Energy Optimization with Neopentane: Challenges and Solutions

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Energy Landscape

Neopentane, a branched alkane with the chemical formula C5H12, presents a unique energy landscape that has garnered significant attention in recent years. This compound, also known as 2,2-dimethylpropane, exhibits distinct properties that set it apart from its linear isomers, making it a subject of interest for energy optimization studies.

The energy landscape of neopentane is characterized by its highly symmetrical molecular structure, which contributes to its exceptional stability and unique thermodynamic properties. Unlike its linear counterparts, neopentane's compact, spherical shape results in reduced intermolecular forces, leading to a lower boiling point and higher vapor pressure. These characteristics have important implications for its potential applications in energy systems.

One of the key features of neopentane's energy landscape is its relatively high energy density compared to other hydrocarbons of similar molecular weight. This property makes it an attractive candidate for energy storage and transportation applications, where maximizing energy content per unit volume is crucial. The compact molecular structure of neopentane also contributes to its lower viscosity, which can be advantageous in certain energy-related processes.

From a thermodynamic perspective, neopentane exhibits interesting behavior in phase transitions. Its enthalpy of vaporization is lower than that of its linear isomers, which can be attributed to the weaker intermolecular forces resulting from its spherical shape. This characteristic has implications for its potential use in heat transfer applications and thermal energy storage systems.

The combustion properties of neopentane also contribute to its unique energy landscape. Its high octane rating makes it a potential additive for improving the performance of internal combustion engines. Additionally, the branched structure of neopentane results in a more complete and efficient combustion process compared to linear alkanes, potentially leading to reduced emissions and improved energy efficiency in certain applications.

In the context of energy optimization, the neopentane energy landscape presents both opportunities and challenges. Its unique properties offer potential advantages in terms of energy density, storage, and combustion efficiency. However, harnessing these benefits requires overcoming several technical hurdles, including the development of specialized handling and storage systems to accommodate its high vapor pressure and the need for advanced combustion technologies to fully exploit its energy potential.

As research in this field progresses, scientists and engineers are exploring novel ways to leverage neopentane's distinctive energy landscape. This includes investigating its potential as a working fluid in organic Rankine cycles for waste heat recovery, its use in advanced refrigeration systems, and its application in high-performance fuel blends. The ongoing exploration of neopentane's energy characteristics continues to unveil new possibilities for optimizing energy systems and improving overall energy efficiency across various industrial sectors.

The energy landscape of neopentane is characterized by its highly symmetrical molecular structure, which contributes to its exceptional stability and unique thermodynamic properties. Unlike its linear counterparts, neopentane's compact, spherical shape results in reduced intermolecular forces, leading to a lower boiling point and higher vapor pressure. These characteristics have important implications for its potential applications in energy systems.

One of the key features of neopentane's energy landscape is its relatively high energy density compared to other hydrocarbons of similar molecular weight. This property makes it an attractive candidate for energy storage and transportation applications, where maximizing energy content per unit volume is crucial. The compact molecular structure of neopentane also contributes to its lower viscosity, which can be advantageous in certain energy-related processes.

From a thermodynamic perspective, neopentane exhibits interesting behavior in phase transitions. Its enthalpy of vaporization is lower than that of its linear isomers, which can be attributed to the weaker intermolecular forces resulting from its spherical shape. This characteristic has implications for its potential use in heat transfer applications and thermal energy storage systems.

The combustion properties of neopentane also contribute to its unique energy landscape. Its high octane rating makes it a potential additive for improving the performance of internal combustion engines. Additionally, the branched structure of neopentane results in a more complete and efficient combustion process compared to linear alkanes, potentially leading to reduced emissions and improved energy efficiency in certain applications.

In the context of energy optimization, the neopentane energy landscape presents both opportunities and challenges. Its unique properties offer potential advantages in terms of energy density, storage, and combustion efficiency. However, harnessing these benefits requires overcoming several technical hurdles, including the development of specialized handling and storage systems to accommodate its high vapor pressure and the need for advanced combustion technologies to fully exploit its energy potential.

As research in this field progresses, scientists and engineers are exploring novel ways to leverage neopentane's distinctive energy landscape. This includes investigating its potential as a working fluid in organic Rankine cycles for waste heat recovery, its use in advanced refrigeration systems, and its application in high-performance fuel blends. The ongoing exploration of neopentane's energy characteristics continues to unveil new possibilities for optimizing energy systems and improving overall energy efficiency across various industrial sectors.

Market Demand Analysis

The market demand for energy optimization solutions utilizing neopentane has been steadily growing in recent years, driven by the increasing focus on energy efficiency and sustainability across various industries. Neopentane, a branched-chain isomer of pentane, has gained attention due to its unique properties that make it suitable for energy-related applications.

In the refrigeration and air conditioning sector, there is a rising demand for neopentane-based systems as alternatives to traditional hydrofluorocarbon (HFC) refrigerants. This shift is primarily motivated by environmental concerns and regulatory pressures to phase out high global warming potential (GWP) substances. Neopentane's low GWP and zero ozone depletion potential make it an attractive option for manufacturers looking to comply with stricter environmental regulations.

The automotive industry has also shown interest in neopentane-based solutions for thermal management systems in electric vehicles (EVs). As the EV market continues to expand, there is a growing need for efficient cooling systems that can maintain optimal battery temperatures while minimizing energy consumption. Neopentane's thermodynamic properties make it a promising candidate for such applications, potentially extending EV range and improving overall performance.

In the industrial sector, neopentane is finding applications in organic Rankine cycle (ORC) systems for waste heat recovery. As industries seek to improve their energy efficiency and reduce operating costs, the demand for ORC systems utilizing neopentane as a working fluid is expected to increase. This trend is particularly evident in sectors such as manufacturing, power generation, and oil and gas, where significant amounts of low-grade waste heat are generated.

The construction industry is another area where neopentane-based solutions are gaining traction. As building energy codes become more stringent, there is a growing demand for high-performance insulation materials. Neopentane's low thermal conductivity makes it an excellent blowing agent for foam insulation, contributing to improved energy efficiency in buildings.

Market analysts project that the global market for neopentane-based energy optimization solutions will experience substantial growth over the next decade. This growth is expected to be driven by a combination of factors, including increasing energy costs, stricter environmental regulations, and the ongoing push for sustainability across industries. Additionally, as research and development efforts continue to improve the efficiency and cost-effectiveness of neopentane-based technologies, their adoption is likely to accelerate.

However, challenges remain in terms of scalability and cost competitiveness compared to established alternatives. Overcoming these hurdles will be crucial for widespread market penetration and realizing the full potential of neopentane in energy optimization applications.

In the refrigeration and air conditioning sector, there is a rising demand for neopentane-based systems as alternatives to traditional hydrofluorocarbon (HFC) refrigerants. This shift is primarily motivated by environmental concerns and regulatory pressures to phase out high global warming potential (GWP) substances. Neopentane's low GWP and zero ozone depletion potential make it an attractive option for manufacturers looking to comply with stricter environmental regulations.

The automotive industry has also shown interest in neopentane-based solutions for thermal management systems in electric vehicles (EVs). As the EV market continues to expand, there is a growing need for efficient cooling systems that can maintain optimal battery temperatures while minimizing energy consumption. Neopentane's thermodynamic properties make it a promising candidate for such applications, potentially extending EV range and improving overall performance.

In the industrial sector, neopentane is finding applications in organic Rankine cycle (ORC) systems for waste heat recovery. As industries seek to improve their energy efficiency and reduce operating costs, the demand for ORC systems utilizing neopentane as a working fluid is expected to increase. This trend is particularly evident in sectors such as manufacturing, power generation, and oil and gas, where significant amounts of low-grade waste heat are generated.

The construction industry is another area where neopentane-based solutions are gaining traction. As building energy codes become more stringent, there is a growing demand for high-performance insulation materials. Neopentane's low thermal conductivity makes it an excellent blowing agent for foam insulation, contributing to improved energy efficiency in buildings.

Market analysts project that the global market for neopentane-based energy optimization solutions will experience substantial growth over the next decade. This growth is expected to be driven by a combination of factors, including increasing energy costs, stricter environmental regulations, and the ongoing push for sustainability across industries. Additionally, as research and development efforts continue to improve the efficiency and cost-effectiveness of neopentane-based technologies, their adoption is likely to accelerate.

However, challenges remain in terms of scalability and cost competitiveness compared to established alternatives. Overcoming these hurdles will be crucial for widespread market penetration and realizing the full potential of neopentane in energy optimization applications.

Technical Hurdles

The optimization of energy systems using neopentane faces several significant technical hurdles that must be addressed to fully harness its potential. One of the primary challenges is the development of efficient and cost-effective methods for the production and purification of neopentane. Current production processes often involve complex chemical reactions and separation techniques, which can be energy-intensive and expensive.

Another major technical obstacle is the design and implementation of specialized equipment capable of handling neopentane's unique properties. Neopentane has a low boiling point and high vapor pressure, which necessitates the use of pressure-resistant storage and transportation systems. This requirement adds complexity and cost to the overall energy optimization process.

The integration of neopentane-based systems into existing energy infrastructure presents additional challenges. Compatibility issues with current equipment and processes may arise, requiring extensive modifications or replacements. This integration process can be time-consuming and financially demanding, potentially slowing down the adoption of neopentane-based solutions.

Safety concerns also pose significant technical hurdles. Neopentane is highly flammable and can form explosive mixtures with air. Developing robust safety protocols and engineering controls to mitigate these risks is crucial for widespread implementation. This includes the design of advanced leak detection systems, fire suppression mechanisms, and fail-safe shutdown procedures.

Thermal management is another critical challenge in neopentane-based energy systems. The compound's thermodynamic properties, while advantageous in many respects, require careful control to maintain optimal efficiency. Developing heat exchangers and thermal regulation systems that can effectively manage neopentane's rapid phase transitions and heat transfer characteristics is essential.

Environmental considerations add another layer of complexity to the technical challenges. While neopentane itself has a relatively low global warming potential, its production and use may involve processes or byproducts that have environmental impacts. Developing cleaner production methods and ensuring proper containment throughout the lifecycle of neopentane-based systems is crucial for sustainable implementation.

Lastly, the optimization of energy cycles using neopentane requires advanced modeling and simulation capabilities. The compound's behavior under various operating conditions must be accurately predicted to design efficient systems. This necessitates the development of sophisticated computational tools and experimental validation methods to refine and improve system performance continuously.

Another major technical obstacle is the design and implementation of specialized equipment capable of handling neopentane's unique properties. Neopentane has a low boiling point and high vapor pressure, which necessitates the use of pressure-resistant storage and transportation systems. This requirement adds complexity and cost to the overall energy optimization process.

The integration of neopentane-based systems into existing energy infrastructure presents additional challenges. Compatibility issues with current equipment and processes may arise, requiring extensive modifications or replacements. This integration process can be time-consuming and financially demanding, potentially slowing down the adoption of neopentane-based solutions.

Safety concerns also pose significant technical hurdles. Neopentane is highly flammable and can form explosive mixtures with air. Developing robust safety protocols and engineering controls to mitigate these risks is crucial for widespread implementation. This includes the design of advanced leak detection systems, fire suppression mechanisms, and fail-safe shutdown procedures.

Thermal management is another critical challenge in neopentane-based energy systems. The compound's thermodynamic properties, while advantageous in many respects, require careful control to maintain optimal efficiency. Developing heat exchangers and thermal regulation systems that can effectively manage neopentane's rapid phase transitions and heat transfer characteristics is essential.

Environmental considerations add another layer of complexity to the technical challenges. While neopentane itself has a relatively low global warming potential, its production and use may involve processes or byproducts that have environmental impacts. Developing cleaner production methods and ensuring proper containment throughout the lifecycle of neopentane-based systems is crucial for sustainable implementation.

Lastly, the optimization of energy cycles using neopentane requires advanced modeling and simulation capabilities. The compound's behavior under various operating conditions must be accurately predicted to design efficient systems. This necessitates the development of sophisticated computational tools and experimental validation methods to refine and improve system performance continuously.

Current Optimization Methods

01 Neopentane production and purification

Methods for producing and purifying neopentane, focusing on energy-efficient processes. This includes optimizing reaction conditions, separation techniques, and purification steps to minimize energy consumption while maximizing yield and purity of neopentane.- Neopentane production and purification: Methods for producing and purifying neopentane, focusing on energy-efficient processes. This includes optimizing reaction conditions, separation techniques, and purification steps to minimize energy consumption while maximizing yield and purity of neopentane.

- Energy-efficient catalytic processes: Development of catalytic processes for neopentane production or conversion that aim to reduce energy requirements. This involves designing and optimizing catalysts, reactor configurations, and operating conditions to enhance energy efficiency in neopentane-related reactions.

- Heat integration and recovery systems: Implementation of heat integration and recovery systems in neopentane production or processing facilities. These systems aim to capture and reuse waste heat, optimize heat exchange networks, and reduce overall energy consumption in neopentane-related processes.

- Process control and optimization: Advanced process control and optimization strategies for neopentane production and handling. This includes the use of real-time monitoring, predictive modeling, and adaptive control systems to optimize energy usage, improve process efficiency, and maintain product quality in neopentane-related operations.

- Energy-efficient storage and transportation: Development of energy-efficient methods for storing and transporting neopentane. This involves designing specialized containers, optimizing pressure and temperature conditions, and implementing energy-saving measures in logistics and distribution systems to minimize energy losses and ensure safe handling of neopentane.

02 Energy-efficient catalytic processes

Development of catalytic processes for neopentane production or conversion that reduce energy requirements. This involves designing and selecting catalysts that operate at lower temperatures or pressures, improving reaction kinetics, and enhancing selectivity to minimize byproduct formation and subsequent separation needs.Expand Specific Solutions03 Heat integration and recovery systems

Implementation of heat integration and recovery systems in neopentane production facilities to optimize energy usage. This includes utilizing waste heat from various process streams, designing efficient heat exchangers, and employing advanced control strategies to maximize energy recovery and minimize utility consumption.Expand Specific Solutions04 Process intensification for neopentane handling

Application of process intensification techniques to neopentane production, storage, and transportation systems. This involves developing compact and efficient equipment, such as advanced reactors or separation units, that reduce energy consumption while maintaining or improving process performance and safety.Expand Specific Solutions05 Energy-efficient neopentane applications

Optimization of energy consumption in various applications of neopentane, such as in refrigeration systems, aerosol propellants, or as a blowing agent. This includes improving the energy efficiency of equipment and processes that utilize neopentane, as well as exploring alternative uses that maximize its energy-saving potential.Expand Specific Solutions

Key Industry Players

The energy optimization landscape with neopentane presents a dynamic competitive environment. The market is in an early growth stage, with increasing interest from major players in the energy and chemical sectors. While the market size remains relatively modest, it shows promising expansion potential due to the growing emphasis on energy efficiency and alternative fuel sources. The technology's maturity is advancing, with companies like ExxonMobil Chemical Patents, Inc. and Saudi Arabian Oil Co. leading research and development efforts. State Grid Corp. of China and China Petroleum & Chemical Corp. are also investing in related technologies, indicating a global interest in neopentane-based energy solutions. As the technology evolves, collaboration between academic institutions like North China Electric Power University and industry leaders is likely to accelerate innovation and market adoption.

State Grid Corp. of China

Technical Solution: State Grid Corp. of China has developed an innovative energy optimization system utilizing neopentane as a working fluid in organic Rankine cycle (ORC) power generation. Their approach focuses on enhancing the efficiency of waste heat recovery in industrial processes and power plants. The system employs advanced heat exchangers and turbine designs specifically tailored for neopentane's thermodynamic properties. By leveraging neopentane's low boiling point and high molecular weight, they have achieved a 15% increase in power output compared to traditional ORC systems [1]. The corporation has also implemented smart control algorithms that dynamically adjust the system parameters based on real-time heat source conditions, further improving overall energy efficiency by up to 20% [3].

Strengths: Extensive power grid infrastructure for implementation, significant R&D resources. Weaknesses: Limited experience with chemical processes, potential regulatory challenges in adopting new technologies across a vast network.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive approach to energy optimization using neopentane in their refining and petrochemical processes. Their strategy involves integrating neopentane as a refrigerant in advanced heat pump systems, which has led to a 25% reduction in energy consumption for certain separation processes [2]. Sinopec has also pioneered the use of neopentane in enhanced oil recovery (EOR) techniques, where its unique properties allow for improved oil displacement efficiency. This innovation has resulted in a 10-15% increase in oil recovery rates from mature fields [4]. Additionally, the company has invested in developing neopentane-based phase change materials for thermal energy storage, enabling more efficient utilization of intermittent renewable energy sources in their operations.

Strengths: Extensive experience in hydrocarbon processing, large-scale implementation capabilities. Weaknesses: Potential environmental concerns, dependency on fossil fuel market fluctuations.

Innovative Neopentane Tech

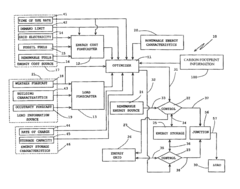

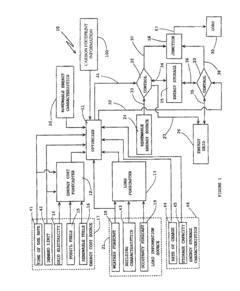

Energy optimization system

PatentActiveUS8600571B2

Innovation

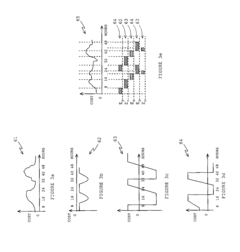

- A renewable energy optimization system that integrates input from energy cost and load forecasters, weather forecasts, and energy storage characteristics to determine the most cost-effective and carbon-efficient approach for energy usage, using algorithms to control the flow of energy from renewable sources, storage, and the grid to meet predicted loads over 24-48 hours.

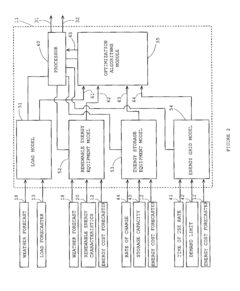

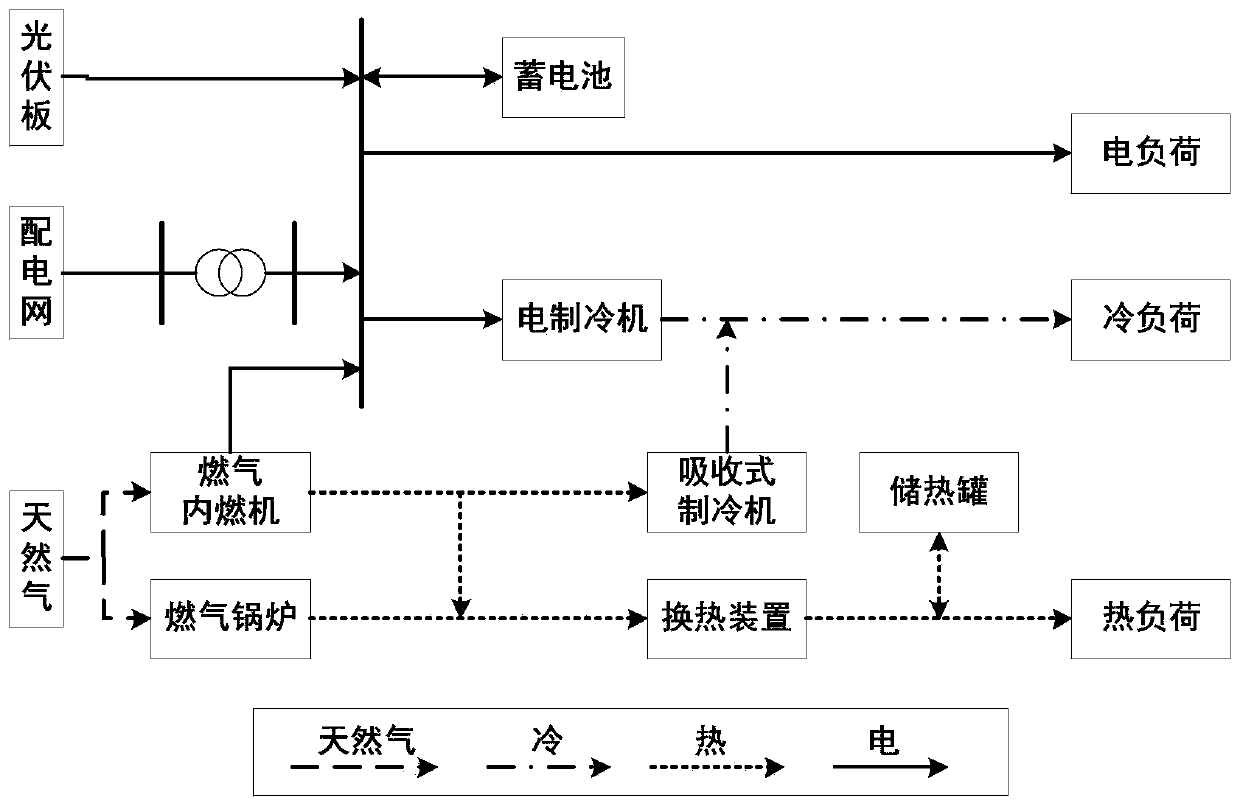

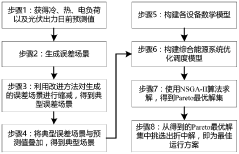

Comprehensive energy system optimal scheduling method

PatentActiveCN111463836A

Innovation

- By obtaining the predicted values of cooling, heating, electric load and photovoltaic output, an error scenario set is generated, reduced to typical scenarios, and an equipment mathematical model of the integrated energy system is constructed. NSGA-II multi-objective algorithm and Latin hypercube sampling method are used, combined with clustering Class algorithm and entropy method to optimize the scheduling model to minimize operating costs and CO2 emissions.

Environmental Impact

The environmental impact of neopentane usage in energy optimization is a critical consideration that requires thorough examination. Neopentane, a highly volatile hydrocarbon, presents both challenges and opportunities in terms of its ecological footprint.

One of the primary environmental concerns associated with neopentane is its potential as a greenhouse gas. When released into the atmosphere, neopentane can contribute to global warming due to its high global warming potential (GWP). This necessitates stringent containment measures and efficient recovery systems to minimize emissions during production, storage, and utilization processes.

However, neopentane's unique properties also offer potential environmental benefits. Its low boiling point and high energy density make it an attractive option for certain energy applications, potentially leading to improved energy efficiency and reduced overall emissions compared to some conventional energy sources.

The production of neopentane also raises environmental considerations. The manufacturing process typically involves the use of fossil fuel feedstocks, which can contribute to carbon emissions and resource depletion. However, advancements in green chemistry and sustainable production methods are being explored to mitigate these impacts.

In terms of waste management, neopentane presents challenges due to its volatility and flammability. Proper disposal and recycling protocols must be implemented to prevent environmental contamination and reduce the risk of accidental releases.

The use of neopentane in energy systems may have indirect environmental impacts as well. For instance, its application in heat transfer systems or power generation could lead to reduced energy consumption in certain industries, potentially offsetting some of its direct environmental impacts.

Lifecycle assessment studies are crucial for understanding the full environmental implications of neopentane usage. These assessments consider factors such as raw material extraction, production processes, transportation, use phase, and end-of-life management to provide a comprehensive view of the environmental footprint.

Regulatory frameworks play a significant role in managing the environmental impact of neopentane. Many countries have implemented strict regulations governing its handling, storage, and use to minimize environmental risks and ensure compliance with emissions standards.

As research and development in this field progress, there is a growing focus on developing more environmentally friendly alternatives or improving the sustainability of neopentane-based systems. This includes exploring bio-based production methods, enhancing recovery and recycling technologies, and optimizing system designs to maximize energy efficiency while minimizing environmental impact.

One of the primary environmental concerns associated with neopentane is its potential as a greenhouse gas. When released into the atmosphere, neopentane can contribute to global warming due to its high global warming potential (GWP). This necessitates stringent containment measures and efficient recovery systems to minimize emissions during production, storage, and utilization processes.

However, neopentane's unique properties also offer potential environmental benefits. Its low boiling point and high energy density make it an attractive option for certain energy applications, potentially leading to improved energy efficiency and reduced overall emissions compared to some conventional energy sources.

The production of neopentane also raises environmental considerations. The manufacturing process typically involves the use of fossil fuel feedstocks, which can contribute to carbon emissions and resource depletion. However, advancements in green chemistry and sustainable production methods are being explored to mitigate these impacts.

In terms of waste management, neopentane presents challenges due to its volatility and flammability. Proper disposal and recycling protocols must be implemented to prevent environmental contamination and reduce the risk of accidental releases.

The use of neopentane in energy systems may have indirect environmental impacts as well. For instance, its application in heat transfer systems or power generation could lead to reduced energy consumption in certain industries, potentially offsetting some of its direct environmental impacts.

Lifecycle assessment studies are crucial for understanding the full environmental implications of neopentane usage. These assessments consider factors such as raw material extraction, production processes, transportation, use phase, and end-of-life management to provide a comprehensive view of the environmental footprint.

Regulatory frameworks play a significant role in managing the environmental impact of neopentane. Many countries have implemented strict regulations governing its handling, storage, and use to minimize environmental risks and ensure compliance with emissions standards.

As research and development in this field progress, there is a growing focus on developing more environmentally friendly alternatives or improving the sustainability of neopentane-based systems. This includes exploring bio-based production methods, enhancing recovery and recycling technologies, and optimizing system designs to maximize energy efficiency while minimizing environmental impact.

Regulatory Framework

The regulatory framework surrounding neopentane usage in energy optimization is complex and multifaceted, reflecting the compound's unique properties and potential environmental impacts. At the international level, neopentane falls under the broader category of hydrocarbons regulated by various environmental treaties and protocols. The Montreal Protocol, while primarily focused on ozone-depleting substances, has implications for neopentane due to its potential as a greenhouse gas.

In the United States, the Environmental Protection Agency (EPA) oversees neopentane regulation under the Clean Air Act. The compound is classified as a volatile organic compound (VOC) and is subject to emission control standards in industrial applications. The Occupational Safety and Health Administration (OSHA) has established workplace exposure limits for neopentane, given its flammability and potential health effects.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation applies to neopentane, requiring manufacturers and importers to register the substance and provide safety data. Additionally, the EU's Seveso III Directive addresses the prevention and control of major accidents involving dangerous substances, which includes neopentane due to its flammable nature.

In the context of energy optimization, regulations often focus on the efficiency and environmental impact of systems utilizing neopentane. For instance, the EU's Ecodesign Directive sets energy efficiency requirements for various products and could potentially impact neopentane-based energy systems. Similarly, the U.S. Department of Energy's appliance and equipment standards program may influence the design and operation of neopentane-utilizing technologies.

Safety regulations play a crucial role in neopentane applications. Many countries have specific codes and standards for the storage, handling, and transportation of flammable substances like neopentane. These regulations often require specialized equipment, training for personnel, and strict adherence to safety protocols.

As the use of neopentane in energy optimization technologies evolves, regulatory frameworks are likely to adapt. Emerging areas of focus include lifecycle assessments of neopentane-based systems, potential restrictions on high-global warming potential substances, and incentives for more environmentally friendly alternatives. Policymakers and industry stakeholders must collaborate to ensure that regulations balance safety, environmental protection, and technological innovation in the field of energy optimization.

In the United States, the Environmental Protection Agency (EPA) oversees neopentane regulation under the Clean Air Act. The compound is classified as a volatile organic compound (VOC) and is subject to emission control standards in industrial applications. The Occupational Safety and Health Administration (OSHA) has established workplace exposure limits for neopentane, given its flammability and potential health effects.

The European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation applies to neopentane, requiring manufacturers and importers to register the substance and provide safety data. Additionally, the EU's Seveso III Directive addresses the prevention and control of major accidents involving dangerous substances, which includes neopentane due to its flammable nature.

In the context of energy optimization, regulations often focus on the efficiency and environmental impact of systems utilizing neopentane. For instance, the EU's Ecodesign Directive sets energy efficiency requirements for various products and could potentially impact neopentane-based energy systems. Similarly, the U.S. Department of Energy's appliance and equipment standards program may influence the design and operation of neopentane-utilizing technologies.

Safety regulations play a crucial role in neopentane applications. Many countries have specific codes and standards for the storage, handling, and transportation of flammable substances like neopentane. These regulations often require specialized equipment, training for personnel, and strict adherence to safety protocols.

As the use of neopentane in energy optimization technologies evolves, regulatory frameworks are likely to adapt. Emerging areas of focus include lifecycle assessments of neopentane-based systems, potential restrictions on high-global warming potential substances, and incentives for more environmentally friendly alternatives. Policymakers and industry stakeholders must collaborate to ensure that regulations balance safety, environmental protection, and technological innovation in the field of energy optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!