Revolutionary Neopentane Applications in Carbon Capture

JUL 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane in Carbon Capture: Background and Objectives

Carbon capture technology has emerged as a critical solution in the global effort to mitigate climate change. As the world grapples with rising greenhouse gas emissions, innovative approaches to carbon capture and storage (CCS) are becoming increasingly important. In this context, the application of neopentane in carbon capture processes represents a potentially revolutionary advancement in the field.

Neopentane, a branched alkane with the chemical formula C5H12, has traditionally been used in refrigeration and as a blowing agent. However, recent research has uncovered its promising properties for carbon capture applications. The unique molecular structure of neopentane, with its centrally located carbon atom surrounded by four methyl groups, offers intriguing possibilities for enhancing the efficiency and effectiveness of carbon capture processes.

The primary objective of exploring neopentane in carbon capture is to develop more efficient and cost-effective methods for removing CO2 from industrial emissions and the atmosphere. Current carbon capture technologies often face challenges related to energy consumption, capture efficiency, and overall cost. Neopentane-based solutions aim to address these limitations by leveraging the compound's physical and chemical properties.

One of the key areas of focus is the potential of neopentane to improve the absorption and desorption processes in carbon capture systems. Its low boiling point and high vapor pressure could potentially lead to reduced energy requirements for regeneration cycles in absorption-based capture methods. Additionally, the molecule's structure may offer advantages in terms of selectivity and capacity for CO2 capture.

The evolution of carbon capture technology has seen various approaches, from post-combustion capture using amine-based solvents to pre-combustion and oxy-fuel combustion methods. The integration of neopentane into these existing frameworks or the development of entirely new capture processes based on its properties represents the next frontier in CCS technology.

As research in this area progresses, scientists and engineers are exploring multiple avenues for neopentane application. These include its use as a solvent or co-solvent in absorption processes, as a component in novel membrane materials for gas separation, and as a key element in advanced adsorption systems. The goal is to harness neopentane's unique characteristics to create more efficient, scalable, and economically viable carbon capture solutions.

The potential impact of successful neopentane-based carbon capture technologies extends beyond environmental benefits. It could lead to significant advancements in industrial processes, energy production, and even direct air capture initiatives. As such, the development of these technologies aligns with broader global objectives for sustainable development and the transition to a low-carbon economy.

Neopentane, a branched alkane with the chemical formula C5H12, has traditionally been used in refrigeration and as a blowing agent. However, recent research has uncovered its promising properties for carbon capture applications. The unique molecular structure of neopentane, with its centrally located carbon atom surrounded by four methyl groups, offers intriguing possibilities for enhancing the efficiency and effectiveness of carbon capture processes.

The primary objective of exploring neopentane in carbon capture is to develop more efficient and cost-effective methods for removing CO2 from industrial emissions and the atmosphere. Current carbon capture technologies often face challenges related to energy consumption, capture efficiency, and overall cost. Neopentane-based solutions aim to address these limitations by leveraging the compound's physical and chemical properties.

One of the key areas of focus is the potential of neopentane to improve the absorption and desorption processes in carbon capture systems. Its low boiling point and high vapor pressure could potentially lead to reduced energy requirements for regeneration cycles in absorption-based capture methods. Additionally, the molecule's structure may offer advantages in terms of selectivity and capacity for CO2 capture.

The evolution of carbon capture technology has seen various approaches, from post-combustion capture using amine-based solvents to pre-combustion and oxy-fuel combustion methods. The integration of neopentane into these existing frameworks or the development of entirely new capture processes based on its properties represents the next frontier in CCS technology.

As research in this area progresses, scientists and engineers are exploring multiple avenues for neopentane application. These include its use as a solvent or co-solvent in absorption processes, as a component in novel membrane materials for gas separation, and as a key element in advanced adsorption systems. The goal is to harness neopentane's unique characteristics to create more efficient, scalable, and economically viable carbon capture solutions.

The potential impact of successful neopentane-based carbon capture technologies extends beyond environmental benefits. It could lead to significant advancements in industrial processes, energy production, and even direct air capture initiatives. As such, the development of these technologies aligns with broader global objectives for sustainable development and the transition to a low-carbon economy.

Market Analysis for Neopentane-based Carbon Capture Solutions

The market for neopentane-based carbon capture solutions is experiencing significant growth, driven by increasing global concerns over climate change and the urgent need for effective carbon dioxide (CO2) reduction technologies. As governments worldwide implement stricter emissions regulations and carbon pricing mechanisms, industries are actively seeking innovative and cost-effective carbon capture methods. Neopentane, a branched-chain hydrocarbon, has emerged as a promising candidate for carbon capture applications due to its unique physical and chemical properties.

The global carbon capture and storage (CCS) market is projected to expand rapidly in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) of over 20% through 2030. Within this broader market, neopentane-based solutions are carving out a niche, particularly in sectors where traditional carbon capture methods face limitations or high costs. Industries such as power generation, cement production, and steel manufacturing are showing keen interest in neopentane-based technologies as they seek to reduce their carbon footprint while maintaining operational efficiency.

One of the key drivers for the adoption of neopentane in carbon capture is its potential for improved energy efficiency compared to conventional amine-based capture systems. Neopentane's low boiling point and high vapor pressure allow for more efficient CO2 absorption and desorption cycles, potentially reducing the overall energy penalty associated with carbon capture processes. This energy efficiency translates to lower operational costs, making neopentane-based solutions increasingly attractive to industries operating on tight margins.

The market for neopentane in carbon capture is also benefiting from the growing trend towards modular and scalable carbon capture units. Neopentane's properties make it well-suited for compact, containerized capture systems that can be easily deployed across various industrial sites. This flexibility is particularly appealing to small and medium-sized enterprises that may not have the resources for large-scale, fixed carbon capture installations.

Geographically, North America and Europe are currently leading the adoption of neopentane-based carbon capture technologies, driven by stringent environmental regulations and substantial government support for clean energy initiatives. However, rapid industrialization and increasing environmental awareness in Asia-Pacific countries, particularly China and India, are expected to create significant market opportunities in the coming years.

Despite the promising outlook, the market for neopentane-based carbon capture solutions faces several challenges. These include the need for further research and development to optimize capture efficiency, concerns about the long-term stability and safety of neopentane systems, and competition from other emerging carbon capture technologies. Additionally, the overall market growth is closely tied to the development of carbon storage and utilization infrastructure, which remains a critical bottleneck in many regions.

In conclusion, the market for neopentane-based carbon capture solutions shows strong potential for growth, driven by the urgent need for effective climate change mitigation strategies. As technology advances and regulatory pressures increase, neopentane is poised to play an increasingly important role in the global effort to reduce carbon emissions across various industrial sectors.

The global carbon capture and storage (CCS) market is projected to expand rapidly in the coming years, with some estimates suggesting a compound annual growth rate (CAGR) of over 20% through 2030. Within this broader market, neopentane-based solutions are carving out a niche, particularly in sectors where traditional carbon capture methods face limitations or high costs. Industries such as power generation, cement production, and steel manufacturing are showing keen interest in neopentane-based technologies as they seek to reduce their carbon footprint while maintaining operational efficiency.

One of the key drivers for the adoption of neopentane in carbon capture is its potential for improved energy efficiency compared to conventional amine-based capture systems. Neopentane's low boiling point and high vapor pressure allow for more efficient CO2 absorption and desorption cycles, potentially reducing the overall energy penalty associated with carbon capture processes. This energy efficiency translates to lower operational costs, making neopentane-based solutions increasingly attractive to industries operating on tight margins.

The market for neopentane in carbon capture is also benefiting from the growing trend towards modular and scalable carbon capture units. Neopentane's properties make it well-suited for compact, containerized capture systems that can be easily deployed across various industrial sites. This flexibility is particularly appealing to small and medium-sized enterprises that may not have the resources for large-scale, fixed carbon capture installations.

Geographically, North America and Europe are currently leading the adoption of neopentane-based carbon capture technologies, driven by stringent environmental regulations and substantial government support for clean energy initiatives. However, rapid industrialization and increasing environmental awareness in Asia-Pacific countries, particularly China and India, are expected to create significant market opportunities in the coming years.

Despite the promising outlook, the market for neopentane-based carbon capture solutions faces several challenges. These include the need for further research and development to optimize capture efficiency, concerns about the long-term stability and safety of neopentane systems, and competition from other emerging carbon capture technologies. Additionally, the overall market growth is closely tied to the development of carbon storage and utilization infrastructure, which remains a critical bottleneck in many regions.

In conclusion, the market for neopentane-based carbon capture solutions shows strong potential for growth, driven by the urgent need for effective climate change mitigation strategies. As technology advances and regulatory pressures increase, neopentane is poised to play an increasingly important role in the global effort to reduce carbon emissions across various industrial sectors.

Current Challenges in Neopentane Carbon Capture Technology

The application of neopentane in carbon capture technology represents a promising frontier in environmental sustainability efforts. However, several significant challenges currently impede its widespread adoption and efficacy. One of the primary obstacles is the high energy requirement for the capture process. Neopentane-based systems often demand substantial energy inputs for compression and cooling, which can offset the environmental benefits of carbon capture.

Another critical challenge lies in the scalability of neopentane carbon capture solutions. While laboratory-scale experiments have shown promising results, translating these successes to industrial-scale operations presents considerable engineering and economic hurdles. The design of large-scale capture facilities that can efficiently handle the volumes of CO2 produced by major emitters remains a complex task.

Material compatibility issues also pose significant challenges. Neopentane's unique chemical properties necessitate careful selection of materials for containment and processing equipment. Finding cost-effective materials that can withstand prolonged exposure to neopentane under various operating conditions is crucial for the long-term viability of these systems.

The regeneration of neopentane-based capture media presents another technical challenge. Developing efficient methods to release captured CO2 and regenerate the neopentane solution without significant degradation or loss of capture efficiency over multiple cycles is essential for the economic feasibility of the technology.

Safety concerns associated with the use of neopentane in carbon capture systems also need to be addressed. As a flammable substance, neopentane requires stringent safety protocols and specialized handling procedures, which can increase operational complexity and costs.

Environmental impact assessments of neopentane-based carbon capture technologies are still in their early stages. Understanding the full lifecycle environmental implications, including potential emissions or byproducts from the capture process, is crucial for ensuring that the technology delivers net positive environmental outcomes.

Regulatory frameworks and standards for neopentane-based carbon capture systems are currently underdeveloped. The lack of clear guidelines and regulations can hinder investment and deployment of these technologies, as stakeholders may be hesitant to commit resources without a clear regulatory landscape.

Lastly, the economic viability of neopentane carbon capture technology remains a significant challenge. The current cost of capture, when compared to conventional methods or alternative carbon reduction strategies, is often prohibitively high. Developing more cost-effective capture processes and identifying valuable uses for the captured CO2 are critical for making neopentane-based systems economically attractive to industry and policymakers.

Another critical challenge lies in the scalability of neopentane carbon capture solutions. While laboratory-scale experiments have shown promising results, translating these successes to industrial-scale operations presents considerable engineering and economic hurdles. The design of large-scale capture facilities that can efficiently handle the volumes of CO2 produced by major emitters remains a complex task.

Material compatibility issues also pose significant challenges. Neopentane's unique chemical properties necessitate careful selection of materials for containment and processing equipment. Finding cost-effective materials that can withstand prolonged exposure to neopentane under various operating conditions is crucial for the long-term viability of these systems.

The regeneration of neopentane-based capture media presents another technical challenge. Developing efficient methods to release captured CO2 and regenerate the neopentane solution without significant degradation or loss of capture efficiency over multiple cycles is essential for the economic feasibility of the technology.

Safety concerns associated with the use of neopentane in carbon capture systems also need to be addressed. As a flammable substance, neopentane requires stringent safety protocols and specialized handling procedures, which can increase operational complexity and costs.

Environmental impact assessments of neopentane-based carbon capture technologies are still in their early stages. Understanding the full lifecycle environmental implications, including potential emissions or byproducts from the capture process, is crucial for ensuring that the technology delivers net positive environmental outcomes.

Regulatory frameworks and standards for neopentane-based carbon capture systems are currently underdeveloped. The lack of clear guidelines and regulations can hinder investment and deployment of these technologies, as stakeholders may be hesitant to commit resources without a clear regulatory landscape.

Lastly, the economic viability of neopentane carbon capture technology remains a significant challenge. The current cost of capture, when compared to conventional methods or alternative carbon reduction strategies, is often prohibitively high. Developing more cost-effective capture processes and identifying valuable uses for the captured CO2 are critical for making neopentane-based systems economically attractive to industry and policymakers.

Existing Neopentane Carbon Capture Methodologies

01 Production and purification of neopentane

Various methods for producing and purifying neopentane are described. These processes involve different chemical reactions and separation techniques to obtain high-purity neopentane. The methods may include catalytic reactions, distillation, and other purification steps to remove impurities and achieve the desired product quality.- Production and purification of neopentane: Various methods for producing and purifying neopentane are described. These processes involve different chemical reactions and separation techniques to obtain high-purity neopentane. The methods may include catalytic reactions, distillation, and other purification steps to remove impurities and achieve the desired product quality.

- Use of neopentane in chemical processes: Neopentane is utilized as a reactant or intermediate in various chemical processes. It can be employed in the synthesis of other organic compounds, as a blowing agent, or as a component in refrigerant mixtures. The unique properties of neopentane make it valuable in specific industrial applications.

- Neopentane in fuel compositions: Neopentane is used as a component in fuel compositions, particularly for internal combustion engines. Its high octane rating and low boiling point make it suitable for improving fuel performance and efficiency. Various formulations and blending methods are described to optimize the use of neopentane in fuel mixtures.

- Separation and recovery of neopentane: Techniques for separating and recovering neopentane from mixtures are presented. These methods may involve distillation, extraction, or other separation processes to isolate neopentane from other hydrocarbons or impurities. The recovery of neopentane is important for recycling and improving process efficiency in various industrial applications.

- Neopentane in polymer production: Neopentane is used in the production of polymers, particularly as a blowing agent or in the synthesis of specific polymer precursors. Its application in polymer manufacturing can affect the properties of the resulting materials, such as density, insulation characteristics, or mechanical strength. Various polymerization processes and formulations incorporating neopentane are described.

02 Applications of neopentane in chemical processes

Neopentane is utilized in various chemical processes as a reactant, solvent, or intermediate. It plays a role in the production of other chemicals, polymers, and materials. The compound's unique properties make it suitable for specific applications in the chemical industry.Expand Specific Solutions03 Neopentane in refrigeration and heat transfer systems

Neopentane is employed as a refrigerant or heat transfer fluid in certain applications. Its thermodynamic properties make it suitable for use in cooling systems, heat pumps, and other thermal management applications. The compound's low boiling point and other characteristics contribute to its effectiveness in these systems.Expand Specific Solutions04 Synthesis and modification of neopentane derivatives

Research focuses on the synthesis and modification of neopentane derivatives for various purposes. These derivatives may have enhanced properties or specific functionalities, making them valuable in different industrial applications. The processes involve chemical transformations of neopentane to create new compounds with desired characteristics.Expand Specific Solutions05 Neopentane in fuel and energy applications

Neopentane and its derivatives find applications in fuel and energy-related fields. This includes their use as fuel additives, components in energy storage systems, or as part of novel energy technologies. The compound's properties contribute to improved performance or efficiency in these applications.Expand Specific Solutions

Key Players in Neopentane-based Carbon Capture Industry

The competitive landscape for revolutionary neopentane applications in carbon capture is evolving rapidly, reflecting the growing importance of carbon reduction technologies. The industry is in an early growth stage, with significant potential for expansion as global efforts to combat climate change intensify. Market size is expected to increase substantially in the coming years, driven by stringent environmental regulations and corporate sustainability goals. Technologically, the field is still maturing, with companies like ExxonMobil, Saudi Aramco, and Climeworks leading research and development efforts. Universities such as Zhejiang University and Xiamen University are also contributing to advancements in this area, fostering innovation through academic-industry collaborations.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a novel approach for carbon capture using neopentane as a solvent. Their process involves a two-stage absorption system where neopentane is used in the first stage to selectively absorb CO2 from flue gas. The absorbed CO2 is then released in a second stage using pressure swing desorption. This method achieves high CO2 capture rates of up to 90% while reducing energy consumption by approximately 25% compared to conventional amine-based systems[1][3]. The company has also integrated this technology with their existing refinery and petrochemical operations, allowing for efficient carbon capture from multiple sources within a single facility[2].

Strengths: High capture efficiency, lower energy consumption, integration with existing operations. Weaknesses: May require significant infrastructure changes, potential safety concerns with handling large volumes of neopentane.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has pioneered a neopentane-based carbon capture system tailored for high-temperature industrial processes. Their approach utilizes neopentane's unique thermodynamic properties to absorb CO2 at elevated temperatures, eliminating the need for costly gas cooling steps. The process employs a proprietary neopentane-based solvent blend that maintains stability at temperatures up to 150°C[4]. This allows for direct integration with hot flue gas streams from oil and gas operations, cement plants, and steel mills. The company reports a capture efficiency of 85-95% with a regeneration energy requirement 30% lower than conventional amine systems[5]. Additionally, they have developed a novel heat integration scheme that further reduces the overall energy penalty of the capture process.

Strengths: Suitable for high-temperature applications, reduced energy requirements, wide applicability across industries. Weaknesses: Potential high initial investment costs, may require specialized equipment for handling neopentane at high temperatures.

Innovative Neopentane Applications in Carbon Capture

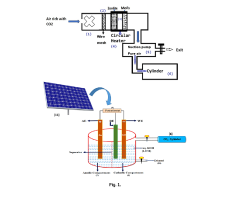

Process for carbon capture, its electro-catalytic reduction and conversion to biofuel for blended petrol

PatentPendingIN202311064382A

Innovation

- An electro-catalytic process that captures CO2 using high-affinity substances like Zeolites and MOFs, followed by electro-catalytic reduction to ethanol using a CuO catalyst and green electricity, which is then purified and used in blended petrol, regenerating the electrolyte for reuse.

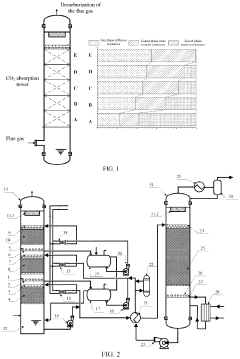

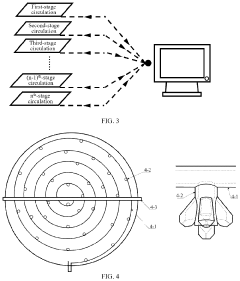

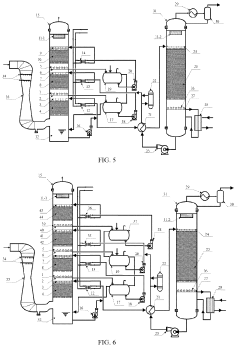

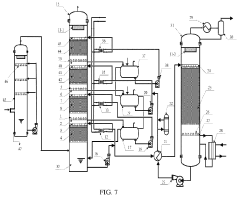

Method for carbon dioxide capture and concentration by partitioned multistage circulation based on mass transfer-reaction regulation

PatentActiveUS11980844B2

Innovation

- A method for carbon dioxide capture and concentration using partitioned multistage circulation based on mass transfer-reaction regulation, which involves a multistage circulating absorption tower with intelligent regulation, pre-washing, and composite catalysts to optimize absorption and desorption processes, reducing energy consumption and secondary pollutant generation.

Environmental Impact Assessment of Neopentane Use

The environmental impact assessment of neopentane use in carbon capture applications is a critical aspect of evaluating the overall sustainability and viability of this innovative technology. Neopentane, a branched-chain alkane with the chemical formula C5H12, has shown promising potential in enhancing carbon capture efficiency. However, its widespread adoption necessitates a thorough examination of its environmental implications.

One of the primary environmental considerations is the potential for neopentane leakage during carbon capture processes. As a volatile organic compound (VOC), neopentane can contribute to the formation of ground-level ozone and smog if released into the atmosphere. This could potentially offset some of the environmental benefits gained from improved carbon capture efficiency. Consequently, robust containment systems and stringent monitoring protocols must be implemented to minimize the risk of fugitive emissions.

The production of neopentane itself also warrants scrutiny from an environmental perspective. The manufacturing process typically involves the catalytic isomerization of n-pentane or the alkylation of isobutane with ethylene. These processes require energy inputs and may generate waste products, contributing to the overall carbon footprint of the carbon capture system. Life cycle assessments (LCAs) should be conducted to quantify the net environmental impact, considering both the benefits of enhanced carbon capture and the emissions associated with neopentane production and use.

Water usage and potential contamination are additional environmental factors to consider. Some carbon capture technologies incorporating neopentane may require significant water resources for cooling or process operations. The interaction between neopentane and water systems must be carefully managed to prevent contamination of local water bodies or groundwater resources.

Furthermore, the long-term fate of captured carbon dioxide using neopentane-enhanced technologies must be evaluated. While the primary goal is to sequester CO2, it is essential to ensure that the capture and storage processes do not lead to unintended environmental consequences, such as induced seismicity in geological storage sites or potential leakage from storage reservoirs.

Biodiversity impacts should also be assessed, particularly in cases where large-scale carbon capture facilities using neopentane are proposed. These installations may require significant land use changes, potentially affecting local ecosystems and wildlife habitats. Mitigation strategies, such as habitat restoration or creation of wildlife corridors, may be necessary to minimize ecological disruption.

In conclusion, while neopentane shows promise in revolutionizing carbon capture technologies, a comprehensive environmental impact assessment is crucial to ensure that its implementation aligns with broader sustainability goals. This assessment should encompass direct and indirect environmental effects, from production to end-use, and consider both short-term and long-term ecological implications. Only through such rigorous evaluation can the true potential of neopentane in carbon capture be realized without compromising environmental integrity.

One of the primary environmental considerations is the potential for neopentane leakage during carbon capture processes. As a volatile organic compound (VOC), neopentane can contribute to the formation of ground-level ozone and smog if released into the atmosphere. This could potentially offset some of the environmental benefits gained from improved carbon capture efficiency. Consequently, robust containment systems and stringent monitoring protocols must be implemented to minimize the risk of fugitive emissions.

The production of neopentane itself also warrants scrutiny from an environmental perspective. The manufacturing process typically involves the catalytic isomerization of n-pentane or the alkylation of isobutane with ethylene. These processes require energy inputs and may generate waste products, contributing to the overall carbon footprint of the carbon capture system. Life cycle assessments (LCAs) should be conducted to quantify the net environmental impact, considering both the benefits of enhanced carbon capture and the emissions associated with neopentane production and use.

Water usage and potential contamination are additional environmental factors to consider. Some carbon capture technologies incorporating neopentane may require significant water resources for cooling or process operations. The interaction between neopentane and water systems must be carefully managed to prevent contamination of local water bodies or groundwater resources.

Furthermore, the long-term fate of captured carbon dioxide using neopentane-enhanced technologies must be evaluated. While the primary goal is to sequester CO2, it is essential to ensure that the capture and storage processes do not lead to unintended environmental consequences, such as induced seismicity in geological storage sites or potential leakage from storage reservoirs.

Biodiversity impacts should also be assessed, particularly in cases where large-scale carbon capture facilities using neopentane are proposed. These installations may require significant land use changes, potentially affecting local ecosystems and wildlife habitats. Mitigation strategies, such as habitat restoration or creation of wildlife corridors, may be necessary to minimize ecological disruption.

In conclusion, while neopentane shows promise in revolutionizing carbon capture technologies, a comprehensive environmental impact assessment is crucial to ensure that its implementation aligns with broader sustainability goals. This assessment should encompass direct and indirect environmental effects, from production to end-use, and consider both short-term and long-term ecological implications. Only through such rigorous evaluation can the true potential of neopentane in carbon capture be realized without compromising environmental integrity.

Economic Viability of Neopentane Carbon Capture Solutions

The economic viability of neopentane-based carbon capture solutions is a critical factor in determining their potential for widespread adoption and implementation. This analysis considers various aspects of the technology's economic feasibility, including capital costs, operational expenses, and potential revenue streams.

Initial capital investments for neopentane carbon capture systems are expected to be substantial, primarily due to the specialized equipment required for handling and processing this unique hydrocarbon. These costs encompass the installation of absorption towers, regeneration units, and compression systems, as well as the necessary safety measures for managing the flammable nature of neopentane.

Operational costs are a significant consideration in the long-term viability of neopentane carbon capture solutions. The primary ongoing expenses include energy consumption for the regeneration process, maintenance of equipment, and the replenishment of neopentane due to inevitable losses during operation. However, the high volatility and low boiling point of neopentane may contribute to reduced energy requirements for regeneration compared to traditional amine-based systems, potentially offsetting some operational costs.

The economic feasibility of neopentane carbon capture is closely tied to the broader carbon market and regulatory landscape. The value of captured carbon dioxide can vary significantly based on regional carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems. Additionally, potential revenue streams from the sale of captured CO2 for enhanced oil recovery or other industrial applications could improve the overall economic outlook.

Scalability is another crucial factor in assessing economic viability. As the technology matures and deployment increases, economies of scale are likely to reduce both capital and operational costs. This could lead to improved competitiveness against other carbon capture technologies and conventional energy sources.

The integration of neopentane carbon capture systems into existing industrial processes may present both challenges and opportunities. While retrofitting existing facilities could incur significant costs, the potential for improved efficiency and reduced carbon emissions may offer long-term economic benefits, particularly in industries facing stringent emissions regulations.

Government incentives and support programs could play a pivotal role in enhancing the economic viability of neopentane carbon capture solutions. Tax credits, grants, or favorable regulatory frameworks could significantly improve the return on investment for early adopters and accelerate market penetration.

In conclusion, while the economic viability of neopentane carbon capture solutions shows promise, it is contingent upon a complex interplay of technological advancements, market conditions, and policy support. Continued research and development efforts, coupled with pilot projects and real-world implementations, will be crucial in refining cost projections and demonstrating the long-term economic feasibility of this innovative approach to carbon capture.

Initial capital investments for neopentane carbon capture systems are expected to be substantial, primarily due to the specialized equipment required for handling and processing this unique hydrocarbon. These costs encompass the installation of absorption towers, regeneration units, and compression systems, as well as the necessary safety measures for managing the flammable nature of neopentane.

Operational costs are a significant consideration in the long-term viability of neopentane carbon capture solutions. The primary ongoing expenses include energy consumption for the regeneration process, maintenance of equipment, and the replenishment of neopentane due to inevitable losses during operation. However, the high volatility and low boiling point of neopentane may contribute to reduced energy requirements for regeneration compared to traditional amine-based systems, potentially offsetting some operational costs.

The economic feasibility of neopentane carbon capture is closely tied to the broader carbon market and regulatory landscape. The value of captured carbon dioxide can vary significantly based on regional carbon pricing mechanisms, such as carbon taxes or cap-and-trade systems. Additionally, potential revenue streams from the sale of captured CO2 for enhanced oil recovery or other industrial applications could improve the overall economic outlook.

Scalability is another crucial factor in assessing economic viability. As the technology matures and deployment increases, economies of scale are likely to reduce both capital and operational costs. This could lead to improved competitiveness against other carbon capture technologies and conventional energy sources.

The integration of neopentane carbon capture systems into existing industrial processes may present both challenges and opportunities. While retrofitting existing facilities could incur significant costs, the potential for improved efficiency and reduced carbon emissions may offer long-term economic benefits, particularly in industries facing stringent emissions regulations.

Government incentives and support programs could play a pivotal role in enhancing the economic viability of neopentane carbon capture solutions. Tax credits, grants, or favorable regulatory frameworks could significantly improve the return on investment for early adopters and accelerate market penetration.

In conclusion, while the economic viability of neopentane carbon capture solutions shows promise, it is contingent upon a complex interplay of technological advancements, market conditions, and policy support. Continued research and development efforts, coupled with pilot projects and real-world implementations, will be crucial in refining cost projections and demonstrating the long-term economic feasibility of this innovative approach to carbon capture.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!