Electropolishing for additive-manufactured metal parts

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM Metal Electropolishing Background and Objectives

Additive manufacturing (AM) has revolutionized the production of complex metal parts across various industries, enabling designs previously impossible with traditional manufacturing methods. However, the surface finish of AM metal parts often presents significant challenges, characterized by roughness, porosity, and inconsistencies that can compromise both aesthetic appeal and functional performance. Electropolishing has emerged as a promising post-processing technique to address these surface quality issues.

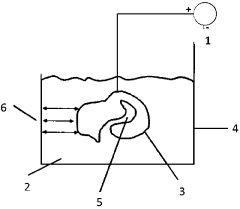

Electropolishing, an electrochemical process that removes material from a metal workpiece, has been utilized in traditional manufacturing for decades. The process involves immersing the metal part in an electrolyte solution and applying an electric current, causing controlled dissolution of the metal surface. This results in material removal primarily from microscopic peaks, effectively smoothing the surface and enhancing its properties.

The application of electropolishing specifically for AM metal parts represents a critical technological intersection that addresses the unique challenges posed by layer-by-layer fabrication methods. AM processes such as Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM) create distinctive surface characteristics that conventional finishing methods struggle to refine effectively.

The historical development of electropolishing for AM metals has accelerated significantly since 2015, driven by the expanding adoption of metal AM in aerospace, medical, and automotive industries. Early research focused primarily on adapting traditional electropolishing parameters for common AM materials like titanium alloys and stainless steels, with limited success due to the unique microstructural features of AM parts.

Recent technological evolution has seen the development of specialized electrolytes, optimized current densities, and modified fixture designs specifically tailored for AM metal components. These advancements aim to accommodate the complex geometries, internal channels, and variable surface conditions inherent to additively manufactured parts.

The primary objectives of electropolishing for AM metal parts include: achieving surface roughness reduction to Ra values below 0.5μm; removing partially melted particles; eliminating support structure remnants; reducing surface stress concentrations; enhancing corrosion resistance; and improving fatigue performance—all while maintaining dimensional accuracy and preserving intricate features.

Current research trends are focusing on developing predictive models for electropolishing outcomes based on AM process parameters, material composition, and part geometry. Additionally, there is growing interest in combining electropolishing with other finishing techniques in hybrid approaches to optimize surface quality while minimizing material removal.

The technological goal is to establish standardized, scalable electropolishing protocols specific to different AM metal alloys and printing technologies, enabling consistent surface quality that meets or exceeds that of traditionally manufactured components while preserving the design freedom that makes AM so valuable.

Electropolishing, an electrochemical process that removes material from a metal workpiece, has been utilized in traditional manufacturing for decades. The process involves immersing the metal part in an electrolyte solution and applying an electric current, causing controlled dissolution of the metal surface. This results in material removal primarily from microscopic peaks, effectively smoothing the surface and enhancing its properties.

The application of electropolishing specifically for AM metal parts represents a critical technological intersection that addresses the unique challenges posed by layer-by-layer fabrication methods. AM processes such as Selective Laser Melting (SLM), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM) create distinctive surface characteristics that conventional finishing methods struggle to refine effectively.

The historical development of electropolishing for AM metals has accelerated significantly since 2015, driven by the expanding adoption of metal AM in aerospace, medical, and automotive industries. Early research focused primarily on adapting traditional electropolishing parameters for common AM materials like titanium alloys and stainless steels, with limited success due to the unique microstructural features of AM parts.

Recent technological evolution has seen the development of specialized electrolytes, optimized current densities, and modified fixture designs specifically tailored for AM metal components. These advancements aim to accommodate the complex geometries, internal channels, and variable surface conditions inherent to additively manufactured parts.

The primary objectives of electropolishing for AM metal parts include: achieving surface roughness reduction to Ra values below 0.5μm; removing partially melted particles; eliminating support structure remnants; reducing surface stress concentrations; enhancing corrosion resistance; and improving fatigue performance—all while maintaining dimensional accuracy and preserving intricate features.

Current research trends are focusing on developing predictive models for electropolishing outcomes based on AM process parameters, material composition, and part geometry. Additionally, there is growing interest in combining electropolishing with other finishing techniques in hybrid approaches to optimize surface quality while minimizing material removal.

The technological goal is to establish standardized, scalable electropolishing protocols specific to different AM metal alloys and printing technologies, enabling consistent surface quality that meets or exceeds that of traditionally manufactured components while preserving the design freedom that makes AM so valuable.

Market Analysis for Post-Processing AM Metal Parts

The post-processing market for additively manufactured metal parts is experiencing robust growth, driven by the increasing adoption of metal AM technologies across various industries. As metal AM transitions from prototyping to production applications, the demand for high-quality surface finishing solutions like electropolishing has surged significantly. The global market for metal AM post-processing was valued at approximately $538 million in 2021 and is projected to reach $1.8 billion by 2028, representing a compound annual growth rate (CAGR) of 18.7%.

Electropolishing specifically occupies a growing segment within this market, currently estimated at $120 million with expectations to double within the next five years. This growth is primarily fueled by industries requiring high-performance metal components with superior surface quality, such as aerospace, medical devices, and high-end industrial applications.

The aerospace sector represents the largest market share (38%) for electropolishing of AM metal parts, driven by stringent requirements for fatigue resistance, corrosion protection, and component longevity. Medical device manufacturing follows closely at 31%, where electropolishing provides the biocompatibility and sterilizability essential for implants and surgical instruments. Automotive and general industrial applications account for 18% and 13% respectively, with growth accelerating as production volumes increase.

Regionally, North America leads the market with 42% share, followed by Europe (35%) and Asia-Pacific (20%). The remaining 3% is distributed across other regions. The Asia-Pacific region is expected to demonstrate the fastest growth rate over the next decade as manufacturing capabilities mature in countries like China, Japan, and South Korea.

Customer demand is increasingly focused on automated electropolishing solutions that can be integrated into digital manufacturing workflows. End-users are seeking systems that offer process parameter optimization, real-time monitoring, and quality assurance documentation to ensure consistent results across production batches.

Price sensitivity varies significantly by application sector. While aerospace and medical industries prioritize quality and performance over cost, automotive and general industrial sectors demonstrate higher price sensitivity, creating market opportunities for tiered solution offerings.

The competitive landscape features both established surface finishing companies expanding into AM applications and new entrants developing specialized solutions for additively manufactured components. Strategic partnerships between AM system manufacturers and post-processing specialists are becoming increasingly common, indicating a trend toward integrated manufacturing solutions.

Electropolishing specifically occupies a growing segment within this market, currently estimated at $120 million with expectations to double within the next five years. This growth is primarily fueled by industries requiring high-performance metal components with superior surface quality, such as aerospace, medical devices, and high-end industrial applications.

The aerospace sector represents the largest market share (38%) for electropolishing of AM metal parts, driven by stringent requirements for fatigue resistance, corrosion protection, and component longevity. Medical device manufacturing follows closely at 31%, where electropolishing provides the biocompatibility and sterilizability essential for implants and surgical instruments. Automotive and general industrial applications account for 18% and 13% respectively, with growth accelerating as production volumes increase.

Regionally, North America leads the market with 42% share, followed by Europe (35%) and Asia-Pacific (20%). The remaining 3% is distributed across other regions. The Asia-Pacific region is expected to demonstrate the fastest growth rate over the next decade as manufacturing capabilities mature in countries like China, Japan, and South Korea.

Customer demand is increasingly focused on automated electropolishing solutions that can be integrated into digital manufacturing workflows. End-users are seeking systems that offer process parameter optimization, real-time monitoring, and quality assurance documentation to ensure consistent results across production batches.

Price sensitivity varies significantly by application sector. While aerospace and medical industries prioritize quality and performance over cost, automotive and general industrial sectors demonstrate higher price sensitivity, creating market opportunities for tiered solution offerings.

The competitive landscape features both established surface finishing companies expanding into AM applications and new entrants developing specialized solutions for additively manufactured components. Strategic partnerships between AM system manufacturers and post-processing specialists are becoming increasingly common, indicating a trend toward integrated manufacturing solutions.

Current Electropolishing Challenges for AM Components

Despite the significant advancements in additive manufacturing (AM) technologies, electropolishing of AM metal components presents unique challenges that differ substantially from those encountered with traditionally manufactured parts. The inherent surface characteristics of AM components—including high roughness, variable porosity, and complex geometries—create fundamental obstacles for conventional electropolishing processes.

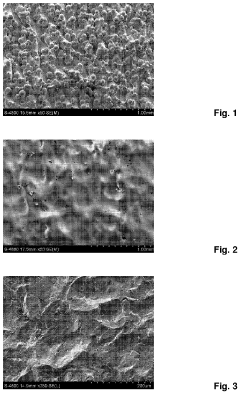

Surface roughness in AM parts typically ranges from 5-20 μm Ra depending on the manufacturing process, compared to 0.8-3.2 μm Ra in traditional machining. This extreme roughness requires longer electropolishing times, often resulting in dimensional inaccuracy and excessive material removal from sharp edges and fine features.

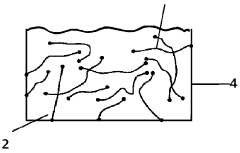

The layer-by-layer building process of AM creates anisotropic surface properties with directional roughness patterns that respond non-uniformly to electropolishing currents. This directional bias leads to preferential dissolution along build layers rather than uniform material removal across the entire surface.

Partially melted powder particles adhered to AM component surfaces create microscopic "islands" that disrupt current distribution during electropolishing. These particles often detach during processing, creating pits and compromising surface integrity. Studies indicate that up to 15% of surface area may be affected by such partially sintered particles in powder bed fusion processes.

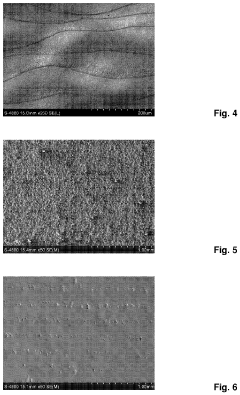

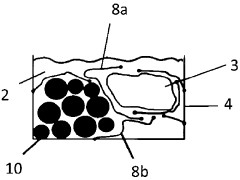

Internal porosity, a common characteristic in AM parts, presents another significant challenge. Electrolyte penetration into subsurface pores can cause localized corrosion and pitting when these pores are exposed during the electropolishing process. Research shows that interconnected porosity can extend electropolishing effects up to 500 μm below the intended surface.

Complex geometries with internal channels, lattice structures, and variable cross-sections—often the primary reason for using AM—create severe current density variations during electropolishing. These variations result in preferential dissolution at external corners and edges while internal features remain underpolished. Current density can vary by factors of 5-10× between external and internal features.

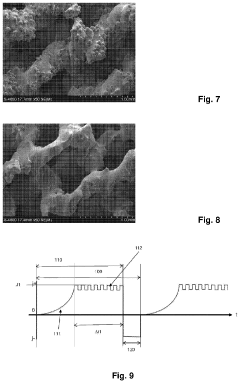

Material-specific challenges also exist. The rapid solidification rates in AM processes create unique microstructures with non-equilibrium phases and high residual stresses that respond differently to electropolishing compared to conventionally processed alloys. This is particularly problematic for titanium alloys and high-entropy alloys increasingly used in AM applications.

Conventional electropolishing electrolytes and parameters optimized for wrought materials often prove ineffective for AM components. The aggressive conditions required to address high surface roughness frequently lead to excessive material removal, dimensional inaccuracy, and loss of fine features that were intentionally designed into the AM component.

Surface roughness in AM parts typically ranges from 5-20 μm Ra depending on the manufacturing process, compared to 0.8-3.2 μm Ra in traditional machining. This extreme roughness requires longer electropolishing times, often resulting in dimensional inaccuracy and excessive material removal from sharp edges and fine features.

The layer-by-layer building process of AM creates anisotropic surface properties with directional roughness patterns that respond non-uniformly to electropolishing currents. This directional bias leads to preferential dissolution along build layers rather than uniform material removal across the entire surface.

Partially melted powder particles adhered to AM component surfaces create microscopic "islands" that disrupt current distribution during electropolishing. These particles often detach during processing, creating pits and compromising surface integrity. Studies indicate that up to 15% of surface area may be affected by such partially sintered particles in powder bed fusion processes.

Internal porosity, a common characteristic in AM parts, presents another significant challenge. Electrolyte penetration into subsurface pores can cause localized corrosion and pitting when these pores are exposed during the electropolishing process. Research shows that interconnected porosity can extend electropolishing effects up to 500 μm below the intended surface.

Complex geometries with internal channels, lattice structures, and variable cross-sections—often the primary reason for using AM—create severe current density variations during electropolishing. These variations result in preferential dissolution at external corners and edges while internal features remain underpolished. Current density can vary by factors of 5-10× between external and internal features.

Material-specific challenges also exist. The rapid solidification rates in AM processes create unique microstructures with non-equilibrium phases and high residual stresses that respond differently to electropolishing compared to conventionally processed alloys. This is particularly problematic for titanium alloys and high-entropy alloys increasingly used in AM applications.

Conventional electropolishing electrolytes and parameters optimized for wrought materials often prove ineffective for AM components. The aggressive conditions required to address high surface roughness frequently lead to excessive material removal, dimensional inaccuracy, and loss of fine features that were intentionally designed into the AM component.

Existing Electropolishing Solutions for Complex Geometries

01 Electrolyte compositions for electropolishing

Various electrolyte compositions can be used in electropolishing processes to achieve optimal surface finishing. These compositions typically include acids such as phosphoric acid, sulfuric acid, or mixtures with organic compounds. The specific formulation affects the polishing rate, surface quality, and selectivity. Advanced electrolytes may incorporate additives to enhance conductivity, improve wetting properties, or reduce environmental impact while maintaining effective metal removal capabilities.- Electropolishing process fundamentals: Electropolishing is an electrochemical process that removes material from a metallic workpiece, resulting in a smooth, polished surface. The process involves immersing the workpiece in an electrolyte solution and applying an electric current, causing controlled dissolution of the metal surface. This technique preferentially removes microscopic peaks and irregularities, leaving a smooth, bright finish with improved corrosion resistance and cleanliness.

- Electrolyte compositions for electropolishing: Various electrolyte compositions are used in electropolishing to achieve optimal results for different metals and applications. These electrolytes typically contain acids (such as phosphoric, sulfuric, or perchloric acid), along with additives that enhance performance. The composition affects polishing rate, surface finish quality, and process efficiency. Specialized formulations have been developed for specific metals like stainless steel, titanium, copper, and aluminum alloys.

- Advanced electropolishing equipment and systems: Modern electropolishing systems incorporate advanced equipment designs and control mechanisms to improve process efficiency and results. These systems may include specialized cathode designs, pulsed current capabilities, temperature control systems, and automated handling equipment. Computer-controlled systems allow precise adjustment of current density, temperature, and process time to achieve consistent results across different workpiece geometries and materials.

- Electropolishing for semiconductor and microelectronics applications: Electropolishing plays a critical role in semiconductor manufacturing and microelectronics, particularly for planarization of wafers and preparation of microstructures. The process enables the removal of excess material with high precision while maintaining critical dimensions. Specialized techniques have been developed for copper interconnects, silicon wafers, and other microelectronic components, allowing for nanometer-scale surface control and integration with other semiconductor fabrication processes.

- Electropolishing for medical and implantable devices: Electropolishing is widely used in the medical device industry, particularly for implantable devices such as stents, orthopedic implants, and surgical instruments. The process creates ultra-smooth surfaces that reduce bacterial adhesion, improve biocompatibility, and enhance corrosion resistance. For medical applications, specialized electropolishing protocols ensure compliance with regulatory requirements while achieving the high-quality surface finish necessary for devices that contact human tissue.

02 Electropolishing methods for specific metals and alloys

Different metals and alloys require specialized electropolishing approaches due to their unique electrochemical properties. Stainless steel, titanium, aluminum, and copper alloys each demand tailored parameters including voltage, current density, temperature, and process duration. For complex alloys, multi-stage processes may be employed to selectively remove surface irregularities while preserving material integrity. These methods can be optimized to achieve specific surface characteristics such as smoothness, reflectivity, or corrosion resistance.Expand Specific Solutions03 Advanced equipment and process control systems

Modern electropolishing utilizes sophisticated equipment and control systems to enhance precision and reproducibility. Computer-controlled power supplies enable precise voltage and current regulation, while advanced cathode designs optimize electric field distribution. Real-time monitoring systems track process parameters and surface quality metrics, allowing for automated adjustments. Pulse electropolishing techniques, where current is applied in controlled intervals rather than continuously, can improve surface finish quality while reducing processing time and energy consumption.Expand Specific Solutions04 Electropolishing for semiconductor and microelectronics applications

Electropolishing plays a critical role in semiconductor manufacturing and microelectronics, where ultra-smooth surfaces and precise dimensional control are essential. Specialized techniques have been developed for wafer processing, interconnect fabrication, and microelectromechanical systems (MEMS). These applications often require integration with other processes such as chemical mechanical planarization or selective etching. The electropolishing parameters must be carefully controlled to achieve nanometer-scale precision while avoiding damage to sensitive electronic components.Expand Specific Solutions05 Environmentally friendly electropolishing processes

Environmental considerations have driven the development of greener electropolishing alternatives that reduce or eliminate hazardous chemicals. These approaches include using biodegradable electrolytes, implementing closed-loop recycling systems for process solutions, and developing low-toxicity formulations that maintain polishing effectiveness. Energy-efficient processes that operate at lower temperatures or with reduced current requirements further minimize environmental impact. These sustainable methods aim to comply with increasingly stringent regulations while delivering comparable or superior surface finishing results.Expand Specific Solutions

Leading Companies in Metal AM Post-Processing

The electropolishing market for additive-manufactured metal parts is currently in its growth phase, with increasing adoption across aerospace, medical, and automotive sectors. The market is expanding rapidly as industries recognize the value of post-processing for AM components to achieve superior surface finish and mechanical properties. Key players include established industrial giants like Robert Bosch GmbH and Medtronic alongside specialized companies such as POLIGRAT GmbH and Integran Technologies. Academic institutions including Colorado School of Mines and Harbin Institute of Technology are advancing fundamental research, while innovative companies like Divergent Technologies and Fabric8Labs are developing integrated solutions combining AM with advanced finishing techniques. The technology is maturing but still evolving, with significant R&D focused on process optimization for complex geometries and novel alloys used in additive manufacturing.

Medtronic, Inc.

Technical Solution: Medtronic has developed a comprehensive electropolishing solution specifically for additively manufactured medical implants and devices. Their proprietary process combines traditional electropolishing techniques with specialized pre-treatments designed to address the unique surface characteristics of AM parts. The company's approach begins with a detailed surface analysis to identify critical features requiring preservation while targeting rough areas for selective material removal. Their multi-stage process incorporates ultrasonic cleaning to remove partially sintered particles, followed by controlled electropolishing using proprietary electrolyte formulations optimized for biocompatible alloys like Ti6Al4V and CoCr. Medtronic's system employs variable current density protocols that adapt to different geometric features within the same part, ensuring uniform finishing of both external surfaces and internal channels. The process has been validated through extensive biocompatibility testing and has demonstrated significant improvements in fatigue life (>30% increase) and corrosion resistance for implantable devices. Their technology achieves surface roughness values below 0.3μm Ra while maintaining critical dimensional tolerances within ±10μm.

Strengths: Validated process for FDA-approved medical devices; comprehensive quality control system; demonstrated improvements in biological response and mechanical performance. Weaknesses: Process is highly specialized for medical applications and may not be cost-effective for general industrial use; requires significant expertise and specialized equipment; longer processing times compared to conventional finishing methods.

POLIGRAT GmbH

Technical Solution: POLIGRAT has developed specialized electropolishing processes specifically tailored for additive-manufactured metal parts. Their POLINOX® EP system utilizes a proprietary electrolyte composition that effectively removes surface irregularities from complex AM geometries while maintaining dimensional accuracy. The process employs controlled current density distribution techniques to ensure uniform material removal even in internal channels and difficult-to-reach areas. POLIGRAT's approach includes a multi-stage treatment protocol beginning with mechanical pre-treatment, followed by electrochemical processing under precisely controlled temperature and agitation conditions, and finishing with passivation treatments to enhance corrosion resistance. Their technology has demonstrated the ability to reduce surface roughness of AM parts from Ra values of 15-20μm down to 0.2-0.5μm, significantly improving fatigue performance and biocompatibility for medical applications.

Strengths: Specialized expertise in electropolishing complex geometries; proven capability to achieve medical-grade surface finishes; established industrial-scale implementation. Weaknesses: Process requires careful parameter optimization for each alloy composition; limited effectiveness for certain AM-specific defects like partially melted powder particles embedded deep in the material.

Key Innovations in Electrolyte Formulations for AM

Electropolishing method and electrolyte for same

PatentActiveUS20200080222A1

Innovation

- An electrolyte containing methanesulfonic acid and at least one phosphonic acid, along with polyvalent alcohols and other additives, is used in an electropolishing process with controlled pulse sequences to effectively smooth rough surfaces, particularly for titanium and aluminum alloys, utilizing the electrolyte's complexing and wetting properties to enhance material removal.

Process and device for electropolishing and/or plasma polishing of additively manufactured components

PatentPendingDE102022100587A1

Innovation

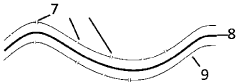

- A device and method utilizing a flexible, multi-part cathode with a protective coating and movable design, allowing for uniform electric field distribution and controlled distance from the component surface, ensuring consistent polishing across complex geometries.

Material-Specific Electropolishing Parameters

Electropolishing parameters vary significantly across different metal materials used in additive manufacturing, requiring precise calibration for optimal surface finishing results. For titanium alloys (Ti6Al4V), commonly used in medical implants and aerospace components, electrolyte solutions typically consist of perchloric acid and methanol mixtures at concentrations between 5-15% by volume. These solutions operate most effectively at temperatures between -30°C and -10°C with current densities of 50-100 mA/cm². The polishing duration for titanium components generally ranges from 3-8 minutes depending on surface complexity.

Stainless steel variants (316L, 17-4PH) require different parameter sets, typically utilizing phosphoric and sulfuric acid mixtures at ratios of 3:1 to 5:1. Optimal processing occurs at room temperature to 50°C with current densities of 10-30 mA/cm². The higher thermal conductivity of stainless steel allows for longer processing times of 5-15 minutes without risking microstructural damage.

Aluminum alloys present unique challenges due to their high reactivity. Electrolytes based on perchloric acid and ethanol (1:4 ratio) yield superior results when maintained at temperatures below 5°C. Current densities must be carefully controlled between 5-15 mA/cm² with shorter processing cycles of 1-3 minutes to prevent excessive material removal.

Nickel-based superalloys (Inconel 718, 625) benefit from electrolytes containing sulfuric acid, phosphoric acid, and glycerol mixtures. These materials require higher operating temperatures (40-70°C) and current densities of 20-40 mA/cm² with processing times of 10-20 minutes due to their inherent corrosion resistance.

Copper alloys respond well to phosphoric acid-based electrolytes with organic additives like propylene glycol. Optimal parameters include moderate temperatures (20-40°C) and current densities of 15-25 mA/cm² with processing durations of 4-8 minutes.

Recent research indicates that pulsed current applications rather than continuous DC current can significantly improve electropolishing outcomes across all material types. Pulse frequencies between 10-100 Hz with duty cycles of 70-90% have demonstrated superior material removal uniformity while minimizing heat-affected zones. This approach has proven particularly valuable for complex geometries with internal features characteristic of additively manufactured parts.

Stainless steel variants (316L, 17-4PH) require different parameter sets, typically utilizing phosphoric and sulfuric acid mixtures at ratios of 3:1 to 5:1. Optimal processing occurs at room temperature to 50°C with current densities of 10-30 mA/cm². The higher thermal conductivity of stainless steel allows for longer processing times of 5-15 minutes without risking microstructural damage.

Aluminum alloys present unique challenges due to their high reactivity. Electrolytes based on perchloric acid and ethanol (1:4 ratio) yield superior results when maintained at temperatures below 5°C. Current densities must be carefully controlled between 5-15 mA/cm² with shorter processing cycles of 1-3 minutes to prevent excessive material removal.

Nickel-based superalloys (Inconel 718, 625) benefit from electrolytes containing sulfuric acid, phosphoric acid, and glycerol mixtures. These materials require higher operating temperatures (40-70°C) and current densities of 20-40 mA/cm² with processing times of 10-20 minutes due to their inherent corrosion resistance.

Copper alloys respond well to phosphoric acid-based electrolytes with organic additives like propylene glycol. Optimal parameters include moderate temperatures (20-40°C) and current densities of 15-25 mA/cm² with processing durations of 4-8 minutes.

Recent research indicates that pulsed current applications rather than continuous DC current can significantly improve electropolishing outcomes across all material types. Pulse frequencies between 10-100 Hz with duty cycles of 70-90% have demonstrated superior material removal uniformity while minimizing heat-affected zones. This approach has proven particularly valuable for complex geometries with internal features characteristic of additively manufactured parts.

Sustainability Aspects of Electropolishing Processes

The sustainability of electropolishing processes for additive-manufactured metal parts has become increasingly important as industries strive to meet environmental regulations and corporate social responsibility goals. Traditional electropolishing methods often involve hazardous chemicals such as phosphoric and sulfuric acids, chromium compounds, and other environmentally problematic substances that require careful handling and disposal.

Environmental impact assessments of electropolishing processes reveal significant concerns regarding wastewater management. The effluents typically contain heavy metals, including chromium, nickel, and copper, which can cause severe ecological damage if improperly discharged. Advanced treatment systems are necessary to ensure compliance with increasingly stringent environmental regulations, adding complexity and cost to the manufacturing process.

Energy consumption represents another critical sustainability aspect of electropolishing. The process requires substantial electrical power, particularly when processing complex additive-manufactured parts with intricate geometries. Recent innovations have focused on optimizing electrical parameters and bath compositions to reduce energy requirements while maintaining surface quality outcomes.

Chemical lifecycle management has emerged as a key focus area for sustainable electropolishing. Developments in green chemistry have led to more environmentally friendly electrolyte formulations that maintain effectiveness while reducing toxicity. Some promising alternatives include organic acid-based electrolytes and ionic liquids that offer comparable performance with significantly reduced environmental impact.

Resource efficiency in electropolishing processes has seen notable improvements through bath life extension techniques. Modern monitoring systems enable precise control of bath chemistry, allowing for continuous adjustment and replenishment rather than complete replacement. This approach substantially reduces chemical consumption and waste generation while maintaining consistent surface quality across production runs.

Closed-loop systems represent the gold standard for sustainable electropolishing operations. These systems incorporate advanced filtration, metal recovery, and electrolyte regeneration technologies to minimize waste and maximize resource utilization. While implementation costs remain high, the long-term environmental and economic benefits make closed-loop processing increasingly attractive for high-volume manufacturing operations.

Worker safety considerations also factor into sustainability assessments. Traditional electropolishing chemicals present significant health hazards, requiring extensive personal protective equipment and specialized handling procedures. Newer, less toxic formulations not only reduce environmental impact but also improve workplace safety conditions and reduce associated healthcare and insurance costs.

Environmental impact assessments of electropolishing processes reveal significant concerns regarding wastewater management. The effluents typically contain heavy metals, including chromium, nickel, and copper, which can cause severe ecological damage if improperly discharged. Advanced treatment systems are necessary to ensure compliance with increasingly stringent environmental regulations, adding complexity and cost to the manufacturing process.

Energy consumption represents another critical sustainability aspect of electropolishing. The process requires substantial electrical power, particularly when processing complex additive-manufactured parts with intricate geometries. Recent innovations have focused on optimizing electrical parameters and bath compositions to reduce energy requirements while maintaining surface quality outcomes.

Chemical lifecycle management has emerged as a key focus area for sustainable electropolishing. Developments in green chemistry have led to more environmentally friendly electrolyte formulations that maintain effectiveness while reducing toxicity. Some promising alternatives include organic acid-based electrolytes and ionic liquids that offer comparable performance with significantly reduced environmental impact.

Resource efficiency in electropolishing processes has seen notable improvements through bath life extension techniques. Modern monitoring systems enable precise control of bath chemistry, allowing for continuous adjustment and replenishment rather than complete replacement. This approach substantially reduces chemical consumption and waste generation while maintaining consistent surface quality across production runs.

Closed-loop systems represent the gold standard for sustainable electropolishing operations. These systems incorporate advanced filtration, metal recovery, and electrolyte regeneration technologies to minimize waste and maximize resource utilization. While implementation costs remain high, the long-term environmental and economic benefits make closed-loop processing increasingly attractive for high-volume manufacturing operations.

Worker safety considerations also factor into sustainability assessments. Traditional electropolishing chemicals present significant health hazards, requiring extensive personal protective equipment and specialized handling procedures. Newer, less toxic formulations not only reduce environmental impact but also improve workplace safety conditions and reduce associated healthcare and insurance costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!