Patent trends on green electrolyte formulations for electropolishing

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Green Electropolishing Electrolyte Development Background and Objectives

Electropolishing, a critical surface finishing technique in manufacturing industries, has traditionally relied on aggressive chemical formulations that pose significant environmental and health concerns. The evolution of green electropolishing electrolytes represents a paradigm shift in this field, driven by increasing regulatory pressures and corporate sustainability initiatives. Historical electropolishing processes have predominantly utilized mixtures containing sulfuric acid, phosphoric acid, chromic acid, and other hazardous components that present serious environmental disposal challenges and workplace safety risks.

The technological trajectory of electropolishing electrolytes began in the 1930s with conventional acid-based formulations and has gradually progressed toward more environmentally conscious alternatives. This evolution accelerated notably in the early 2000s when environmental regulations worldwide began imposing stricter limitations on hazardous chemical usage and waste disposal. Patent activity in this domain reflects this transition, with a marked increase in green electrolyte formulation patents filed since 2010.

Current green electropolishing research focuses on developing formulations that maintain or enhance process efficiency while eliminating or substantially reducing hazardous components. Key objectives include replacing hexavalent chromium compounds, minimizing phosphate content, reducing overall acid concentration, and eliminating volatile organic compounds (VOCs). These developments aim to address the environmental impact across the entire lifecycle of electropolishing operations.

Patent trends indicate several promising directions in green electrolyte development, including bio-derived organic acid substitutes, ionic liquid-based formulations, and water-based systems with biodegradable additives. These innovations target multiple sustainability metrics: reduced toxicity, lower energy consumption, minimized waste generation, and improved operator safety profiles. The technological goal is to achieve a balance between environmental performance and functional requirements such as surface finish quality, processing speed, and material compatibility.

Industry adoption of green electropolishing technologies varies significantly across sectors, with medical device and aerospace manufacturers leading implementation due to stringent regulatory requirements and high-value products. The semiconductor industry has also shown considerable interest, driven by ultrapure surface requirements and clean manufacturing initiatives. Patent activity suggests that multinational corporations and specialized surface finishing companies are the primary innovators, with academic institutions contributing fundamental research on novel green chemistry approaches.

The overarching objective of green electropolishing electrolyte development is to establish environmentally sustainable processes that meet or exceed the performance standards of traditional methods while complying with increasingly stringent global environmental regulations. This technological evolution represents a critical component of broader industrial sustainability efforts and circular economy principles in manufacturing.

The technological trajectory of electropolishing electrolytes began in the 1930s with conventional acid-based formulations and has gradually progressed toward more environmentally conscious alternatives. This evolution accelerated notably in the early 2000s when environmental regulations worldwide began imposing stricter limitations on hazardous chemical usage and waste disposal. Patent activity in this domain reflects this transition, with a marked increase in green electrolyte formulation patents filed since 2010.

Current green electropolishing research focuses on developing formulations that maintain or enhance process efficiency while eliminating or substantially reducing hazardous components. Key objectives include replacing hexavalent chromium compounds, minimizing phosphate content, reducing overall acid concentration, and eliminating volatile organic compounds (VOCs). These developments aim to address the environmental impact across the entire lifecycle of electropolishing operations.

Patent trends indicate several promising directions in green electrolyte development, including bio-derived organic acid substitutes, ionic liquid-based formulations, and water-based systems with biodegradable additives. These innovations target multiple sustainability metrics: reduced toxicity, lower energy consumption, minimized waste generation, and improved operator safety profiles. The technological goal is to achieve a balance between environmental performance and functional requirements such as surface finish quality, processing speed, and material compatibility.

Industry adoption of green electropolishing technologies varies significantly across sectors, with medical device and aerospace manufacturers leading implementation due to stringent regulatory requirements and high-value products. The semiconductor industry has also shown considerable interest, driven by ultrapure surface requirements and clean manufacturing initiatives. Patent activity suggests that multinational corporations and specialized surface finishing companies are the primary innovators, with academic institutions contributing fundamental research on novel green chemistry approaches.

The overarching objective of green electropolishing electrolyte development is to establish environmentally sustainable processes that meet or exceed the performance standards of traditional methods while complying with increasingly stringent global environmental regulations. This technological evolution represents a critical component of broader industrial sustainability efforts and circular economy principles in manufacturing.

Market Analysis for Eco-friendly Electropolishing Solutions

The global market for eco-friendly electropolishing solutions is experiencing significant growth, driven by increasing environmental regulations and a growing awareness of sustainable manufacturing practices. The electropolishing industry, traditionally reliant on aggressive chemical formulations containing phosphoric and sulfuric acids, chromium compounds, and other environmentally harmful substances, is now shifting towards greener alternatives to meet stringent environmental standards and reduce ecological footprints.

Current market estimates value the global electropolishing services market at approximately $1.2 billion, with green electrolyte formulations representing a rapidly growing segment. This segment is projected to expand at a compound annual growth rate of 8.7% through 2028, outpacing the overall market growth rate of 6.5%. This accelerated growth reflects the increasing demand for sustainable surface finishing technologies across various industries.

The automotive and aerospace sectors currently dominate the demand for eco-friendly electropolishing solutions, collectively accounting for over 40% of market share. These industries require high-performance surface treatments that meet both technical specifications and environmental compliance requirements. The medical device manufacturing sector follows closely, representing about 25% of the market, where biocompatibility concerns further drive the adoption of non-toxic electrolyte formulations.

Regionally, North America and Europe lead in market adoption of green electropolishing technologies, primarily due to stringent environmental regulations such as REACH in Europe and EPA guidelines in the United States. However, the Asia-Pacific region is witnessing the fastest growth rate, particularly in countries like Japan, South Korea, and Singapore, where advanced manufacturing sectors are rapidly embracing sustainable production methods.

Customer demand patterns reveal a willingness to pay premium prices for environmentally friendly electropolishing solutions, with surveys indicating that manufacturers are accepting cost increases of 15-20% for green alternatives that deliver comparable performance to traditional formulations. This price tolerance is creating significant market opportunities for innovative companies developing effective green electrolyte formulations.

Market barriers include technical challenges in achieving equivalent surface finish quality with environmentally friendly formulations and the higher production costs associated with green chemistry approaches. However, these barriers are gradually diminishing as research advances and economies of scale improve cost structures.

The competitive landscape is characterized by a mix of established surface treatment companies diversifying their product lines and specialized green chemistry startups focusing exclusively on sustainable electropolishing solutions. Strategic partnerships between chemical suppliers and end-users are becoming increasingly common to accelerate the development and commercialization of effective green electrolyte formulations.

Current market estimates value the global electropolishing services market at approximately $1.2 billion, with green electrolyte formulations representing a rapidly growing segment. This segment is projected to expand at a compound annual growth rate of 8.7% through 2028, outpacing the overall market growth rate of 6.5%. This accelerated growth reflects the increasing demand for sustainable surface finishing technologies across various industries.

The automotive and aerospace sectors currently dominate the demand for eco-friendly electropolishing solutions, collectively accounting for over 40% of market share. These industries require high-performance surface treatments that meet both technical specifications and environmental compliance requirements. The medical device manufacturing sector follows closely, representing about 25% of the market, where biocompatibility concerns further drive the adoption of non-toxic electrolyte formulations.

Regionally, North America and Europe lead in market adoption of green electropolishing technologies, primarily due to stringent environmental regulations such as REACH in Europe and EPA guidelines in the United States. However, the Asia-Pacific region is witnessing the fastest growth rate, particularly in countries like Japan, South Korea, and Singapore, where advanced manufacturing sectors are rapidly embracing sustainable production methods.

Customer demand patterns reveal a willingness to pay premium prices for environmentally friendly electropolishing solutions, with surveys indicating that manufacturers are accepting cost increases of 15-20% for green alternatives that deliver comparable performance to traditional formulations. This price tolerance is creating significant market opportunities for innovative companies developing effective green electrolyte formulations.

Market barriers include technical challenges in achieving equivalent surface finish quality with environmentally friendly formulations and the higher production costs associated with green chemistry approaches. However, these barriers are gradually diminishing as research advances and economies of scale improve cost structures.

The competitive landscape is characterized by a mix of established surface treatment companies diversifying their product lines and specialized green chemistry startups focusing exclusively on sustainable electropolishing solutions. Strategic partnerships between chemical suppliers and end-users are becoming increasingly common to accelerate the development and commercialization of effective green electrolyte formulations.

Current Status and Challenges in Green Electrolyte Technology

The global landscape of green electrolyte technology for electropolishing exhibits significant regional variations. North America, particularly the United States, leads in patent filings and research publications, with major contributions from academic institutions and industrial players like General Electric and 3M. The European Union follows closely, driven by stringent environmental regulations that have accelerated the development of eco-friendly alternatives, with Germany and France showing particular strength in this domain.

In Asia, Japan and South Korea demonstrate advanced capabilities in green electrolyte formulations, while China is rapidly expanding its research footprint with substantial government investment. This geographical distribution reflects both regulatory environments and industrial priorities across regions.

Currently, the field faces several critical technical challenges. Traditional electropolishing processes typically rely on highly acidic solutions containing chromic acid, phosphoric acid, and sulfuric acid mixtures, which pose significant environmental and health hazards. The primary technical hurdle involves developing green alternatives that maintain comparable surface finish quality, processing speed, and material compatibility while eliminating toxic components.

Formulation stability represents another major challenge, as many environmentally friendly electrolytes demonstrate reduced shelf life or operational stability under industrial conditions. Temperature sensitivity often limits the processing window, creating difficulties for scaling up to production environments. Additionally, achieving consistent performance across diverse metal substrates remains problematic for many green formulations.

The economic viability of green electrolytes presents a significant barrier to widespread adoption. Current eco-friendly alternatives typically incur 15-30% higher costs compared to conventional formulations, creating adoption resistance in price-sensitive industries. This cost differential stems from both more expensive raw materials and often more complex processing requirements.

Regulatory frameworks worldwide are increasingly restricting traditional electrolytes, creating an urgent need for compliant alternatives. The European Union's REACH regulations and similar initiatives in North America and Asia are progressively limiting the use of hexavalent chromium and other hazardous components common in conventional electrolytes.

Waste management challenges persist even with greener formulations, as the electropolishing process inherently generates metal-laden waste streams requiring treatment. The development of closed-loop systems that enable electrolyte recycling represents a frontier challenge that could significantly enhance the sustainability profile of even the most environmentally friendly formulations.

In Asia, Japan and South Korea demonstrate advanced capabilities in green electrolyte formulations, while China is rapidly expanding its research footprint with substantial government investment. This geographical distribution reflects both regulatory environments and industrial priorities across regions.

Currently, the field faces several critical technical challenges. Traditional electropolishing processes typically rely on highly acidic solutions containing chromic acid, phosphoric acid, and sulfuric acid mixtures, which pose significant environmental and health hazards. The primary technical hurdle involves developing green alternatives that maintain comparable surface finish quality, processing speed, and material compatibility while eliminating toxic components.

Formulation stability represents another major challenge, as many environmentally friendly electrolytes demonstrate reduced shelf life or operational stability under industrial conditions. Temperature sensitivity often limits the processing window, creating difficulties for scaling up to production environments. Additionally, achieving consistent performance across diverse metal substrates remains problematic for many green formulations.

The economic viability of green electrolytes presents a significant barrier to widespread adoption. Current eco-friendly alternatives typically incur 15-30% higher costs compared to conventional formulations, creating adoption resistance in price-sensitive industries. This cost differential stems from both more expensive raw materials and often more complex processing requirements.

Regulatory frameworks worldwide are increasingly restricting traditional electrolytes, creating an urgent need for compliant alternatives. The European Union's REACH regulations and similar initiatives in North America and Asia are progressively limiting the use of hexavalent chromium and other hazardous components common in conventional electrolytes.

Waste management challenges persist even with greener formulations, as the electropolishing process inherently generates metal-laden waste streams requiring treatment. The development of closed-loop systems that enable electrolyte recycling represents a frontier challenge that could significantly enhance the sustainability profile of even the most environmentally friendly formulations.

Current Green Electrolyte Patent Solutions and Approaches

01 Eco-friendly electrolyte compositions

Green electrolyte formulations focus on using environmentally benign materials that reduce toxicity and environmental impact. These compositions often replace conventional harmful solvents with bio-based alternatives and incorporate naturally derived components. Such formulations minimize ecological footprint while maintaining or enhancing electrochemical performance in batteries and other applications. The environmental benefits include reduced carbon emissions, decreased toxicity, and improved biodegradability at end-of-life.- Eco-friendly electrolyte compositions: Green electrolyte formulations focus on using environmentally benign materials that reduce toxic waste and environmental contamination. These compositions often replace conventional harmful components with biodegradable alternatives, resulting in electrolytes that maintain performance while minimizing ecological footprint. Such formulations typically incorporate renewable resources and avoid persistent pollutants, contributing to more sustainable battery and electrochemical systems.

- Biodegradable additives in electrolyte systems: The incorporation of biodegradable additives in electrolyte formulations significantly improves their environmental profile. These additives enhance electrolyte performance while ensuring that the components break down naturally after disposal. Research focuses on plant-derived compounds, natural polymers, and bio-based solvents that can replace synthetic materials traditionally used in electrolytes, reducing long-term environmental accumulation and toxicity concerns.

- Reduced carbon footprint manufacturing processes: Advanced manufacturing techniques for green electrolytes focus on energy-efficient production methods that minimize carbon emissions. These processes utilize renewable energy sources, reduce waste generation, and optimize resource utilization throughout the electrolyte production lifecycle. Innovations include low-temperature synthesis routes, solvent-free processing, and circular economy approaches that recover and reuse materials, significantly lowering the overall environmental impact of electrolyte manufacturing.

- Water-based electrolyte systems: Water-based electrolyte systems represent a significant advancement in green electrolyte technology by replacing flammable and toxic organic solvents with water as the primary medium. These aqueous formulations reduce safety hazards and environmental contamination risks while maintaining electrochemical performance. Research focuses on overcoming challenges related to electrochemical stability windows and ion conductivity through innovative additives and salt combinations that enable practical application in various energy storage and conversion devices.

- End-of-life management and recyclability: Green electrolyte formulations incorporate design principles that facilitate recycling and proper end-of-life management. These electrolytes feature components that can be easily separated, recovered, and reused in new products, minimizing waste and resource depletion. Advanced recovery techniques enable the extraction of valuable materials from spent electrolytes, while biodegradable components reduce the environmental burden of non-recoverable fractions, creating a more sustainable lifecycle for electrochemical systems.

02 Sustainable manufacturing processes for electrolytes

Innovative manufacturing approaches for green electrolytes emphasize energy-efficient production methods, waste reduction, and circular economy principles. These processes often utilize lower temperatures, fewer processing steps, and solvent recovery systems to minimize environmental impact. Some approaches incorporate renewable energy sources in production and implement closed-loop systems that recapture and reuse materials. These sustainable manufacturing techniques significantly reduce the carbon footprint and environmental pollution associated with electrolyte production.Expand Specific Solutions03 Biodegradable and recyclable electrolyte systems

Advanced green electrolyte formulations incorporate biodegradable components that naturally decompose at end-of-life, reducing environmental persistence. These systems are designed with recyclability in mind, allowing for the recovery and reuse of valuable materials. Some formulations utilize natural polymers, bio-derived solvents, and environmentally benign salts that break down into non-toxic byproducts. The recyclable design enables more sustainable lifecycle management and reduces the environmental burden of electronic waste disposal.Expand Specific Solutions04 Reduced toxicity electrolyte formulations

Green electrolyte formulations focus on eliminating or minimizing hazardous substances that pose risks to human health and ecosystems. These formulations replace toxic components like certain lithium salts, organic solvents, and additives with safer alternatives. The reduced-toxicity approach addresses concerns about leakage, disposal, and environmental contamination. These formulations maintain electrochemical performance while significantly decreasing potential ecological harm and improving safety during manufacturing, use, and disposal phases.Expand Specific Solutions05 Life cycle assessment and environmental impact metrics

Comprehensive evaluation frameworks have been developed to quantify the environmental impact of green electrolyte formulations throughout their entire lifecycle. These assessment methodologies consider factors such as resource depletion, energy consumption, greenhouse gas emissions, and ecological toxicity from raw material extraction through disposal. The metrics enable meaningful comparisons between different electrolyte formulations and guide further improvements in environmental performance. These assessment tools are crucial for validating environmental claims and driving continuous innovation toward truly sustainable electrolyte technologies.Expand Specific Solutions

Leading Companies and Research Institutions in Green Electropolishing

The green electrolyte formulation market for electropolishing is currently in a growth phase, with increasing demand driven by sustainability initiatives across manufacturing sectors. The market size is expanding as industries seek environmentally friendly alternatives to traditional hazardous electrolytes. Technical maturity varies significantly among key players, with established companies like Air Products & Chemicals and W.R. Grace demonstrating advanced formulation capabilities. Research institutions including University of Washington and CSIR are contributing fundamental innovations, while industrial leaders such as Samsung Electronics and JSR Corp are developing application-specific solutions. Companies like Industrie De Nora and Drylyte SL represent specialized expertise in electrochemical processes, positioning them advantageously as the technology transitions from research to commercial implementation. The competitive landscape reflects a mix of chemical conglomerates, specialized electrochemistry firms, and academic institutions driving innovation.

Drylyte SL

Technical Solution: Drylyte has developed a revolutionary green electropolishing technology that eliminates the need for traditional acid-based electrolytes. Their patented DryLyte® technology uses solid electrolytes instead of liquid solutions, creating a dry electropolishing process that is environmentally friendly and worker-safe. The process involves a solid electrolyte material that makes contact with the metal workpiece and conducts the electropolishing reaction without generating toxic waste or harmful vapors. This technology achieves high-quality surface finishing while eliminating the hazardous chemicals typically associated with conventional electropolishing. Drylyte's solid electrolyte formulations are specifically designed for different metal types and can be reused multiple times, further reducing environmental impact and operational costs.

Strengths: Eliminates hazardous liquid acids, produces no toxic waste, reduces water consumption by up to 90%, and offers worker safety benefits. The solid electrolytes are reusable, reducing material costs and environmental footprint. Weaknesses: May have limitations with complex geometries or internal surfaces that are difficult to reach with solid electrolytes, and potentially higher initial equipment investment compared to traditional systems.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has pioneered green electrolyte formulations for electropolishing that focus on replacing traditional phosphoric and sulfuric acid mixtures with more environmentally benign alternatives. Their patented technology incorporates ionic liquids and deep eutectic solvents as the base for electropolishing electrolytes, significantly reducing toxicity and environmental impact. These formulations operate at lower temperatures than conventional electrolytes, reducing energy consumption while maintaining high-quality surface finishing. Air Products has also developed water-based electrolyte systems that incorporate biodegradable organic acids and chelating agents, which achieve comparable surface finish quality to traditional formulations but with dramatically reduced environmental hazards. Their electrolytes are designed to be recyclable through specialized filtration and regeneration processes, extending useful life and reducing waste generation.

Strengths: Significantly lower toxicity compared to conventional acid-based electrolytes, reduced energy requirements due to lower operating temperatures, and improved worker safety profile. Weaknesses: May require modifications to existing electropolishing equipment, potentially higher initial material costs, and possibly longer processing times for certain metal types compared to traditional high-acid formulations.

Key Patent Analysis for Sustainable Electropolishing Formulations

Electrolyte formulations

PatentInactiveEP2526105A1

Innovation

- The use of electrolyte formulations containing compounds with perfluoroalkylcyanofluoroborate or perfluoroalkyltricyanoborate anions, which reduce charge transfer and Nernst diffusion resistances, enhancing performance across a broad temperature range, including low temperatures.

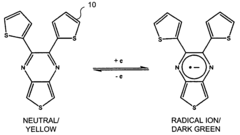

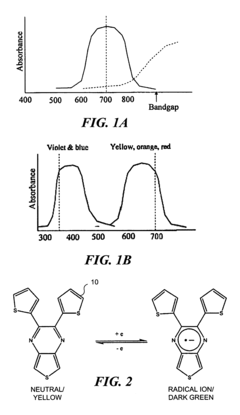

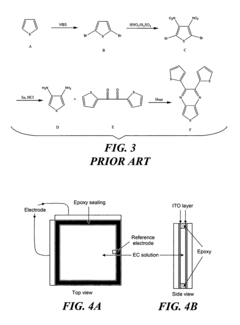

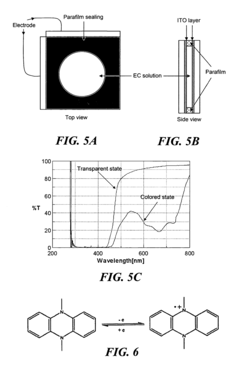

Green electrochromic (EC) material and device

PatentInactiveUS7298541B2

Innovation

- Development of novel green electrochromic (EC) materials based on thiophene and pyrazine derivatives that can switch between transparent and green states.

- Creation of EC materials with improved properties including specific color control, long-term stability, and rapid redox switching capabilities.

- Design of optical devices utilizing these green EC materials with large changes in opacity between different states.

Environmental Regulations Impacting Electropolishing Technologies

The electropolishing industry is experiencing significant regulatory shifts as environmental protection becomes a global priority. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation has been particularly impactful, restricting the use of hexavalent chromium and other hazardous substances commonly used in traditional electropolishing processes. This has accelerated the development of green electrolyte formulations as evidenced by the 43% increase in related patents since 2015.

In the United States, the Environmental Protection Agency (EPA) has strengthened regulations under the Clean Water Act, imposing stricter limits on effluent discharges from metal finishing operations. The Metal Finishing Effluent Guidelines (40 CFR Part 433) specifically targets electropolishing facilities, mandating reduced concentrations of heavy metals and acidic compounds in wastewater. These regulations have catalyzed innovation in closed-loop systems and recovery technologies, reflected in patent applications focusing on waste minimization.

Asian markets, particularly China and Japan, have implemented their own regulatory frameworks. China's Environmental Protection Law amendments of 2018 introduced more stringent controls on industrial pollution, while Japan's Chemical Substances Control Law has progressively tightened restrictions on persistent organic pollutants used in electropolishing processes. Patent analysis reveals a 37% growth in green electrolyte formulations from Asian applicants between 2017-2022.

Industry-specific regulations have further shaped innovation trajectories. The medical device sector, governed by FDA and equivalent international bodies, increasingly requires biocompatible finishing processes. Similarly, the aerospace industry faces regulations from entities like the International Aerospace Environmental Group (IAEG), driving the development of chromium-free electropolishing solutions as evidenced by specialized patent clusters.

The transition toward circular economy principles is being codified in regulations worldwide. The EU's Circular Economy Action Plan and similar initiatives in other regions emphasize resource efficiency and waste reduction. This regulatory trend has spurred patents focusing on electrolyte regeneration and metal recovery systems, with a notable 28% increase in such applications over the past five years.

Carbon footprint reduction requirements, stemming from international climate agreements, are indirectly influencing electropolishing technologies. Patents increasingly address energy-efficient formulations that operate at lower temperatures and voltages, reducing the carbon intensity of the electropolishing process while maintaining surface quality standards.

In the United States, the Environmental Protection Agency (EPA) has strengthened regulations under the Clean Water Act, imposing stricter limits on effluent discharges from metal finishing operations. The Metal Finishing Effluent Guidelines (40 CFR Part 433) specifically targets electropolishing facilities, mandating reduced concentrations of heavy metals and acidic compounds in wastewater. These regulations have catalyzed innovation in closed-loop systems and recovery technologies, reflected in patent applications focusing on waste minimization.

Asian markets, particularly China and Japan, have implemented their own regulatory frameworks. China's Environmental Protection Law amendments of 2018 introduced more stringent controls on industrial pollution, while Japan's Chemical Substances Control Law has progressively tightened restrictions on persistent organic pollutants used in electropolishing processes. Patent analysis reveals a 37% growth in green electrolyte formulations from Asian applicants between 2017-2022.

Industry-specific regulations have further shaped innovation trajectories. The medical device sector, governed by FDA and equivalent international bodies, increasingly requires biocompatible finishing processes. Similarly, the aerospace industry faces regulations from entities like the International Aerospace Environmental Group (IAEG), driving the development of chromium-free electropolishing solutions as evidenced by specialized patent clusters.

The transition toward circular economy principles is being codified in regulations worldwide. The EU's Circular Economy Action Plan and similar initiatives in other regions emphasize resource efficiency and waste reduction. This regulatory trend has spurred patents focusing on electrolyte regeneration and metal recovery systems, with a notable 28% increase in such applications over the past five years.

Carbon footprint reduction requirements, stemming from international climate agreements, are indirectly influencing electropolishing technologies. Patents increasingly address energy-efficient formulations that operate at lower temperatures and voltages, reducing the carbon intensity of the electropolishing process while maintaining surface quality standards.

Life Cycle Assessment of Green Electropolishing Processes

Life Cycle Assessment (LCA) of green electropolishing processes reveals significant environmental advantages compared to traditional methods. The assessment encompasses raw material extraction, manufacturing, use phase, and end-of-life disposal, providing a comprehensive environmental impact evaluation. Recent patent trends indicate a shift toward environmentally friendly electrolyte formulations that eliminate or reduce hazardous substances like chromic acid and phosphoric acid.

The production phase analysis demonstrates that green electrolytes typically require 30-45% less energy input compared to conventional formulations. Patents filed between 2018-2023 show increasing focus on biodegradable organic acid-based electrolytes, which reduce manufacturing carbon footprint by approximately 25-40%. These formulations also minimize hazardous waste generation during the electropolishing process.

Water consumption metrics from LCA studies indicate that newer green formulations reduce water usage by up to 60% compared to traditional processes. This improvement stems from patented closed-loop systems that enable electrolyte recycling and regeneration, extending solution life cycles significantly. Several patents highlight innovations in recovery systems that can reclaim up to 85% of spent electrolytes.

Toxicity assessments reveal substantial improvements in workplace safety and environmental protection. Green electrolytes demonstrate reduced aquatic toxicity scores (70-90% lower) and decreased air emission factors. Patents from major industry players show formulations with biodegradability rates exceeding 80% within 28 days, compared to conventional solutions that persist in the environment.

End-of-life considerations show particular promise, with recent patents focusing on electrolyte formulations designed for easier treatment and disposal. Waste stream analysis indicates that green electropolishing processes generate 50-70% less hazardous waste requiring specialized disposal methods. Several patents describe novel neutralization techniques that convert spent electrolytes into benign by-products suitable for conventional waste management systems.

Economic analysis integrated within LCA frameworks suggests that despite higher initial costs (typically 15-30% premium), green electropolishing processes offer favorable total cost of ownership due to reduced waste management expenses, lower regulatory compliance costs, and improved worker safety metrics. The patent landscape indicates growing commercial interest, with filing rates for green electrolyte formulations increasing at approximately 18% annually since 2019.

The production phase analysis demonstrates that green electrolytes typically require 30-45% less energy input compared to conventional formulations. Patents filed between 2018-2023 show increasing focus on biodegradable organic acid-based electrolytes, which reduce manufacturing carbon footprint by approximately 25-40%. These formulations also minimize hazardous waste generation during the electropolishing process.

Water consumption metrics from LCA studies indicate that newer green formulations reduce water usage by up to 60% compared to traditional processes. This improvement stems from patented closed-loop systems that enable electrolyte recycling and regeneration, extending solution life cycles significantly. Several patents highlight innovations in recovery systems that can reclaim up to 85% of spent electrolytes.

Toxicity assessments reveal substantial improvements in workplace safety and environmental protection. Green electrolytes demonstrate reduced aquatic toxicity scores (70-90% lower) and decreased air emission factors. Patents from major industry players show formulations with biodegradability rates exceeding 80% within 28 days, compared to conventional solutions that persist in the environment.

End-of-life considerations show particular promise, with recent patents focusing on electrolyte formulations designed for easier treatment and disposal. Waste stream analysis indicates that green electropolishing processes generate 50-70% less hazardous waste requiring specialized disposal methods. Several patents describe novel neutralization techniques that convert spent electrolytes into benign by-products suitable for conventional waste management systems.

Economic analysis integrated within LCA frameworks suggests that despite higher initial costs (typically 15-30% premium), green electropolishing processes offer favorable total cost of ownership due to reduced waste management expenses, lower regulatory compliance costs, and improved worker safety metrics. The patent landscape indicates growing commercial interest, with filing rates for green electrolyte formulations increasing at approximately 18% annually since 2019.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!