What role does temperature play in electropolishing efficiency

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electropolishing Temperature Dynamics and Objectives

Electropolishing, a critical surface finishing technique in manufacturing, has evolved significantly since its inception in the early 20th century. The process fundamentally relies on electrochemical principles where metal ions are selectively removed from a workpiece surface in an electrolytic bath. Temperature has emerged as one of the most influential parameters affecting the efficiency and quality of this process.

Historical development of electropolishing technology shows a progressive understanding of temperature dynamics. Initial applications in the 1930s operated at ambient temperatures with limited control mechanisms, resulting in inconsistent surface finishes. By the 1950s, researchers had established that temperature regulation could dramatically improve process outcomes, leading to the development of temperature-controlled systems in industrial applications.

The relationship between temperature and electropolishing efficiency follows complex electrochemical principles. Higher temperatures generally increase ionic mobility and reaction kinetics, enhancing the dissolution rate of metal ions. However, this relationship is non-linear and material-specific, with optimal temperature ranges varying significantly across different metal substrates and electrolyte compositions.

Current technological trends indicate a move toward precision temperature control systems that can maintain stability within ±0.5°C throughout the process duration. This precision has become increasingly important as industries demand higher quality standards for critical applications in medical devices, aerospace components, and semiconductor manufacturing.

The primary technical objective in electropolishing temperature management is to establish optimal temperature profiles for specific material-electrolyte combinations. This includes determining not only the ideal operating temperature but also the heating and cooling rates that maximize surface quality while minimizing processing time. Secondary objectives include developing adaptive temperature control systems that can respond to real-time process variables.

Challenges in temperature management include electrolyte degradation at elevated temperatures, heat distribution uniformity in large processing tanks, and energy efficiency considerations. The heat generated during the electrochemical reaction itself creates additional complexity, requiring sophisticated modeling and control systems to maintain stable conditions.

Recent research has focused on understanding the microscopic mechanisms by which temperature affects the formation and behavior of the viscous layer at the metal-electrolyte interface. This fundamental research aims to develop predictive models that can optimize temperature parameters for novel materials and complex geometries, potentially revolutionizing electropolishing efficiency across multiple industries.

Historical development of electropolishing technology shows a progressive understanding of temperature dynamics. Initial applications in the 1930s operated at ambient temperatures with limited control mechanisms, resulting in inconsistent surface finishes. By the 1950s, researchers had established that temperature regulation could dramatically improve process outcomes, leading to the development of temperature-controlled systems in industrial applications.

The relationship between temperature and electropolishing efficiency follows complex electrochemical principles. Higher temperatures generally increase ionic mobility and reaction kinetics, enhancing the dissolution rate of metal ions. However, this relationship is non-linear and material-specific, with optimal temperature ranges varying significantly across different metal substrates and electrolyte compositions.

Current technological trends indicate a move toward precision temperature control systems that can maintain stability within ±0.5°C throughout the process duration. This precision has become increasingly important as industries demand higher quality standards for critical applications in medical devices, aerospace components, and semiconductor manufacturing.

The primary technical objective in electropolishing temperature management is to establish optimal temperature profiles for specific material-electrolyte combinations. This includes determining not only the ideal operating temperature but also the heating and cooling rates that maximize surface quality while minimizing processing time. Secondary objectives include developing adaptive temperature control systems that can respond to real-time process variables.

Challenges in temperature management include electrolyte degradation at elevated temperatures, heat distribution uniformity in large processing tanks, and energy efficiency considerations. The heat generated during the electrochemical reaction itself creates additional complexity, requiring sophisticated modeling and control systems to maintain stable conditions.

Recent research has focused on understanding the microscopic mechanisms by which temperature affects the formation and behavior of the viscous layer at the metal-electrolyte interface. This fundamental research aims to develop predictive models that can optimize temperature parameters for novel materials and complex geometries, potentially revolutionizing electropolishing efficiency across multiple industries.

Market Analysis of Temperature-Controlled Electropolishing Systems

The global market for temperature-controlled electropolishing systems is experiencing significant growth, driven by increasing demand for precision-finished metal components across various industries. Currently valued at approximately $2.3 billion, this specialized segment of the surface treatment market is projected to grow at a compound annual growth rate of 6.8% through 2028, according to recent industry analyses.

The aerospace and medical device manufacturing sectors represent the largest market segments, collectively accounting for over 45% of the total market share. These industries require exceptionally high-quality surface finishes with strict compliance to regulatory standards, making precise temperature control during electropolishing processes essential. The semiconductor industry follows closely behind, contributing about 18% of market demand, with requirements for ultra-clean and precisely finished components increasing as chip architectures become more complex.

Regionally, North America and Europe dominate the market with a combined share of 58%, attributed to their established manufacturing bases in aerospace, medical devices, and automotive industries. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.5% annually, driven by rapid industrialization in China and India, alongside the expanding semiconductor manufacturing sector in Taiwan, South Korea, and Singapore.

A notable market trend is the increasing adoption of fully automated temperature-controlled electropolishing systems that offer real-time monitoring and adjustment capabilities. These systems command premium pricing, typically 30-40% higher than conventional systems, but deliver superior consistency and reduced rejection rates, providing compelling return on investment for high-value component manufacturers.

Customer segmentation reveals distinct market needs: large-scale manufacturers prioritize throughput and consistency, while specialty fabricators focus on versatility and precision for diverse small-batch applications. This has led to market differentiation between high-volume industrial systems (62% of market) and specialized precision systems (38% of market).

The competitive landscape features established players like Able Electropolishing, Best Technology, and Technic Inc. controlling approximately 45% of the global market. However, emerging companies offering innovative temperature control technologies are gaining traction, particularly those integrating IoT capabilities for predictive maintenance and process optimization.

Market barriers include high initial investment costs and technical expertise requirements, which limit adoption among smaller manufacturers. Nevertheless, the growing emphasis on quality surface finishing across industries continues to drive market expansion for temperature-controlled electropolishing systems.

The aerospace and medical device manufacturing sectors represent the largest market segments, collectively accounting for over 45% of the total market share. These industries require exceptionally high-quality surface finishes with strict compliance to regulatory standards, making precise temperature control during electropolishing processes essential. The semiconductor industry follows closely behind, contributing about 18% of market demand, with requirements for ultra-clean and precisely finished components increasing as chip architectures become more complex.

Regionally, North America and Europe dominate the market with a combined share of 58%, attributed to their established manufacturing bases in aerospace, medical devices, and automotive industries. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.5% annually, driven by rapid industrialization in China and India, alongside the expanding semiconductor manufacturing sector in Taiwan, South Korea, and Singapore.

A notable market trend is the increasing adoption of fully automated temperature-controlled electropolishing systems that offer real-time monitoring and adjustment capabilities. These systems command premium pricing, typically 30-40% higher than conventional systems, but deliver superior consistency and reduced rejection rates, providing compelling return on investment for high-value component manufacturers.

Customer segmentation reveals distinct market needs: large-scale manufacturers prioritize throughput and consistency, while specialty fabricators focus on versatility and precision for diverse small-batch applications. This has led to market differentiation between high-volume industrial systems (62% of market) and specialized precision systems (38% of market).

The competitive landscape features established players like Able Electropolishing, Best Technology, and Technic Inc. controlling approximately 45% of the global market. However, emerging companies offering innovative temperature control technologies are gaining traction, particularly those integrating IoT capabilities for predictive maintenance and process optimization.

Market barriers include high initial investment costs and technical expertise requirements, which limit adoption among smaller manufacturers. Nevertheless, the growing emphasis on quality surface finishing across industries continues to drive market expansion for temperature-controlled electropolishing systems.

Current Temperature Challenges in Electropolishing Processes

Temperature control represents one of the most significant challenges in modern electropolishing processes, directly impacting efficiency, quality, and reproducibility. Current industrial applications struggle with temperature fluctuations that occur during the electropolishing process, primarily due to the exothermic nature of the reactions involved. As current passes through the electrolyte, Joule heating generates substantial thermal energy, creating temperature gradients within the bath that can vary by as much as 15-20°C between different regions.

These temperature variations lead to inconsistent material removal rates across workpiece surfaces, resulting in non-uniform finishes that fail to meet increasingly stringent industry specifications. For precision components in medical devices and aerospace applications, where surface roughness tolerances may be specified to within nanometers, such inconsistencies are particularly problematic.

Conventional temperature control systems typically employ external cooling jackets or heat exchangers, but these solutions often cannot respond quickly enough to localized temperature spikes. The thermal inertia of large electrolyte baths presents a significant challenge, as rapid temperature adjustments become increasingly difficult with larger bath volumes. This limitation is especially pronounced in high-throughput manufacturing environments where continuous processing is required.

Another critical challenge involves temperature-dependent viscosity changes in the electrolyte. As temperature increases, electrolyte viscosity generally decreases, altering the diffusion rates of metal ions away from the workpiece surface. This phenomenon creates a complex feedback loop where temperature affects viscosity, which affects current distribution, which in turn generates more heat in specific regions.

The industry also faces difficulties in accurate temperature measurement during active electropolishing. Traditional thermocouples may interfere with electric field distribution, while non-contact infrared methods struggle with the reflective nature of electrolyte surfaces. This measurement uncertainty compounds control problems, as systems cannot correct what they cannot accurately detect.

Energy efficiency concerns further complicate temperature management strategies. Cooling systems represent a significant portion of the energy consumption in electropolishing operations, with some facilities reporting that temperature control accounts for up to 30% of the total process energy requirements. As sustainability becomes increasingly important, developing more energy-efficient temperature management solutions has become a priority.

Recent research indicates that temperature fluctuations also impact the formation and behavior of the viscous layer at the anode surface, which is crucial for preferential dissolution of microscopic peaks. When temperature is not optimally controlled, this layer's properties become unpredictable, compromising the fundamental mechanism by which electropolishing achieves surface smoothing.

These temperature variations lead to inconsistent material removal rates across workpiece surfaces, resulting in non-uniform finishes that fail to meet increasingly stringent industry specifications. For precision components in medical devices and aerospace applications, where surface roughness tolerances may be specified to within nanometers, such inconsistencies are particularly problematic.

Conventional temperature control systems typically employ external cooling jackets or heat exchangers, but these solutions often cannot respond quickly enough to localized temperature spikes. The thermal inertia of large electrolyte baths presents a significant challenge, as rapid temperature adjustments become increasingly difficult with larger bath volumes. This limitation is especially pronounced in high-throughput manufacturing environments where continuous processing is required.

Another critical challenge involves temperature-dependent viscosity changes in the electrolyte. As temperature increases, electrolyte viscosity generally decreases, altering the diffusion rates of metal ions away from the workpiece surface. This phenomenon creates a complex feedback loop where temperature affects viscosity, which affects current distribution, which in turn generates more heat in specific regions.

The industry also faces difficulties in accurate temperature measurement during active electropolishing. Traditional thermocouples may interfere with electric field distribution, while non-contact infrared methods struggle with the reflective nature of electrolyte surfaces. This measurement uncertainty compounds control problems, as systems cannot correct what they cannot accurately detect.

Energy efficiency concerns further complicate temperature management strategies. Cooling systems represent a significant portion of the energy consumption in electropolishing operations, with some facilities reporting that temperature control accounts for up to 30% of the total process energy requirements. As sustainability becomes increasingly important, developing more energy-efficient temperature management solutions has become a priority.

Recent research indicates that temperature fluctuations also impact the formation and behavior of the viscous layer at the anode surface, which is crucial for preferential dissolution of microscopic peaks. When temperature is not optimally controlled, this layer's properties become unpredictable, compromising the fundamental mechanism by which electropolishing achieves surface smoothing.

Contemporary Temperature Management Solutions in Electropolishing

01 Electrolyte composition optimization for electropolishing efficiency

The composition of the electrolyte solution significantly impacts electropolishing efficiency. Various additives, acid concentrations, and chemical components can be optimized to enhance the removal rate of material, improve surface finish quality, and reduce processing time. Properly formulated electrolytes can selectively dissolve microscopic peaks on metal surfaces while leaving valleys intact, resulting in a smoother surface with improved reflectivity and corrosion resistance.- Electrolyte composition optimization: The composition of the electrolyte solution significantly impacts electropolishing efficiency. Various formulations including specific acids (phosphoric, sulfuric, or mixed acids), organic additives, and surfactants can enhance the dissolution rate of metal surfaces. Optimized electrolyte compositions can improve surface finish quality, reduce processing time, and allow for more uniform material removal across complex geometries.

- Pulse and modulated current techniques: Advanced current delivery methods such as pulsed current, periodic reverse current, and modulated waveforms can significantly improve electropolishing efficiency. These techniques provide better control over the polishing process by allowing recovery periods that prevent electrolyte depletion near the workpiece surface, reducing heat generation, and enabling more uniform material removal, particularly in recessed areas and complex geometries.

- Temperature and agitation control: Maintaining optimal temperature ranges and implementing effective electrolyte agitation methods are crucial for electropolishing efficiency. Controlled heating of the electrolyte solution accelerates the polishing reaction, while proper agitation techniques (mechanical stirring, ultrasonic agitation, or electrolyte circulation) ensure fresh electrolyte reaches all surfaces and prevents localized overheating. These parameters help achieve consistent results and prevent defects in the finished surface.

- Electrode design and positioning: The configuration of electrodes, including their geometry, material composition, and positioning relative to the workpiece, significantly affects electropolishing efficiency. Optimized electrode designs ensure uniform current distribution across the workpiece surface, particularly for complex shapes. Adjustable electrode systems and specialized cathode configurations can target specific areas requiring more intensive polishing, reducing overall process time while improving finish quality.

- Process automation and monitoring: Implementation of automated control systems and real-time monitoring technologies enhances electropolishing efficiency. Advanced systems incorporate feedback mechanisms that adjust process parameters based on continuous measurements of current density, temperature, and solution chemistry. Computer-controlled processes ensure consistency across batches, optimize energy consumption, and reduce operator intervention, resulting in higher throughput and more predictable surface quality outcomes.

02 Pulse and modulated current techniques for enhanced electropolishing

Applying pulsed or modulated electric current during electropolishing can significantly improve process efficiency. These techniques allow for better control of the diffusion layer, reduce heat generation, and enable more uniform material removal. By alternating between different current densities or including rest periods, the process can achieve superior surface finish with reduced processing time and energy consumption compared to conventional direct current methods.Expand Specific Solutions03 Temperature control systems for optimized electropolishing

Maintaining optimal temperature during electropolishing significantly affects process efficiency. Temperature control systems can regulate the electrolyte temperature to enhance dissolution rates, improve surface finish quality, and ensure process consistency. Proper thermal management prevents overheating that could lead to uneven polishing, gas evolution issues, or degradation of the electrolyte solution, while also optimizing energy consumption during the electropolishing process.Expand Specific Solutions04 Agitation and flow dynamics in electropolishing systems

Effective agitation and controlled flow dynamics of the electrolyte solution play crucial roles in electropolishing efficiency. Proper movement of the electrolyte removes reaction products from the workpiece surface, prevents gas bubble accumulation, and ensures fresh electrolyte contact with the surface being polished. Various methods including mechanical stirring, ultrasonic agitation, or pumped circulation systems can be implemented to improve mass transfer, resulting in more uniform material removal and superior surface finish.Expand Specific Solutions05 Advanced electrode designs and configurations

Innovative electrode designs and configurations can significantly enhance electropolishing efficiency. Specialized cathode geometries, adjustable electrode spacing, and multi-electrode setups enable more uniform current distribution across complex workpiece surfaces. These advanced designs help overcome challenges in polishing irregular shapes, internal cavities, or high-aspect-ratio features, resulting in more consistent material removal rates and improved surface quality while reducing processing time and energy consumption.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Electropolishing

Electropolishing efficiency is significantly influenced by temperature, with the market currently in a growth phase as industries seek improved surface finishing solutions. The global electropolishing market is expanding, driven by demands in semiconductor, medical, and aerospace sectors. Technology maturity varies, with established players like Lam Research and Faraday Technology demonstrating advanced capabilities in temperature control systems. Emerging innovations come from research institutions like Zhejiang University of Technology and companies such as Steros GPA Innovative, which is developing AI-enhanced electropolishing solutions. Temperature optimization remains a critical factor in achieving superior surface quality, reduced processing times, and enhanced material properties, making it a focal point for competitive differentiation in this evolving field.

Lam Research Corp.

Technical Solution: Lam Research has pioneered temperature-controlled electropolishing systems specifically designed for semiconductor manufacturing applications. Their approach integrates advanced thermal management into electropolishing chambers, utilizing precision temperature control within ±0.5°C to optimize material removal rates and surface finish quality. The company's research has established that temperature directly influences the formation and dissolution of the viscous layer critical to the electropolishing mechanism. Their systems incorporate multi-zone temperature control that compensates for thermal gradients across large wafers, ensuring uniform polishing results. Lam's proprietary electrolyte formulations are specifically engineered to have optimal viscosity and conductivity characteristics within narrow temperature bands, typically between 30-60°C depending on the specific metal being processed. Their data shows that maintaining precise temperature control can improve process repeatability by up to 40% and reduce defect rates by 25-30% compared to conventional systems with less sophisticated temperature management[2][4].

Strengths: Exceptional temperature uniformity across large substrates enables consistent electropolishing results for critical semiconductor components. Advanced thermal management systems provide superior process control and repeatability. Weaknesses: Systems are highly specialized for semiconductor applications and may be less adaptable to general industrial electropolishing needs. The sophisticated temperature control technology significantly increases equipment costs.

Faraday Technology, Inc.

Technical Solution: Faraday Technology has developed advanced pulse/pulse reverse electropolishing technologies that precisely control temperature parameters to optimize surface finishing. Their FARADAYIC® Process utilizes modulated electric fields to manage temperature distribution at the electrode-electrolyte interface, allowing for controlled dissolution rates and improved surface quality. The company's research demonstrates that temperature significantly impacts electropolishing efficiency by affecting electrolyte viscosity, conductivity, and reaction kinetics. Their proprietary systems incorporate real-time temperature monitoring and feedback control mechanisms that adjust current density parameters based on temperature fluctuations, maintaining optimal processing conditions. Faraday has documented that temperature increases of 10-15°C can increase polishing rates by 25-40% while maintaining surface quality, but requires precise control to prevent overheating that could lead to pitting or uneven material removal[1][3].

Strengths: Precise temperature control through pulse modulation technology allows for optimized material removal rates while maintaining surface quality. Their systems can adapt to different materials and geometries with customized temperature profiles. Weaknesses: The sophisticated temperature control systems require more complex equipment and expertise to operate compared to conventional DC electropolishing methods. Higher implementation costs may limit adoption in price-sensitive applications.

Critical Patents and Research on Temperature Effects

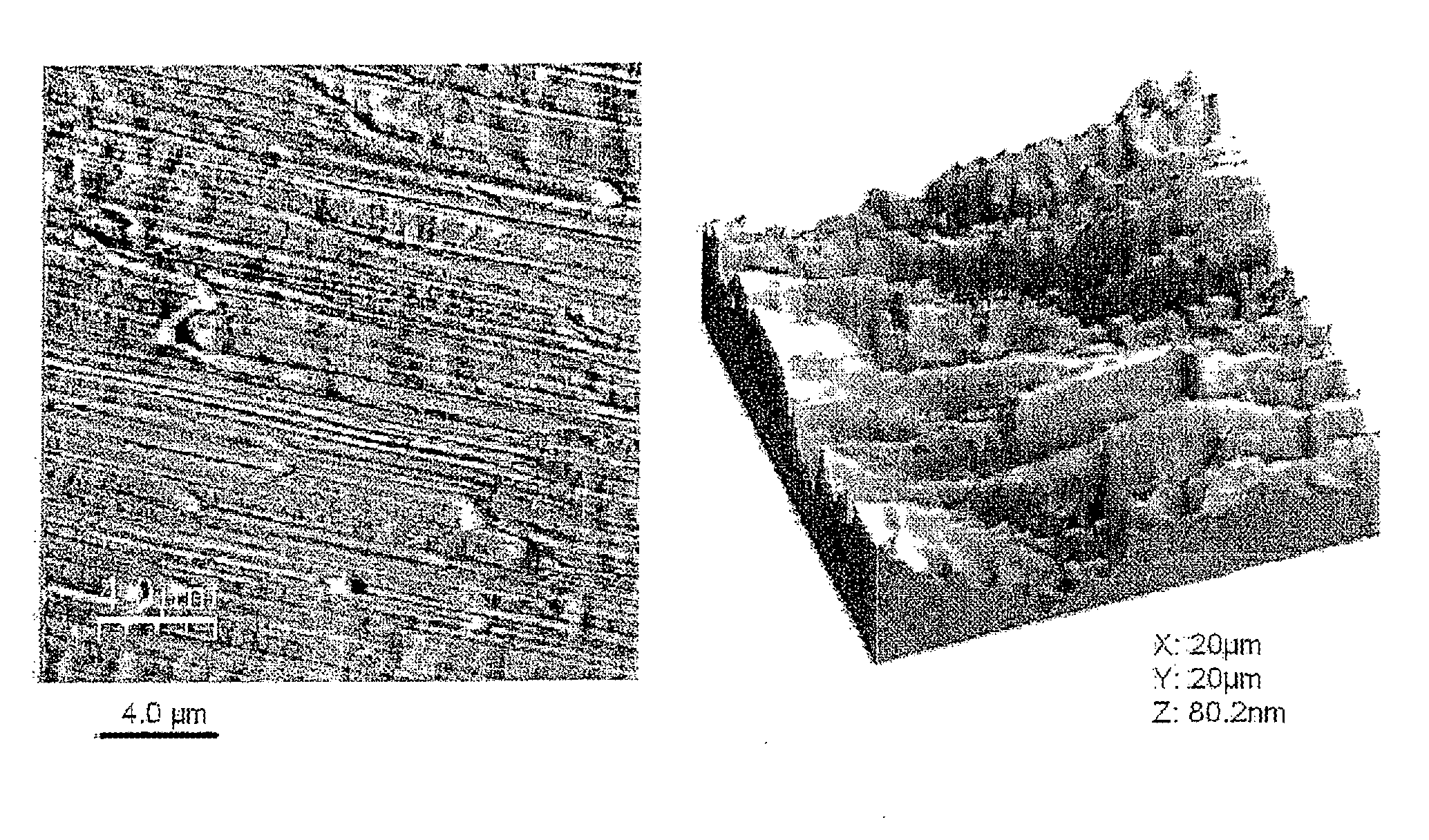

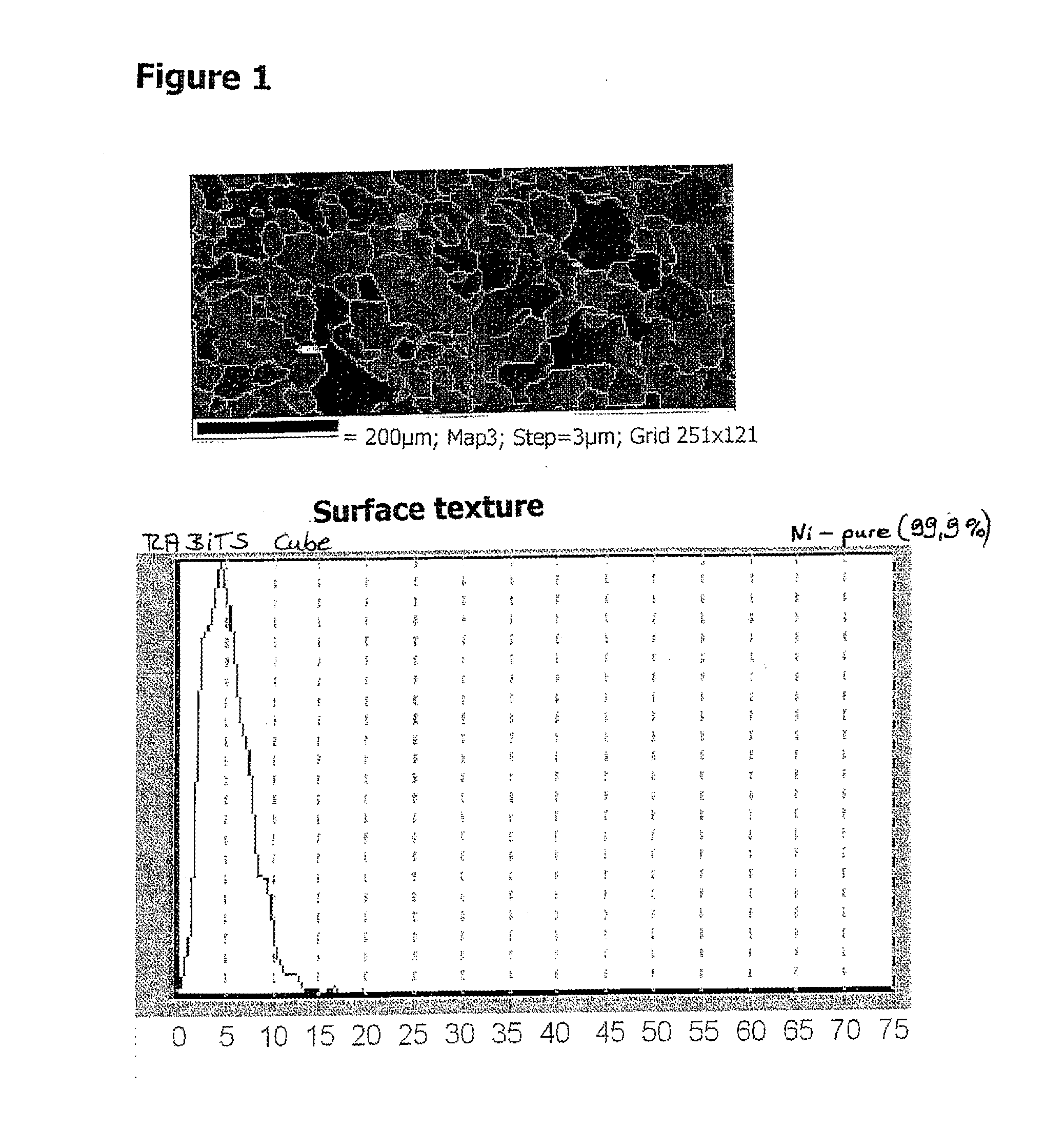

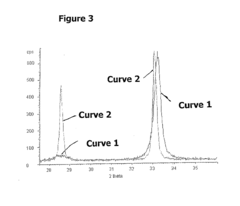

Method for producing metal substrates for HTS coating arrangements

PatentInactiveUS20110237441A1

Innovation

- A method involving a polishing treatment followed by a post-annealing treatment of the metal substrate before epitaxial deposition of HTS coating layers, which restructures the surface to enable high texture transfer and improved crystallization, allowing for the growth of high-quality HTS layers with increased texturing and reduced surface roughness.

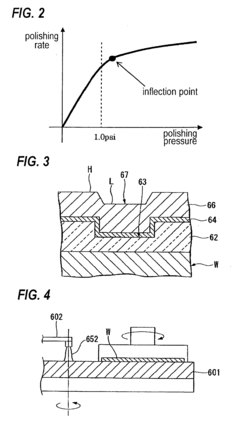

Electrochemical mechanical polishing method and electrochemical mechanical polishing apparatus

PatentInactiveUS20090078583A1

Innovation

- An electrochemical mechanical polishing method is employed, where a voltage is applied between electrodes to a conductive film on a substrate, with an electrolytic liquid and a polishing pad, gradually exposing the barrier film from the center to the periphery while controlling the polishing rate and pressure to prevent excessive conductive film removal and ensure uniformity.

Energy Efficiency Considerations in Electropolishing Processes

Temperature plays a critical role in determining the energy efficiency of electropolishing processes. The operational temperature directly impacts the electrochemical reaction rates, solution conductivity, and overall process performance. At higher temperatures, the mobility of ions increases significantly, reducing the electrical resistance of the electrolyte solution. This enhanced conductivity allows the same electropolishing results to be achieved with lower voltage requirements, potentially reducing energy consumption by 15-25% compared to processes conducted at room temperature.

However, temperature optimization presents a complex energy balance equation. While higher temperatures improve reaction efficiency, they also necessitate additional energy input for heating and maintaining the electrolyte bath. Modern electropolishing facilities implement sophisticated heat recovery systems that capture and recycle thermal energy from the process, achieving energy recovery rates of up to 60-70% in well-designed systems.

The relationship between temperature and energy consumption follows a non-linear pattern. Research indicates an optimal temperature range exists for each specific metal-electrolyte combination, typically between 40-70°C depending on the material being processed. Operating outside this optimal range can lead to diminishing returns in terms of energy efficiency, with excessive temperatures potentially causing unnecessary energy waste through evaporation and increased ventilation requirements.

Temperature stability throughout the process represents another crucial factor affecting energy efficiency. Fluctuations in temperature can lead to inconsistent electropolishing results, necessitating rework and consequently increasing overall energy consumption. Advanced temperature control systems utilizing PID controllers maintain temperature variations within ±1°C, significantly improving process consistency and energy utilization.

Recent innovations in electropolishing technology have focused on pulsed current techniques that can achieve comparable surface finishes at lower average temperatures, reducing the thermal energy requirements by up to 30%. These approaches modify the electrical parameters rather than relying solely on elevated temperatures to achieve efficient material removal, representing a paradigm shift in energy-efficient electropolishing methodology.

The economic implications of temperature optimization are substantial, with energy costs typically accounting for 15-25% of operational expenses in electropolishing facilities. Comprehensive energy audits of industrial electropolishing operations reveal that temperature management improvements can yield return on investment periods as short as 8-14 months through reduced electricity consumption and improved process throughput.

However, temperature optimization presents a complex energy balance equation. While higher temperatures improve reaction efficiency, they also necessitate additional energy input for heating and maintaining the electrolyte bath. Modern electropolishing facilities implement sophisticated heat recovery systems that capture and recycle thermal energy from the process, achieving energy recovery rates of up to 60-70% in well-designed systems.

The relationship between temperature and energy consumption follows a non-linear pattern. Research indicates an optimal temperature range exists for each specific metal-electrolyte combination, typically between 40-70°C depending on the material being processed. Operating outside this optimal range can lead to diminishing returns in terms of energy efficiency, with excessive temperatures potentially causing unnecessary energy waste through evaporation and increased ventilation requirements.

Temperature stability throughout the process represents another crucial factor affecting energy efficiency. Fluctuations in temperature can lead to inconsistent electropolishing results, necessitating rework and consequently increasing overall energy consumption. Advanced temperature control systems utilizing PID controllers maintain temperature variations within ±1°C, significantly improving process consistency and energy utilization.

Recent innovations in electropolishing technology have focused on pulsed current techniques that can achieve comparable surface finishes at lower average temperatures, reducing the thermal energy requirements by up to 30%. These approaches modify the electrical parameters rather than relying solely on elevated temperatures to achieve efficient material removal, representing a paradigm shift in energy-efficient electropolishing methodology.

The economic implications of temperature optimization are substantial, with energy costs typically accounting for 15-25% of operational expenses in electropolishing facilities. Comprehensive energy audits of industrial electropolishing operations reveal that temperature management improvements can yield return on investment periods as short as 8-14 months through reduced electricity consumption and improved process throughput.

Material-Specific Temperature Requirements and Adaptations

Different materials exhibit unique electropolishing behavior at varying temperature ranges, necessitating specific temperature adaptations for optimal results. For stainless steel alloys, the ideal electropolishing temperature typically ranges between 40-70°C, with 304 and 316L grades showing peak efficiency around 55°C. At this temperature, the viscosity of the electrolyte solution achieves optimal balance, allowing for controlled dissolution of surface irregularities while maintaining the protective passive layer integrity.

Aluminum alloys demonstrate markedly different temperature requirements, generally performing best at lower temperatures between 20-35°C. Higher temperatures can lead to excessive material removal and pitting in aluminum due to its higher reactivity compared to stainless steel. The temperature sensitivity increases with higher silicon content in aluminum alloys, requiring more precise temperature control during the electropolishing process.

Copper and its alloys present another distinct temperature profile, with optimal electropolishing occurring between 30-50°C. The temperature dependency correlates strongly with the specific electrolyte composition, particularly when phosphoric acid-based solutions are employed. Research indicates that brass components show a narrower optimal temperature window (35-45°C) compared to pure copper.

Temperature gradients within the electropolishing bath represent a significant challenge across all material types. Uneven temperature distribution can lead to inconsistent surface finish quality, especially in components with complex geometries. Implementation of circulation systems with temperature monitoring at multiple points has proven effective in maintaining uniform temperature profiles, with studies showing up to 40% improvement in surface finish consistency.

Titanium and its alloys require particularly stringent temperature control, typically between 25-40°C, due to their propensity for oxide formation. Temperature fluctuations beyond ±3°C can significantly impact the electropolishing efficiency and surface quality. Recent developments in temperature-controlled pulse electropolishing techniques have shown promising results for titanium medical implants, achieving Ra values below 0.1μm consistently.

Emerging research indicates that temperature modulation during the electropolishing process—rather than maintaining constant temperature—may offer advantages for certain specialized alloys. This approach involves programmed temperature variations throughout the electropolishing cycle, potentially addressing the different temperature requirements of various phases present in complex alloy systems such as nickel-titanium shape memory alloys and high-entropy alloys used in advanced engineering applications.

Aluminum alloys demonstrate markedly different temperature requirements, generally performing best at lower temperatures between 20-35°C. Higher temperatures can lead to excessive material removal and pitting in aluminum due to its higher reactivity compared to stainless steel. The temperature sensitivity increases with higher silicon content in aluminum alloys, requiring more precise temperature control during the electropolishing process.

Copper and its alloys present another distinct temperature profile, with optimal electropolishing occurring between 30-50°C. The temperature dependency correlates strongly with the specific electrolyte composition, particularly when phosphoric acid-based solutions are employed. Research indicates that brass components show a narrower optimal temperature window (35-45°C) compared to pure copper.

Temperature gradients within the electropolishing bath represent a significant challenge across all material types. Uneven temperature distribution can lead to inconsistent surface finish quality, especially in components with complex geometries. Implementation of circulation systems with temperature monitoring at multiple points has proven effective in maintaining uniform temperature profiles, with studies showing up to 40% improvement in surface finish consistency.

Titanium and its alloys require particularly stringent temperature control, typically between 25-40°C, due to their propensity for oxide formation. Temperature fluctuations beyond ±3°C can significantly impact the electropolishing efficiency and surface quality. Recent developments in temperature-controlled pulse electropolishing techniques have shown promising results for titanium medical implants, achieving Ra values below 0.1μm consistently.

Emerging research indicates that temperature modulation during the electropolishing process—rather than maintaining constant temperature—may offer advantages for certain specialized alloys. This approach involves programmed temperature variations throughout the electropolishing cycle, potentially addressing the different temperature requirements of various phases present in complex alloy systems such as nickel-titanium shape memory alloys and high-entropy alloys used in advanced engineering applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!