Electropolishing of nickel alloys for aerospace hardware

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Nickel Alloy Electropolishing Background and Objectives

Electropolishing of nickel alloys represents a critical surface finishing technology that has evolved significantly since its inception in the early 20th century. This electrochemical process selectively removes material from a metallic workpiece, resulting in improved surface finish, enhanced corrosion resistance, and superior mechanical properties. For aerospace applications, where component reliability under extreme conditions is paramount, electropolishing has become an indispensable manufacturing step for nickel alloy hardware.

The historical trajectory of nickel alloy electropolishing began with rudimentary processes in the 1930s and has progressed to highly sophisticated, computer-controlled systems capable of achieving nanometer-level surface modifications. The technology gained significant momentum during the aerospace boom of the 1960s when the demand for high-performance alloys in jet engines and spacecraft components drove innovation in surface treatment technologies.

Current technological trends indicate a shift toward environmentally sustainable electropolishing solutions that minimize the use of hazardous chemicals while maintaining or improving performance characteristics. Additionally, there is growing interest in developing electropolishing techniques specifically optimized for advanced nickel-based superalloys such as Inconel, Hastelloy, and Waspaloy, which are increasingly utilized in next-generation aerospace applications.

The primary technical objectives of nickel alloy electropolishing for aerospace hardware encompass several critical dimensions. First, achieving ultra-smooth surfaces with roughness values below 0.1 μm Ra to minimize drag and improve fluid dynamics in aerospace components. Second, enhancing fatigue resistance by eliminating surface microcracks and stress concentration points that could lead to component failure under cyclic loading conditions.

Third, improving corrosion resistance by removing free iron contamination and creating a chromium-enriched passive layer on the alloy surface. Fourth, ensuring dimensional precision while maintaining tight tolerances required for aerospace applications, particularly for complex geometries and thin-walled components. Finally, developing processes that can be validated and certified to meet stringent aerospace industry standards such as AMS 2700 and ASTM B912.

The technological evolution in this field aims to address persistent challenges including the electropolishing of complex internal passages, uniform material removal across varying geometries, and the development of real-time monitoring systems to ensure process consistency. As aerospace hardware continues to push performance boundaries, electropolishing technology must evolve to meet increasingly demanding specifications for surface quality and component reliability.

The historical trajectory of nickel alloy electropolishing began with rudimentary processes in the 1930s and has progressed to highly sophisticated, computer-controlled systems capable of achieving nanometer-level surface modifications. The technology gained significant momentum during the aerospace boom of the 1960s when the demand for high-performance alloys in jet engines and spacecraft components drove innovation in surface treatment technologies.

Current technological trends indicate a shift toward environmentally sustainable electropolishing solutions that minimize the use of hazardous chemicals while maintaining or improving performance characteristics. Additionally, there is growing interest in developing electropolishing techniques specifically optimized for advanced nickel-based superalloys such as Inconel, Hastelloy, and Waspaloy, which are increasingly utilized in next-generation aerospace applications.

The primary technical objectives of nickel alloy electropolishing for aerospace hardware encompass several critical dimensions. First, achieving ultra-smooth surfaces with roughness values below 0.1 μm Ra to minimize drag and improve fluid dynamics in aerospace components. Second, enhancing fatigue resistance by eliminating surface microcracks and stress concentration points that could lead to component failure under cyclic loading conditions.

Third, improving corrosion resistance by removing free iron contamination and creating a chromium-enriched passive layer on the alloy surface. Fourth, ensuring dimensional precision while maintaining tight tolerances required for aerospace applications, particularly for complex geometries and thin-walled components. Finally, developing processes that can be validated and certified to meet stringent aerospace industry standards such as AMS 2700 and ASTM B912.

The technological evolution in this field aims to address persistent challenges including the electropolishing of complex internal passages, uniform material removal across varying geometries, and the development of real-time monitoring systems to ensure process consistency. As aerospace hardware continues to push performance boundaries, electropolishing technology must evolve to meet increasingly demanding specifications for surface quality and component reliability.

Aerospace Industry Demand Analysis for Electropolished Components

The aerospace industry has witnessed a significant increase in demand for electropolished nickel alloy components over the past decade. This growth is primarily driven by the industry's stringent requirements for surface quality, corrosion resistance, and mechanical performance in extreme operating conditions. Market analysis indicates that the global aerospace electropolishing services market reached approximately $1.2 billion in 2022, with a compound annual growth rate of 7.3% projected through 2028.

Commercial aircraft manufacturers represent the largest segment of demand, accounting for nearly 45% of the market. These manufacturers require electropolished components for critical systems including engine parts, fuel delivery systems, and hydraulic components. The superior fatigue resistance and reduced friction coefficients achieved through electropolishing directly translate to enhanced safety metrics and extended service intervals.

Defense aerospace applications constitute approximately 32% of the market, with particular emphasis on military aircraft and missile systems. In these applications, the demand for electropolished nickel alloys stems from their exceptional performance in high-stress environments and resistance to thermal cycling. The defense sector's requirements typically exceed commercial standards, driving innovation in electropolishing techniques.

Space exploration represents the fastest-growing segment, expanding at 9.8% annually. As both governmental and private space initiatives accelerate, the demand for ultra-high-performance components has intensified. Electropolished nickel alloy components are particularly valued in propulsion systems, where they must withstand extreme temperature fluctuations and aggressive chemical environments.

Regional analysis reveals that North America dominates the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the most rapid growth, driven by expanding aerospace manufacturing capabilities in China, Japan, and India.

Key market drivers include increasingly stringent regulatory requirements for component performance and reliability. The FAA, EASA, and other regulatory bodies have progressively raised standards for surface finish quality and material performance, particularly for flight-critical components. Additionally, the industry-wide push toward longer maintenance intervals and reduced lifecycle costs has elevated the importance of surface treatments that enhance durability.

Emerging trends indicate growing demand for electropolished components in next-generation aircraft designs, particularly those incorporating advanced nickel superalloys. The development of more fuel-efficient engines operating at higher temperatures has created new applications for electropolished components that can maintain structural integrity and surface properties under extreme thermal stress.

Commercial aircraft manufacturers represent the largest segment of demand, accounting for nearly 45% of the market. These manufacturers require electropolished components for critical systems including engine parts, fuel delivery systems, and hydraulic components. The superior fatigue resistance and reduced friction coefficients achieved through electropolishing directly translate to enhanced safety metrics and extended service intervals.

Defense aerospace applications constitute approximately 32% of the market, with particular emphasis on military aircraft and missile systems. In these applications, the demand for electropolished nickel alloys stems from their exceptional performance in high-stress environments and resistance to thermal cycling. The defense sector's requirements typically exceed commercial standards, driving innovation in electropolishing techniques.

Space exploration represents the fastest-growing segment, expanding at 9.8% annually. As both governmental and private space initiatives accelerate, the demand for ultra-high-performance components has intensified. Electropolished nickel alloy components are particularly valued in propulsion systems, where they must withstand extreme temperature fluctuations and aggressive chemical environments.

Regional analysis reveals that North America dominates the market with 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is experiencing the most rapid growth, driven by expanding aerospace manufacturing capabilities in China, Japan, and India.

Key market drivers include increasingly stringent regulatory requirements for component performance and reliability. The FAA, EASA, and other regulatory bodies have progressively raised standards for surface finish quality and material performance, particularly for flight-critical components. Additionally, the industry-wide push toward longer maintenance intervals and reduced lifecycle costs has elevated the importance of surface treatments that enhance durability.

Emerging trends indicate growing demand for electropolished components in next-generation aircraft designs, particularly those incorporating advanced nickel superalloys. The development of more fuel-efficient engines operating at higher temperatures has created new applications for electropolished components that can maintain structural integrity and surface properties under extreme thermal stress.

Current Electropolishing Technologies and Challenges for Nickel Alloys

Electropolishing is a critical surface finishing process widely employed in aerospace applications for nickel alloys. The current dominant technology utilizes an electrolytic cell setup where the workpiece serves as the anode in an electrolyte solution, typically containing phosphoric and sulfuric acids. When direct current passes through the system, metal ions are selectively removed from the surface, resulting in a smooth, bright finish with enhanced corrosion resistance.

Conventional electropolishing systems for nickel alloys typically operate at temperatures between 40-70°C with current densities ranging from 10-50 A/dm². The process parameters must be precisely controlled to achieve optimal results, with processing times typically ranging from 5-20 minutes depending on the specific alloy composition and desired surface characteristics.

Advanced electropolishing technologies have emerged in recent years, including pulse electropolishing, which applies intermittent current to improve surface quality while reducing processing time. Another innovation is the development of environmentally friendly electrolytes that reduce or eliminate hazardous components while maintaining performance standards required for aerospace applications.

Despite technological advancements, electropolishing nickel alloys presents several significant challenges. The heterogeneous microstructure of nickel superalloys, particularly those containing high percentages of chromium, titanium, and aluminum, can lead to preferential dissolution of certain phases, resulting in uneven surface finishes. This selective etching effect is particularly problematic for precipitation-hardened alloys like Inconel 718 and Waspaloy.

Temperature control remains a critical challenge, as fluctuations as small as ±2°C can significantly impact surface quality. Additionally, complex geometries common in aerospace components create issues with current distribution, leading to inconsistent polishing results in recessed areas, internal passages, and sharp edges.

Environmental and safety concerns represent another major challenge. Traditional electrolytes contain highly corrosive acids and generate hazardous waste streams that require specialized handling and disposal procedures. Regulatory pressures are driving the industry toward greener alternatives, but these often struggle to match the performance of conventional formulations for high-specification aerospace applications.

Scale-up challenges persist when transitioning from laboratory to production environments. Maintaining consistent results across large batches of components with varying geometries requires sophisticated process control systems and extensive validation protocols to meet the stringent quality requirements of aerospace standards such as AMS 2700 and ASTM B912.

Recent research has focused on developing computational models to predict electropolishing outcomes based on alloy composition and component geometry, but these models still require significant refinement to achieve reliable predictive capability for complex nickel alloy systems used in critical aerospace hardware.

Conventional electropolishing systems for nickel alloys typically operate at temperatures between 40-70°C with current densities ranging from 10-50 A/dm². The process parameters must be precisely controlled to achieve optimal results, with processing times typically ranging from 5-20 minutes depending on the specific alloy composition and desired surface characteristics.

Advanced electropolishing technologies have emerged in recent years, including pulse electropolishing, which applies intermittent current to improve surface quality while reducing processing time. Another innovation is the development of environmentally friendly electrolytes that reduce or eliminate hazardous components while maintaining performance standards required for aerospace applications.

Despite technological advancements, electropolishing nickel alloys presents several significant challenges. The heterogeneous microstructure of nickel superalloys, particularly those containing high percentages of chromium, titanium, and aluminum, can lead to preferential dissolution of certain phases, resulting in uneven surface finishes. This selective etching effect is particularly problematic for precipitation-hardened alloys like Inconel 718 and Waspaloy.

Temperature control remains a critical challenge, as fluctuations as small as ±2°C can significantly impact surface quality. Additionally, complex geometries common in aerospace components create issues with current distribution, leading to inconsistent polishing results in recessed areas, internal passages, and sharp edges.

Environmental and safety concerns represent another major challenge. Traditional electrolytes contain highly corrosive acids and generate hazardous waste streams that require specialized handling and disposal procedures. Regulatory pressures are driving the industry toward greener alternatives, but these often struggle to match the performance of conventional formulations for high-specification aerospace applications.

Scale-up challenges persist when transitioning from laboratory to production environments. Maintaining consistent results across large batches of components with varying geometries requires sophisticated process control systems and extensive validation protocols to meet the stringent quality requirements of aerospace standards such as AMS 2700 and ASTM B912.

Recent research has focused on developing computational models to predict electropolishing outcomes based on alloy composition and component geometry, but these models still require significant refinement to achieve reliable predictive capability for complex nickel alloy systems used in critical aerospace hardware.

Established Electropolishing Processes for Aerospace-Grade Nickel Alloys

01 Electropolishing processes for nickel alloys

Electropolishing processes specifically designed for nickel alloys involve the use of specialized electrolyte solutions and controlled electrical parameters to achieve optimal surface finishing. These processes remove microscopic surface irregularities and create a smooth, bright surface on nickel alloy components. The technique typically involves making the workpiece anodic in an appropriate electrolyte solution while controlling current density, temperature, and process duration to achieve the desired surface quality.- Electropolishing processes for nickel alloys: Various electropolishing processes have been developed specifically for nickel alloys to improve surface finish and corrosion resistance. These processes typically involve using specialized electrolyte solutions and controlled current densities to selectively remove material from the surface of the alloy. The electropolishing creates a smooth, passive surface layer that enhances the performance and durability of nickel alloy components.

- Electrolyte compositions for nickel alloy electropolishing: Specific electrolyte compositions have been formulated for the effective electropolishing of nickel alloys. These electrolytes typically contain acids such as phosphoric acid, sulfuric acid, or mixtures with organic compounds that facilitate controlled dissolution of the metal surface. The composition of the electrolyte significantly affects the quality of the electropolished surface, with optimized formulations providing superior smoothness and brightness.

- Electropolishing for semiconductor and electronic applications: Electropolishing techniques for nickel alloys are particularly important in semiconductor and electronic applications where ultra-smooth surfaces are required. The process removes microscopic irregularities and contaminants from components such as connectors, leads, and device housings. This results in improved electrical performance, reduced contact resistance, and enhanced reliability of electronic components made from nickel alloys.

- Electropolishing of nickel alloy medical devices: Medical devices manufactured from nickel alloys often undergo electropolishing to improve biocompatibility and performance. The process creates an exceptionally smooth surface that reduces bacterial adhesion, prevents corrosion in biological environments, and enhances fatigue resistance. Electropolished nickel alloy medical implants and surgical instruments exhibit improved functionality and longevity when implanted or used in medical procedures.

- Advanced electropolishing techniques for complex nickel alloy components: Advanced electropolishing techniques have been developed to address the challenges of processing complex-shaped nickel alloy components. These methods include pulse electropolishing, selective area electropolishing, and automated systems with precise control over process parameters. These techniques enable uniform material removal from intricate geometries, internal passages, and hard-to-reach areas, resulting in consistent surface finish across the entire component.

02 Electrolyte compositions for nickel alloy electropolishing

Specific electrolyte compositions are crucial for effective electropolishing of nickel alloys. These formulations typically contain acids such as phosphoric acid, sulfuric acid, or mixtures with organic compounds that facilitate controlled dissolution of the metal surface. The electrolyte composition determines the polishing rate, surface brightness, and overall quality of the finished surface. Optimized electrolyte formulations can enhance the electropolishing efficiency while minimizing unwanted etching or pitting of the nickel alloy surface.Expand Specific Solutions03 Surface preparation and post-treatment methods

Proper surface preparation before electropolishing and post-treatment methods after the process significantly impact the quality of electropolished nickel alloys. Pre-treatment may include degreasing, mechanical polishing, or chemical cleaning to remove contaminants and ensure uniform electropolishing. Post-treatment processes often involve neutralization, passivation, or application of protective coatings to enhance corrosion resistance and maintain the polished surface. These complementary steps are essential for achieving optimal results in industrial applications.Expand Specific Solutions04 Electropolishing for specific nickel alloy applications

Electropolishing techniques tailored for specific nickel alloy applications, such as medical implants, aerospace components, or semiconductor parts, require specialized parameters and processes. These application-specific methods consider the unique properties of different nickel alloys and the performance requirements of the final components. For instance, electropolishing of nickel superalloys for turbine components focuses on enhancing fatigue resistance and high-temperature performance, while medical applications prioritize biocompatibility and corrosion resistance.Expand Specific Solutions05 Advanced electropolishing technologies for nickel alloys

Advanced electropolishing technologies incorporate innovations such as pulse electropolishing, computer-controlled systems, or hybrid processes that combine electropolishing with other surface treatments. These technologies offer improved control over the electropolishing process, enhanced efficiency, and superior surface quality for nickel alloys. Some advanced methods also focus on reducing environmental impact by using more environmentally friendly electrolytes or closed-loop systems that minimize waste generation and resource consumption.Expand Specific Solutions

Leading Manufacturers and Suppliers in Aerospace Electropolishing

The electropolishing of nickel alloys for aerospace hardware market is in a growth phase, driven by increasing demand for high-performance components in aerospace applications. The market size is expanding steadily, with projections indicating significant growth due to rising aircraft production and maintenance requirements. Technologically, the field is moderately mature but continues to evolve, with companies like Safran SA, MTU Aero Engines, and Rolls-Royce Deutschland leading innovation in specialized surface finishing techniques. VDM Metals and Aubert & Duval contribute significantly through advanced nickel alloy development, while Coventya GmbH and Dalic SASU provide cutting-edge electropolishing chemicals and processes. Research institutions like KIST and Dalian University of Technology are advancing fundamental understanding, creating a competitive landscape balanced between established aerospace manufacturers and specialized surface treatment providers.

Safran SA

Technical Solution: Safran has developed an advanced electropolishing technology specifically optimized for nickel-based superalloys used in aerospace propulsion systems. Their process employs a proprietary electrolyte formulation containing glycolic acid derivatives and specialized surfactants that enable superior surface finishing on complex geometries like turbine blades and combustion chambers. The system utilizes variable pulse reverse current technology with frequencies ranging from 5-200Hz and duty cycles optimized for specific alloy compositions. Safran's approach incorporates real-time impedance monitoring to dynamically adjust process parameters based on surface conditions, ensuring consistent material removal rates of 3-8μm across varying geometries. Their integrated manufacturing cell combines pre-electropolishing surface preparation, multi-stage electropolishing, and post-treatment passivation in a semi-automated workflow. The company has also developed specialized tooling and fixturing systems that enable precise masking and selective processing of critical aerospace components, maintaining tight dimensional tolerances while achieving surface roughness values below Ra 0.1μm.

Strengths: Exceptional surface finish quality on complex aerospace components; excellent process consistency across production batches; enhanced fatigue resistance properties; comprehensive quality control integration. Weaknesses: Higher processing costs compared to conventional finishing methods; limited effectiveness on certain cast microstructures; requires specialized waste treatment systems.

MTU Aero Engines AG

Technical Solution: MTU Aero Engines has developed a sophisticated electropolishing technology specifically for nickel-based superalloys used in high-performance aerospace applications. Their process utilizes a proprietary electrolyte system containing modified perchloric acid mixtures with organic stabilizers that enable superior material removal characteristics while maintaining tight dimensional tolerances. The company's approach incorporates advanced cathode design with computer-modeled field distribution to ensure uniform current density across complex component geometries such as turbine blades and combustor components. MTU's system features precision temperature control (±0.5°C) and programmable current waveforms with microsecond-level modulation capabilities to optimize the dissolution of surface asperities while minimizing base material removal. Their integrated process includes specialized pre-treatment protocols for various nickel alloys (including Inconel 718, Waspaloy, and René 80) and post-electropolishing treatments that enhance surface passivation. The technology has been optimized to achieve surface roughness values below Ra 0.15μm while improving fatigue resistance through the elimination of micro-stress concentrations.

Strengths: Exceptional surface quality on complex aerospace components; precise dimensional control (±2μm); excellent reproducibility across production batches; enhanced component service life. Weaknesses: Higher processing costs compared to conventional finishing methods; requires specialized operator expertise; limited effectiveness on certain cast microstructures with carbide precipitates.

Critical Patents and Research in Nickel Alloy Electropolishing

Electrolytic polishing treatment method for nickel-based alloy workpiece

PatentPendingUS20240191388A1

Innovation

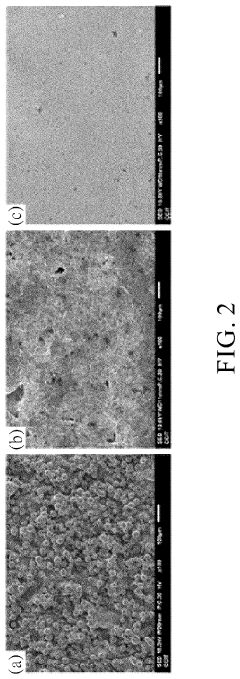

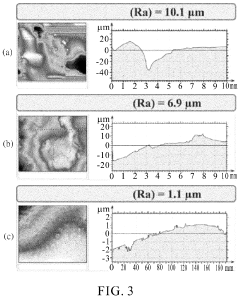

- An electrolytic polishing method for nickel-based alloy workpieces involving sandblasting followed by oxalic acid activation and ultrasonic oscillation, then electrolytic polishing in a solution containing methanol, sulfuric acid, and perchloric acid at constant voltage, which addresses residual stress and processing directionality issues by ensuring uniform surface properties.

Electrolytic polishing treatment method for nickel-based alloy workpiece capable of avoiding residual stress and processing directionality caused by conventional mechanical processing, and making surface properties of the entire workpiece uniform

PatentActiveTW202424282A

Innovation

- An electrolytic polishing method using oxalic acid activation and a specific electrolyte composition (methanol, sulfuric acid, and perchloric acid) at controlled voltage and temperature to uniformly smooth and gloss the surface of nickel-based alloy workpieces.

Environmental and Safety Considerations in Electropolishing Processes

Electropolishing processes for nickel alloys in aerospace applications involve significant environmental and safety considerations that must be addressed to ensure regulatory compliance and worker protection. The chemical solutions used in these processes typically contain acids such as phosphoric, sulfuric, and hydrofluoric acids, which pose serious environmental hazards if not properly managed. These chemicals can contaminate water systems and soil, leading to long-term ecological damage if discharged without appropriate treatment.

Waste management represents a critical component of electropolishing operations. The process generates metal-laden acidic waste streams that require neutralization, heavy metal precipitation, and filtration before disposal. Advanced facilities implement closed-loop systems that recover and recycle both chemicals and metals, significantly reducing environmental impact while improving cost efficiency. Such systems align with increasingly stringent environmental regulations governing industrial waste disposal.

Worker safety demands comprehensive protocols due to the hazardous nature of electropolishing chemicals. Exposure risks include chemical burns, respiratory irritation from acid vapors, and potential long-term health effects from repeated low-level exposure. Facilities must provide appropriate personal protective equipment including chemical-resistant gloves, face shields, respiratory protection, and full-body protection for workers directly handling these solutions.

Engineering controls represent the primary defense against workplace exposure. These include properly designed ventilation systems with local exhaust ventilation at process tanks, automated handling systems to minimize direct worker contact with chemicals, and enclosed processing equipment that contains vapors and splashes. Regular air quality monitoring ensures that exposure levels remain below permissible limits established by occupational safety authorities.

Recent regulatory developments have placed increased emphasis on replacing particularly hazardous substances in electropolishing formulations. The aerospace industry has been transitioning away from chromium-based solutions and exploring alternatives to hydrofluoric acid, which presents extreme hazards. Green electropolishing technologies utilizing more environmentally benign chemicals are emerging, though they must meet the exacting performance standards required for aerospace hardware.

Emergency response planning constitutes an essential element of facility safety programs. This includes installation of emergency showers and eyewash stations, spill containment systems, and detailed procedures for chemical spill management. Regular training ensures workers can respond effectively to incidents, potentially preventing minor situations from escalating into major environmental or safety events.

Waste management represents a critical component of electropolishing operations. The process generates metal-laden acidic waste streams that require neutralization, heavy metal precipitation, and filtration before disposal. Advanced facilities implement closed-loop systems that recover and recycle both chemicals and metals, significantly reducing environmental impact while improving cost efficiency. Such systems align with increasingly stringent environmental regulations governing industrial waste disposal.

Worker safety demands comprehensive protocols due to the hazardous nature of electropolishing chemicals. Exposure risks include chemical burns, respiratory irritation from acid vapors, and potential long-term health effects from repeated low-level exposure. Facilities must provide appropriate personal protective equipment including chemical-resistant gloves, face shields, respiratory protection, and full-body protection for workers directly handling these solutions.

Engineering controls represent the primary defense against workplace exposure. These include properly designed ventilation systems with local exhaust ventilation at process tanks, automated handling systems to minimize direct worker contact with chemicals, and enclosed processing equipment that contains vapors and splashes. Regular air quality monitoring ensures that exposure levels remain below permissible limits established by occupational safety authorities.

Recent regulatory developments have placed increased emphasis on replacing particularly hazardous substances in electropolishing formulations. The aerospace industry has been transitioning away from chromium-based solutions and exploring alternatives to hydrofluoric acid, which presents extreme hazards. Green electropolishing technologies utilizing more environmentally benign chemicals are emerging, though they must meet the exacting performance standards required for aerospace hardware.

Emergency response planning constitutes an essential element of facility safety programs. This includes installation of emergency showers and eyewash stations, spill containment systems, and detailed procedures for chemical spill management. Regular training ensures workers can respond effectively to incidents, potentially preventing minor situations from escalating into major environmental or safety events.

Quality Assurance and Certification Standards for Aerospace Hardware

The aerospace industry demands exceptional quality standards for all components, with electropolished nickel alloys being no exception. Quality assurance for these critical parts is governed by stringent certification frameworks that ensure reliability and safety in extreme operating conditions.

AS9100 certification represents the cornerstone standard specifically developed for aerospace manufacturing, incorporating ISO 9001 requirements with additional aerospace-specific protocols. For electropolishing processes involving nickel alloys, this certification mandates comprehensive documentation of process parameters, material traceability, and verification testing. Manufacturers must demonstrate consistent adherence to specified surface finish requirements, typically measured in Ra (roughness average) values.

NADCAP (National Aerospace and Defense Contractors Accreditation Program) accreditation provides specialized oversight for special processes including electropolishing. This industry-managed approach requires rigorous auditing of equipment calibration, chemical bath composition monitoring, and personnel qualification. For nickel alloy components, NADCAP certification ensures that electropolishing processes maintain tight tolerances while preserving the alloy's critical properties.

Material testing standards such as ASTM B912 specifically address electropolished nickel alloys, establishing protocols for evaluating surface finish quality, corrosion resistance, and dimensional accuracy. These standards require non-destructive testing methods including visual inspection, profilometry, and electrochemical testing to verify compliance with aerospace specifications.

Aerospace primes like Boeing, Airbus, and Lockheed Martin maintain proprietary quality specifications that often exceed industry standards. These specifications typically include detailed requirements for hydrogen embrittlement testing after electropolishing, as nickel alloys can be susceptible to this condition which compromises structural integrity.

Documentation and traceability form critical components of aerospace quality systems. Each electropolished component must maintain a complete processing history, including pre-treatment conditions, bath chemistry parameters, current densities, and post-processing verification. This documentation chain enables root cause analysis should any issues arise during service.

Statistical process control (SPC) methodologies are increasingly mandated for electropolishing operations, requiring continuous monitoring of key process variables and finished part characteristics. For nickel alloy components, these systems track parameters including surface roughness consistency, dimensional stability, and material removal uniformity across production batches.

Environmental compliance standards are also integrated into aerospace quality frameworks, with regulations governing the handling of electropolishing chemicals, waste treatment, and worker safety protocols. These requirements ensure that electropolishing operations minimize environmental impact while maintaining the exceptional quality demanded by aerospace applications.

AS9100 certification represents the cornerstone standard specifically developed for aerospace manufacturing, incorporating ISO 9001 requirements with additional aerospace-specific protocols. For electropolishing processes involving nickel alloys, this certification mandates comprehensive documentation of process parameters, material traceability, and verification testing. Manufacturers must demonstrate consistent adherence to specified surface finish requirements, typically measured in Ra (roughness average) values.

NADCAP (National Aerospace and Defense Contractors Accreditation Program) accreditation provides specialized oversight for special processes including electropolishing. This industry-managed approach requires rigorous auditing of equipment calibration, chemical bath composition monitoring, and personnel qualification. For nickel alloy components, NADCAP certification ensures that electropolishing processes maintain tight tolerances while preserving the alloy's critical properties.

Material testing standards such as ASTM B912 specifically address electropolished nickel alloys, establishing protocols for evaluating surface finish quality, corrosion resistance, and dimensional accuracy. These standards require non-destructive testing methods including visual inspection, profilometry, and electrochemical testing to verify compliance with aerospace specifications.

Aerospace primes like Boeing, Airbus, and Lockheed Martin maintain proprietary quality specifications that often exceed industry standards. These specifications typically include detailed requirements for hydrogen embrittlement testing after electropolishing, as nickel alloys can be susceptible to this condition which compromises structural integrity.

Documentation and traceability form critical components of aerospace quality systems. Each electropolished component must maintain a complete processing history, including pre-treatment conditions, bath chemistry parameters, current densities, and post-processing verification. This documentation chain enables root cause analysis should any issues arise during service.

Statistical process control (SPC) methodologies are increasingly mandated for electropolishing operations, requiring continuous monitoring of key process variables and finished part characteristics. For nickel alloy components, these systems track parameters including surface roughness consistency, dimensional stability, and material removal uniformity across production batches.

Environmental compliance standards are also integrated into aerospace quality frameworks, with regulations governing the handling of electropolishing chemicals, waste treatment, and worker safety protocols. These requirements ensure that electropolishing operations minimize environmental impact while maintaining the exceptional quality demanded by aerospace applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!