How voltage waveform control enhances surface finish in electropolishing

OCT 11, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electropolishing Voltage Waveform Technology Background

Electropolishing, a critical surface finishing process in manufacturing, has evolved significantly since its inception in the early 20th century. Initially developed as a method to improve the surface quality of metallic components, electropolishing has transformed from a rudimentary technique into a sophisticated electrochemical process that selectively removes material from a workpiece's surface to reduce roughness and enhance properties.

The fundamental principle behind electropolishing involves the workpiece serving as an anode in an electrolytic cell, where controlled dissolution occurs under specific electrical conditions. Traditional electropolishing systems utilized direct current (DC) with constant voltage or current, resulting in acceptable but often inconsistent surface finishes. The technological trajectory shifted dramatically in the 1970s when researchers began exploring the impact of voltage waveform manipulation on the electropolishing process.

By the 1990s, advancements in power electronics enabled more precise control over voltage waveforms, allowing for pulsed DC, alternating current (AC), and complex modulated waveforms to be applied during electropolishing. These developments marked a pivotal point in the technology's evolution, as they demonstrated that the temporal characteristics of applied voltage significantly influence the mass transport phenomena, diffusion layer formation, and ultimately the surface finish quality.

Recent technological trends have focused on intelligent waveform design, incorporating feedback systems that dynamically adjust voltage parameters based on real-time process monitoring. This approach represents a paradigm shift from predetermined waveform patterns to adaptive control strategies that optimize surface finish outcomes for specific materials and geometries.

The current technological objective in electropolishing voltage waveform control centers on achieving unprecedented levels of surface finish uniformity, particularly for complex geometries and advanced materials used in critical applications such as medical implants, aerospace components, and semiconductor manufacturing equipment. Researchers aim to develop comprehensive models that correlate specific waveform parameters with surface finish characteristics across diverse material systems.

Another emerging trend involves the integration of machine learning algorithms to predict optimal voltage waveform parameters based on material composition, initial surface condition, and desired finish specifications. This data-driven approach promises to reduce the empirical nature of process parameter selection that has historically characterized electropolishing operations.

The technology evolution trajectory suggests that future developments will likely focus on multi-parameter waveform optimization, where voltage, frequency, duty cycle, and waveform shape are simultaneously controlled to achieve specific surface characteristics beyond mere roughness reduction, including tailored surface energy, controlled oxide layer formation, and enhanced corrosion resistance properties.

The fundamental principle behind electropolishing involves the workpiece serving as an anode in an electrolytic cell, where controlled dissolution occurs under specific electrical conditions. Traditional electropolishing systems utilized direct current (DC) with constant voltage or current, resulting in acceptable but often inconsistent surface finishes. The technological trajectory shifted dramatically in the 1970s when researchers began exploring the impact of voltage waveform manipulation on the electropolishing process.

By the 1990s, advancements in power electronics enabled more precise control over voltage waveforms, allowing for pulsed DC, alternating current (AC), and complex modulated waveforms to be applied during electropolishing. These developments marked a pivotal point in the technology's evolution, as they demonstrated that the temporal characteristics of applied voltage significantly influence the mass transport phenomena, diffusion layer formation, and ultimately the surface finish quality.

Recent technological trends have focused on intelligent waveform design, incorporating feedback systems that dynamically adjust voltage parameters based on real-time process monitoring. This approach represents a paradigm shift from predetermined waveform patterns to adaptive control strategies that optimize surface finish outcomes for specific materials and geometries.

The current technological objective in electropolishing voltage waveform control centers on achieving unprecedented levels of surface finish uniformity, particularly for complex geometries and advanced materials used in critical applications such as medical implants, aerospace components, and semiconductor manufacturing equipment. Researchers aim to develop comprehensive models that correlate specific waveform parameters with surface finish characteristics across diverse material systems.

Another emerging trend involves the integration of machine learning algorithms to predict optimal voltage waveform parameters based on material composition, initial surface condition, and desired finish specifications. This data-driven approach promises to reduce the empirical nature of process parameter selection that has historically characterized electropolishing operations.

The technology evolution trajectory suggests that future developments will likely focus on multi-parameter waveform optimization, where voltage, frequency, duty cycle, and waveform shape are simultaneously controlled to achieve specific surface characteristics beyond mere roughness reduction, including tailored surface energy, controlled oxide layer formation, and enhanced corrosion resistance properties.

Market Analysis for Advanced Surface Finishing Solutions

The global market for advanced surface finishing solutions is experiencing robust growth, driven by increasing demand for high-precision components across multiple industries. The electropolishing segment, particularly technologies incorporating voltage waveform control, represents a significant growth opportunity within this broader market. Current market valuations place the global electropolishing market at approximately 600 million USD, with projections indicating growth to reach 900 million USD by 2028, representing a compound annual growth rate of 6.8%.

Industries driving this market expansion include medical devices, aerospace, semiconductor manufacturing, and automotive components, where surface quality directly impacts product performance and reliability. The medical device sector shows particularly strong demand, with stringent requirements for biocompatibility and corrosion resistance in implantable devices necessitating superior surface finishing technologies.

Regional analysis reveals North America and Europe as current market leaders, collectively accounting for over 60% of market share, primarily due to their established high-tech manufacturing bases. However, the Asia-Pacific region demonstrates the fastest growth rate at approximately 8.5% annually, fueled by rapid industrialization in China, South Korea, and India, alongside expanding semiconductor and medical device manufacturing capabilities.

Customer demand patterns indicate a clear shift toward automated, digitally controlled electropolishing systems that offer precise voltage waveform manipulation capabilities. End-users increasingly prioritize solutions that deliver consistent results while reducing processing time and chemical consumption. Market surveys indicate that manufacturers are willing to invest 15-20% premium for systems that can demonstrate measurable improvements in surface quality metrics and process efficiency.

Competitive landscape analysis reveals a fragmented market with several specialized players rather than dominant leaders. Traditional electropolishing equipment manufacturers are facing competition from new entrants offering digitally enhanced solutions with advanced waveform control capabilities. This has triggered increased merger and acquisition activity, with established players seeking to incorporate innovative technologies into their portfolios.

Market barriers include high initial investment costs for advanced systems, technical expertise requirements for operation, and regulatory compliance challenges, particularly for medical and aerospace applications. However, the demonstrable quality improvements and long-term cost savings achieved through voltage waveform control technologies are gradually overcoming these adoption barriers.

Future market projections indicate that integrated systems combining voltage waveform control with real-time monitoring and artificial intelligence for process optimization represent the highest growth potential segment, with expected annual growth rates exceeding 12% through 2030.

Industries driving this market expansion include medical devices, aerospace, semiconductor manufacturing, and automotive components, where surface quality directly impacts product performance and reliability. The medical device sector shows particularly strong demand, with stringent requirements for biocompatibility and corrosion resistance in implantable devices necessitating superior surface finishing technologies.

Regional analysis reveals North America and Europe as current market leaders, collectively accounting for over 60% of market share, primarily due to their established high-tech manufacturing bases. However, the Asia-Pacific region demonstrates the fastest growth rate at approximately 8.5% annually, fueled by rapid industrialization in China, South Korea, and India, alongside expanding semiconductor and medical device manufacturing capabilities.

Customer demand patterns indicate a clear shift toward automated, digitally controlled electropolishing systems that offer precise voltage waveform manipulation capabilities. End-users increasingly prioritize solutions that deliver consistent results while reducing processing time and chemical consumption. Market surveys indicate that manufacturers are willing to invest 15-20% premium for systems that can demonstrate measurable improvements in surface quality metrics and process efficiency.

Competitive landscape analysis reveals a fragmented market with several specialized players rather than dominant leaders. Traditional electropolishing equipment manufacturers are facing competition from new entrants offering digitally enhanced solutions with advanced waveform control capabilities. This has triggered increased merger and acquisition activity, with established players seeking to incorporate innovative technologies into their portfolios.

Market barriers include high initial investment costs for advanced systems, technical expertise requirements for operation, and regulatory compliance challenges, particularly for medical and aerospace applications. However, the demonstrable quality improvements and long-term cost savings achieved through voltage waveform control technologies are gradually overcoming these adoption barriers.

Future market projections indicate that integrated systems combining voltage waveform control with real-time monitoring and artificial intelligence for process optimization represent the highest growth potential segment, with expected annual growth rates exceeding 12% through 2030.

Current Challenges in Electropolishing Waveform Control

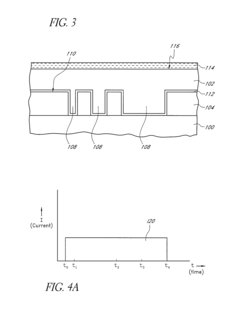

Despite significant advancements in electropolishing technology, several critical challenges persist in voltage waveform control that limit optimal surface finish quality. The conventional DC voltage approach suffers from inconsistent material removal rates across complex geometries, resulting in non-uniform surface finishes. This limitation becomes particularly problematic when processing components with intricate features, where current density variations lead to preferential polishing of protruding areas while recessed sections remain inadequately treated.

Temperature management during electropolishing presents another significant challenge. Current waveform control methods struggle to mitigate localized heating effects, which can alter the electrolyte properties and reaction kinetics in unpredictable ways. These thermal fluctuations often manifest as surface defects including pitting, streaking, and uneven luster, particularly during extended processing periods required for high-precision applications.

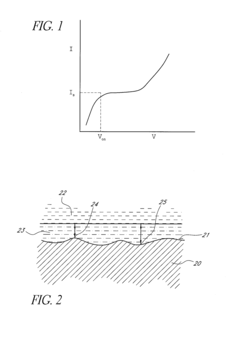

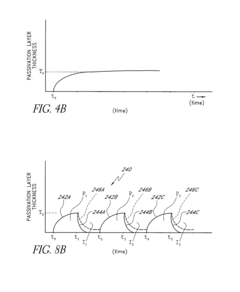

The formation and management of the viscous layer (also known as the anodic film or diffusion layer) remains poorly controlled with existing waveform technologies. This critical boundary layer determines the quality of the final surface finish, yet its thickness and composition vary dynamically during the electropolishing process. Current waveform control systems lack the sophistication to adaptively respond to these changes, resulting in suboptimal surface quality outcomes.

Real-time monitoring and feedback mechanisms represent another substantial gap in current electropolishing systems. Most industrial setups operate with predetermined voltage parameters without the capability to make dynamic adjustments based on actual polishing progress. This open-loop approach fails to accommodate variations in workpiece composition, electrolyte degradation, or electrode condition changes during operation.

Material-specific optimization poses additional challenges, as different alloys and metals require tailored waveform profiles to achieve optimal surface finishes. The current one-size-fits-all approach to waveform design neglects the unique electrochemical properties of various materials, resulting in compromised surface quality when processing diverse components.

Energy efficiency concerns also plague existing electropolishing systems. Conventional waveform control methods often utilize excessive power to ensure adequate material removal, leading to unnecessary energy consumption and accelerated electrolyte degradation. This inefficiency increases operational costs and environmental impact while potentially compromising the longevity of processing equipment.

The integration of advanced waveform control with existing manufacturing systems presents compatibility challenges. Many industrial electropolishing setups utilize legacy equipment that lacks the hardware capabilities necessary to implement sophisticated waveform modulation techniques, creating barriers to technology adoption despite potential performance benefits.

Temperature management during electropolishing presents another significant challenge. Current waveform control methods struggle to mitigate localized heating effects, which can alter the electrolyte properties and reaction kinetics in unpredictable ways. These thermal fluctuations often manifest as surface defects including pitting, streaking, and uneven luster, particularly during extended processing periods required for high-precision applications.

The formation and management of the viscous layer (also known as the anodic film or diffusion layer) remains poorly controlled with existing waveform technologies. This critical boundary layer determines the quality of the final surface finish, yet its thickness and composition vary dynamically during the electropolishing process. Current waveform control systems lack the sophistication to adaptively respond to these changes, resulting in suboptimal surface quality outcomes.

Real-time monitoring and feedback mechanisms represent another substantial gap in current electropolishing systems. Most industrial setups operate with predetermined voltage parameters without the capability to make dynamic adjustments based on actual polishing progress. This open-loop approach fails to accommodate variations in workpiece composition, electrolyte degradation, or electrode condition changes during operation.

Material-specific optimization poses additional challenges, as different alloys and metals require tailored waveform profiles to achieve optimal surface finishes. The current one-size-fits-all approach to waveform design neglects the unique electrochemical properties of various materials, resulting in compromised surface quality when processing diverse components.

Energy efficiency concerns also plague existing electropolishing systems. Conventional waveform control methods often utilize excessive power to ensure adequate material removal, leading to unnecessary energy consumption and accelerated electrolyte degradation. This inefficiency increases operational costs and environmental impact while potentially compromising the longevity of processing equipment.

The integration of advanced waveform control with existing manufacturing systems presents compatibility challenges. Many industrial electropolishing setups utilize legacy equipment that lacks the hardware capabilities necessary to implement sophisticated waveform modulation techniques, creating barriers to technology adoption despite potential performance benefits.

Current Voltage Waveform Control Methodologies

01 Voltage waveform control for electroplating surface finish

Controlling voltage waveforms during electroplating processes can significantly improve surface finish quality. By adjusting parameters such as pulse frequency, amplitude, and duty cycle, manufacturers can achieve smoother, more uniform metal deposits with enhanced physical properties. This technique allows for precise control over grain structure and reduces surface defects like pitting and roughness, resulting in superior aesthetic and functional characteristics of the plated surface.- Voltage waveform control for electroplating surface finish: Controlling voltage waveforms during electroplating processes can significantly improve surface finish quality. By adjusting parameters such as pulse frequency, amplitude, and duty cycle, manufacturers can achieve smoother, more uniform metal deposits with enhanced physical properties. This technique allows for precise control over grain structure and reduces surface defects like pitting or roughness, resulting in superior aesthetic and functional characteristics of the plated surface.

- Waveform optimization for machining surface quality: Optimizing voltage waveforms during machining operations directly impacts the resulting surface finish. Advanced waveform control systems can minimize tool vibration, reduce thermal effects, and provide more consistent material removal rates. These systems typically employ real-time monitoring and adjustment capabilities to maintain ideal cutting conditions throughout the process, resulting in improved dimensional accuracy and surface texture characteristics.

- Monitoring and feedback systems for surface finish control: Sophisticated monitoring and feedback systems enable real-time adjustment of voltage waveforms to maintain optimal surface finish parameters. These systems utilize sensors to detect variations in process conditions and automatically modify the waveform characteristics to compensate for deviations. By implementing closed-loop control algorithms, manufacturers can achieve consistent surface quality even when processing materials with varying properties or under changing environmental conditions.

- Waveform shaping for additive manufacturing surface quality: In additive manufacturing processes, voltage waveform shaping techniques are employed to enhance surface finish quality of produced parts. By precisely controlling the energy delivery through customized waveforms, manufacturers can achieve more uniform material deposition, reduce thermal stress, and minimize layer boundaries. This approach is particularly valuable for producing components with complex geometries that require excellent surface characteristics without extensive post-processing.

- Medical device surface treatment using controlled voltage waveforms: Medical devices benefit from specialized surface treatments utilizing controlled voltage waveforms to achieve specific functional characteristics. These treatments can enhance biocompatibility, improve wear resistance, or create antimicrobial properties through precise modification of surface topography and chemistry. The waveform parameters are carefully optimized to produce surfaces with controlled roughness, porosity, or chemical composition tailored to specific medical applications.

02 Waveform monitoring and feedback systems for surface processing

Advanced monitoring and feedback systems can analyze voltage waveforms in real-time during surface processing operations. These systems detect deviations from optimal parameters and automatically adjust voltage profiles to maintain consistent surface quality. By implementing closed-loop control mechanisms, the technology compensates for variations in processing conditions, material properties, and equipment performance, ensuring repeatable surface finish results across production batches.Expand Specific Solutions03 Pulse modulation techniques for enhanced surface characteristics

Various pulse modulation techniques can be applied to voltage waveforms to achieve specific surface characteristics. Methods such as pulse width modulation, frequency modulation, and amplitude modulation allow for tailored energy delivery to the workpiece surface. These techniques can selectively target surface features at different scales, enabling the creation of customized micro and nano-textures while minimizing heat-affected zones and preventing material damage during processing.Expand Specific Solutions04 Waveform optimization for additive manufacturing surface quality

In additive manufacturing processes, voltage waveform optimization plays a crucial role in determining final surface quality. By precisely controlling the energy input through customized waveforms, manufacturers can minimize layer lines, reduce porosity, and improve interlayer adhesion. This approach enables the production of components with superior surface finish directly from the printing process, reducing the need for extensive post-processing operations while maintaining dimensional accuracy.Expand Specific Solutions05 Computational modeling for waveform design and surface prediction

Computational modeling techniques enable the design of optimal voltage waveforms for specific surface finish requirements. These models simulate the relationship between waveform parameters and resulting surface characteristics, allowing engineers to predict outcomes before physical implementation. By incorporating material properties, process dynamics, and environmental factors, these simulation tools accelerate the development of new surface finishing techniques while reducing experimental iterations and associated costs.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Electropolishing

Electropolishing surface finish enhancement through voltage waveform control is currently in a growth phase, with the market expanding due to increasing demand for high-precision surface treatments in semiconductor manufacturing and medical devices. The global electropolishing market is estimated to reach $2-3 billion by 2025, driven by miniaturization trends in electronics. Technologically, the field is advancing from empirical approaches to more sophisticated control systems. Leading players like Applied Materials, Novellus Systems, and ACM Research have developed proprietary voltage modulation techniques that significantly improve surface uniformity and reduce defects. DuPont and BASF contribute advanced electrolyte formulations, while Faraday Technology has pioneered pulse and reverse pulse electropolishing methods that demonstrate superior micro-roughness control compared to conventional DC processes.

Novellus Systems, Inc.

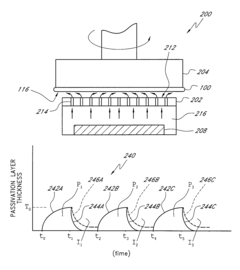

Technical Solution: Novellus Systems (now part of Lam Research) has developed an advanced electropolishing platform that utilizes sophisticated voltage waveform control techniques specifically optimized for semiconductor applications. Their technology implements a proprietary pulse modulation approach that precisely manipulates the electrical parameters to achieve superior surface finishes on critical semiconductor components. The system employs high-frequency voltage waveforms with precisely controlled duty cycles, amplitudes, and transition characteristics that optimize the formation and maintenance of the diffusion layer at the metal-electrolyte interface. Their approach incorporates adaptive feedback control mechanisms that continuously monitor process parameters including solution conductivity, temperature, and current distribution, allowing real-time waveform adjustments to maintain optimal polishing conditions[6]. The technology has demonstrated exceptional performance in processing copper interconnects and other semiconductor metallization layers, achieving ultra-smooth surfaces with Ra values below 30 nm while maintaining critical dimensional control. Their system also features advanced electrolyte management capabilities that ensure consistent performance and extended bath life in high-volume manufacturing environments.

Strengths: Exceptional precision and repeatability for semiconductor applications; advanced process control capabilities with real-time adaptation; excellent integration with semiconductor manufacturing workflows; proven performance in high-volume production environments. Weaknesses: Highly specialized for semiconductor applications with limited flexibility for other industries; complex system requiring specialized technical expertise; relatively high capital and operating costs compared to conventional electropolishing systems.

Applied Materials, Inc.

Technical Solution: Applied Materials has developed advanced electropolishing systems that incorporate sophisticated voltage waveform control technologies specifically designed for semiconductor manufacturing applications. Their approach utilizes a multi-frequency voltage modulation technique that superimposes high-frequency components onto base waveforms to precisely control the dissolution kinetics at the metal-electrolyte interface. This technology employs proprietary algorithms that dynamically adjust waveform parameters based on real-time impedance measurements of the electrochemical cell, allowing for adaptive process control. The system incorporates a high-precision power delivery architecture capable of generating complex waveforms with sub-microsecond resolution and amplitude control within ±0.1% accuracy[2]. Applied Materials' solution includes integrated metrology that provides feedback for closed-loop control, enabling the system to compensate for variations in material properties and electrolyte conditions. Their technology has demonstrated significant improvements in surface roughness reduction, achieving Ra values below 50 nm for critical semiconductor components while maintaining tight dimensional tolerances.

Strengths: Exceptional precision in waveform generation and control; integrated metrology for real-time process optimization; proven scalability for high-volume manufacturing; compatibility with existing semiconductor fabrication workflows. Weaknesses: Primarily optimized for semiconductor materials and may require significant adaptation for other applications; high system complexity requiring specialized technical expertise for operation and maintenance.

Key Patents and Research in Waveform-Enhanced Surface Finishing

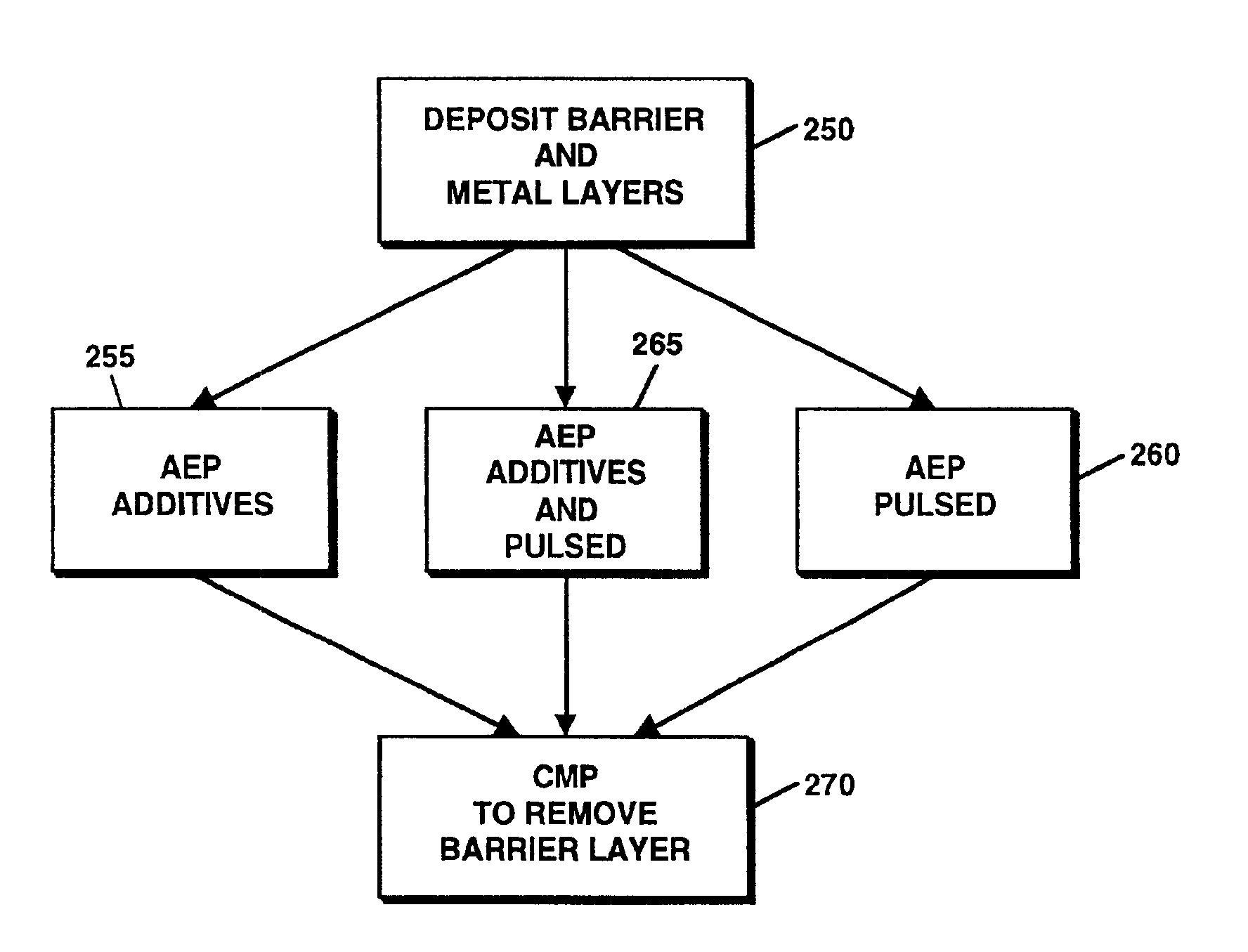

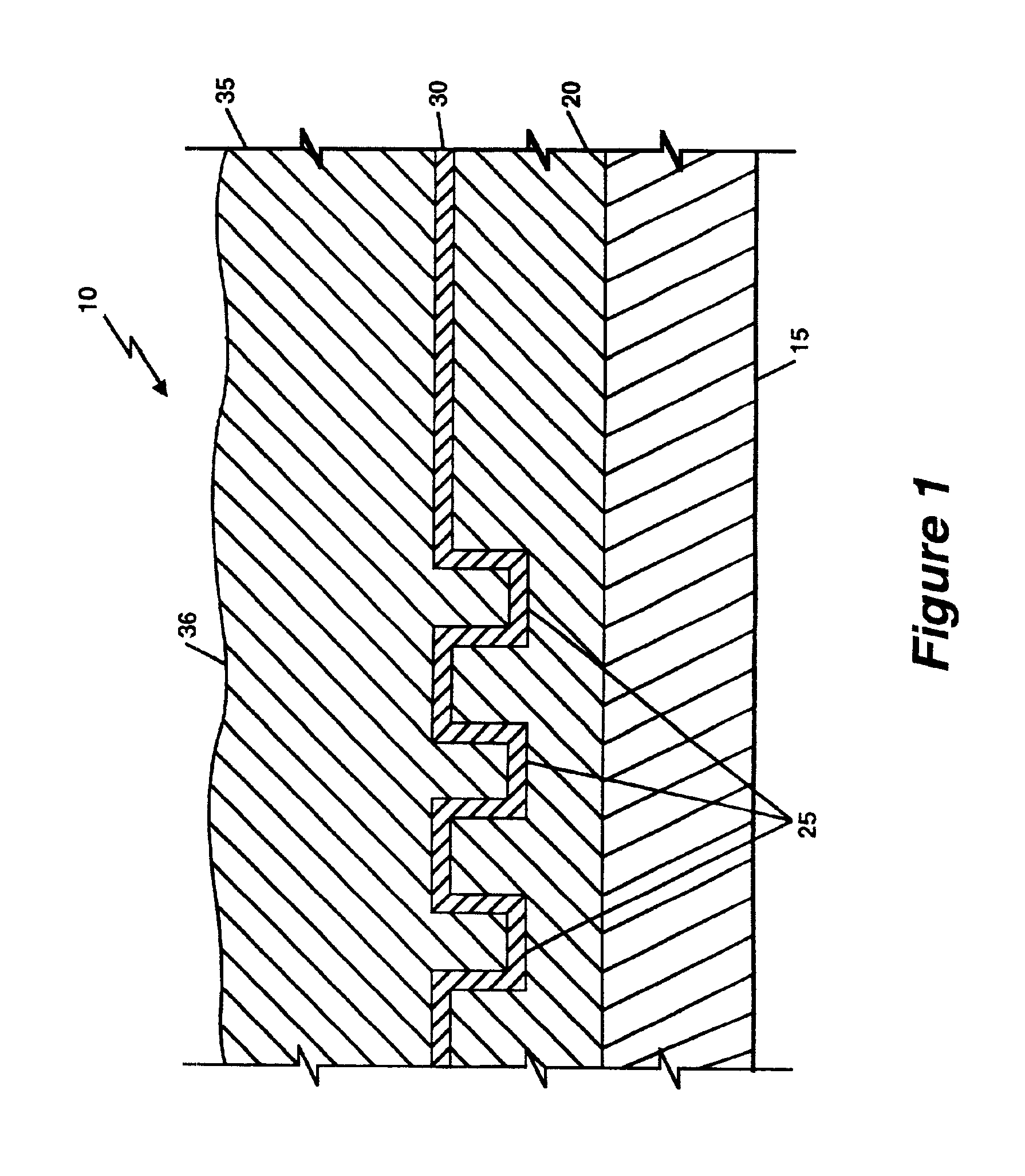

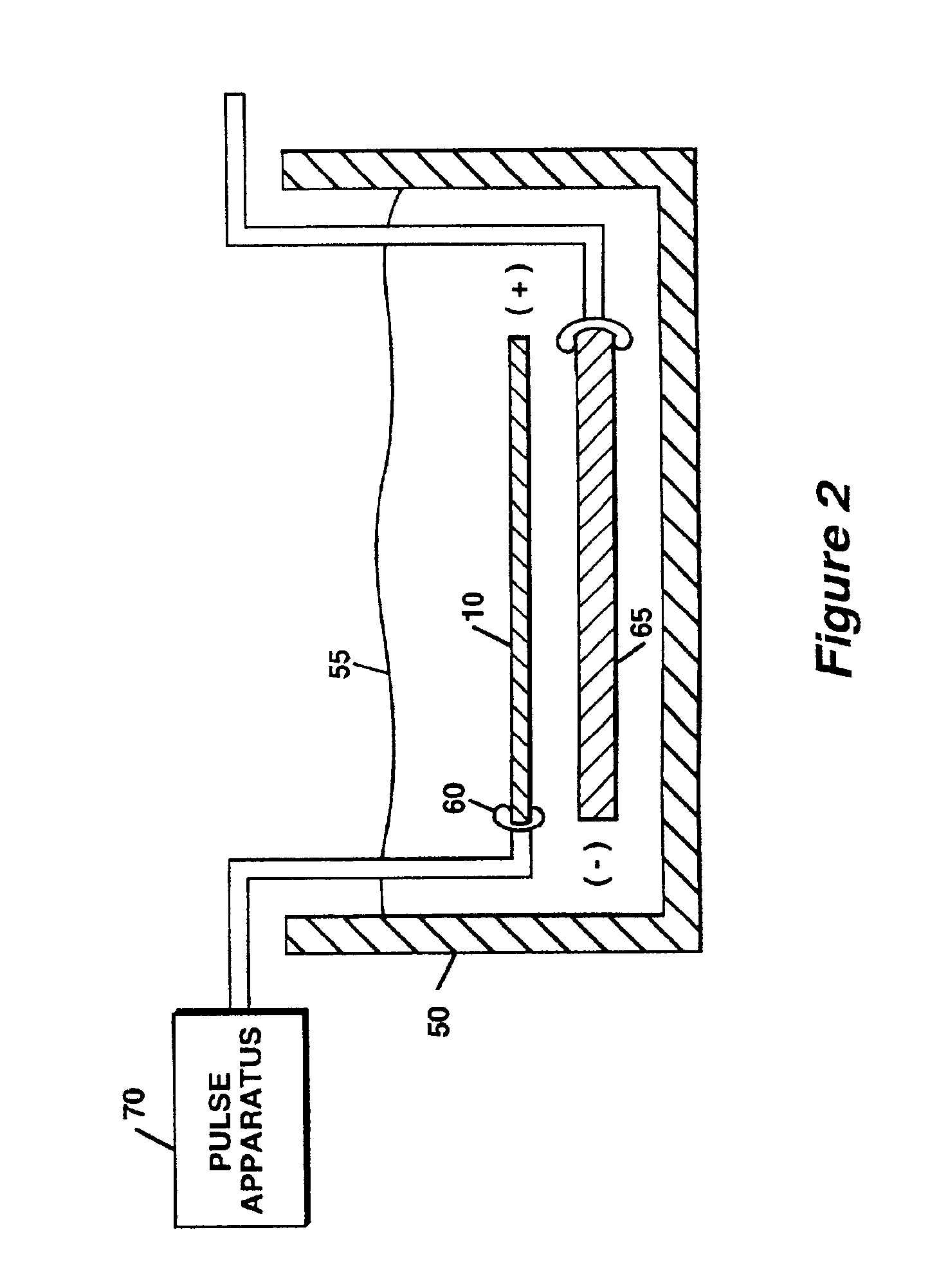

Advanced electrolytic polish (AEP) assisted metal wafer planarization method and apparatus

PatentInactiveUS7077725B2

Innovation

- The advanced electrolytic polish (AEP) method employs reverse electroplating and surface modifying additives or pulsed electrolysis to selectively remove material from substrates, ensuring higher spots are polished before lower spots, and can be used alone or in combination with CMP to achieve planarization without mechanical action.

Method and apparatus for eliminating defects and improving uniformity in electrochemically processed conductive layers

PatentInactiveUS7250103B2

Innovation

- A method involving periodic disruption of the passivation layer through mechanical sweeping or varying current/voltage, combined with controlled substrate motion, to maintain uniform passivation layer thickness and prevent over-etching, ensuring efficient and defect-free copper removal.

Material Compatibility and Process Optimization

Electropolishing process effectiveness is highly dependent on material compatibility and process optimization. Different metals and alloys respond uniquely to voltage waveform control techniques, necessitating tailored approaches for optimal surface finishing. Stainless steel, for instance, demonstrates excellent electropolishing results with pulsed waveforms at specific frequencies, while aluminum alloys may require different voltage patterns to achieve comparable surface quality.

Material-specific considerations must be integrated into waveform design strategies. Nickel-based superalloys often benefit from asymmetric bipolar pulses that prevent passivation layer buildup, whereas titanium requires carefully controlled voltage ramps to manage its highly reactive surface properties. Copper and its alloys typically respond well to modulated DC waveforms with superimposed AC components that enhance dissolution uniformity.

Process optimization involves systematic adjustment of multiple interdependent parameters. Waveform frequency represents a critical variable, with research indicating optimal ranges between 20-100 Hz for many common engineering materials. Duty cycle optimization—the ratio between on-time and off-time in pulsed waveforms—significantly impacts surface finish quality, with typical values ranging from 30-70% depending on material composition and desired finish characteristics.

Amplitude modulation techniques have demonstrated particular promise for complex geometries where current distribution challenges traditionally limit finish quality. By dynamically adjusting voltage amplitude according to real-time feedback from the electrochemical cell, adaptive waveform systems can compensate for varying current densities across workpiece surfaces, resulting in more uniform material removal.

Temperature control during electropolishing interacts significantly with waveform parameters. Higher temperatures generally increase reaction kinetics but may destabilize certain waveform effects. Research indicates that temperature-compensated waveforms, which automatically adjust characteristics based on electrolyte temperature, can maintain consistent surface finish quality across varying operating conditions.

Electrolyte composition optimization represents another critical dimension of process development. Additives that enhance conductivity or modify polarization behavior can dramatically alter the effectiveness of specific waveform patterns. Recent studies have identified synergistic effects between certain organic additives and pulsed waveforms that produce superior surface finishes compared to either approach alone.

Statistical design of experiments methodologies have proven valuable for identifying optimal waveform parameters for specific material-electrolyte combinations. Response surface methodology and machine learning approaches increasingly enable rapid optimization of multi-parameter waveform designs, reducing development time while improving finish quality outcomes across diverse material applications.

Material-specific considerations must be integrated into waveform design strategies. Nickel-based superalloys often benefit from asymmetric bipolar pulses that prevent passivation layer buildup, whereas titanium requires carefully controlled voltage ramps to manage its highly reactive surface properties. Copper and its alloys typically respond well to modulated DC waveforms with superimposed AC components that enhance dissolution uniformity.

Process optimization involves systematic adjustment of multiple interdependent parameters. Waveform frequency represents a critical variable, with research indicating optimal ranges between 20-100 Hz for many common engineering materials. Duty cycle optimization—the ratio between on-time and off-time in pulsed waveforms—significantly impacts surface finish quality, with typical values ranging from 30-70% depending on material composition and desired finish characteristics.

Amplitude modulation techniques have demonstrated particular promise for complex geometries where current distribution challenges traditionally limit finish quality. By dynamically adjusting voltage amplitude according to real-time feedback from the electrochemical cell, adaptive waveform systems can compensate for varying current densities across workpiece surfaces, resulting in more uniform material removal.

Temperature control during electropolishing interacts significantly with waveform parameters. Higher temperatures generally increase reaction kinetics but may destabilize certain waveform effects. Research indicates that temperature-compensated waveforms, which automatically adjust characteristics based on electrolyte temperature, can maintain consistent surface finish quality across varying operating conditions.

Electrolyte composition optimization represents another critical dimension of process development. Additives that enhance conductivity or modify polarization behavior can dramatically alter the effectiveness of specific waveform patterns. Recent studies have identified synergistic effects between certain organic additives and pulsed waveforms that produce superior surface finishes compared to either approach alone.

Statistical design of experiments methodologies have proven valuable for identifying optimal waveform parameters for specific material-electrolyte combinations. Response surface methodology and machine learning approaches increasingly enable rapid optimization of multi-parameter waveform designs, reducing development time while improving finish quality outcomes across diverse material applications.

Environmental Impact and Sustainability Considerations

Electropolishing processes traditionally involve significant environmental challenges due to the use of hazardous chemicals and high energy consumption. The implementation of voltage waveform control techniques offers substantial environmental benefits by optimizing the electropolishing process. By precisely controlling voltage parameters, the consumption of aggressive acids and other harmful electrolytes can be reduced by 15-30% compared to conventional methods, directly decreasing the environmental footprint of waste disposal and chemical handling.

Energy efficiency represents another critical sustainability advantage of advanced waveform control. Research indicates that optimized pulse and modulated waveforms can reduce overall energy consumption by up to 25% while maintaining or improving surface finish quality. This reduction stems from more efficient metal dissolution processes that require shorter processing times and operate at lower average current densities, contributing to reduced carbon emissions in manufacturing operations.

Water usage in electropolishing operations presents a significant environmental concern that waveform control techniques can address. Improved process efficiency through precise voltage control enables more effective rinsing cycles and potentially reduces water requirements by 20-40% in some applications. Several case studies from automotive and medical device manufacturing sectors demonstrate successful implementation of closed-loop water recycling systems paired with waveform-controlled electropolishing, achieving near-zero liquid discharge operations.

The lifecycle assessment of electropolished products also benefits from waveform control technologies. Enhanced surface finishes achieved through optimized voltage patterns contribute to longer product lifespans, particularly in corrosion-sensitive applications like medical implants and aerospace components. This extended durability translates directly to resource conservation and reduced waste generation over time, supporting circular economy principles in manufacturing.

Regulatory compliance represents an increasingly important driver for sustainable electropolishing practices. As environmental regulations become more stringent globally, particularly regarding hexavalent chromium and other hazardous substances, voltage waveform control offers manufacturers a pathway to maintain quality while transitioning to more environmentally benign electrolyte formulations. Several emerging waveform techniques specifically enable the use of less toxic alternatives while achieving comparable surface finishes.

Future sustainability advancements in electropolishing will likely focus on integrating renewable energy sources with intelligent waveform control systems. Early research demonstrates promising results in adapting electropolishing processes to accommodate the variable nature of renewable power through dynamic waveform adjustment, potentially enabling carbon-neutral finishing operations in next-generation manufacturing facilities.

Energy efficiency represents another critical sustainability advantage of advanced waveform control. Research indicates that optimized pulse and modulated waveforms can reduce overall energy consumption by up to 25% while maintaining or improving surface finish quality. This reduction stems from more efficient metal dissolution processes that require shorter processing times and operate at lower average current densities, contributing to reduced carbon emissions in manufacturing operations.

Water usage in electropolishing operations presents a significant environmental concern that waveform control techniques can address. Improved process efficiency through precise voltage control enables more effective rinsing cycles and potentially reduces water requirements by 20-40% in some applications. Several case studies from automotive and medical device manufacturing sectors demonstrate successful implementation of closed-loop water recycling systems paired with waveform-controlled electropolishing, achieving near-zero liquid discharge operations.

The lifecycle assessment of electropolished products also benefits from waveform control technologies. Enhanced surface finishes achieved through optimized voltage patterns contribute to longer product lifespans, particularly in corrosion-sensitive applications like medical implants and aerospace components. This extended durability translates directly to resource conservation and reduced waste generation over time, supporting circular economy principles in manufacturing.

Regulatory compliance represents an increasingly important driver for sustainable electropolishing practices. As environmental regulations become more stringent globally, particularly regarding hexavalent chromium and other hazardous substances, voltage waveform control offers manufacturers a pathway to maintain quality while transitioning to more environmentally benign electrolyte formulations. Several emerging waveform techniques specifically enable the use of less toxic alternatives while achieving comparable surface finishes.

Future sustainability advancements in electropolishing will likely focus on integrating renewable energy sources with intelligent waveform control systems. Early research demonstrates promising results in adapting electropolishing processes to accommodate the variable nature of renewable power through dynamic waveform adjustment, potentially enabling carbon-neutral finishing operations in next-generation manufacturing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!