Standards and ASTM specifications for electropolishing of metal components

OCT 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electropolishing Technology Background and Objectives

Electropolishing emerged in the early 20th century as a surface finishing technique, with significant advancements occurring during the 1930s and 1940s. This electrochemical process selectively removes material from a metallic workpiece, resulting in improved surface finish, enhanced corrosion resistance, and reduced microscopic roughness. The evolution of electropolishing technology has been driven by increasing demands for precision components in industries such as medical devices, aerospace, semiconductor manufacturing, and food processing equipment.

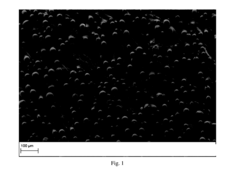

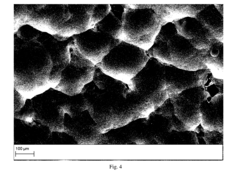

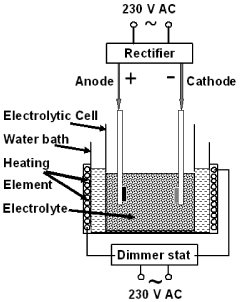

The fundamental principle of electropolishing involves the workpiece serving as the anode in an electrolytic cell, where controlled dissolution occurs preferentially at microscopic peaks, leading to surface smoothing. This process stands in contrast to mechanical polishing methods, offering advantages in processing complex geometries and achieving consistent results without introducing mechanical stress or surface contamination.

Historical development of electropolishing standards has been closely tied to industrial applications requiring stringent surface quality specifications. The American Society for Testing and Materials (ASTM) has played a pivotal role in establishing standardized testing methods and acceptance criteria for electropolished surfaces, beginning with basic specifications and evolving toward more comprehensive standards addressing various metal types and application-specific requirements.

Current technological objectives in electropolishing standardization focus on several key areas: establishing quantifiable parameters for surface quality assessment, developing industry-specific acceptance criteria, standardizing testing methodologies for consistent quality verification, and addressing environmental considerations related to process chemicals and waste management.

The integration of digital monitoring systems and automation has introduced new dimensions to electropolishing technology, creating opportunities for real-time process control and documentation that align with modern quality management systems. These advancements necessitate corresponding evolution in standards to incorporate digital verification methods and data management protocols.

Looking forward, the technology trajectory points toward more environmentally sustainable electropolishing processes, with research focused on developing less hazardous electrolyte formulations and closed-loop systems for chemical recovery. Additionally, there is growing interest in developing standards that address the unique requirements of advanced materials, including high-performance alloys and additively manufactured components that present novel surface characteristics requiring specialized electropolishing parameters.

The fundamental principle of electropolishing involves the workpiece serving as the anode in an electrolytic cell, where controlled dissolution occurs preferentially at microscopic peaks, leading to surface smoothing. This process stands in contrast to mechanical polishing methods, offering advantages in processing complex geometries and achieving consistent results without introducing mechanical stress or surface contamination.

Historical development of electropolishing standards has been closely tied to industrial applications requiring stringent surface quality specifications. The American Society for Testing and Materials (ASTM) has played a pivotal role in establishing standardized testing methods and acceptance criteria for electropolished surfaces, beginning with basic specifications and evolving toward more comprehensive standards addressing various metal types and application-specific requirements.

Current technological objectives in electropolishing standardization focus on several key areas: establishing quantifiable parameters for surface quality assessment, developing industry-specific acceptance criteria, standardizing testing methodologies for consistent quality verification, and addressing environmental considerations related to process chemicals and waste management.

The integration of digital monitoring systems and automation has introduced new dimensions to electropolishing technology, creating opportunities for real-time process control and documentation that align with modern quality management systems. These advancements necessitate corresponding evolution in standards to incorporate digital verification methods and data management protocols.

Looking forward, the technology trajectory points toward more environmentally sustainable electropolishing processes, with research focused on developing less hazardous electrolyte formulations and closed-loop systems for chemical recovery. Additionally, there is growing interest in developing standards that address the unique requirements of advanced materials, including high-performance alloys and additively manufactured components that present novel surface characteristics requiring specialized electropolishing parameters.

Market Demand Analysis for Electropolished Metal Components

The global market for electropolished metal components has been experiencing steady growth, driven primarily by increasing demand from industries requiring high-performance, corrosion-resistant, and ultra-clean metal surfaces. The healthcare sector, particularly medical device manufacturing, represents the largest market segment, accounting for approximately 35% of the total market share. This dominance stems from stringent regulatory requirements for implantable devices, surgical instruments, and pharmaceutical processing equipment where surface quality directly impacts patient safety.

Aerospace and semiconductor industries follow as significant market contributors, collectively representing about 30% of market demand. These sectors require precision-finished components with exceptional surface properties to ensure reliability in critical applications. The food and beverage industry has also emerged as a rapidly growing segment, with increasing adoption of electropolished stainless steel equipment to meet hygiene standards and prevent bacterial contamination.

Market analysis indicates regional variations in demand patterns. North America and Europe currently lead the market with well-established medical device and pharmaceutical manufacturing bases. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years, driven by expanding healthcare infrastructure, increasing manufacturing capabilities, and growing adoption of advanced manufacturing technologies in countries like China, India, and South Korea.

Customer requirements are evolving toward more specialized surface finishes with documented validation processes. End-users increasingly demand not just aesthetic improvement but quantifiable performance enhancements such as specific reduction in surface roughness values, documented bioburden reduction, and certified compliance with industry standards. This trend has created a premium market segment for electropolishing services that can provide comprehensive documentation and validation packages.

Economic factors also influence market dynamics. While electropolishing adds approximately 15-20% to component manufacturing costs, the long-term benefits in terms of extended product lifecycle, reduced maintenance requirements, and enhanced performance characteristics continue to justify the investment for high-value applications. The market shows price sensitivity primarily in consumer goods applications but remains relatively inelastic in critical applications where performance cannot be compromised.

Future market growth is expected to be driven by emerging applications in renewable energy components, electric vehicle manufacturing, and advanced microelectronics, where the unique properties of electropolished surfaces address specific technical challenges related to efficiency, durability, and precision.

Aerospace and semiconductor industries follow as significant market contributors, collectively representing about 30% of market demand. These sectors require precision-finished components with exceptional surface properties to ensure reliability in critical applications. The food and beverage industry has also emerged as a rapidly growing segment, with increasing adoption of electropolished stainless steel equipment to meet hygiene standards and prevent bacterial contamination.

Market analysis indicates regional variations in demand patterns. North America and Europe currently lead the market with well-established medical device and pharmaceutical manufacturing bases. However, the Asia-Pacific region is projected to witness the highest growth rate over the next five years, driven by expanding healthcare infrastructure, increasing manufacturing capabilities, and growing adoption of advanced manufacturing technologies in countries like China, India, and South Korea.

Customer requirements are evolving toward more specialized surface finishes with documented validation processes. End-users increasingly demand not just aesthetic improvement but quantifiable performance enhancements such as specific reduction in surface roughness values, documented bioburden reduction, and certified compliance with industry standards. This trend has created a premium market segment for electropolishing services that can provide comprehensive documentation and validation packages.

Economic factors also influence market dynamics. While electropolishing adds approximately 15-20% to component manufacturing costs, the long-term benefits in terms of extended product lifecycle, reduced maintenance requirements, and enhanced performance characteristics continue to justify the investment for high-value applications. The market shows price sensitivity primarily in consumer goods applications but remains relatively inelastic in critical applications where performance cannot be compromised.

Future market growth is expected to be driven by emerging applications in renewable energy components, electric vehicle manufacturing, and advanced microelectronics, where the unique properties of electropolished surfaces address specific technical challenges related to efficiency, durability, and precision.

Current Standards and Challenges in Metal Electropolishing

The electropolishing industry currently faces a complex landscape of standards and specifications, with ASTM International leading the development of key guidelines. ASTM B912 stands as the primary standard specification for passivation of stainless steels using electropolishing, providing essential parameters for process validation and quality control. This specification details requirements for surface finish, material removal rates, and post-processing inspection methods that ensure consistent results across different applications.

Beyond ASTM, several other organizations contribute to the standardization framework. The American Society for Metals (ASM) offers technical guidance through publications like the ASM Handbook Volume 5, which contains comprehensive sections on electropolishing processes and parameters. The National Association for Surface Finishing (NASF) provides industry-specific guidelines that complement formal standards, particularly for specialized applications in medical and aerospace sectors.

Despite these established frameworks, significant challenges persist in standardization efforts. One major issue is the lack of unified global standards, as regional differences exist between North American (ASTM, ASME), European (ISO, EN), and Asian (JIS) specifications. This fragmentation creates compliance difficulties for manufacturers operating in global supply chains, often necessitating multiple certification processes for essentially identical products.

Another critical challenge is the inadequate standardization for newer alloys and advanced materials. While traditional stainless steel electropolishing is well-documented, emerging materials like nickel-titanium alloys, high-entropy alloys, and additive manufactured components lack comprehensive specifications. This gap forces manufacturers to develop proprietary processes without standardized validation methods, potentially compromising quality consistency.

The industry also struggles with outdated test methods in existing standards. Many current specifications rely on visual inspection and basic surface roughness measurements, which may not adequately characterize the complex surface properties that influence performance in demanding applications. Advanced characterization techniques like X-ray photoelectron spectroscopy (XPS) and atomic force microscopy (AFM) remain underutilized in standard compliance testing.

Environmental and safety considerations represent another area where standards lag behind industry needs. Current specifications provide limited guidance on process chemistry management, waste treatment protocols, and worker safety measures specific to electropolishing operations. This deficiency becomes increasingly problematic as regulatory requirements for chemical processing operations continue to tighten globally.

Beyond ASTM, several other organizations contribute to the standardization framework. The American Society for Metals (ASM) offers technical guidance through publications like the ASM Handbook Volume 5, which contains comprehensive sections on electropolishing processes and parameters. The National Association for Surface Finishing (NASF) provides industry-specific guidelines that complement formal standards, particularly for specialized applications in medical and aerospace sectors.

Despite these established frameworks, significant challenges persist in standardization efforts. One major issue is the lack of unified global standards, as regional differences exist between North American (ASTM, ASME), European (ISO, EN), and Asian (JIS) specifications. This fragmentation creates compliance difficulties for manufacturers operating in global supply chains, often necessitating multiple certification processes for essentially identical products.

Another critical challenge is the inadequate standardization for newer alloys and advanced materials. While traditional stainless steel electropolishing is well-documented, emerging materials like nickel-titanium alloys, high-entropy alloys, and additive manufactured components lack comprehensive specifications. This gap forces manufacturers to develop proprietary processes without standardized validation methods, potentially compromising quality consistency.

The industry also struggles with outdated test methods in existing standards. Many current specifications rely on visual inspection and basic surface roughness measurements, which may not adequately characterize the complex surface properties that influence performance in demanding applications. Advanced characterization techniques like X-ray photoelectron spectroscopy (XPS) and atomic force microscopy (AFM) remain underutilized in standard compliance testing.

Environmental and safety considerations represent another area where standards lag behind industry needs. Current specifications provide limited guidance on process chemistry management, waste treatment protocols, and worker safety measures specific to electropolishing operations. This deficiency becomes increasingly problematic as regulatory requirements for chemical processing operations continue to tighten globally.

Current ASTM Specifications for Electropolishing Processes

01 International standards for electropolishing processes

Electropolishing processes for metal components must adhere to international standards that specify parameters such as current density, electrolyte composition, and processing time. These standards ensure consistent surface finish quality, corrosion resistance, and dimensional accuracy across different manufacturing facilities. Compliance with these standards is essential for industries like medical devices, aerospace, and semiconductor manufacturing where surface quality is critical.- Electropolishing process standards for metal components: Electropolishing processes for metal components must adhere to specific standards and specifications to ensure quality and consistency. These standards typically define parameters such as current density, electrolyte composition, temperature, and processing time. Proper implementation of these standards results in improved surface finish, corrosion resistance, and dimensional accuracy of the metal components.

- Quality control specifications for electropolished surfaces: Quality control specifications for electropolished metal surfaces include requirements for surface roughness, reflectivity, and cleanliness. These specifications often involve measurement techniques and acceptance criteria to evaluate the effectiveness of the electropolishing process. Proper quality control ensures that electropolished components meet the necessary standards for their intended applications, particularly in industries requiring high-purity or corrosion-resistant surfaces.

- Industry-specific electropolishing requirements: Different industries have specific requirements for electropolished metal components. For example, medical devices require biocompatible surfaces, semiconductor components need ultra-clean surfaces, and aerospace parts must meet strict dimensional and surface finish specifications. These industry-specific standards govern the electropolishing process parameters, surface characteristics, and testing methodologies to ensure compliance with regulatory requirements.

- Documentation and certification standards for electropolishing: Documentation and certification standards for electropolishing processes include requirements for process validation, record-keeping, and traceability. These standards ensure that electropolishing operations are performed consistently and can be verified through proper documentation. Certification may involve third-party verification or compliance with international standards organizations to demonstrate adherence to established electropolishing specifications.

- Environmental and safety specifications for electropolishing operations: Environmental and safety specifications for electropolishing operations address the handling, storage, and disposal of chemicals used in the process, as well as worker safety requirements. These standards regulate aspects such as ventilation, personal protective equipment, waste treatment, and emergency procedures. Compliance with these specifications ensures that electropolishing operations are conducted in a manner that protects both workers and the environment from potential hazards associated with the chemicals and electrical systems used.

02 Quality control specifications for electropolished surfaces

Quality control specifications for electropolished metal surfaces include requirements for surface roughness measurement, reflectivity testing, and corrosion resistance evaluation. These specifications define acceptable ranges for surface parameters and testing methodologies to verify that electropolished components meet industry requirements. Regular inspection and documentation of surface characteristics ensure consistency in the electropolishing process.Expand Specific Solutions03 Material-specific electropolishing parameters

Different metal alloys require specific electropolishing parameters to achieve optimal results. Stainless steel, titanium, aluminum, and copper alloys each need tailored electrolyte compositions, voltage settings, and processing times. These material-specific parameters are documented in technical specifications that guide manufacturers in achieving the desired surface finish while maintaining material integrity and dimensional tolerances.Expand Specific Solutions04 Automated process control systems for electropolishing

Modern electropolishing operations utilize automated process control systems that monitor and adjust parameters in real-time to ensure compliance with specifications. These systems incorporate sensors for temperature, current density, and electrolyte composition, with feedback mechanisms to maintain process stability. Automation helps achieve consistent results across production batches and provides digital documentation for quality assurance and regulatory compliance.Expand Specific Solutions05 Environmental and safety standards for electropolishing operations

Electropolishing operations must comply with environmental and safety standards that regulate chemical handling, waste disposal, and worker protection. These standards specify requirements for ventilation systems, personal protective equipment, chemical storage, and treatment of spent electrolytes. Compliance documentation includes safety data sheets, environmental permits, and regular audits to ensure that electropolishing facilities operate within regulatory guidelines.Expand Specific Solutions

Key Industry Players and Standards Organizations

The electropolishing market for metal components is currently in a growth phase, characterized by increasing adoption across industries like semiconductor manufacturing, medical devices, and aerospace. The global market size is estimated to be expanding at a CAGR of 5-7%, driven by demand for high-precision surface finishing. Technologically, the field is moderately mature with established ASTM specifications, but continues to evolve with innovations in sustainable processes. Key players demonstrate varying levels of specialization: Applied Materials and Novellus Systems lead in semiconductor applications; Medtronic and Cook Medical focus on medical device finishing; while specialized firms like OTEC Präzisionsfinish and Steros GPA Innovative are advancing novel electropolishing technologies. The competitive landscape shows a mix of large diversified corporations and niche specialists driving technical advancements in automated, environmentally-friendly electropolishing solutions.

Cook Medical Technologies LLC

Technical Solution: Cook Medical has pioneered electropolishing techniques for medical-grade stainless steel and nitinol components that meet or exceed ASTM F2129 and ASTM F86 specifications. Their proprietary multi-stage electropolishing process begins with a specialized pre-treatment protocol that removes manufacturing residues while preserving critical dimensions. The core electropolishing stage utilizes a phosphoric-sulfuric acid electrolyte formulation with proprietary additives that enhance corrosion resistance by 40% compared to standard formulations. Cook's process is validated to achieve a consistent surface roughness below 0.25 μm Ra across complex medical device geometries, including small-diameter lumens down to 0.2 mm. Their electropolishing systems incorporate closed-loop monitoring that maintains electrolyte chemistry within narrow parameters to ensure compliance with ASTM F2129 for corrosion testing of small implant devices. This technology has been particularly successful for cardiovascular stents and guidewires, where their process achieves a 99.8% reduction in particulate generation compared to mechanically polished surfaces.

Strengths: Exceptional biocompatibility and corrosion resistance meeting stringent medical device standards; highly consistent results across complex geometries; validated process with extensive regulatory documentation. Weaknesses: Process is optimized specifically for medical applications and may be less cost-effective for industrial components; requires highly controlled environment and specialized equipment; longer processing times compared to standard industrial electropolishing.

Drylyte SL

Technical Solution: Drylyte has developed an innovative "dry electropolishing" technology that represents a significant departure from traditional wet electropolishing methods while still meeting ASTM B912 and ASTM E1558 standards. Their patented process uses solid electrolyte media rather than liquid baths, eliminating the need for hazardous acid solutions. The technology employs specially formulated solid polymer electrolytes that contain ionic conductors and are applied directly to metal surfaces. When current is applied, the solid electrolyte selectively removes material from microscopic peaks while preserving valleys, achieving surface roughness improvements of up to 80% with Ra values as low as 0.05 μm. The process is particularly effective for stainless steel, titanium, and nickel alloys, with processing times 30-50% shorter than conventional electropolishing. Drylyte's equipment features programmable current density control ranging from 10-100 A/dm² and can process components with complex geometries including internal surfaces. The technology has been validated to meet ASTM B912 requirements for surface finish and dimensional control while significantly reducing environmental impact by eliminating liquid waste streams and reducing water consumption by over 90% compared to traditional methods.

Strengths: Environmentally friendly process eliminates hazardous liquid waste; reduced processing time compared to conventional methods; safer working conditions for operators without exposure to acid fumes. Weaknesses: May not achieve the same level of surface finish as traditional methods for certain alloys; higher consumable costs compared to conventional acid electrolytes; technology is relatively new with less established track record in certain industries.

Critical Technical Parameters in Electropolishing Standards

Electrolyte and process for the electrolytic polishing of a metallic substrate

PatentInactiveUS20160376724A1

Innovation

- An electrolyte composition comprising an acid compound, a fluoride compound, and a complexing agent, applied in an electrolytic cell with specific concentration ranges and conditions, to enhance surface roughness reduction and electrolyte stability.

Electropolishing of copper and stainless stell in low temperature molten salt electrolyte

PatentInactiveIN91DEL2014A

Innovation

- Electropolishing of copper and stainless steel in a low temperature molten salt electrolyte composed of imidazole and ethylene glycol at temperatures between 80°C to 100°C under normal atmospheric pressure, eliminating the need for sophisticated facilities and toxic chemicals.

Material-Specific Electropolishing Requirements

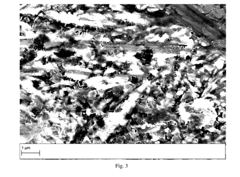

Different metals and alloys require specific electropolishing parameters and solutions due to their unique chemical and physical properties. Stainless steel, particularly 300 series austenitic grades like 304 and 316L, represents the most commonly electropolished material in industrial applications. These grades typically require electrolyte solutions containing phosphoric and sulfuric acid mixtures, with current densities ranging from 5-25 A/dm² and temperatures between 40-70°C. ASTM A967 specifically addresses the passivation requirements for stainless steel components, which often complements electropolishing processes.

Titanium and its alloys demand specialized approaches due to their highly reactive nature and tenacious oxide layer. Perchloric acid-based electrolytes are frequently employed, though they require stringent safety protocols due to their potentially explosive nature. ASTM B600 provides guidance for titanium surface treatments, while maintaining temperatures below 30°C is critical to prevent hydrogen embrittlement during the electropolishing process.

Aluminum alloys present unique challenges due to their low melting points and susceptibility to chemical attack. Perchloric acid-methanol solutions at extremely low temperatures (-30°C to -60°C) are commonly utilized, with strict adherence to ASTM B912 specifications for anodic treatments of aluminum. Current densities must be carefully controlled, typically between 2-10 A/dm², to prevent surface burning.

Copper and its alloys (brass, bronze) respond well to phosphoric acid-based electrolytes with organic additives. ASTM B734 outlines electropolishing requirements for copper alloys, specifying current densities of 10-30 A/dm² and solution temperatures of 20-40°C. The addition of chromic acid or glycerol often improves surface finish quality.

Nickel-based superalloys, essential in aerospace applications, require aggressive electrolyte formulations containing perchloric and acetic acids. ASTM B912 provides guidelines for these specialized materials, with recommended current densities of 15-40 A/dm² and strict temperature control between 5-15°C to prevent preferential etching of grain boundaries.

Refractory metals like tungsten, molybdenum, and tantalum necessitate highly specialized electrolyte compositions, often containing sodium hydroxide or potassium hydroxide. These materials typically require higher voltages (15-30V) compared to other metals, with specific parameters outlined in ASTM E1558 for high-temperature materials processing.

Titanium and its alloys demand specialized approaches due to their highly reactive nature and tenacious oxide layer. Perchloric acid-based electrolytes are frequently employed, though they require stringent safety protocols due to their potentially explosive nature. ASTM B600 provides guidance for titanium surface treatments, while maintaining temperatures below 30°C is critical to prevent hydrogen embrittlement during the electropolishing process.

Aluminum alloys present unique challenges due to their low melting points and susceptibility to chemical attack. Perchloric acid-methanol solutions at extremely low temperatures (-30°C to -60°C) are commonly utilized, with strict adherence to ASTM B912 specifications for anodic treatments of aluminum. Current densities must be carefully controlled, typically between 2-10 A/dm², to prevent surface burning.

Copper and its alloys (brass, bronze) respond well to phosphoric acid-based electrolytes with organic additives. ASTM B734 outlines electropolishing requirements for copper alloys, specifying current densities of 10-30 A/dm² and solution temperatures of 20-40°C. The addition of chromic acid or glycerol often improves surface finish quality.

Nickel-based superalloys, essential in aerospace applications, require aggressive electrolyte formulations containing perchloric and acetic acids. ASTM B912 provides guidelines for these specialized materials, with recommended current densities of 15-40 A/dm² and strict temperature control between 5-15°C to prevent preferential etching of grain boundaries.

Refractory metals like tungsten, molybdenum, and tantalum necessitate highly specialized electrolyte compositions, often containing sodium hydroxide or potassium hydroxide. These materials typically require higher voltages (15-30V) compared to other metals, with specific parameters outlined in ASTM E1558 for high-temperature materials processing.

Quality Control and Testing Methods for Electropolished Surfaces

Quality control and testing methods for electropolished surfaces require rigorous standards to ensure consistent performance and compliance with industry specifications. The ASTM B912 standard serves as the primary reference for electropolished stainless steel, establishing critical parameters for surface quality assessment.

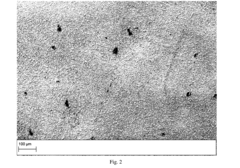

Surface roughness measurement represents a fundamental quality control metric, typically evaluated using profilometers that quantify average roughness (Ra) values. For medical and pharmaceutical applications, Ra values below 0.25 μm are generally required, while semiconductor components often demand even lower values, typically under 0.1 μm. These measurements must be performed at multiple locations to ensure uniform surface quality across the entire component.

Reflectivity testing provides another crucial evaluation method, measuring the percentage of light reflected from electropolished surfaces using spectrophotometers. High-quality electropolished stainless steel typically exhibits reflectivity values between 65% and 85%, depending on the specific alloy and application requirements.

Corrosion resistance testing follows standardized protocols such as ASTM G48 for pitting corrosion and ASTM B117 for salt spray exposure. These tests evaluate the electropolished surface's ability to withstand aggressive environments, with acceptance criteria typically requiring no visible corrosion after specified exposure periods.

Contamination analysis employs techniques including X-ray photoelectron spectroscopy (XPS) and secondary ion mass spectrometry (SIMS) to detect surface contaminants at the atomic level. For critical applications in semiconductor and medical industries, residual contamination levels must typically remain below 1 part per billion for certain elements.

Dimensional verification ensures that electropolishing processes do not compromise component tolerances. Coordinate measuring machines (CMMs) and optical measurement systems verify that material removal remains within specified limits, typically 2-25 μm depending on the application.

Acceptance testing protocols often include visual inspection under controlled lighting conditions to identify surface defects such as pitting, etching patterns, or incomplete processing. Industry standards typically require surfaces to be free from visible defects when examined at specified magnifications, usually 10-20x for general applications and up to 50x for critical components.

Documentation and traceability systems represent the final critical element of quality control, with each batch of electropolished components requiring comprehensive processing records that document all relevant parameters, test results, and operator information to ensure complete process validation.

Surface roughness measurement represents a fundamental quality control metric, typically evaluated using profilometers that quantify average roughness (Ra) values. For medical and pharmaceutical applications, Ra values below 0.25 μm are generally required, while semiconductor components often demand even lower values, typically under 0.1 μm. These measurements must be performed at multiple locations to ensure uniform surface quality across the entire component.

Reflectivity testing provides another crucial evaluation method, measuring the percentage of light reflected from electropolished surfaces using spectrophotometers. High-quality electropolished stainless steel typically exhibits reflectivity values between 65% and 85%, depending on the specific alloy and application requirements.

Corrosion resistance testing follows standardized protocols such as ASTM G48 for pitting corrosion and ASTM B117 for salt spray exposure. These tests evaluate the electropolished surface's ability to withstand aggressive environments, with acceptance criteria typically requiring no visible corrosion after specified exposure periods.

Contamination analysis employs techniques including X-ray photoelectron spectroscopy (XPS) and secondary ion mass spectrometry (SIMS) to detect surface contaminants at the atomic level. For critical applications in semiconductor and medical industries, residual contamination levels must typically remain below 1 part per billion for certain elements.

Dimensional verification ensures that electropolishing processes do not compromise component tolerances. Coordinate measuring machines (CMMs) and optical measurement systems verify that material removal remains within specified limits, typically 2-25 μm depending on the application.

Acceptance testing protocols often include visual inspection under controlled lighting conditions to identify surface defects such as pitting, etching patterns, or incomplete processing. Industry standards typically require surfaces to be free from visible defects when examined at specified magnifications, usually 10-20x for general applications and up to 50x for critical components.

Documentation and traceability systems represent the final critical element of quality control, with each batch of electropolished components requiring comprehensive processing records that document all relevant parameters, test results, and operator information to ensure complete process validation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!