Electropolishing of aluminum alloys for high-reflectivity surfaces

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aluminum Electropolishing Technology Evolution and Objectives

Electropolishing of aluminum alloys has evolved significantly since its inception in the early 20th century. Initially developed as a surface treatment method for metallographic examination, this electrochemical process has transformed into a sophisticated technique for achieving high-reflectivity surfaces. The fundamental principle involves the controlled dissolution of metal surface irregularities in an electrolytic bath, resulting in a smoother, more reflective finish than mechanical polishing alone can achieve.

The evolution of aluminum electropolishing technology has been marked by several key advancements. In the 1940s and 1950s, basic phosphoric and sulfuric acid electrolytes were established as standard solutions. The 1970s saw significant improvements in process control and bath chemistry, enabling more consistent results across varying aluminum alloy compositions. By the 1990s, computer-controlled systems began to revolutionize the precision and repeatability of the process, allowing for automated parameter adjustments based on real-time monitoring.

Recent technological developments have focused on environmentally friendly electrolyte formulations to replace traditional hazardous chemicals. Innovations in pulse current techniques and temperature control systems have further enhanced surface quality and process efficiency. Additionally, the integration of spectrophotometric analysis during processing has enabled real-time quality control of reflectivity parameters.

The primary technical objective in aluminum electropolishing for high-reflectivity surfaces is to achieve specular reflectance exceeding 95% across the visible and near-infrared spectrum. This requires nanometer-scale surface smoothness with Ra values below 5nm. Secondary objectives include developing processes compatible with complex geometries and maintaining reflectivity stability under various environmental conditions, particularly important for aerospace and optical applications.

Current research aims to overcome several persistent challenges, including the differential dissolution rates of various phases in complex aluminum alloys, which can lead to non-uniform reflectivity. Another objective is to reduce processing time while maintaining quality, as traditional electropolishing can be time-intensive for achieving ultra-high reflectivity surfaces.

The technology trajectory indicates a growing convergence with advanced materials science, where tailored electropolishing protocols are being developed for specific aluminum alloy compositions. Future objectives include the development of intelligent electropolishing systems that can adapt to material variations in real-time and the creation of hybrid processes combining electropolishing with other surface treatments to achieve previously unattainable optical properties.

The evolution of aluminum electropolishing technology has been marked by several key advancements. In the 1940s and 1950s, basic phosphoric and sulfuric acid electrolytes were established as standard solutions. The 1970s saw significant improvements in process control and bath chemistry, enabling more consistent results across varying aluminum alloy compositions. By the 1990s, computer-controlled systems began to revolutionize the precision and repeatability of the process, allowing for automated parameter adjustments based on real-time monitoring.

Recent technological developments have focused on environmentally friendly electrolyte formulations to replace traditional hazardous chemicals. Innovations in pulse current techniques and temperature control systems have further enhanced surface quality and process efficiency. Additionally, the integration of spectrophotometric analysis during processing has enabled real-time quality control of reflectivity parameters.

The primary technical objective in aluminum electropolishing for high-reflectivity surfaces is to achieve specular reflectance exceeding 95% across the visible and near-infrared spectrum. This requires nanometer-scale surface smoothness with Ra values below 5nm. Secondary objectives include developing processes compatible with complex geometries and maintaining reflectivity stability under various environmental conditions, particularly important for aerospace and optical applications.

Current research aims to overcome several persistent challenges, including the differential dissolution rates of various phases in complex aluminum alloys, which can lead to non-uniform reflectivity. Another objective is to reduce processing time while maintaining quality, as traditional electropolishing can be time-intensive for achieving ultra-high reflectivity surfaces.

The technology trajectory indicates a growing convergence with advanced materials science, where tailored electropolishing protocols are being developed for specific aluminum alloy compositions. Future objectives include the development of intelligent electropolishing systems that can adapt to material variations in real-time and the creation of hybrid processes combining electropolishing with other surface treatments to achieve previously unattainable optical properties.

Market Analysis for High-Reflectivity Aluminum Applications

The global market for high-reflectivity aluminum applications has experienced significant growth in recent years, driven by increasing demand across multiple industries. The aerospace sector represents one of the largest markets, where high-reflectivity aluminum surfaces are essential for thermal management in satellites, spacecraft, and aircraft components. According to industry reports, the aerospace aluminum market reached $6.7 billion in 2022 and is projected to grow at a CAGR of 4.2% through 2030.

The optical industry constitutes another major market segment, utilizing high-reflectivity aluminum in mirrors, reflectors, and precision optical instruments. This sector values aluminum's ability to reflect across the entire visible spectrum and into the infrared and ultraviolet ranges. The global optical components market utilizing reflective aluminum surfaces was valued at approximately $3.5 billion in 2022, with specialized high-reflectivity applications accounting for roughly 18% of this figure.

Solar energy applications represent the fastest-growing market segment, with high-reflectivity aluminum surfaces being increasingly deployed in concentrated solar power systems and photovoltaic installations. The reflectivity properties directly correlate with energy generation efficiency, making electropolished aluminum alloys particularly valuable. Market analysis indicates this segment is growing at 7.8% annually, outpacing most other application areas.

Consumer electronics manufacturers have also begun incorporating high-reflectivity aluminum components in premium products, particularly for aesthetic purposes and thermal management. This trend is especially prominent in high-end smartphones, tablets, and laptops, where electropolished aluminum surfaces provide both functional benefits and premium visual appeal.

Automotive applications are expanding beyond traditional decorative uses, with high-reflectivity aluminum now being utilized in advanced lighting systems, heads-up displays, and autonomous vehicle sensor arrays. The automotive aluminum market specifically for high-reflectivity applications reached $1.2 billion in 2022 and is expected to double by 2028.

Regional analysis reveals that North America and Europe currently dominate the high-reflectivity aluminum market in terms of technology development and premium applications, while Asia-Pacific leads in production volume and is rapidly advancing in technical capabilities. China, in particular, has made significant investments in electropolishing technology, aiming to capture higher-value segments of the market.

Market forecasts suggest that demand for high-reflectivity aluminum surfaces will continue to grow at 5.3% annually through 2030, with the most substantial growth occurring in renewable energy applications and advanced electronics. Price sensitivity varies significantly by application, with aerospace and optical industries willing to pay premium prices for superior reflectivity performance.

The optical industry constitutes another major market segment, utilizing high-reflectivity aluminum in mirrors, reflectors, and precision optical instruments. This sector values aluminum's ability to reflect across the entire visible spectrum and into the infrared and ultraviolet ranges. The global optical components market utilizing reflective aluminum surfaces was valued at approximately $3.5 billion in 2022, with specialized high-reflectivity applications accounting for roughly 18% of this figure.

Solar energy applications represent the fastest-growing market segment, with high-reflectivity aluminum surfaces being increasingly deployed in concentrated solar power systems and photovoltaic installations. The reflectivity properties directly correlate with energy generation efficiency, making electropolished aluminum alloys particularly valuable. Market analysis indicates this segment is growing at 7.8% annually, outpacing most other application areas.

Consumer electronics manufacturers have also begun incorporating high-reflectivity aluminum components in premium products, particularly for aesthetic purposes and thermal management. This trend is especially prominent in high-end smartphones, tablets, and laptops, where electropolished aluminum surfaces provide both functional benefits and premium visual appeal.

Automotive applications are expanding beyond traditional decorative uses, with high-reflectivity aluminum now being utilized in advanced lighting systems, heads-up displays, and autonomous vehicle sensor arrays. The automotive aluminum market specifically for high-reflectivity applications reached $1.2 billion in 2022 and is expected to double by 2028.

Regional analysis reveals that North America and Europe currently dominate the high-reflectivity aluminum market in terms of technology development and premium applications, while Asia-Pacific leads in production volume and is rapidly advancing in technical capabilities. China, in particular, has made significant investments in electropolishing technology, aiming to capture higher-value segments of the market.

Market forecasts suggest that demand for high-reflectivity aluminum surfaces will continue to grow at 5.3% annually through 2030, with the most substantial growth occurring in renewable energy applications and advanced electronics. Price sensitivity varies significantly by application, with aerospace and optical industries willing to pay premium prices for superior reflectivity performance.

Current Challenges in Aluminum Alloy Electropolishing

Despite significant advancements in electropolishing techniques for aluminum alloys, several persistent challenges continue to impede the achievement of consistently high-reflectivity surfaces. The primary obstacle remains the heterogeneous microstructure of aluminum alloys, particularly those containing copper, silicon, or magnesium. These alloying elements create intermetallic compounds that respond differently to electropolishing processes, resulting in non-uniform material removal and surface irregularities that diminish reflectivity.

The formation of oxide films during electropolishing presents another significant challenge. Aluminum's high reactivity with oxygen leads to rapid formation of passive oxide layers that can interfere with the electropolishing process. These films often exhibit varying thicknesses across the surface, creating optical inconsistencies that reduce reflective properties. Current electrolyte formulations struggle to maintain consistent dissolution rates across these oxide barriers.

Temperature control during electropolishing emerges as a critical factor affecting surface quality. Even minor temperature fluctuations in the electrolyte bath can dramatically alter reaction kinetics, leading to uneven material removal. This is particularly problematic for large components where maintaining uniform temperature distribution becomes increasingly difficult, resulting in reflectivity variations across the surface.

Hydrogen evolution during electropolishing constitutes another major challenge. The cathodic reaction produces hydrogen bubbles that can adhere to the workpiece surface, creating localized masking effects. These areas receive reduced current density, leading to unpolished regions and pitting that significantly compromise reflective properties. Current bubble management techniques remain inadequate for high-precision applications.

The environmental and health concerns associated with traditional phosphoric-sulfuric acid electrolytes represent both technical and regulatory challenges. These electrolytes, while effective, contain hazardous components that pose workplace safety risks and environmental disposal issues. Alternative green electrolytes currently under development often deliver inferior surface finish quality, presenting a difficult trade-off between environmental sustainability and optical performance.

Scale-up challenges persist when transitioning from laboratory to industrial applications. Processes that produce excellent results on small test specimens often fail to deliver consistent performance on larger components due to current distribution issues, electrolyte flow dynamics, and heat management complications. This scalability gap significantly hinders widespread adoption of advanced electropolishing techniques in high-volume manufacturing environments for optical applications.

The formation of oxide films during electropolishing presents another significant challenge. Aluminum's high reactivity with oxygen leads to rapid formation of passive oxide layers that can interfere with the electropolishing process. These films often exhibit varying thicknesses across the surface, creating optical inconsistencies that reduce reflective properties. Current electrolyte formulations struggle to maintain consistent dissolution rates across these oxide barriers.

Temperature control during electropolishing emerges as a critical factor affecting surface quality. Even minor temperature fluctuations in the electrolyte bath can dramatically alter reaction kinetics, leading to uneven material removal. This is particularly problematic for large components where maintaining uniform temperature distribution becomes increasingly difficult, resulting in reflectivity variations across the surface.

Hydrogen evolution during electropolishing constitutes another major challenge. The cathodic reaction produces hydrogen bubbles that can adhere to the workpiece surface, creating localized masking effects. These areas receive reduced current density, leading to unpolished regions and pitting that significantly compromise reflective properties. Current bubble management techniques remain inadequate for high-precision applications.

The environmental and health concerns associated with traditional phosphoric-sulfuric acid electrolytes represent both technical and regulatory challenges. These electrolytes, while effective, contain hazardous components that pose workplace safety risks and environmental disposal issues. Alternative green electrolytes currently under development often deliver inferior surface finish quality, presenting a difficult trade-off between environmental sustainability and optical performance.

Scale-up challenges persist when transitioning from laboratory to industrial applications. Processes that produce excellent results on small test specimens often fail to deliver consistent performance on larger components due to current distribution issues, electrolyte flow dynamics, and heat management complications. This scalability gap significantly hinders widespread adoption of advanced electropolishing techniques in high-volume manufacturing environments for optical applications.

Current Electropolishing Methods for Aluminum Alloys

01 Electropolishing processes for enhanced reflectivity

Electropolishing processes specifically designed for aluminum alloys can significantly enhance surface reflectivity. These processes typically involve controlled electrolytic removal of material from the surface in specific electrolyte solutions, resulting in a smooth, highly reflective finish. The process parameters such as current density, temperature, and treatment time are optimized to achieve maximum reflectivity while maintaining the structural integrity of the aluminum alloy.- Electropolishing processes for enhanced reflectivity: Electropolishing processes specifically designed for aluminum alloys can significantly enhance surface reflectivity. These processes typically involve controlled electrolytic removal of material from the surface, resulting in a smooth, highly reflective finish. The process parameters such as current density, electrolyte composition, and treatment time are optimized to achieve maximum reflectivity while maintaining the structural integrity of the aluminum alloy.

- Electrolyte compositions for aluminum alloy electropolishing: Specialized electrolyte compositions play a crucial role in achieving high reflectivity during electropolishing of aluminum alloys. These formulations typically contain acids (such as phosphoric, sulfuric, or perchloric acid), along with specific additives that enhance the dissolution of surface irregularities while preserving the base material. The electrolyte composition directly influences the surface finish quality and reflective properties of the treated aluminum alloys.

- Pre-treatment and post-treatment methods: Various pre-treatment and post-treatment methods are employed to maximize reflectivity in electropolished aluminum alloys. Pre-treatments may include mechanical polishing, degreasing, or chemical etching to prepare the surface. Post-treatments often involve passivation processes, protective coatings, or anodizing to preserve the reflective finish and enhance durability. These additional steps significantly impact the final reflectivity and longevity of the reflective properties.

- Reflectivity enhancement for specific aluminum alloy compositions: Different aluminum alloy compositions require tailored electropolishing approaches to achieve optimal reflectivity. The presence of alloying elements such as copper, magnesium, silicon, or zinc affects the electropolishing behavior and resulting surface properties. Specialized techniques have been developed for high-strength aluminum alloys, anodized aluminum, and aluminum-lithium alloys to maximize reflectivity while maintaining the beneficial properties of these specific alloy compositions.

- Applications requiring high-reflectivity electropolished aluminum: Electropolished aluminum alloys with enhanced reflectivity find applications in various high-tech industries. These include solar energy systems where high reflectivity improves energy collection efficiency, optical instruments requiring precise light reflection, aerospace components where weight and reflective properties are critical, and architectural elements where aesthetic appearance and weather resistance are important. The electropolishing processes are often customized based on the specific reflectivity requirements of these applications.

02 Electrolyte composition for aluminum alloy electropolishing

The composition of electrolytes used in electropolishing significantly impacts the reflectivity of aluminum alloys. Specialized electrolyte formulations containing acids (such as phosphoric, sulfuric, or perchloric acids), along with specific additives and stabilizers, can produce superior reflective surfaces. These formulations are designed to selectively dissolve microscopic peaks on the aluminum surface while leaving the valleys intact, resulting in a highly smooth and reflective finish.Expand Specific Solutions03 Pre-treatment and post-treatment methods

Various pre-treatment and post-treatment methods can enhance the reflectivity achieved through electropolishing of aluminum alloys. Pre-treatments may include mechanical polishing, chemical cleaning, or degreasing to prepare the surface. Post-treatments often involve passivation processes, application of protective coatings, or anodizing to preserve the reflective properties and prevent oxidation. These additional steps can significantly improve the final reflectivity and durability of the electropolished aluminum surface.Expand Specific Solutions04 Specialized techniques for high-reflectivity applications

Advanced electropolishing techniques have been developed specifically for applications requiring extremely high reflectivity, such as optical components, solar reflectors, and decorative finishes. These techniques may involve pulse electropolishing, multi-stage processes, or hybrid approaches combining electropolishing with other surface treatments. Such specialized methods can achieve reflectivity levels approaching theoretical maximums for aluminum alloys, with carefully controlled surface topography at the nanoscale.Expand Specific Solutions05 Alloy-specific electropolishing parameters

Different aluminum alloys require specific electropolishing parameters to achieve optimal reflectivity. The electropolishing process must be tailored based on the alloy composition, with particular attention to elements like copper, magnesium, and silicon that can affect the electrochemical behavior. Research has established optimal parameter ranges for various commercial aluminum alloys, including treatment times, current densities, and electrolyte compositions that maximize reflectivity while minimizing surface defects.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The electropolishing of aluminum alloys for high-reflectivity surfaces market is in a growth phase, driven by increasing demand in optical, aerospace, and electronics applications. The global market size is expanding steadily, with projections indicating significant growth potential due to rising requirements for precision surfaces. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include POLIGRAT GmbH, specializing in metal surface treatments; Samsung Electronics and Applied Materials, advancing semiconductor-related applications; Sumitomo Light Metal Industries and Chinalco entities, focusing on aluminum processing technologies; and automotive manufacturers like Mercedes-Benz and Honda, implementing high-reflectivity surfaces in vehicle components. Research institutions such as RIST and National University of Defense Technology are contributing to technological advancements, while companies like 3M and Toshiba Materials are developing specialized materials and processes.

POLIGRAT GmbH

Technical Solution: POLIGRAT has developed advanced electropolishing processes specifically for aluminum alloys that achieve superior surface reflectivity. Their proprietary electrolyte formulations combine phosphoric and sulfuric acids with organic additives to create uniform dissolution of the aluminum surface while minimizing pitting. Their EP-AL process utilizes precise temperature control (20-40°C) and current density modulation (5-20 A/dm²) to achieve reflectivity values exceeding 95% in the visible spectrum. The company has pioneered pulse electropolishing techniques that alternate between anodic and cathodic cycles, allowing for better control of the diffusion layer and resulting in more consistent surface finishing across complex geometries. POLIGRAT's systems incorporate real-time monitoring of process parameters with automated adjustment capabilities to maintain optimal polishing conditions throughout the treatment cycle.

Strengths: Specialized expertise in aluminum surface treatments with proprietary electrolyte formulations that achieve superior reflectivity. Their pulse electropolishing technology provides exceptional control over surface quality even on complex parts. Weaknesses: Their high-end solutions typically require significant capital investment and specialized training, making them less accessible for smaller operations. The process chemistry requires careful waste treatment protocols.

Applied Materials, Inc.

Technical Solution: Applied Materials has engineered a high-throughput electropolishing platform specifically for aluminum reflectors used in semiconductor and display manufacturing. Their system employs a vertical continuous processing design that allows for uniform treatment of large aluminum sheets with dimensional tolerances below 2μm. The company's proprietary electrolyte management system continuously filters and replenishes the solution to maintain consistent polishing performance over extended production runs. Applied Materials' process incorporates real-time spectrophotometric monitoring that measures reflectivity during processing and automatically adjusts current density parameters to achieve target specifications. Their technology utilizes segmented cathode arrays that can be independently controlled to compensate for edge effects and ensure uniform current distribution across the entire workpiece. The system also features advanced thermal management that maintains electrolyte temperature within ±0.5°C, critical for achieving consistent surface finish quality on aluminum alloys with varying compositions.

Strengths: Industry-leading throughput capabilities with excellent process control for high-volume manufacturing environments. Their in-situ monitoring and feedback systems ensure consistent quality across large production batches. Weaknesses: The system is primarily designed for flat or simple curved surfaces and has limitations when processing complex three-dimensional components. The high capital cost is justified only for large-scale production operations.

Key Patents and Innovations in Electropolishing Technology

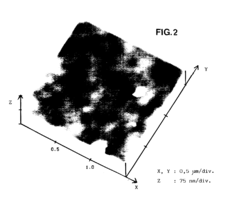

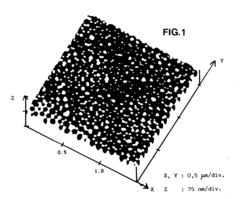

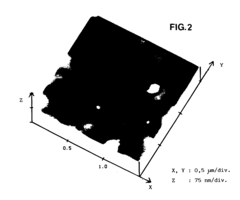

Process for electrolytic polishing of metallic surfaces in two steps for improving their optical properties and resulting products

PatentInactiveEP0745703A1

Innovation

- A two-step process involving conventional chemical or electrolytic polishing followed by electrolytic micropolishing using mineral, organic, or mixed acid solutions to form a porous or barrier oxide layer with a very fine structure, which significantly reduces micro-roughness and enhances reflectivity.

Environmental Impact and Sustainability Considerations

The electropolishing process of aluminum alloys for high-reflectivity surfaces presents significant environmental and sustainability considerations that must be addressed in modern manufacturing contexts. Traditional electropolishing methods typically employ aggressive chemical solutions containing phosphoric and sulfuric acids, chromic acid compounds, and other hazardous substances that pose substantial environmental risks if not properly managed.

Waste management represents a primary environmental concern, as electropolishing operations generate acidic waste streams containing dissolved aluminum and heavy metals. These effluents require specialized treatment systems to neutralize acids and precipitate metals before discharge, adding complexity and cost to the manufacturing process. Advanced treatment technologies such as ion exchange, membrane filtration, and electrocoagulation are increasingly being implemented to minimize environmental impact.

Energy consumption during electropolishing constitutes another significant sustainability factor. The process requires continuous electrical current application, often at high voltages, resulting in considerable energy demands. Recent innovations focus on optimizing electrical parameters and developing more energy-efficient power supplies that reduce overall consumption while maintaining surface quality outcomes.

Chemical usage reduction strategies have gained prominence in sustainable electropolishing practices. Research indicates that modified electrolyte formulations with lower toxicity profiles can achieve comparable reflectivity results while reducing environmental hazards. Some facilities have successfully implemented closed-loop systems that recover and reuse process chemicals, significantly decreasing fresh chemical requirements and waste generation.

Water conservation presents an additional sustainability challenge, as electropolishing typically involves multiple rinsing stages consuming substantial water volumes. Implementation of cascade rinsing systems, water recycling technologies, and conductivity-controlled rinse stations has demonstrated water usage reductions of up to 60% in optimized facilities without compromising surface quality.

Regulatory compliance frameworks worldwide are increasingly stringent regarding electropolishing operations. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in other regions impose strict controls on chemical usage, emissions, and waste disposal. Forward-thinking manufacturers are adopting proactive approaches that exceed minimum compliance requirements, positioning themselves advantageously for future regulatory developments.

Life cycle assessment studies of electropolished aluminum components reveal that despite the environmental impacts of the process itself, the enhanced durability and reflectivity of treated surfaces can contribute to sustainability through extended product lifespans and improved energy efficiency in applications such as lighting systems and solar collectors.

Waste management represents a primary environmental concern, as electropolishing operations generate acidic waste streams containing dissolved aluminum and heavy metals. These effluents require specialized treatment systems to neutralize acids and precipitate metals before discharge, adding complexity and cost to the manufacturing process. Advanced treatment technologies such as ion exchange, membrane filtration, and electrocoagulation are increasingly being implemented to minimize environmental impact.

Energy consumption during electropolishing constitutes another significant sustainability factor. The process requires continuous electrical current application, often at high voltages, resulting in considerable energy demands. Recent innovations focus on optimizing electrical parameters and developing more energy-efficient power supplies that reduce overall consumption while maintaining surface quality outcomes.

Chemical usage reduction strategies have gained prominence in sustainable electropolishing practices. Research indicates that modified electrolyte formulations with lower toxicity profiles can achieve comparable reflectivity results while reducing environmental hazards. Some facilities have successfully implemented closed-loop systems that recover and reuse process chemicals, significantly decreasing fresh chemical requirements and waste generation.

Water conservation presents an additional sustainability challenge, as electropolishing typically involves multiple rinsing stages consuming substantial water volumes. Implementation of cascade rinsing systems, water recycling technologies, and conductivity-controlled rinse stations has demonstrated water usage reductions of up to 60% in optimized facilities without compromising surface quality.

Regulatory compliance frameworks worldwide are increasingly stringent regarding electropolishing operations. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in other regions impose strict controls on chemical usage, emissions, and waste disposal. Forward-thinking manufacturers are adopting proactive approaches that exceed minimum compliance requirements, positioning themselves advantageously for future regulatory developments.

Life cycle assessment studies of electropolished aluminum components reveal that despite the environmental impacts of the process itself, the enhanced durability and reflectivity of treated surfaces can contribute to sustainability through extended product lifespans and improved energy efficiency in applications such as lighting systems and solar collectors.

Quality Control Standards for High-Reflectivity Surfaces

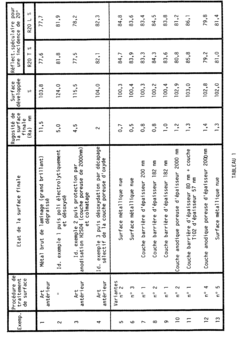

Quality control standards for high-reflectivity aluminum surfaces require rigorous measurement protocols and acceptance criteria to ensure consistent performance in optical applications. The primary standard metrics include specular reflectance (typically measured at multiple wavelengths across the UV-visible-IR spectrum), surface roughness (measured in nanometers Ra or RMS), and defect density (quantified as number of defects per unit area).

Industry standards such as ASTM E430 for specular gloss measurements and ISO 10110 for optical surface quality provide foundational frameworks for quality assessment. For aluminum reflectors in aerospace and precision optical applications, reflectivity requirements typically exceed 95% in the visible spectrum, with surface roughness below 5nm RMS.

Non-destructive testing methods form a critical component of quality control protocols. These include optical profilometry for surface topography mapping, spectrophotometry for reflectance measurement, and automated visual inspection systems utilizing machine vision algorithms to detect microscopic defects. Advanced facilities implement interferometric techniques capable of detecting surface irregularities at the nanometer scale.

Statistical process control (SPC) methodologies are essential for maintaining consistent electropolishing quality. Control charts tracking key parameters such as electrolyte composition, temperature, current density, and process time help identify process drift before it affects product quality. Sampling plans following standards like ANSI/ASQ Z1.4 determine inspection frequency and acceptance criteria based on production volume and criticality.

Documentation requirements include material certification, process parameter records, and measurement data traceability. Each high-reflectivity component typically receives a unique identifier linked to its complete processing history, enabling root cause analysis if performance issues arise in field applications.

Environmental testing standards assess the durability of electropolished surfaces under various conditions. These include salt spray resistance (ASTM B117), humidity exposure (ASTM D2247), and accelerated weathering tests (ASTM G154). For space applications, additional standards address outgassing characteristics and radiation resistance.

Emerging quality control technologies include automated surface inspection systems utilizing artificial intelligence for defect classification and predictive analytics to anticipate process deviations before they manifest as quality issues. These systems can detect subtle patterns in process data that might escape traditional SPC methods, enabling proactive quality management rather than reactive inspection.

Industry standards such as ASTM E430 for specular gloss measurements and ISO 10110 for optical surface quality provide foundational frameworks for quality assessment. For aluminum reflectors in aerospace and precision optical applications, reflectivity requirements typically exceed 95% in the visible spectrum, with surface roughness below 5nm RMS.

Non-destructive testing methods form a critical component of quality control protocols. These include optical profilometry for surface topography mapping, spectrophotometry for reflectance measurement, and automated visual inspection systems utilizing machine vision algorithms to detect microscopic defects. Advanced facilities implement interferometric techniques capable of detecting surface irregularities at the nanometer scale.

Statistical process control (SPC) methodologies are essential for maintaining consistent electropolishing quality. Control charts tracking key parameters such as electrolyte composition, temperature, current density, and process time help identify process drift before it affects product quality. Sampling plans following standards like ANSI/ASQ Z1.4 determine inspection frequency and acceptance criteria based on production volume and criticality.

Documentation requirements include material certification, process parameter records, and measurement data traceability. Each high-reflectivity component typically receives a unique identifier linked to its complete processing history, enabling root cause analysis if performance issues arise in field applications.

Environmental testing standards assess the durability of electropolished surfaces under various conditions. These include salt spray resistance (ASTM B117), humidity exposure (ASTM D2247), and accelerated weathering tests (ASTM G154). For space applications, additional standards address outgassing characteristics and radiation resistance.

Emerging quality control technologies include automated surface inspection systems utilizing artificial intelligence for defect classification and predictive analytics to anticipate process deviations before they manifest as quality issues. These systems can detect subtle patterns in process data that might escape traditional SPC methods, enabling proactive quality management rather than reactive inspection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!