmentally friendly and easily recyclable materials, aligning with the principles of circular economy and sustainable energy storage.

The early 2000s marked a resurgence in Na-ion battery research, prompted by concerns over lithium resource scarcity and cost. This period saw intensive efforts to develop suitable electrode materials and electrolytes, laying the groundwork for future advancements. The discovery of hard carbon as an anode material in 2000 was a crucial milestone, offering a viable alternative to graphite used in Li-ion batteries.

By the mid-2010s, Na-ion technology had made substantial strides. Researchers successfully developed high-performance cathode materials, such as layered oxides and polyanionic compounds, significantly improving energy density and cycle life. Concurrently, electrolyte formulations were optimized to enhance stability and conductivity, addressing key challenges in Na-ion systems.

The late 2010s witnessed the emergence of practical Na-ion battery prototypes, with several companies and research institutions demonstrating their potential in real-world applications. This period also saw increased focus on scalability and manufacturing processes, paving the way for commercial viability.

Recent years have seen accelerated progress in Na-ion technology. Breakthroughs in electrode materials, such as Prussian blue analogs and organic compounds, have pushed the boundaries of performance and sustainability. Advanced engineering techniques, including nanostructuring and composite materials, have further enhanced battery characteristics.

The current state of Na-ion batteries represents a convergence of scientific innovation and practical implementation. While still lagging behind Li-ion batteries in some aspects, Na-ion technology has reached a point where it offers a compelling alternative for certain applications, particularly in stationary energy storage and low-cost portable electronics.

Looking ahead, the evolution of Na-ion batteries is expected to continue at a rapid pace. Research efforts are focused on further improving energy density, cycle life, and rate capability. Additionally, there is growing emphasis on developing environmentally friendly and easily recyclable materials, aligning with the principles of circular economy and sustainable energy storage.

Market Demand Analysis

The market demand for sodium-ion batteries (SIBs) is experiencing a significant upward trajectory, driven by the increasing need for sustainable and cost-effective energy storage solutions. As the world transitions towards renewable energy sources and electrification of transportation, the demand for large-scale energy storage systems continues to grow. SIBs are emerging as a promising alternative to lithium-ion batteries, particularly in applications where cost and resource availability are critical factors.

The electric vehicle (EV) sector represents a substantial market opportunity for SIBs. With the global push towards reducing carbon emissions, the EV market is expanding rapidly, creating a surge in demand for high-performance, low-cost battery technologies. SIBs offer potential advantages in terms of cost reduction and supply chain stability, making them attractive for mass-market EV applications.

In the stationary energy storage sector, SIBs are gaining traction for grid-scale applications. The intermittent nature of renewable energy sources like solar and wind necessitates efficient and economical energy storage solutions. SIBs' potential for lower costs and improved safety characteristics position them as a viable option for large-scale grid storage projects.

The consumer electronics market also presents opportunities for SIB adoption. As manufacturers seek to reduce reliance on lithium and cobalt, sodium-ion technology could offer a more sustainable and cost-effective alternative for portable devices and small appliances.

Market analysis indicates that the Asia-Pacific region, particularly China, is leading in SIB development and adoption. This is driven by strong government support, abundant sodium resources, and a robust manufacturing base. Europe and North America are also showing increasing interest in SIB technology, with several research initiatives and pilot projects underway.

The market demand for SIBs is closely tied to advancements in their performance and lifecycle management. As research progresses in improving energy density, cycle life, and overall performance of SIBs, their market potential is expected to expand. The development of efficient recycling and end-of-life management strategies for SIBs will be crucial in enhancing their market appeal and ensuring long-term sustainability.

While the current market share of SIBs is relatively small compared to lithium-ion batteries, industry forecasts suggest significant growth potential. The market is expected to expand as technology matures and production scales up, potentially reaching a substantial market value within the next decade. This growth will be driven by increasing adoption in various sectors and ongoing improvements in SIB technology and lifecycle management.

The electric vehicle (EV) sector represents a substantial market opportunity for SIBs. With the global push towards reducing carbon emissions, the EV market is expanding rapidly, creating a surge in demand for high-performance, low-cost battery technologies. SIBs offer potential advantages in terms of cost reduction and supply chain stability, making them attractive for mass-market EV applications.

In the stationary energy storage sector, SIBs are gaining traction for grid-scale applications. The intermittent nature of renewable energy sources like solar and wind necessitates efficient and economical energy storage solutions. SIBs' potential for lower costs and improved safety characteristics position them as a viable option for large-scale grid storage projects.

The consumer electronics market also presents opportunities for SIB adoption. As manufacturers seek to reduce reliance on lithium and cobalt, sodium-ion technology could offer a more sustainable and cost-effective alternative for portable devices and small appliances.

Market analysis indicates that the Asia-Pacific region, particularly China, is leading in SIB development and adoption. This is driven by strong government support, abundant sodium resources, and a robust manufacturing base. Europe and North America are also showing increasing interest in SIB technology, with several research initiatives and pilot projects underway.

The market demand for SIBs is closely tied to advancements in their performance and lifecycle management. As research progresses in improving energy density, cycle life, and overall performance of SIBs, their market potential is expected to expand. The development of efficient recycling and end-of-life management strategies for SIBs will be crucial in enhancing their market appeal and ensuring long-term sustainability.

While the current market share of SIBs is relatively small compared to lithium-ion batteries, industry forecasts suggest significant growth potential. The market is expected to expand as technology matures and production scales up, potentially reaching a substantial market value within the next decade. This growth will be driven by increasing adoption in various sectors and ongoing improvements in SIB technology and lifecycle management.

Technical Challenges

Sodium-ion batteries (SIBs) face several technical challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is the lower energy density compared to lithium-ion batteries. This limitation stems from the larger size of sodium ions, which affects the electrode materials' capacity and overall battery performance. Researchers are actively exploring novel electrode materials and optimizing existing ones to enhance energy density, but significant improvements are still needed to compete with lithium-ion technology.

Another critical challenge lies in the development of suitable electrolytes for SIBs. The reactivity of sodium with conventional organic electrolytes leads to safety concerns and reduced cycle life. Finding stable electrolyte formulations that can withstand the electrochemical environment of SIBs while maintaining high ionic conductivity remains a key research focus. Solid-state electrolytes show promise but face challenges in terms of interfacial stability and manufacturing scalability.

The cycling stability of SIBs is another area requiring substantial improvement. The repeated insertion and extraction of sodium ions can cause structural degradation in electrode materials, leading to capacity fade and shortened battery life. This issue is particularly pronounced in anode materials, where the formation of a stable solid electrolyte interphase (SEI) is crucial but challenging due to the different chemistry compared to lithium-ion systems.

Manufacturing processes for SIBs also present technical hurdles. While some existing lithium-ion battery production lines can be adapted for SIBs, specific modifications are necessary to accommodate the unique characteristics of sodium-based materials. Developing cost-effective and scalable manufacturing techniques that ensure consistent quality and performance is essential for the commercial viability of SIBs.

The management of thermal issues in SIBs poses another significant challenge. Sodium's higher reactivity can lead to increased heat generation during cycling, potentially compromising safety and performance. Effective thermal management systems and safety mechanisms need to be designed and integrated into SIB packs to mitigate these risks.

Lastly, the end-of-life management and recycling of SIBs present unique challenges. While the abundance of sodium reduces raw material concerns, developing efficient recycling processes for other components, such as transition metals in cathodes, is crucial for sustainability. The different chemistry of SIBs compared to lithium-ion batteries necessitates the development of new recycling technologies and infrastructure.

Another critical challenge lies in the development of suitable electrolytes for SIBs. The reactivity of sodium with conventional organic electrolytes leads to safety concerns and reduced cycle life. Finding stable electrolyte formulations that can withstand the electrochemical environment of SIBs while maintaining high ionic conductivity remains a key research focus. Solid-state electrolytes show promise but face challenges in terms of interfacial stability and manufacturing scalability.

The cycling stability of SIBs is another area requiring substantial improvement. The repeated insertion and extraction of sodium ions can cause structural degradation in electrode materials, leading to capacity fade and shortened battery life. This issue is particularly pronounced in anode materials, where the formation of a stable solid electrolyte interphase (SEI) is crucial but challenging due to the different chemistry compared to lithium-ion systems.

Manufacturing processes for SIBs also present technical hurdles. While some existing lithium-ion battery production lines can be adapted for SIBs, specific modifications are necessary to accommodate the unique characteristics of sodium-based materials. Developing cost-effective and scalable manufacturing techniques that ensure consistent quality and performance is essential for the commercial viability of SIBs.

The management of thermal issues in SIBs poses another significant challenge. Sodium's higher reactivity can lead to increased heat generation during cycling, potentially compromising safety and performance. Effective thermal management systems and safety mechanisms need to be designed and integrated into SIB packs to mitigate these risks.

Lastly, the end-of-life management and recycling of SIBs present unique challenges. While the abundance of sodium reduces raw material concerns, developing efficient recycling processes for other components, such as transition metals in cathodes, is crucial for sustainability. The different chemistry of SIBs compared to lithium-ion batteries necessitates the development of new recycling technologies and infrastructure.

Current LCM Solutions

01 Electrode materials for sodium-ion batteries

Development of advanced electrode materials is crucial for improving the lifecycle of sodium-ion batteries. This includes research on novel cathode and anode materials that offer higher capacity, better stability, and improved cycling performance. These materials aim to enhance the overall energy density and longevity of sodium-ion batteries.- Electrode materials for sodium-ion batteries: Development of advanced electrode materials is crucial for improving the lifecycle of sodium-ion batteries. This includes research on novel cathode and anode materials that offer higher capacity, better stability, and improved cycling performance. These materials aim to enhance the overall energy density and longevity of sodium-ion batteries.

- Electrolyte optimization for sodium-ion batteries: Optimizing electrolyte compositions is essential for enhancing the lifecycle of sodium-ion batteries. This involves developing electrolytes that provide better ionic conductivity, improved interfacial stability, and reduced side reactions. Advanced electrolyte formulations can significantly impact the battery's performance, safety, and lifespan.

- Battery management systems for sodium-ion batteries: Implementing sophisticated battery management systems is crucial for extending the lifecycle of sodium-ion batteries. These systems monitor and control various parameters such as temperature, voltage, and current to optimize battery performance and prevent degradation. Advanced algorithms and sensing technologies are employed to enhance the overall efficiency and lifespan of the battery.

- Recycling and end-of-life management of sodium-ion batteries: Developing efficient recycling processes and end-of-life management strategies is essential for the sustainable lifecycle of sodium-ion batteries. This includes methods for recovering valuable materials, reducing environmental impact, and creating closed-loop systems for battery components. Innovative recycling technologies aim to make sodium-ion batteries more environmentally friendly and economically viable.

- Manufacturing processes for sodium-ion batteries: Improving manufacturing processes is critical for enhancing the lifecycle of sodium-ion batteries. This involves developing advanced production techniques, quality control measures, and scalable manufacturing methods. Innovations in this area focus on reducing defects, improving consistency, and optimizing the overall production efficiency to create more durable and reliable sodium-ion batteries.

02 Electrolyte formulations for enhanced battery performance

Optimizing electrolyte compositions is essential for extending the lifecycle of sodium-ion batteries. This involves developing electrolyte additives and formulations that improve the stability of the solid-electrolyte interphase (SEI) layer, reduce side reactions, and enhance the overall electrochemical performance of the battery.Expand Specific Solutions03 Battery management systems for sodium-ion batteries

Implementing advanced battery management systems is crucial for optimizing the lifecycle of sodium-ion batteries. These systems monitor and control various parameters such as temperature, voltage, and current to ensure safe operation, prevent overcharging or deep discharging, and extend the overall lifespan of the battery.Expand Specific Solutions04 Recycling and end-of-life management of sodium-ion batteries

Developing efficient recycling processes and end-of-life management strategies is essential for improving the overall lifecycle of sodium-ion batteries. This includes methods for recovering valuable materials, reducing environmental impact, and creating a circular economy for battery components.Expand Specific Solutions05 Manufacturing processes for sodium-ion batteries

Optimizing manufacturing processes is crucial for enhancing the lifecycle of sodium-ion batteries. This involves developing innovative production techniques, improving quality control measures, and implementing advanced assembly methods to ensure consistent performance and longevity of the batteries.Expand Specific Solutions

Key Industry Players

The sodium-ion battery lifecycle management landscape is evolving rapidly, with the industry currently in an early growth phase. Market size is expanding as companies recognize the potential of this technology for sustainable energy storage solutions. While still emerging, the technology is progressing towards maturity, with key players like LG Energy Solution, CATL, and Tesla investing in research and development. Companies such as StoreDot and Tiamat are focusing on innovative approaches to improve battery performance and longevity. The competitive landscape is diverse, including established battery manufacturers, automotive companies, and specialized startups, all vying to advance sodium-ion technology and capture market share in this promising sector.

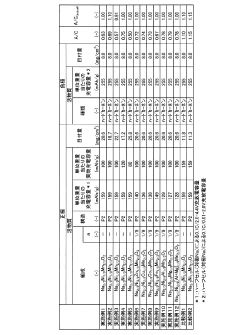

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed a first-generation sodium-ion battery with an energy density of up to 160Wh/kg[1]. Their approach focuses on improving the cathode material using a Prussian white material with a higher specific capacity and redesigning the bulk structure of the anode material. CATL's sodium-ion batteries feature fast-charging capability, reaching 80% SOC in 15 minutes at room temperature[2]. They have also developed a battery management system that can integrate sodium-ion cells with lithium-ion cells, allowing for complementary advantages in a mixed system[3].

Strengths: High energy density for sodium-ion technology, fast charging capability, and innovative integration with lithium-ion cells. Weaknesses: Still lower energy density compared to lithium-ion batteries, potential challenges in large-scale production and supply chain establishment.

Beijing Zhongke Haina Technology Co. Ltd.

Technical Solution: Beijing Zhongke Haina has developed sodium-ion batteries with a focus on large-scale energy storage applications. Their technology utilizes a hard carbon anode and a layered oxide cathode, achieving an energy density of up to 145Wh/kg[7]. The company has demonstrated long cycle life, with their batteries retaining over 80% capacity after 4500 cycles[8]. They have also implemented advanced thermal management systems to enhance safety and reliability in grid-scale installations[9].

Strengths: Long cycle life, focus on large-scale energy storage, and advanced safety features. Weaknesses: Lower energy density compared to some competitors, potentially higher costs due to specialized thermal management systems.

Key LCM Innovations

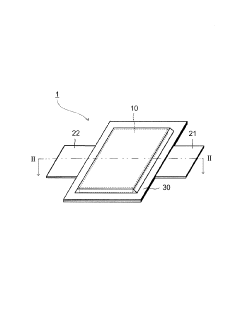

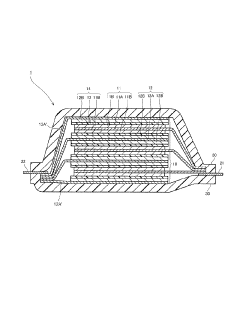

Control method of sodium ion secondary battery, controller for sodium ion secondary battery, and sodium ion secondary battery for use in control method or controller for sodium ion secondary battery

PatentInactiveJP2017045600A

Innovation

- The method involves controlling the ratio of the charge capacity of the negative electrode to the positive electrode within a specific range (0.5 to 0.9) using sodium layered compounds with compositions such as Na2/3[Ni1/3Mn2/3]O2 or Na2/3[Ni1/3-aM]aMn2/3O2 (where M = Zn, Cu, Co, Fe, Al, Mg) to avoid the irreversible capacity region, thereby enhancing cycle durability.

Sodium ion battery

PatentWO2023241299A1

Innovation

- By optimizing the comprehensive design of the mass fraction of the negative active material, specific surface area, density of the non-aqueous electrolyte and molar conductivity, ensuring 0.3≤a×b×x/y≤1.5, the adsorption capacity per unit volume of the electrolyte is reduced, and the load capacity is increased. Improve flow utilization and form a thinner interface film.

Environmental Impact

The environmental impact of sodium-ion batteries (SIBs) throughout their lifecycle is a critical consideration in their development and adoption. While SIBs are often touted as a more sustainable alternative to lithium-ion batteries, their environmental footprint requires careful examination across all stages of production, use, and disposal.

During the production phase, the extraction and processing of raw materials for SIBs generally have a lower environmental impact compared to lithium-ion batteries. Sodium is abundant and widely distributed, reducing the need for extensive mining operations. However, the production of other components, such as cathode materials and electrolytes, still involves energy-intensive processes and potential chemical pollution.

The manufacturing stage of SIBs presents opportunities for reduced environmental impact through the use of less toxic materials and potentially simpler production processes. However, the scale of production and energy consumption in manufacturing facilities remains a significant factor in the overall environmental footprint.

In the use phase, SIBs demonstrate promising characteristics for environmental sustainability. Their potential for longer cycle life and improved safety features may lead to reduced waste generation and lower risks of environmental contamination from battery failures or accidents.

End-of-life management for SIBs is an area that requires further research and development. While the materials used in SIBs are generally less toxic and more abundant than those in lithium-ion batteries, effective recycling processes are still needed to maximize resource recovery and minimize waste. The development of efficient recycling technologies for SIBs could significantly enhance their overall environmental performance.

The environmental impact of SIBs also extends to their role in enabling renewable energy storage and electrification of transportation. By providing a potentially more sustainable energy storage solution, SIBs could contribute to reducing greenhouse gas emissions and dependence on fossil fuels in various sectors.

However, the full lifecycle assessment of SIBs must consider factors such as energy consumption, water usage, and potential ecological disruptions associated with increased sodium extraction. As the technology matures, ongoing research and innovation in materials science and manufacturing processes will be crucial in further reducing the environmental footprint of SIBs.

In conclusion, while sodium-ion batteries show promise for reduced environmental impact compared to current lithium-ion technologies, a comprehensive and continual assessment of their lifecycle environmental effects is essential. This will ensure that the development and deployment of SIBs align with broader sustainability goals and contribute positively to global efforts in mitigating climate change and resource depletion.

During the production phase, the extraction and processing of raw materials for SIBs generally have a lower environmental impact compared to lithium-ion batteries. Sodium is abundant and widely distributed, reducing the need for extensive mining operations. However, the production of other components, such as cathode materials and electrolytes, still involves energy-intensive processes and potential chemical pollution.

The manufacturing stage of SIBs presents opportunities for reduced environmental impact through the use of less toxic materials and potentially simpler production processes. However, the scale of production and energy consumption in manufacturing facilities remains a significant factor in the overall environmental footprint.

In the use phase, SIBs demonstrate promising characteristics for environmental sustainability. Their potential for longer cycle life and improved safety features may lead to reduced waste generation and lower risks of environmental contamination from battery failures or accidents.

End-of-life management for SIBs is an area that requires further research and development. While the materials used in SIBs are generally less toxic and more abundant than those in lithium-ion batteries, effective recycling processes are still needed to maximize resource recovery and minimize waste. The development of efficient recycling technologies for SIBs could significantly enhance their overall environmental performance.

The environmental impact of SIBs also extends to their role in enabling renewable energy storage and electrification of transportation. By providing a potentially more sustainable energy storage solution, SIBs could contribute to reducing greenhouse gas emissions and dependence on fossil fuels in various sectors.

However, the full lifecycle assessment of SIBs must consider factors such as energy consumption, water usage, and potential ecological disruptions associated with increased sodium extraction. As the technology matures, ongoing research and innovation in materials science and manufacturing processes will be crucial in further reducing the environmental footprint of SIBs.

In conclusion, while sodium-ion batteries show promise for reduced environmental impact compared to current lithium-ion technologies, a comprehensive and continual assessment of their lifecycle environmental effects is essential. This will ensure that the development and deployment of SIBs align with broader sustainability goals and contribute positively to global efforts in mitigating climate change and resource depletion.

Regulatory Framework

The regulatory framework surrounding sodium-ion battery lifecycle management is still in its nascent stages, as the technology itself is relatively new compared to more established battery chemistries. However, as sodium-ion batteries gain traction in the market, regulatory bodies are beginning to take notice and develop guidelines to ensure their safe and sustainable use throughout their lifecycle.

At present, many existing regulations for lithium-ion batteries are being adapted to cover sodium-ion batteries. This includes safety standards for transportation, storage, and disposal. The United Nations Manual of Tests and Criteria, which provides guidelines for the transport of dangerous goods, has been updated to include sodium-ion batteries, classifying them under UN3480 alongside lithium-ion batteries.

In the European Union, the proposed Battery Regulation aims to create a comprehensive framework for the entire battery lifecycle, including sodium-ion batteries. This regulation emphasizes the importance of sustainable sourcing, responsible manufacturing, and efficient recycling processes. It also introduces requirements for carbon footprint declarations and the use of recycled materials in battery production.

The United States Environmental Protection Agency (EPA) is also considering the inclusion of sodium-ion batteries in its existing battery recycling programs. The agency is working on guidelines for the proper disposal and recycling of these batteries to prevent environmental contamination and promote resource recovery.

In China, where sodium-ion battery development is particularly active, the government has included this technology in its New Energy Vehicle (NEV) subsidy program, indicating a supportive regulatory environment for the growth of this industry. The Chinese Ministry of Industry and Information Technology is developing specific standards for sodium-ion batteries, focusing on performance, safety, and environmental impact.

As the technology matures, it is expected that more specific regulations will be developed to address the unique characteristics of sodium-ion batteries. This may include guidelines for battery design to facilitate easier disassembly and recycling, as well as standards for the reuse of sodium-ion batteries in second-life applications, such as stationary energy storage systems.

Regulatory bodies are also likely to focus on the environmental impact of sodium-ion battery production and disposal. This may lead to the implementation of extended producer responsibility (EPR) schemes, where manufacturers are held accountable for the entire lifecycle of their products, including end-of-life management.

At present, many existing regulations for lithium-ion batteries are being adapted to cover sodium-ion batteries. This includes safety standards for transportation, storage, and disposal. The United Nations Manual of Tests and Criteria, which provides guidelines for the transport of dangerous goods, has been updated to include sodium-ion batteries, classifying them under UN3480 alongside lithium-ion batteries.

In the European Union, the proposed Battery Regulation aims to create a comprehensive framework for the entire battery lifecycle, including sodium-ion batteries. This regulation emphasizes the importance of sustainable sourcing, responsible manufacturing, and efficient recycling processes. It also introduces requirements for carbon footprint declarations and the use of recycled materials in battery production.

The United States Environmental Protection Agency (EPA) is also considering the inclusion of sodium-ion batteries in its existing battery recycling programs. The agency is working on guidelines for the proper disposal and recycling of these batteries to prevent environmental contamination and promote resource recovery.

In China, where sodium-ion battery development is particularly active, the government has included this technology in its New Energy Vehicle (NEV) subsidy program, indicating a supportive regulatory environment for the growth of this industry. The Chinese Ministry of Industry and Information Technology is developing specific standards for sodium-ion batteries, focusing on performance, safety, and environmental impact.

As the technology matures, it is expected that more specific regulations will be developed to address the unique characteristics of sodium-ion batteries. This may include guidelines for battery design to facilitate easier disassembly and recycling, as well as standards for the reuse of sodium-ion batteries in second-life applications, such as stationary energy storage systems.

Regulatory bodies are also likely to focus on the environmental impact of sodium-ion battery production and disposal. This may lead to the implementation of extended producer responsibility (EPR) schemes, where manufacturers are held accountable for the entire lifecycle of their products, including end-of-life management.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!