Research on automated process control in electropolishing systems

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electropolishing Automation Background and Objectives

Electropolishing, a critical surface finishing process in manufacturing, has evolved significantly since its inception in the early 20th century. Initially performed as a manual operation requiring skilled technicians, the process has gradually incorporated various levels of automation over decades. The evolution from manual to semi-automated and now toward fully automated systems represents a fundamental shift in how industries approach surface finishing requirements for critical components in aerospace, medical, semiconductor, and automotive sectors.

The technological trajectory of electropolishing has been shaped by increasing demands for precision, consistency, and efficiency in manufacturing processes. Early electropolishing systems relied heavily on operator experience and subjective assessment, resulting in variable outcomes and limited scalability. The introduction of basic automation elements in the 1970s and 1980s, such as timers and simple monitoring devices, marked the beginning of a transition toward more controlled processes.

Recent advancements in sensing technologies, real-time analytics, and control systems have accelerated the development of sophisticated automated electropolishing solutions. The integration of machine learning algorithms and advanced process control methodologies has opened new possibilities for achieving unprecedented levels of surface finish quality while minimizing resource consumption and environmental impact.

The primary objective of current research in automated process control for electropolishing systems is to develop comprehensive solutions that can dynamically adjust process parameters in real-time based on material characteristics, surface conditions, and desired outcomes. This includes the creation of closed-loop control systems capable of monitoring critical variables such as current density, temperature, electrolyte composition, and material removal rates while making autonomous adjustments to maintain optimal processing conditions.

Additional research goals include the development of predictive models that can anticipate process outcomes based on initial conditions, reducing the need for iterative processing and quality control inspections. The establishment of standardized protocols for automated electropolishing across different material types and geometries represents another significant objective, as current solutions often require extensive customization for specific applications.

The ultimate aim is to transform electropolishing from an art dependent on operator skill into a science-based, repeatable manufacturing process with quantifiable parameters and predictable outcomes. This transformation aligns with broader Industry 4.0 initiatives focused on smart manufacturing, where data-driven decision making and autonomous process optimization become standard practice rather than aspirational goals.

The technological trajectory of electropolishing has been shaped by increasing demands for precision, consistency, and efficiency in manufacturing processes. Early electropolishing systems relied heavily on operator experience and subjective assessment, resulting in variable outcomes and limited scalability. The introduction of basic automation elements in the 1970s and 1980s, such as timers and simple monitoring devices, marked the beginning of a transition toward more controlled processes.

Recent advancements in sensing technologies, real-time analytics, and control systems have accelerated the development of sophisticated automated electropolishing solutions. The integration of machine learning algorithms and advanced process control methodologies has opened new possibilities for achieving unprecedented levels of surface finish quality while minimizing resource consumption and environmental impact.

The primary objective of current research in automated process control for electropolishing systems is to develop comprehensive solutions that can dynamically adjust process parameters in real-time based on material characteristics, surface conditions, and desired outcomes. This includes the creation of closed-loop control systems capable of monitoring critical variables such as current density, temperature, electrolyte composition, and material removal rates while making autonomous adjustments to maintain optimal processing conditions.

Additional research goals include the development of predictive models that can anticipate process outcomes based on initial conditions, reducing the need for iterative processing and quality control inspections. The establishment of standardized protocols for automated electropolishing across different material types and geometries represents another significant objective, as current solutions often require extensive customization for specific applications.

The ultimate aim is to transform electropolishing from an art dependent on operator skill into a science-based, repeatable manufacturing process with quantifiable parameters and predictable outcomes. This transformation aligns with broader Industry 4.0 initiatives focused on smart manufacturing, where data-driven decision making and autonomous process optimization become standard practice rather than aspirational goals.

Market Analysis for Automated Electropolishing Solutions

The global market for automated electropolishing solutions is experiencing significant growth, driven by increasing demand for precision-finished metal components across multiple industries. Currently valued at approximately $2.1 billion, this market segment is projected to expand at a compound annual growth rate of 6.8% through 2028, reaching an estimated $3.2 billion. This growth trajectory is primarily fueled by advancements in automation technologies and the rising need for high-quality surface finishing in critical applications.

The medical device manufacturing sector represents the largest market share at 32%, where electropolished components are essential for implantable devices, surgical instruments, and diagnostic equipment. The stringent regulatory requirements in this sector, particularly FDA and EU MDR compliance, necessitate consistent, documentable finishing processes that automated systems can reliably deliver.

Semiconductor fabrication constitutes the second-largest market segment at 27%, with demand driven by the need for ultra-clean, contamination-free components in chip manufacturing environments. The aerospace industry follows at 18%, where electropolished components are crucial for fuel systems, hydraulic components, and critical engine parts requiring superior corrosion resistance and fatigue strength.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). The Asia-Pacific region, particularly China and South Korea, is demonstrating the fastest growth rate at 8.9% annually, attributed to rapid industrialization and increasing adoption of advanced manufacturing technologies.

Customer demand patterns reveal a clear shift toward fully integrated electropolishing systems that offer real-time process monitoring, adaptive control capabilities, and comprehensive data analytics. End-users are increasingly prioritizing solutions that can demonstrate measurable improvements in consistency, reduced rejection rates, and lower operational costs. Market research indicates that customers are willing to pay a premium of 15-20% for systems that can provide documented quality improvements and reduced labor requirements.

The market is also witnessing growing demand for modular, scalable solutions that can be integrated into existing production lines with minimal disruption. This trend is particularly pronounced among mid-sized manufacturers seeking to gradually automate their finishing operations without committing to complete system overhauls.

The medical device manufacturing sector represents the largest market share at 32%, where electropolished components are essential for implantable devices, surgical instruments, and diagnostic equipment. The stringent regulatory requirements in this sector, particularly FDA and EU MDR compliance, necessitate consistent, documentable finishing processes that automated systems can reliably deliver.

Semiconductor fabrication constitutes the second-largest market segment at 27%, with demand driven by the need for ultra-clean, contamination-free components in chip manufacturing environments. The aerospace industry follows at 18%, where electropolished components are crucial for fuel systems, hydraulic components, and critical engine parts requiring superior corrosion resistance and fatigue strength.

Regionally, North America leads the market with 38% share, followed by Europe (29%) and Asia-Pacific (26%). The Asia-Pacific region, particularly China and South Korea, is demonstrating the fastest growth rate at 8.9% annually, attributed to rapid industrialization and increasing adoption of advanced manufacturing technologies.

Customer demand patterns reveal a clear shift toward fully integrated electropolishing systems that offer real-time process monitoring, adaptive control capabilities, and comprehensive data analytics. End-users are increasingly prioritizing solutions that can demonstrate measurable improvements in consistency, reduced rejection rates, and lower operational costs. Market research indicates that customers are willing to pay a premium of 15-20% for systems that can provide documented quality improvements and reduced labor requirements.

The market is also witnessing growing demand for modular, scalable solutions that can be integrated into existing production lines with minimal disruption. This trend is particularly pronounced among mid-sized manufacturers seeking to gradually automate their finishing operations without committing to complete system overhauls.

Current Challenges in Electropolishing Process Control

Despite significant advancements in electropolishing technology, the industry continues to face substantial challenges in achieving consistent, automated process control. The inherent complexity of electropolishing processes stems from the multitude of interdependent variables that must be precisely managed, including current density, temperature, electrolyte composition, and processing time. These parameters exhibit non-linear relationships that complicate the development of reliable predictive models for process optimization.

A primary challenge lies in real-time monitoring capabilities. Traditional electropolishing systems often rely on periodic sampling and offline analysis, creating significant delays between process deviations and corrective actions. The harsh chemical environment of electropolishing baths presents extreme difficulties for sensor deployment, with many conventional monitoring devices suffering from rapid degradation or providing inconsistent readings when exposed to highly acidic or basic electrolytes.

The heterogeneity of workpiece geometries compounds these challenges. Complex parts with varying surface areas and recessed features experience inconsistent current distribution, leading to uneven material removal rates. Current automated systems struggle to dynamically adjust processing parameters to compensate for these geometric variations, resulting in quality inconsistencies that often require manual intervention and inspection.

Electrolyte management represents another significant hurdle. As electropolishing processes continue, the chemical composition of the bath gradually changes due to metal dissolution and contaminant accumulation. These changes alter the electrochemical behavior of the system, yet most existing control systems lack the capability to automatically adjust processing parameters in response to these evolving conditions.

Data integration and analysis limitations further impede progress. Many electropolishing facilities operate with disparate control systems that generate substantial volumes of process data but lack the sophisticated analytics infrastructure needed to extract actionable insights. This data fragmentation prevents the implementation of advanced control strategies such as machine learning algorithms that could potentially identify subtle patterns and optimize process parameters.

Regulatory compliance adds another layer of complexity, particularly in industries like medical device manufacturing and aerospace. Automated systems must not only optimize process outcomes but also maintain comprehensive documentation of process parameters and deviations to satisfy increasingly stringent quality assurance requirements.

The economic barriers to implementing advanced control systems cannot be overlooked. Many electropolishing operations, particularly smaller facilities, face significant challenges in justifying the substantial capital investment required for comprehensive automation upgrades, despite the long-term benefits in quality improvement and operational efficiency.

A primary challenge lies in real-time monitoring capabilities. Traditional electropolishing systems often rely on periodic sampling and offline analysis, creating significant delays between process deviations and corrective actions. The harsh chemical environment of electropolishing baths presents extreme difficulties for sensor deployment, with many conventional monitoring devices suffering from rapid degradation or providing inconsistent readings when exposed to highly acidic or basic electrolytes.

The heterogeneity of workpiece geometries compounds these challenges. Complex parts with varying surface areas and recessed features experience inconsistent current distribution, leading to uneven material removal rates. Current automated systems struggle to dynamically adjust processing parameters to compensate for these geometric variations, resulting in quality inconsistencies that often require manual intervention and inspection.

Electrolyte management represents another significant hurdle. As electropolishing processes continue, the chemical composition of the bath gradually changes due to metal dissolution and contaminant accumulation. These changes alter the electrochemical behavior of the system, yet most existing control systems lack the capability to automatically adjust processing parameters in response to these evolving conditions.

Data integration and analysis limitations further impede progress. Many electropolishing facilities operate with disparate control systems that generate substantial volumes of process data but lack the sophisticated analytics infrastructure needed to extract actionable insights. This data fragmentation prevents the implementation of advanced control strategies such as machine learning algorithms that could potentially identify subtle patterns and optimize process parameters.

Regulatory compliance adds another layer of complexity, particularly in industries like medical device manufacturing and aerospace. Automated systems must not only optimize process outcomes but also maintain comprehensive documentation of process parameters and deviations to satisfy increasingly stringent quality assurance requirements.

The economic barriers to implementing advanced control systems cannot be overlooked. Many electropolishing operations, particularly smaller facilities, face significant challenges in justifying the substantial capital investment required for comprehensive automation upgrades, despite the long-term benefits in quality improvement and operational efficiency.

Current Automated Control Solutions for Electropolishing

01 Real-time monitoring and feedback systems

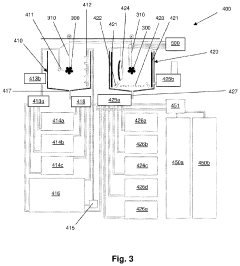

Advanced electropolishing systems incorporate real-time monitoring capabilities to continuously track process parameters such as current density, temperature, and electrolyte composition. These systems use sensors and data analysis to provide immediate feedback, allowing for automatic adjustments to maintain optimal polishing conditions. Real-time monitoring helps ensure consistent surface finish quality and reduces the risk of over-polishing or under-polishing by detecting deviations from the target parameters.- Real-time monitoring and feedback systems: Electropolishing systems incorporate real-time monitoring technologies to continuously track process parameters such as current density, temperature, and electrolyte composition. These systems use sensors and data analysis to provide immediate feedback, allowing for automatic adjustments to maintain optimal polishing conditions. Real-time monitoring ensures consistent surface finish quality and reduces process variability by detecting and correcting deviations before they affect the workpiece.

- Electrolyte composition control mechanisms: Advanced electropolishing systems feature mechanisms for precise control of electrolyte composition, which is critical for process stability and finish quality. These systems monitor and adjust electrolyte parameters including pH, conductivity, and concentration of active components. Some implementations include automated dosing systems that maintain optimal chemical balance, filtration systems to remove contaminants, and temperature regulation to ensure consistent reaction kinetics throughout the polishing process.

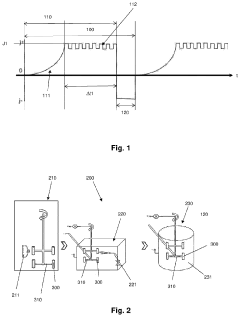

- Pulse and waveform modulation techniques: Modern electropolishing systems employ sophisticated pulse and waveform modulation techniques to enhance process control and results. By precisely controlling the electrical parameters such as current density, pulse frequency, duty cycle, and waveform shape, these systems can optimize material removal rates and surface finish quality. This approach allows for more uniform polishing across complex geometries and can reduce processing time while improving the consistency of the final surface characteristics.

- Automated process sequencing and recipe management: Electropolishing systems incorporate automated process sequencing and recipe management capabilities to ensure reproducibility and efficiency. These systems store optimized process parameters for different materials and geometries, allowing operators to select pre-defined recipes for specific applications. The automation includes sequential control of pre-treatment, polishing, rinsing, and post-treatment steps with precise timing and parameter adjustments. This approach minimizes operator variability and enables consistent results across production batches.

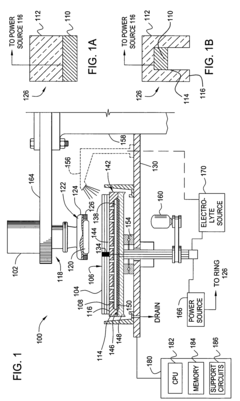

- Advanced endpoint detection methods: Sophisticated endpoint detection methods are implemented in modern electropolishing systems to determine when the optimal surface finish has been achieved. These methods include optical monitoring of surface reflectivity, electrical resistance measurements, and analysis of process current characteristics. By accurately identifying the endpoint, these systems prevent under-polishing or over-polishing, optimize process time, and ensure consistent quality. Some advanced systems incorporate machine learning algorithms to improve endpoint prediction based on historical process data.

02 Electrolyte composition control methods

Precise control of electrolyte composition is critical in electropolishing processes. Systems employ various methods to maintain optimal electrolyte conditions, including automated chemical analysis, dosing systems for replenishment of depleted components, and filtration systems to remove contaminants. These control methods help maintain consistent electrolyte conductivity, pH levels, and chemical balance, which directly impact the quality and efficiency of the electropolishing process.Expand Specific Solutions03 Current and voltage regulation techniques

Sophisticated power supply systems are employed to precisely control the electrical parameters during electropolishing. These systems can deliver pulsed current, variable voltage, or modulated waveforms to optimize the polishing effect for different materials and geometries. Advanced regulation techniques include programmable power supplies that can adjust current density based on workpiece characteristics, automated ramping protocols to prevent damage to sensitive surfaces, and compensation mechanisms for varying surface areas.Expand Specific Solutions04 Automated process sequencing and timing control

Modern electropolishing systems feature automated sequencing capabilities that control the timing and duration of each process step. These systems can manage pre-treatment, polishing, rinsing, and post-treatment operations with precise timing to ensure optimal results. Programmable logic controllers (PLCs) or specialized software platforms enable operators to create, store, and execute process recipes for different materials and applications, ensuring consistency across production batches.Expand Specific Solutions05 Quality assessment and endpoint detection

Advanced electropolishing systems incorporate methods for determining when the desired surface finish has been achieved. These include optical monitoring systems that measure surface reflectivity, impedance-based techniques that detect changes in the electrochemical behavior as the surface becomes polished, and automated inspection systems that can identify surface defects. Endpoint detection prevents excessive material removal while ensuring that the required surface quality specifications are met, optimizing both quality and processing time.Expand Specific Solutions

Leading Companies in Electropolishing Automation Industry

The electropolishing systems automation market is in a growth phase, characterized by increasing adoption across semiconductor, electronics, and manufacturing industries. The market size is expanding due to rising demand for precision surface finishing in high-tech applications, with projections indicating substantial growth over the next five years. Technologically, the field is advancing rapidly with varying maturity levels among key players. Industry leaders like Applied Materials, DuPont, and Taiwan Semiconductor Manufacturing Co. have established sophisticated automated electropolishing solutions, while companies such as Nova Ltd. and Cabot Microelectronics are developing specialized process control technologies. Emerging players including Advanced Micro Fabrication Equipment and Hwatsing Technology are introducing innovative approaches to automation and real-time monitoring, creating a competitive landscape that balances established expertise with technological innovation.

Applied Materials, Inc.

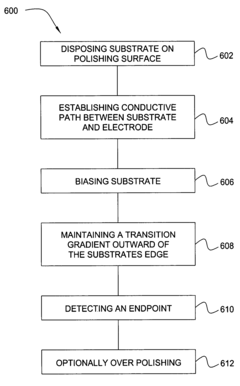

Technical Solution: Applied Materials has developed an advanced electropolishing control system that integrates real-time monitoring and feedback mechanisms. Their solution employs multiple sensor arrays to continuously measure critical parameters including current density, temperature, electrolyte composition, and surface finish quality. The system utilizes proprietary algorithms to analyze these inputs and automatically adjust process parameters to maintain optimal polishing conditions. A key innovation is their closed-loop control architecture that incorporates machine learning models trained on extensive process data to predict and prevent defects before they occur[1]. The system features a distributed control network that enables precise coordination between electrolyte flow, electrical current modulation, and workpiece positioning, allowing for uniform material removal across complex geometries. Applied Materials' solution also includes advanced analytics capabilities that provide comprehensive process traceability and quality assurance documentation.

Strengths: Superior process consistency with reported 30% reduction in surface finish variability compared to manual systems; comprehensive integration with existing semiconductor manufacturing lines; extensive data analytics capabilities for continuous process improvement. Weaknesses: Higher initial implementation costs; requires specialized technical expertise for system maintenance and calibration; may need customization for specific material applications.

Taiwan Semiconductor Manufacturing Co., Ltd.

Technical Solution: TSMC has developed a comprehensive automated electropolishing control system specifically optimized for semiconductor manufacturing processes. Their solution integrates directly with their advanced process control (APC) framework, creating a seamless manufacturing environment with real-time data exchange between process steps. The system employs a network of high-precision sensors that monitor not only standard electropolishing parameters but also upstream and downstream process conditions to enable predictive control strategies[3]. TSMC's approach incorporates multi-variable statistical process control algorithms that can detect subtle pattern deviations that might impact final wafer quality. Their technology features an adaptive control mechanism that automatically compensates for bath aging effects and maintains consistent performance throughout the electrolyte lifecycle. The system also includes advanced endpoint detection capabilities using multiple sensing modalities (electrical, optical, and chemical) to precisely determine when optimal surface conditions have been achieved. TSMC's solution is particularly notable for its integration of historical process data with real-time measurements to continuously refine control parameters.

Strengths: Exceptional integration with semiconductor manufacturing workflows; demonstrated capability to handle high-volume production with minimal process variation; sophisticated fault detection and classification systems that minimize yield impact. Weaknesses: Highly specialized for semiconductor applications with limited applicability to other industries; significant customization required for implementation outside TSMC's manufacturing ecosystem; high complexity requiring specialized engineering support.

Key Technical Innovations in Electropolishing Process Control

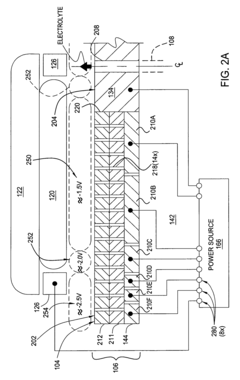

Electropolishing method and system therefor

PatentActiveUS20190345628A1

Innovation

- The method employs anodic pulses with a steady increase in current intensity over time, accompanied by micropulses, allowing for controlled material removal and surface smoothing by selectively managing the polishing film's formation and degradation, and adjusting pulse frequency and shape to address inhomogeneous surfaces.

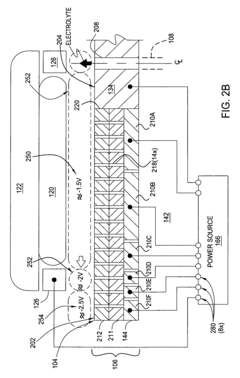

Electroprocessing profile control

PatentInactiveUS7655565B2

Innovation

- The method involves biasing a first electrode to establish an electroprocessing zone between the electrode and the substrate, with a second electrode disposed radially outward having opposite polarity to create a transition voltage gradient, improving control at the substrate edge by maintaining the gradient outward.

Environmental Impact and Sustainability Considerations

Electropolishing processes traditionally involve the use of hazardous chemicals and significant energy consumption, raising important environmental and sustainability concerns. Modern automated electropolishing systems are increasingly designed with environmental impact reduction as a core consideration. These systems optimize chemical usage through precise dosing and monitoring, reducing waste by up to 30-40% compared to manual processes. Advanced filtration and recycling technologies integrated into automated systems enable the recovery and reuse of electrolyte solutions, extending their operational lifespan and minimizing disposal requirements.

Energy efficiency represents another critical environmental dimension of automated electropolishing. Intelligent power management systems dynamically adjust electrical parameters based on real-time feedback, reducing overall energy consumption by 15-25%. Some cutting-edge systems incorporate renewable energy integration capabilities, allowing facilities to utilize solar or other clean energy sources during non-peak production periods, further reducing carbon footprint.

Water conservation has become increasingly important in industrial processes. Automated electropolishing systems implement closed-loop water systems that can reduce freshwater consumption by up to 60% compared to conventional methods. These systems incorporate advanced water treatment modules that enable safe recycling of process water while maintaining quality standards for the electropolishing process.

Waste management represents a significant sustainability challenge in electropolishing operations. Automated systems address this through integrated waste treatment modules that neutralize harmful compounds before discharge. Real-time monitoring of effluent quality ensures compliance with increasingly stringent environmental regulations across different jurisdictions. Some advanced systems incorporate precipitation and separation technologies that can recover valuable metals from waste streams, creating potential for secondary revenue streams while reducing environmental impact.

The lifecycle assessment of automated electropolishing systems demonstrates significant sustainability advantages. While the initial resource investment for manufacturing and implementing these systems is higher than manual alternatives, the extended operational lifespan and reduced resource consumption typically result in a favorable environmental balance within 3-5 years of operation. Industry data suggests that fully automated systems can reduce the overall environmental footprint of electropolishing operations by 40-50% when considering the complete lifecycle impact.

Energy efficiency represents another critical environmental dimension of automated electropolishing. Intelligent power management systems dynamically adjust electrical parameters based on real-time feedback, reducing overall energy consumption by 15-25%. Some cutting-edge systems incorporate renewable energy integration capabilities, allowing facilities to utilize solar or other clean energy sources during non-peak production periods, further reducing carbon footprint.

Water conservation has become increasingly important in industrial processes. Automated electropolishing systems implement closed-loop water systems that can reduce freshwater consumption by up to 60% compared to conventional methods. These systems incorporate advanced water treatment modules that enable safe recycling of process water while maintaining quality standards for the electropolishing process.

Waste management represents a significant sustainability challenge in electropolishing operations. Automated systems address this through integrated waste treatment modules that neutralize harmful compounds before discharge. Real-time monitoring of effluent quality ensures compliance with increasingly stringent environmental regulations across different jurisdictions. Some advanced systems incorporate precipitation and separation technologies that can recover valuable metals from waste streams, creating potential for secondary revenue streams while reducing environmental impact.

The lifecycle assessment of automated electropolishing systems demonstrates significant sustainability advantages. While the initial resource investment for manufacturing and implementing these systems is higher than manual alternatives, the extended operational lifespan and reduced resource consumption typically result in a favorable environmental balance within 3-5 years of operation. Industry data suggests that fully automated systems can reduce the overall environmental footprint of electropolishing operations by 40-50% when considering the complete lifecycle impact.

Quality Assurance Standards for Automated Electropolishing

Quality assurance in automated electropolishing systems requires adherence to rigorous standards to ensure consistent surface finish quality, dimensional accuracy, and material integrity. The International Organization for Standardization (ISO) has established several standards specifically applicable to electropolishing processes, including ISO 15730 for metallic materials and ISO 16348 for stainless steel components. These standards define acceptable ranges for surface roughness measurements, typically expressed in Ra (arithmetic average roughness) values, which for medical implants often must be below 0.1 μm.

The ASTM International provides complementary standards, particularly ASTM B912, which outlines testing methods for evaluating electropolished surfaces. These standards mandate regular calibration of measurement equipment and verification procedures to ensure reliability of quality assessments. For automated systems, ASTM E2500 offers guidelines for verification practices in equipment used for regulated processes.

In pharmaceutical and medical device manufacturing, electropolished components must comply with FDA 21 CFR Part 11 for electronic records and signatures when automated quality control systems are implemented. Additionally, the European Medical Device Regulation (MDR) imposes strict requirements on surface treatments for implantable devices, necessitating comprehensive documentation of electropolishing parameters and outcomes.

Quality assurance protocols for automated electropolishing typically involve in-process monitoring of critical parameters including current density, temperature, solution chemistry, and immersion time. Statistical Process Control (SPC) methodologies are increasingly integrated into automated systems, enabling real-time detection of process deviations before they result in quality issues. Six Sigma principles are commonly applied to establish control limits and reduce variability in the electropolishing process.

Non-destructive testing methods form an essential component of quality assurance standards. These include reflectometry for surface brightness measurement, X-ray fluorescence for chemical composition verification, and optical profilometry for three-dimensional surface characterization. Advanced systems incorporate machine vision technology capable of detecting surface defects as small as 1-2 micrometers.

Documentation requirements for automated electropolishing systems have become increasingly stringent, with standards mandating complete traceability from raw material to finished product. This includes recording of all process parameters, operator interventions, and equipment maintenance activities. Modern automated systems typically incorporate digital twins that maintain virtual representations of physical assets, enabling predictive quality assurance through simulation and historical data analysis.

The ASTM International provides complementary standards, particularly ASTM B912, which outlines testing methods for evaluating electropolished surfaces. These standards mandate regular calibration of measurement equipment and verification procedures to ensure reliability of quality assessments. For automated systems, ASTM E2500 offers guidelines for verification practices in equipment used for regulated processes.

In pharmaceutical and medical device manufacturing, electropolished components must comply with FDA 21 CFR Part 11 for electronic records and signatures when automated quality control systems are implemented. Additionally, the European Medical Device Regulation (MDR) imposes strict requirements on surface treatments for implantable devices, necessitating comprehensive documentation of electropolishing parameters and outcomes.

Quality assurance protocols for automated electropolishing typically involve in-process monitoring of critical parameters including current density, temperature, solution chemistry, and immersion time. Statistical Process Control (SPC) methodologies are increasingly integrated into automated systems, enabling real-time detection of process deviations before they result in quality issues. Six Sigma principles are commonly applied to establish control limits and reduce variability in the electropolishing process.

Non-destructive testing methods form an essential component of quality assurance standards. These include reflectometry for surface brightness measurement, X-ray fluorescence for chemical composition verification, and optical profilometry for three-dimensional surface characterization. Advanced systems incorporate machine vision technology capable of detecting surface defects as small as 1-2 micrometers.

Documentation requirements for automated electropolishing systems have become increasingly stringent, with standards mandating complete traceability from raw material to finished product. This includes recording of all process parameters, operator interventions, and equipment maintenance activities. Modern automated systems typically incorporate digital twins that maintain virtual representations of physical assets, enabling predictive quality assurance through simulation and historical data analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!