Neopentane in Fluid Dynamics: Beyond Basic Applications

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Fluid Dynamics Background and Objectives

Neopentane, a branched alkane with the molecular formula C5H12, has emerged as a subject of significant interest in the field of fluid dynamics. This compound's unique molecular structure, characterized by a central carbon atom bonded to four methyl groups, imparts distinctive properties that set it apart from its linear isomers. The study of neopentane in fluid dynamics has evolved from basic applications to more complex and nuanced investigations, reflecting the growing importance of understanding the behavior of specialized fluids in various industrial and scientific contexts.

The historical trajectory of neopentane research in fluid dynamics can be traced back to fundamental studies of hydrocarbon properties. Initially, the focus was primarily on its thermodynamic characteristics and basic flow behaviors. However, as industrial applications for specialized hydrocarbons expanded, so did the need for a more comprehensive understanding of neopentane's fluid dynamic properties.

In recent years, the objectives of neopentane fluid dynamics research have broadened significantly. One key aim is to elucidate the compound's behavior under extreme conditions, such as high pressures and temperatures, which is crucial for its application in advanced heat transfer systems and specialized lubricants. Another important goal is to understand the interactions between neopentane and other substances in multi-component fluid systems, a critical aspect for its use in refrigeration cycles and as a blowing agent in foam production.

The advancement of computational fluid dynamics (CFD) has played a pivotal role in deepening our understanding of neopentane's behavior. These sophisticated simulation techniques have enabled researchers to model complex flow scenarios and predict neopentane's performance in various applications with unprecedented accuracy. This has, in turn, driven the development of more efficient and effective industrial processes involving neopentane.

As we look to the future, the objectives of neopentane fluid dynamics research are likely to expand further. There is growing interest in exploring its potential in emerging fields such as microfluidics and nanofluidics, where the unique properties of neopentane could offer novel solutions. Additionally, the environmental impact of neopentane use is becoming an increasingly important consideration, prompting research into more sustainable applications and potential alternatives.

The evolving landscape of neopentane fluid dynamics research reflects broader trends in scientific inquiry, where the boundaries between traditional disciplines are becoming increasingly blurred. This interdisciplinary approach, combining elements of chemistry, physics, and engineering, is essential for addressing the complex challenges associated with advanced fluid applications. As such, the study of neopentane in fluid dynamics serves as a microcosm of the broader scientific endeavor to push the boundaries of knowledge and application in the pursuit of technological advancement.

The historical trajectory of neopentane research in fluid dynamics can be traced back to fundamental studies of hydrocarbon properties. Initially, the focus was primarily on its thermodynamic characteristics and basic flow behaviors. However, as industrial applications for specialized hydrocarbons expanded, so did the need for a more comprehensive understanding of neopentane's fluid dynamic properties.

In recent years, the objectives of neopentane fluid dynamics research have broadened significantly. One key aim is to elucidate the compound's behavior under extreme conditions, such as high pressures and temperatures, which is crucial for its application in advanced heat transfer systems and specialized lubricants. Another important goal is to understand the interactions between neopentane and other substances in multi-component fluid systems, a critical aspect for its use in refrigeration cycles and as a blowing agent in foam production.

The advancement of computational fluid dynamics (CFD) has played a pivotal role in deepening our understanding of neopentane's behavior. These sophisticated simulation techniques have enabled researchers to model complex flow scenarios and predict neopentane's performance in various applications with unprecedented accuracy. This has, in turn, driven the development of more efficient and effective industrial processes involving neopentane.

As we look to the future, the objectives of neopentane fluid dynamics research are likely to expand further. There is growing interest in exploring its potential in emerging fields such as microfluidics and nanofluidics, where the unique properties of neopentane could offer novel solutions. Additionally, the environmental impact of neopentane use is becoming an increasingly important consideration, prompting research into more sustainable applications and potential alternatives.

The evolving landscape of neopentane fluid dynamics research reflects broader trends in scientific inquiry, where the boundaries between traditional disciplines are becoming increasingly blurred. This interdisciplinary approach, combining elements of chemistry, physics, and engineering, is essential for addressing the complex challenges associated with advanced fluid applications. As such, the study of neopentane in fluid dynamics serves as a microcosm of the broader scientific endeavor to push the boundaries of knowledge and application in the pursuit of technological advancement.

Market Demand Analysis for Neopentane Applications

The market demand for neopentane applications in fluid dynamics has been steadily growing, driven by its unique properties and versatile applications across various industries. Neopentane, a branched alkane with the chemical formula C5H12, exhibits exceptional characteristics that make it valuable in advanced fluid dynamics applications beyond its basic uses.

In the automotive sector, neopentane has gained traction as a potential alternative refrigerant in air conditioning systems. Its low global warming potential and favorable thermodynamic properties position it as a promising substitute for traditional hydrofluorocarbon (HFC) refrigerants. The automotive industry's shift towards more environmentally friendly solutions has created a significant market opportunity for neopentane-based cooling systems.

The aerospace industry has also shown increasing interest in neopentane for its potential in thermal management systems. As aircraft designs become more complex and energy-efficient, the demand for advanced cooling solutions has risen. Neopentane's low boiling point and high heat capacity make it an attractive option for managing heat in critical aerospace components, potentially leading to improved fuel efficiency and overall performance.

In the electronics sector, the miniaturization of devices and the increasing power density of processors have created a need for more effective cooling solutions. Neopentane's properties make it suitable for use in phase-change cooling systems, addressing the thermal challenges faced by high-performance computing and data centers. This application area represents a growing market segment as the demand for more powerful and compact electronic devices continues to rise.

The energy sector, particularly in geothermal power plants, has identified neopentane as a potential working fluid in organic Rankine cycle (ORC) systems. Its low critical temperature and pressure, combined with good thermal stability, make it an efficient choice for converting low-grade heat into electricity. As the push for renewable energy sources intensifies, the demand for neopentane in geothermal applications is expected to grow.

Furthermore, the chemical industry has shown interest in neopentane as a blowing agent for polymer foams, replacing some of the more environmentally harmful alternatives. This application aligns with the global trend towards sustainable and eco-friendly manufacturing processes, potentially opening up new market opportunities in construction and insulation materials.

While the market demand for neopentane in advanced fluid dynamics applications is promising, it is important to note that regulatory frameworks and environmental policies play a crucial role in shaping its adoption. The ongoing phase-out of high global warming potential substances under international agreements like the Kigali Amendment to the Montreal Protocol creates a favorable environment for neopentane's market growth in certain applications.

In the automotive sector, neopentane has gained traction as a potential alternative refrigerant in air conditioning systems. Its low global warming potential and favorable thermodynamic properties position it as a promising substitute for traditional hydrofluorocarbon (HFC) refrigerants. The automotive industry's shift towards more environmentally friendly solutions has created a significant market opportunity for neopentane-based cooling systems.

The aerospace industry has also shown increasing interest in neopentane for its potential in thermal management systems. As aircraft designs become more complex and energy-efficient, the demand for advanced cooling solutions has risen. Neopentane's low boiling point and high heat capacity make it an attractive option for managing heat in critical aerospace components, potentially leading to improved fuel efficiency and overall performance.

In the electronics sector, the miniaturization of devices and the increasing power density of processors have created a need for more effective cooling solutions. Neopentane's properties make it suitable for use in phase-change cooling systems, addressing the thermal challenges faced by high-performance computing and data centers. This application area represents a growing market segment as the demand for more powerful and compact electronic devices continues to rise.

The energy sector, particularly in geothermal power plants, has identified neopentane as a potential working fluid in organic Rankine cycle (ORC) systems. Its low critical temperature and pressure, combined with good thermal stability, make it an efficient choice for converting low-grade heat into electricity. As the push for renewable energy sources intensifies, the demand for neopentane in geothermal applications is expected to grow.

Furthermore, the chemical industry has shown interest in neopentane as a blowing agent for polymer foams, replacing some of the more environmentally harmful alternatives. This application aligns with the global trend towards sustainable and eco-friendly manufacturing processes, potentially opening up new market opportunities in construction and insulation materials.

While the market demand for neopentane in advanced fluid dynamics applications is promising, it is important to note that regulatory frameworks and environmental policies play a crucial role in shaping its adoption. The ongoing phase-out of high global warming potential substances under international agreements like the Kigali Amendment to the Montreal Protocol creates a favorable environment for neopentane's market growth in certain applications.

Current State and Challenges in Neopentane Fluid Dynamics

The current state of neopentane in fluid dynamics reveals a complex landscape of advancements and challenges. Neopentane, a branched alkane with unique properties, has garnered increasing attention in various fluid dynamics applications beyond its traditional uses. Recent research has focused on leveraging its low boiling point and high vapor pressure for enhanced heat transfer and energy storage systems.

One of the primary challenges in neopentane fluid dynamics lies in accurately modeling its behavior under diverse conditions. Computational fluid dynamics (CFD) simulations struggle to capture the nuanced interactions between neopentane and other fluids or surfaces, particularly in multi-phase flow scenarios. This limitation hinders the development of more efficient and precise engineering solutions.

The thermophysical properties of neopentane present both opportunities and obstacles. Its low viscosity and high compressibility make it attractive for certain applications, but these same characteristics complicate flow control and measurement in experimental setups. Researchers are actively working on developing new measurement techniques and calibration methods to overcome these challenges.

In the realm of microfluidics, neopentane's unique properties offer potential for novel applications. However, the current understanding of neopentane behavior at microscale levels is limited, presenting a significant research gap. Overcoming this knowledge deficit could unlock new possibilities in areas such as lab-on-a-chip devices and micro-cooling systems.

Environmental concerns also pose challenges to the widespread adoption of neopentane in fluid dynamics applications. While it has a lower global warming potential compared to many refrigerants, its volatile organic compound (VOC) status necessitates careful handling and containment strategies. Developing environmentally friendly alternatives or mitigation techniques remains an active area of research.

The integration of neopentane into existing fluid systems presents another hurdle. Compatibility issues with common materials and the need for specialized equipment can increase implementation costs and complexity. Engineers are exploring innovative designs and material combinations to address these challenges and expand the practical applications of neopentane in fluid dynamics.

Lastly, the scaling of neopentane-based systems from laboratory to industrial levels encounters significant obstacles. Maintaining consistent performance and safety across different scales requires extensive testing and validation. The lack of standardized protocols and industry-wide best practices for neopentane handling in large-scale fluid dynamics applications further complicates this process.

One of the primary challenges in neopentane fluid dynamics lies in accurately modeling its behavior under diverse conditions. Computational fluid dynamics (CFD) simulations struggle to capture the nuanced interactions between neopentane and other fluids or surfaces, particularly in multi-phase flow scenarios. This limitation hinders the development of more efficient and precise engineering solutions.

The thermophysical properties of neopentane present both opportunities and obstacles. Its low viscosity and high compressibility make it attractive for certain applications, but these same characteristics complicate flow control and measurement in experimental setups. Researchers are actively working on developing new measurement techniques and calibration methods to overcome these challenges.

In the realm of microfluidics, neopentane's unique properties offer potential for novel applications. However, the current understanding of neopentane behavior at microscale levels is limited, presenting a significant research gap. Overcoming this knowledge deficit could unlock new possibilities in areas such as lab-on-a-chip devices and micro-cooling systems.

Environmental concerns also pose challenges to the widespread adoption of neopentane in fluid dynamics applications. While it has a lower global warming potential compared to many refrigerants, its volatile organic compound (VOC) status necessitates careful handling and containment strategies. Developing environmentally friendly alternatives or mitigation techniques remains an active area of research.

The integration of neopentane into existing fluid systems presents another hurdle. Compatibility issues with common materials and the need for specialized equipment can increase implementation costs and complexity. Engineers are exploring innovative designs and material combinations to address these challenges and expand the practical applications of neopentane in fluid dynamics.

Lastly, the scaling of neopentane-based systems from laboratory to industrial levels encounters significant obstacles. Maintaining consistent performance and safety across different scales requires extensive testing and validation. The lack of standardized protocols and industry-wide best practices for neopentane handling in large-scale fluid dynamics applications further complicates this process.

Existing Solutions for Neopentane Fluid Dynamics

01 Production and purification of neopentane

Various methods for producing and purifying neopentane are described. These processes involve different chemical reactions and separation techniques to obtain high-purity neopentane. The methods may include catalytic reactions, distillation, and other purification steps to remove impurities and achieve the desired product quality.- Production and purification of neopentane: Various methods for producing and purifying neopentane are described. These include processes for separating neopentane from other hydrocarbons, such as isobutane, using distillation techniques. The purification methods aim to obtain high-purity neopentane for industrial applications.

- Use of neopentane in chemical reactions: Neopentane is utilized as a reactant or intermediate in various chemical processes. It can be used in the production of other organic compounds, such as neopentyl derivatives. The unique structure of neopentane makes it valuable in certain synthetic pathways.

- Neopentane as a refrigerant or propellant: Neopentane finds applications as a refrigerant or propellant due to its physical properties. It can be used in cooling systems or as a component in aerosol formulations. The low boiling point and stability of neopentane make it suitable for these applications.

- Neopentane in polymer production: Neopentane is used in the production of certain polymers and plastics. It can serve as a blowing agent in the manufacture of foam materials or as a component in polymer formulations. The incorporation of neopentane can impart specific properties to the resulting materials.

- Separation and analysis of neopentane: Methods for separating and analyzing neopentane from mixtures are described. These include chromatographic techniques, spectroscopic methods, and other analytical approaches for identifying and quantifying neopentane in various samples. Such methods are important for quality control and research purposes.

02 Use of neopentane in chemical processes

Neopentane is utilized as a reactant or intermediate in various chemical processes. It can be employed in the synthesis of other organic compounds, as a blowing agent, or as a component in refrigerant mixtures. The unique properties of neopentane make it valuable in specific industrial applications.Expand Specific Solutions03 Neopentane in fuel compositions

Neopentane is used as a component in fuel compositions, particularly in specialized applications. Its high octane rating and low boiling point make it suitable for certain fuel blends. The incorporation of neopentane can enhance the performance characteristics of fuels in specific engines or under particular operating conditions.Expand Specific Solutions04 Separation and analysis of neopentane

Techniques for separating neopentane from other hydrocarbons and analyzing its purity are described. These methods may involve chromatography, spectroscopy, or other analytical techniques to identify and quantify neopentane in mixtures. Such processes are crucial for quality control and research purposes in industries utilizing neopentane.Expand Specific Solutions05 Environmental and safety considerations for neopentane

Due to its flammability and potential environmental impact, handling and storage of neopentane require specific safety measures. Regulations and guidelines for its use, transportation, and disposal are discussed. Additionally, research into the environmental fate and potential alternatives to neopentane in certain applications is ongoing to address sustainability concerns.Expand Specific Solutions

Key Players in Neopentane Fluid Dynamics Industry

The neopentane fluid dynamics market is in a growth phase, with increasing applications beyond basic uses driving expansion. The market size is moderate but growing, as industries explore advanced applications of this unique hydrocarbon. Technologically, the field is advancing rapidly, with companies like Sinopec Shanghai Petrochemical and China Petroleum & Chemical Corp leading in petrochemical applications. Baker Hughes and ExxonMobil Chemical Patents are pushing boundaries in energy and chemical sectors, while Lam Research is exploring potential semiconductor applications. Academic institutions like Tianjin University and Sabanci University are contributing to fundamental research, indicating a maturing but still evolving technological landscape with significant potential for innovation and market growth.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced computational fluid dynamics (CFD) models to simulate neopentane behavior in complex petrochemical processes. Their approach integrates molecular dynamics simulations with machine learning algorithms to predict neopentane's thermodynamic properties and phase behavior under extreme conditions. This enables more accurate design of separation and reaction processes involving neopentane [1]. Sinopec has also pioneered the use of neopentane as a blowing agent in polymer foam production, leveraging its unique physical properties to create lightweight, high-performance materials for various applications [2].

Strengths: Comprehensive understanding of neopentane behavior in industrial processes, leading to optimized process designs. Weaknesses: High computational costs for complex simulations may limit real-time applications.

Baker Hughes Co.

Technical Solution: Baker Hughes has developed innovative drilling fluids incorporating neopentane-based additives to enhance performance in high-temperature, high-pressure (HTHP) wells. Their proprietary formulation utilizes neopentane's thermal stability and low viscosity to improve fluid circulation and heat transfer in extreme downhole conditions [3]. The company has also implemented advanced multiphase flow models that account for neopentane's unique properties in gas-liquid mixtures, enabling more accurate predictions of fluid behavior in complex wellbore geometries [4]. Additionally, Baker Hughes has explored the use of neopentane in enhanced oil recovery (EOR) techniques, leveraging its miscibility with hydrocarbons to improve oil displacement efficiency [5].

Strengths: Specialized solutions for challenging drilling environments and improved oil recovery. Weaknesses: Limited applicability outside of oil and gas industry, potential environmental concerns with neopentane use.

Core Innovations in Neopentane Fluid Behavior

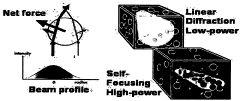

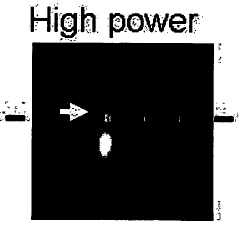

Method and system for manipulating fluid medium

PatentWO2009122399A1

Innovation

- The use of nonlinear optics to induce drag forces in fluid media by irradiating particles with light, creating optical intensity gradient forces that modify the refractive index and control hydrodynamic flow, surface tension, viscosity, and other fluid properties.

Production of neopentane

PatentWO2018044596A1

Innovation

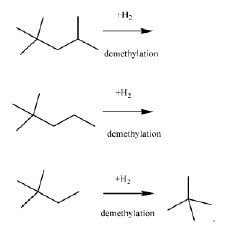

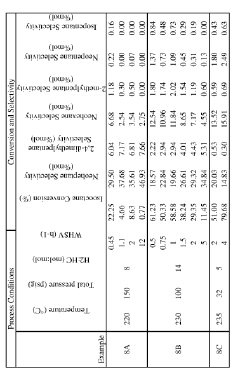

- A process involving the alkylation of isobutane with butylenes to produce isooctane, followed by demethylation in the presence of a catalyst, using a C4olefinic feed stream, such as a refinery raffinate, to achieve high yields of neopentane under mild conditions.

Environmental Impact of Neopentane Usage

The environmental impact of neopentane usage in fluid dynamics applications extends beyond its immediate technical benefits, necessitating a comprehensive assessment of its ecological footprint. Neopentane, a branched-chain alkane, has gained attention in various industrial processes due to its unique thermodynamic properties. However, its widespread adoption raises concerns about potential environmental consequences.

One of the primary environmental considerations is the atmospheric impact of neopentane. As a volatile organic compound (VOC), neopentane can contribute to the formation of ground-level ozone when released into the atmosphere. This photochemical smog precursor can have detrimental effects on air quality, particularly in urban areas with high industrial activity. Moreover, neopentane has a global warming potential, albeit lower than some other hydrocarbons, which adds to the cumulative greenhouse gas emissions when used in large-scale applications.

The production and disposal of neopentane also present environmental challenges. The manufacturing process typically involves energy-intensive petrochemical operations, contributing to carbon emissions and resource depletion. Additionally, the improper disposal or accidental release of neopentane can lead to soil and water contamination, potentially affecting local ecosystems and biodiversity.

In fluid dynamics applications, the use of neopentane as a working fluid or heat transfer medium may result in fugitive emissions during operation or maintenance. These emissions, while often small in quantity, can accumulate over time and contribute to the overall environmental burden. Furthermore, the potential for leaks or spills in industrial settings poses risks to both human health and the environment, necessitating stringent safety protocols and containment measures.

Despite these concerns, it is important to note that neopentane's efficiency in certain fluid dynamics applications may offer indirect environmental benefits. Its use in heat transfer systems or as a refrigerant can lead to improved energy efficiency, potentially reducing overall energy consumption and associated emissions. This highlights the need for a balanced approach in assessing the environmental impact, considering both direct and indirect effects.

To mitigate the environmental risks associated with neopentane usage, several strategies can be employed. These include implementing closed-loop systems to minimize emissions, developing more efficient production methods, and exploring bio-based alternatives. Additionally, enhancing recycling and recovery processes can reduce the demand for new neopentane production, thereby lessening the overall environmental footprint.

As regulations surrounding VOCs and greenhouse gases continue to evolve, the future of neopentane in fluid dynamics applications may depend on the industry's ability to address these environmental concerns. Ongoing research into eco-friendly alternatives and improved containment technologies will play a crucial role in determining the long-term sustainability of neopentane usage in advanced fluid dynamics applications.

One of the primary environmental considerations is the atmospheric impact of neopentane. As a volatile organic compound (VOC), neopentane can contribute to the formation of ground-level ozone when released into the atmosphere. This photochemical smog precursor can have detrimental effects on air quality, particularly in urban areas with high industrial activity. Moreover, neopentane has a global warming potential, albeit lower than some other hydrocarbons, which adds to the cumulative greenhouse gas emissions when used in large-scale applications.

The production and disposal of neopentane also present environmental challenges. The manufacturing process typically involves energy-intensive petrochemical operations, contributing to carbon emissions and resource depletion. Additionally, the improper disposal or accidental release of neopentane can lead to soil and water contamination, potentially affecting local ecosystems and biodiversity.

In fluid dynamics applications, the use of neopentane as a working fluid or heat transfer medium may result in fugitive emissions during operation or maintenance. These emissions, while often small in quantity, can accumulate over time and contribute to the overall environmental burden. Furthermore, the potential for leaks or spills in industrial settings poses risks to both human health and the environment, necessitating stringent safety protocols and containment measures.

Despite these concerns, it is important to note that neopentane's efficiency in certain fluid dynamics applications may offer indirect environmental benefits. Its use in heat transfer systems or as a refrigerant can lead to improved energy efficiency, potentially reducing overall energy consumption and associated emissions. This highlights the need for a balanced approach in assessing the environmental impact, considering both direct and indirect effects.

To mitigate the environmental risks associated with neopentane usage, several strategies can be employed. These include implementing closed-loop systems to minimize emissions, developing more efficient production methods, and exploring bio-based alternatives. Additionally, enhancing recycling and recovery processes can reduce the demand for new neopentane production, thereby lessening the overall environmental footprint.

As regulations surrounding VOCs and greenhouse gases continue to evolve, the future of neopentane in fluid dynamics applications may depend on the industry's ability to address these environmental concerns. Ongoing research into eco-friendly alternatives and improved containment technologies will play a crucial role in determining the long-term sustainability of neopentane usage in advanced fluid dynamics applications.

Safety Considerations in Neopentane Handling

Neopentane, a highly volatile hydrocarbon, requires stringent safety measures in its handling and application within fluid dynamics contexts. The primary concern stems from its low boiling point and high vapor pressure, which contribute to its flammability and potential for rapid vaporization under ambient conditions.

In laboratory and industrial settings, proper ventilation is crucial when working with neopentane. Adequate air circulation helps prevent the accumulation of vapors, reducing the risk of fire or explosion. Additionally, all equipment and storage containers must be properly grounded to prevent static electricity buildup, which could potentially ignite neopentane vapors.

Personal protective equipment (PPE) is essential for individuals handling neopentane. This includes chemical-resistant gloves, safety goggles, and flame-resistant clothing. In cases where exposure to vapors is possible, respiratory protection may also be necessary. Regular training on the proper use of PPE and emergency procedures is vital for personnel working with neopentane.

Storage considerations are paramount in neopentane safety protocols. The compound should be kept in tightly sealed containers in cool, well-ventilated areas away from sources of heat, sparks, or open flames. Due to its propensity to expand with temperature increases, containers should never be filled to capacity, allowing room for thermal expansion.

Spill response procedures must be established and regularly practiced. In the event of a neopentane spill, immediate evacuation of the area is necessary, followed by the activation of emergency response teams trained in handling volatile hydrocarbons. Specialized absorbent materials and non-sparking tools should be readily available for containment and cleanup operations.

When incorporating neopentane into fluid dynamics experiments or applications, researchers and engineers must consider the compound's unique properties. Its low viscosity and high compressibility can lead to unexpected behavior in fluid systems, potentially causing equipment failures if not properly accounted for in design and operation.

Transportation of neopentane requires adherence to strict regulations. It is typically classified as a hazardous material, necessitating specialized containers and handling procedures during transit. Proper labeling and documentation are essential to ensure safe transport and to inform emergency responders in case of accidents.

Regular maintenance and inspection of equipment used with neopentane are critical. This includes checking for leaks, ensuring the integrity of seals and gaskets, and verifying the proper functioning of safety systems such as pressure relief valves and emergency shutoffs.

In laboratory and industrial settings, proper ventilation is crucial when working with neopentane. Adequate air circulation helps prevent the accumulation of vapors, reducing the risk of fire or explosion. Additionally, all equipment and storage containers must be properly grounded to prevent static electricity buildup, which could potentially ignite neopentane vapors.

Personal protective equipment (PPE) is essential for individuals handling neopentane. This includes chemical-resistant gloves, safety goggles, and flame-resistant clothing. In cases where exposure to vapors is possible, respiratory protection may also be necessary. Regular training on the proper use of PPE and emergency procedures is vital for personnel working with neopentane.

Storage considerations are paramount in neopentane safety protocols. The compound should be kept in tightly sealed containers in cool, well-ventilated areas away from sources of heat, sparks, or open flames. Due to its propensity to expand with temperature increases, containers should never be filled to capacity, allowing room for thermal expansion.

Spill response procedures must be established and regularly practiced. In the event of a neopentane spill, immediate evacuation of the area is necessary, followed by the activation of emergency response teams trained in handling volatile hydrocarbons. Specialized absorbent materials and non-sparking tools should be readily available for containment and cleanup operations.

When incorporating neopentane into fluid dynamics experiments or applications, researchers and engineers must consider the compound's unique properties. Its low viscosity and high compressibility can lead to unexpected behavior in fluid systems, potentially causing equipment failures if not properly accounted for in design and operation.

Transportation of neopentane requires adherence to strict regulations. It is typically classified as a hazardous material, necessitating specialized containers and handling procedures during transit. Proper labeling and documentation are essential to ensure safe transport and to inform emergency responders in case of accidents.

Regular maintenance and inspection of equipment used with neopentane are critical. This includes checking for leaks, ensuring the integrity of seals and gaskets, and verifying the proper functioning of safety systems such as pressure relief valves and emergency shutoffs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!