Research on pulse electropolishing for complex geometries

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pulse Electropolishing Technology Background and Objectives

Pulse electropolishing (PE) represents a significant evolution in surface finishing technology, emerging from traditional electropolishing methods that have been utilized since the early 20th century. While conventional electropolishing applies continuous direct current to remove material from metal surfaces, pulse electropolishing introduces controlled intermittent current patterns, offering superior precision and efficiency, particularly for components with complex geometries.

The development trajectory of pulse electropolishing began in the 1970s with rudimentary applications, gaining momentum in the 1990s as electronics and control systems advanced. The last two decades have witnessed accelerated refinement of this technology, driven by increasing demands from aerospace, medical device manufacturing, and semiconductor industries where surface quality requirements have become increasingly stringent.

Current technological trends in the field focus on optimizing pulse parameters (frequency, duty cycle, amplitude), electrolyte composition innovations, and integration with computational modeling to predict material removal patterns. The convergence of these developments has positioned pulse electropolishing as a critical enabling technology for high-performance components with intricate features that conventional methods struggle to process effectively.

The primary objective of pulse electropolishing research for complex geometries centers on overcoming the fundamental limitations of traditional electropolishing, particularly the "edge effect" where current density concentrates at protruding features, resulting in uneven material removal. By precisely controlling current pulses, researchers aim to achieve uniform material removal across varying surface geometries, including internal channels, undercuts, and micro-features that characterize modern precision components.

Additional technical goals include reducing processing time compared to conventional methods, minimizing environmental impact through electrolyte optimization, enhancing surface quality metrics (roughness values below 0.1 μm Ra), and developing adaptive control systems that can automatically adjust parameters based on real-time feedback from the electropolishing process.

The ultimate technological objective is to establish pulse electropolishing as a standardized, scalable manufacturing process capable of consistently delivering mirror-finish surfaces on complex three-dimensional components across various metal alloys, including difficult-to-polish materials such as titanium alloys, nickel-based superalloys, and specialized stainless steels used in critical applications. This would represent a significant advancement in surface finishing technology with broad implications for multiple high-value manufacturing sectors.

The development trajectory of pulse electropolishing began in the 1970s with rudimentary applications, gaining momentum in the 1990s as electronics and control systems advanced. The last two decades have witnessed accelerated refinement of this technology, driven by increasing demands from aerospace, medical device manufacturing, and semiconductor industries where surface quality requirements have become increasingly stringent.

Current technological trends in the field focus on optimizing pulse parameters (frequency, duty cycle, amplitude), electrolyte composition innovations, and integration with computational modeling to predict material removal patterns. The convergence of these developments has positioned pulse electropolishing as a critical enabling technology for high-performance components with intricate features that conventional methods struggle to process effectively.

The primary objective of pulse electropolishing research for complex geometries centers on overcoming the fundamental limitations of traditional electropolishing, particularly the "edge effect" where current density concentrates at protruding features, resulting in uneven material removal. By precisely controlling current pulses, researchers aim to achieve uniform material removal across varying surface geometries, including internal channels, undercuts, and micro-features that characterize modern precision components.

Additional technical goals include reducing processing time compared to conventional methods, minimizing environmental impact through electrolyte optimization, enhancing surface quality metrics (roughness values below 0.1 μm Ra), and developing adaptive control systems that can automatically adjust parameters based on real-time feedback from the electropolishing process.

The ultimate technological objective is to establish pulse electropolishing as a standardized, scalable manufacturing process capable of consistently delivering mirror-finish surfaces on complex three-dimensional components across various metal alloys, including difficult-to-polish materials such as titanium alloys, nickel-based superalloys, and specialized stainless steels used in critical applications. This would represent a significant advancement in surface finishing technology with broad implications for multiple high-value manufacturing sectors.

Market Demand Analysis for Advanced Surface Finishing

The global market for advanced surface finishing technologies has witnessed significant growth in recent years, driven primarily by increasing demands for high-precision components across multiple industries. The pulse electropolishing market specifically is experiencing robust expansion, with an estimated annual growth rate of 6.8% from 2020 to 2025. This growth is particularly pronounced in sectors requiring complex geometrical components with superior surface quality.

Aerospace and medical device industries represent the largest market segments for advanced electropolishing technologies. In aerospace manufacturing, the demand for complex geometrical components with exceptional surface finish has increased dramatically due to the industry's push toward more efficient and lightweight designs. Similarly, the medical device industry requires implants and surgical instruments with complex geometries that demand flawless surface finishing to ensure biocompatibility and prevent bacterial adhesion.

The automotive sector presents another substantial market opportunity, particularly with the rise of electric vehicles and advanced powertrain systems requiring precision-finished components. Manufacturers are increasingly seeking surface finishing solutions that can effectively process complex internal passages and intricate geometries while maintaining tight dimensional tolerances.

Geographically, North America and Europe currently dominate the market for advanced electropolishing technologies, accounting for approximately 65% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rapid industrialization in countries like China, India, and South Korea, along with increasing investments in high-tech manufacturing capabilities.

Customer requirements are evolving toward more environmentally sustainable processes. Traditional electropolishing methods often involve hazardous chemicals and generate significant waste. Market research indicates that 78% of potential customers express preference for greener alternatives that maintain or exceed current quality standards, creating a significant opportunity for pulse electropolishing technologies that typically use less aggressive electrolytes.

Cost considerations remain paramount in market adoption decisions. While advanced surface finishing technologies command premium pricing, manufacturers increasingly evaluate total cost of ownership, including reduced post-processing requirements, improved part longevity, and decreased rejection rates. Pulse electropolishing for complex geometries offers compelling value propositions in these areas, particularly for high-value components where surface quality directly impacts functionality and reliability.

The market also shows growing demand for automated and integrated solutions that can be incorporated into existing production lines, reducing handling requirements and improving throughput for components with complex geometries.

Aerospace and medical device industries represent the largest market segments for advanced electropolishing technologies. In aerospace manufacturing, the demand for complex geometrical components with exceptional surface finish has increased dramatically due to the industry's push toward more efficient and lightweight designs. Similarly, the medical device industry requires implants and surgical instruments with complex geometries that demand flawless surface finishing to ensure biocompatibility and prevent bacterial adhesion.

The automotive sector presents another substantial market opportunity, particularly with the rise of electric vehicles and advanced powertrain systems requiring precision-finished components. Manufacturers are increasingly seeking surface finishing solutions that can effectively process complex internal passages and intricate geometries while maintaining tight dimensional tolerances.

Geographically, North America and Europe currently dominate the market for advanced electropolishing technologies, accounting for approximately 65% of global demand. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rapid industrialization in countries like China, India, and South Korea, along with increasing investments in high-tech manufacturing capabilities.

Customer requirements are evolving toward more environmentally sustainable processes. Traditional electropolishing methods often involve hazardous chemicals and generate significant waste. Market research indicates that 78% of potential customers express preference for greener alternatives that maintain or exceed current quality standards, creating a significant opportunity for pulse electropolishing technologies that typically use less aggressive electrolytes.

Cost considerations remain paramount in market adoption decisions. While advanced surface finishing technologies command premium pricing, manufacturers increasingly evaluate total cost of ownership, including reduced post-processing requirements, improved part longevity, and decreased rejection rates. Pulse electropolishing for complex geometries offers compelling value propositions in these areas, particularly for high-value components where surface quality directly impacts functionality and reliability.

The market also shows growing demand for automated and integrated solutions that can be incorporated into existing production lines, reducing handling requirements and improving throughput for components with complex geometries.

Current Challenges in Complex Geometry Electropolishing

Despite significant advancements in electropolishing technology, processing components with complex geometries remains one of the most challenging aspects in the field. Traditional electropolishing methods often struggle with achieving uniform material removal across intricate surfaces, resulting in inconsistent surface finishes. The primary challenge stems from the fundamental nature of the electropolishing process itself, where current density distribution naturally concentrates at protruding features and external edges while being significantly reduced in recessed areas, internal corners, and deep cavities.

This non-uniform current distribution creates what industry experts term as the "field effect" problem, leading to preferential polishing of easily accessible surfaces while leaving hard-to-reach areas inadequately processed. For components with varying cross-sections, blind holes, internal channels, or undercuts, this issue becomes particularly pronounced, often requiring specialized tooling or multiple processing steps that significantly increase production costs and time.

Another significant challenge is the difficulty in controlling electrolyte flow dynamics within complex geometrical features. Proper electrolyte circulation is essential for removing dissolution products and maintaining consistent electrochemical conditions at the workpiece surface. In confined spaces or deep recesses, electrolyte stagnation can occur, leading to localized heating, gas bubble entrapment, and inconsistent polishing results.

The development of suitable masking techniques for selective polishing presents additional complications. While masking is often necessary to protect certain features from the electropolishing process, applying and maintaining effective masks on complex three-dimensional geometries requires specialized expertise and can be labor-intensive.

Temperature management across varying surface geometries also poses significant difficulties. Heat dissipation rates differ between thick and thin sections of components, potentially causing uneven polishing rates and surface quality variations. This thermal gradient effect becomes more pronounced as component complexity increases.

Monitoring and quality control present further challenges, as inspection of internal features or complex surfaces often requires specialized equipment and techniques. The inability to directly observe the polishing process in real-time within complex geometries makes process optimization largely empirical and experience-based rather than data-driven.

These challenges collectively highlight the need for innovative approaches in electropolishing technology, particularly for industries such as aerospace, medical device manufacturing, and advanced engineering, where complex geometries are increasingly common and surface quality requirements are becoming more stringent.

This non-uniform current distribution creates what industry experts term as the "field effect" problem, leading to preferential polishing of easily accessible surfaces while leaving hard-to-reach areas inadequately processed. For components with varying cross-sections, blind holes, internal channels, or undercuts, this issue becomes particularly pronounced, often requiring specialized tooling or multiple processing steps that significantly increase production costs and time.

Another significant challenge is the difficulty in controlling electrolyte flow dynamics within complex geometrical features. Proper electrolyte circulation is essential for removing dissolution products and maintaining consistent electrochemical conditions at the workpiece surface. In confined spaces or deep recesses, electrolyte stagnation can occur, leading to localized heating, gas bubble entrapment, and inconsistent polishing results.

The development of suitable masking techniques for selective polishing presents additional complications. While masking is often necessary to protect certain features from the electropolishing process, applying and maintaining effective masks on complex three-dimensional geometries requires specialized expertise and can be labor-intensive.

Temperature management across varying surface geometries also poses significant difficulties. Heat dissipation rates differ between thick and thin sections of components, potentially causing uneven polishing rates and surface quality variations. This thermal gradient effect becomes more pronounced as component complexity increases.

Monitoring and quality control present further challenges, as inspection of internal features or complex surfaces often requires specialized equipment and techniques. The inability to directly observe the polishing process in real-time within complex geometries makes process optimization largely empirical and experience-based rather than data-driven.

These challenges collectively highlight the need for innovative approaches in electropolishing technology, particularly for industries such as aerospace, medical device manufacturing, and advanced engineering, where complex geometries are increasingly common and surface quality requirements are becoming more stringent.

Current Pulse Electropolishing Methodologies

01 Pulse parameters optimization for surface quality

Optimizing pulse parameters such as frequency, duration, and amplitude is crucial for achieving high-quality surface finishes in electropolishing. Controlled pulse sequences can reduce surface roughness and improve uniformity by allowing for precise material removal. The proper timing between pulses enables electrolyte refreshment at the workpiece surface, preventing localized overheating and ensuring consistent ion transport, which results in superior surface quality with reduced pitting and improved microstructure.- Pulse parameters optimization for surface quality: Optimizing pulse parameters such as frequency, duration, and amplitude is crucial for achieving high-quality surface finishes in electropolishing. By controlling these parameters, the process can selectively remove microscopic peaks from the metal surface while preserving the overall structure. This controlled dissolution results in reduced surface roughness and improved surface quality, with enhanced smoothness and brightness. The proper tuning of pulse parameters also helps in minimizing heat generation and preventing unwanted etching.

- Electrolyte composition for enhanced surface finish: The composition of the electrolyte solution plays a significant role in pulse electropolishing surface quality. Specialized electrolyte formulations containing acids, salts, and additives can improve the dissolution process and enhance the final surface finish. These formulations help in controlling the diffusion layer thickness, improving current distribution, and preventing passivation. Additives in the electrolyte can also promote brightness, reduce pitting, and enhance the overall smoothness of the polished surface.

- Temperature control during pulse electropolishing: Maintaining optimal temperature during the pulse electropolishing process is essential for achieving consistent surface quality. Temperature affects the viscosity of the electrolyte, the rate of chemical reactions, and the formation of the diffusion layer. Proper temperature control systems help prevent overheating, which can lead to uneven polishing, pitting, or burning of the workpiece. Cooling mechanisms and temperature monitoring equipment ensure stable processing conditions and reproducible surface quality results.

- Workpiece preparation and post-processing techniques: The quality of pulse electropolished surfaces is significantly influenced by proper workpiece preparation and post-processing techniques. Pre-treatment steps such as degreasing, mechanical pre-polishing, and chemical cleaning remove contaminants and create a uniform starting surface. Post-processing treatments including rinsing, passivation, and drying help preserve the achieved surface quality and enhance corrosion resistance. These complementary processes ensure optimal results from pulse electropolishing and extend the longevity of the polished surface.

- Advanced monitoring and control systems: Advanced monitoring and control systems are essential for maintaining consistent surface quality in pulse electropolishing processes. Real-time monitoring of electrical parameters, electrolyte conditions, and surface characteristics allows for dynamic adjustments during processing. Feedback control systems can automatically modify pulse parameters based on measured results, ensuring uniform polishing across complex geometries. Computer-aided process control and data analysis help optimize processing conditions and achieve reproducible high-quality surface finishes across multiple production batches.

02 Electrolyte composition and management

The composition and management of electrolytes significantly impact surface quality in pulse electropolishing. Specialized electrolyte formulations containing specific acids, salts, and additives can enhance material removal rates while maintaining surface integrity. Temperature control and circulation of the electrolyte solution prevent concentration gradients and ensure consistent polishing across the workpiece. Regular filtration and replenishment of electrolyte components maintain optimal chemical balance for superior surface finish.Expand Specific Solutions03 Workpiece material-specific electropolishing techniques

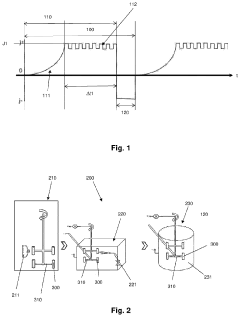

Different materials require tailored pulse electropolishing approaches to achieve optimal surface quality. For instance, stainless steel, titanium alloys, and aluminum each demand specific pulse waveforms, electrolyte compositions, and process parameters. Material-specific techniques account for differences in electrochemical behavior, oxide layer formation, and dissolution mechanisms. Customized approaches can address unique challenges such as preventing preferential grain boundary etching in certain alloys or managing passive layer formation in others.Expand Specific Solutions04 Advanced pulse waveform designs

Innovative pulse waveform designs beyond simple rectangular pulses can significantly enhance surface quality in electropolishing. Bipolar pulses, modulated waveforms, and multi-level pulse sequences offer superior control over the electrochemical dissolution process. These advanced waveforms can selectively target surface irregularities while preserving the base material, resulting in lower roughness values and higher surface reflectivity. Customized waveform patterns can also reduce processing time while achieving superior finish quality.Expand Specific Solutions05 Process monitoring and feedback control systems

Real-time monitoring and feedback control systems significantly improve surface quality consistency in pulse electropolishing. Advanced sensors measure parameters such as current density, electrolyte conductivity, and surface characteristics during processing. Integrated control systems adjust pulse parameters dynamically based on these measurements to maintain optimal polishing conditions throughout the process. This adaptive approach compensates for variations in workpiece geometry, material properties, and electrolyte conditions, ensuring uniform high-quality surface finish across complex components.Expand Specific Solutions

Key Industry Players in Pulse Electropolishing

Pulse electropolishing for complex geometries is currently in a growth phase, with increasing adoption across aerospace, medical, and semiconductor industries. The market is expanding at approximately 8-10% annually, driven by demand for high-precision surface finishing solutions. Technologically, the field shows varying maturity levels, with companies like Siemens, Rolls-Royce, and Applied Materials leading commercial applications, while academic institutions such as Dalian University of Technology and Huazhong University of Science & Technology focus on fundamental research. Fraunhofer-Gesellschaft and RENA Technologies have established specialized expertise in process optimization for intricate geometries, while newer entrants like Inkron are developing niche applications. The competitive landscape features both established industrial players and specialized technology providers working to overcome challenges in uniform treatment of complex surfaces.

Rena Technologies Austria GmbH

Technical Solution: Rena Technologies has developed advanced pulse electropolishing systems specifically designed for complex geometries. Their technology utilizes precisely controlled current pulses with optimized waveforms to achieve superior surface finishing on intricate parts. The system employs proprietary electrolyte formulations that enhance mass transport in recessed areas and tight corners, overcoming traditional limitations of DC electropolishing. Their approach incorporates real-time monitoring with feedback control systems that adjust pulse parameters based on surface conditions and geometry variations[1]. For medical implants and aerospace components with complex internal channels, Rena has implemented multi-electrode configurations that ensure uniform current distribution throughout the workpiece. The company has also pioneered temperature-controlled pulse electropolishing that maintains consistent electrolyte properties during the process, resulting in more predictable material removal rates across varying geometries[3].

Strengths: Superior finishing quality on complex internal geometries; precise control over material removal rates; ability to process multiple materials with the same system through parameter adjustment. Weaknesses: Higher initial equipment investment compared to conventional methods; requires specialized electrolyte formulations that need regular maintenance; process optimization can be time-consuming for new part geometries.

Electro Scientific Industries, Inc.

Technical Solution: Electro Scientific Industries (ESI) has developed a comprehensive pulse electropolishing solution for complex geometries that combines advanced power supply technology with sophisticated process control. Their system utilizes high-frequency bipolar pulse patterns that alternate between anodic dissolution and cathodic cleaning phases, effectively preventing passivation in difficult-to-reach areas. ESI's technology incorporates multi-channel power delivery systems that can independently control current distribution to different regions of complex parts, ensuring uniform material removal across varying cross-sections and depths[2]. The company has also implemented machine learning algorithms that analyze part geometry and automatically optimize pulse parameters for specific features. For aerospace components with cooling channels and medical devices with intricate surface textures, ESI has demonstrated the ability to achieve Ra values below 0.1μm while maintaining tight dimensional tolerances. Their electrolyte circulation system incorporates advanced filtration and temperature control to maintain consistent processing conditions throughout extended production runs[4].

Strengths: Exceptional surface finish quality on components with varying cross-sections; automated parameter optimization reduces setup time; integrated quality control systems ensure process consistency. Weaknesses: Complex system requires specialized operator training; higher operating costs due to proprietary electrolyte formulations; limited effectiveness on certain exotic alloys without extensive process development.

Core Technical Innovations in Complex Geometry Processing

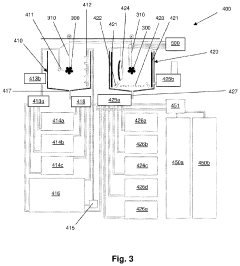

Method for electrochemically processing material

PatentInactiveEP1146984A1

Innovation

- The method employs pulsating or alternating electrical voltage to control the charge reversal of the electrochemical double layer, allowing for precise spatial resolution by selectively charging specific areas of the workpiece, ensuring that only the desired regions undergo electrochemical reactions, while maintaining a defined distance between the tool and workpiece to prevent unwanted reactions.

Electropolishing method and system therefor

PatentActiveUS20190345628A1

Innovation

- The method employs anodic pulses with a steady increase in current intensity over time, accompanied by micropulses, allowing for controlled material removal and surface smoothing by selectively managing the polishing film's formation and degradation, and adjusting pulse frequency and shape to address inhomogeneous surfaces.

Material Compatibility and Process Parameters

Pulse electropolishing (PEP) demonstrates varying effectiveness across different material types, necessitating careful parameter optimization for each specific application. Stainless steel alloys, particularly 316L and 304 grades, exhibit excellent compatibility with PEP processes, achieving surface roughness reductions of up to 90% under optimized conditions. Nickel-based superalloys such as Inconel 718 and titanium alloys (Ti-6Al-4V) also respond favorably, though requiring modified electrolyte compositions to prevent selective etching of alloying elements.

The electrolyte composition represents a critical process parameter, with phosphoric-sulfuric acid mixtures proving most versatile for complex geometries. Recent research indicates that adding organic additives like glycerol (3-5% by volume) significantly improves polishing uniformity in recessed areas. Temperature control between 40-60°C has been identified as optimal for most applications, with higher temperatures accelerating material removal but potentially compromising surface quality in intricate features.

Pulse parameters fundamentally determine process outcomes in complex geometry applications. Current density typically ranges from 5-50 A/dm², with lower values preferred for intricate features to prevent preferential dissolution at edges and corners. The pulse on-time to off-time ratio (duty cycle) critically influences polishing uniformity, with research demonstrating that shorter on-times (1-10 ms) combined with longer off-times (10-50 ms) significantly improve results in deep recesses and internal channels.

Agitation methods must be carefully selected based on geometry complexity. Ultrasonic agitation (20-40 kHz) has proven particularly effective for components with internal features, enhancing electrolyte exchange in otherwise inaccessible areas. For parts with varying cross-sections, programmable pulse sequences that adjust current density based on local geometry have demonstrated up to 40% improvement in uniformity compared to fixed parameter approaches.

The interrelationship between parameters necessitates a systems approach to optimization. Recent studies utilizing Design of Experiments (DOE) methodologies have established that pulse frequency and electrolyte viscosity exhibit particularly strong interaction effects in complex geometries. Higher frequencies (500-2000 Hz) combined with lower viscosity electrolytes show superior performance in narrow channels, while lower frequencies (50-200 Hz) with higher viscosity solutions better address surface features with significant variation in curvature.

The electrolyte composition represents a critical process parameter, with phosphoric-sulfuric acid mixtures proving most versatile for complex geometries. Recent research indicates that adding organic additives like glycerol (3-5% by volume) significantly improves polishing uniformity in recessed areas. Temperature control between 40-60°C has been identified as optimal for most applications, with higher temperatures accelerating material removal but potentially compromising surface quality in intricate features.

Pulse parameters fundamentally determine process outcomes in complex geometry applications. Current density typically ranges from 5-50 A/dm², with lower values preferred for intricate features to prevent preferential dissolution at edges and corners. The pulse on-time to off-time ratio (duty cycle) critically influences polishing uniformity, with research demonstrating that shorter on-times (1-10 ms) combined with longer off-times (10-50 ms) significantly improve results in deep recesses and internal channels.

Agitation methods must be carefully selected based on geometry complexity. Ultrasonic agitation (20-40 kHz) has proven particularly effective for components with internal features, enhancing electrolyte exchange in otherwise inaccessible areas. For parts with varying cross-sections, programmable pulse sequences that adjust current density based on local geometry have demonstrated up to 40% improvement in uniformity compared to fixed parameter approaches.

The interrelationship between parameters necessitates a systems approach to optimization. Recent studies utilizing Design of Experiments (DOE) methodologies have established that pulse frequency and electrolyte viscosity exhibit particularly strong interaction effects in complex geometries. Higher frequencies (500-2000 Hz) combined with lower viscosity electrolytes show superior performance in narrow channels, while lower frequencies (50-200 Hz) with higher viscosity solutions better address surface features with significant variation in curvature.

Environmental Impact and Sustainability Considerations

Pulse electropolishing processes for complex geometries present significant environmental and sustainability implications that warrant careful consideration. Traditional electropolishing methods often utilize highly concentrated acids and other hazardous chemicals that pose substantial environmental risks through improper disposal and workplace exposure. In contrast, pulse electropolishing techniques offer opportunities for reduced environmental impact through optimized electrolyte formulations and decreased chemical consumption.

The adoption of pulse parameters enables more efficient material removal with lower overall energy consumption compared to conventional DC electropolishing. Research indicates that properly configured pulse waveforms can reduce energy requirements by 15-30% while maintaining or improving surface quality outcomes. This energy efficiency translates directly to reduced carbon footprint when implemented at industrial scales, particularly important for high-volume manufacturing operations in aerospace and medical device industries.

Waste management represents another critical environmental consideration. Pulse electropolishing generates spent electrolytes containing dissolved metals that require proper treatment before disposal. Advanced recovery systems can extract valuable metals like nickel, chromium, and titanium from these waste streams, creating potential for closed-loop material cycles. Several studies demonstrate recovery rates exceeding 85% for certain metal species, significantly reducing environmental burden while recovering economically valuable materials.

Water consumption patterns in pulse electropolishing also demonstrate sustainability advantages. The precise control afforded by pulsed current allows for more efficient rinsing protocols and reduced water usage in post-processing steps. Implementations in production environments have documented water savings of 20-40% compared to conventional methods, contributing to resource conservation efforts particularly valuable in water-stressed regions.

Worker safety considerations intersect with environmental impact through reduced exposure to hazardous chemicals. Pulse electropolishing often permits the use of less aggressive electrolyte formulations while achieving comparable surface finishes, thereby decreasing workplace hazards and associated environmental risks from accidental releases or routine handling procedures.

Regulatory compliance frameworks increasingly emphasize sustainable manufacturing practices, with particular attention to metal finishing operations. Pulse electropolishing technologies align with evolving environmental standards such as the European Union's Restriction of Hazardous Substances (RoHS) directive and similar global initiatives. Companies implementing these advanced processes gain competitive advantages through regulatory preparedness while demonstrating environmental stewardship commitments to increasingly conscious consumer markets.

The adoption of pulse parameters enables more efficient material removal with lower overall energy consumption compared to conventional DC electropolishing. Research indicates that properly configured pulse waveforms can reduce energy requirements by 15-30% while maintaining or improving surface quality outcomes. This energy efficiency translates directly to reduced carbon footprint when implemented at industrial scales, particularly important for high-volume manufacturing operations in aerospace and medical device industries.

Waste management represents another critical environmental consideration. Pulse electropolishing generates spent electrolytes containing dissolved metals that require proper treatment before disposal. Advanced recovery systems can extract valuable metals like nickel, chromium, and titanium from these waste streams, creating potential for closed-loop material cycles. Several studies demonstrate recovery rates exceeding 85% for certain metal species, significantly reducing environmental burden while recovering economically valuable materials.

Water consumption patterns in pulse electropolishing also demonstrate sustainability advantages. The precise control afforded by pulsed current allows for more efficient rinsing protocols and reduced water usage in post-processing steps. Implementations in production environments have documented water savings of 20-40% compared to conventional methods, contributing to resource conservation efforts particularly valuable in water-stressed regions.

Worker safety considerations intersect with environmental impact through reduced exposure to hazardous chemicals. Pulse electropolishing often permits the use of less aggressive electrolyte formulations while achieving comparable surface finishes, thereby decreasing workplace hazards and associated environmental risks from accidental releases or routine handling procedures.

Regulatory compliance frameworks increasingly emphasize sustainable manufacturing practices, with particular attention to metal finishing operations. Pulse electropolishing technologies align with evolving environmental standards such as the European Union's Restriction of Hazardous Substances (RoHS) directive and similar global initiatives. Companies implementing these advanced processes gain competitive advantages through regulatory preparedness while demonstrating environmental stewardship commitments to increasingly conscious consumer markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!