Neopentane in Additive Manufacturing: A New Era

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane AM Evolution

The evolution of neopentane in additive manufacturing (AM) represents a significant milestone in the field, marking a new era of innovation and potential. This highly branched alkane has emerged as a promising material for various AM applications, particularly in the realm of 3D printing.

The journey of neopentane in AM began with the recognition of its unique properties, including its low boiling point and high vapor pressure. These characteristics initially posed challenges for traditional manufacturing methods but have proven advantageous in certain AM processes. The timeline of neopentane's integration into AM can be traced through several key developmental stages.

In the early phases, researchers focused on understanding the behavior of neopentane under different AM conditions. This period was characterized by extensive experimentation and the development of specialized equipment capable of handling the volatile nature of neopentane. As the technology progressed, the focus shifted towards optimizing process parameters and exploring potential applications.

A significant breakthrough came with the development of neopentane-based foams for AM. This innovation opened up new possibilities in lightweight structure fabrication, particularly in aerospace and automotive industries. The ability to create complex, lightweight structures with superior insulation properties marked a turning point in the use of neopentane in AM.

Subsequently, advancements in neopentane-based AM techniques led to improved control over pore size and distribution in printed structures. This development expanded the potential applications to include areas such as tissue engineering and drug delivery systems, where precise control over material porosity is crucial.

Recent years have seen a surge in research focused on combining neopentane with other materials to create novel composites for AM. These efforts have resulted in materials with enhanced properties, such as improved thermal stability and mechanical strength, further broadening the scope of neopentane in AM applications.

The latest frontier in neopentane AM evolution involves the development of multi-material printing techniques. This approach allows for the creation of objects with varying material properties within a single print, offering unprecedented design flexibility and functional integration.

As we look to the future, the evolution of neopentane in AM is poised to continue its rapid pace. Emerging trends suggest a focus on sustainability, with research aimed at developing recyclable neopentane-based materials and closed-loop AM processes. Additionally, the integration of artificial intelligence and machine learning in neopentane AM processes promises to further optimize material usage and enhance print quality.

The journey of neopentane in AM began with the recognition of its unique properties, including its low boiling point and high vapor pressure. These characteristics initially posed challenges for traditional manufacturing methods but have proven advantageous in certain AM processes. The timeline of neopentane's integration into AM can be traced through several key developmental stages.

In the early phases, researchers focused on understanding the behavior of neopentane under different AM conditions. This period was characterized by extensive experimentation and the development of specialized equipment capable of handling the volatile nature of neopentane. As the technology progressed, the focus shifted towards optimizing process parameters and exploring potential applications.

A significant breakthrough came with the development of neopentane-based foams for AM. This innovation opened up new possibilities in lightweight structure fabrication, particularly in aerospace and automotive industries. The ability to create complex, lightweight structures with superior insulation properties marked a turning point in the use of neopentane in AM.

Subsequently, advancements in neopentane-based AM techniques led to improved control over pore size and distribution in printed structures. This development expanded the potential applications to include areas such as tissue engineering and drug delivery systems, where precise control over material porosity is crucial.

Recent years have seen a surge in research focused on combining neopentane with other materials to create novel composites for AM. These efforts have resulted in materials with enhanced properties, such as improved thermal stability and mechanical strength, further broadening the scope of neopentane in AM applications.

The latest frontier in neopentane AM evolution involves the development of multi-material printing techniques. This approach allows for the creation of objects with varying material properties within a single print, offering unprecedented design flexibility and functional integration.

As we look to the future, the evolution of neopentane in AM is poised to continue its rapid pace. Emerging trends suggest a focus on sustainability, with research aimed at developing recyclable neopentane-based materials and closed-loop AM processes. Additionally, the integration of artificial intelligence and machine learning in neopentane AM processes promises to further optimize material usage and enhance print quality.

Market Demand Analysis

The market demand for neopentane in additive manufacturing is experiencing a significant upward trajectory, driven by the unique properties this compound offers to the 3D printing industry. Neopentane, with its low boiling point and high vapor pressure, is emerging as a game-changing blowing agent in the production of lightweight, high-performance materials for additive manufacturing processes.

The global additive manufacturing market, valued at $12.6 billion in 2020, is projected to reach $37.2 billion by 2026, growing at a CAGR of 19.8%. Within this rapidly expanding sector, the demand for advanced materials, including those utilizing neopentane, is expected to surge. The lightweight materials segment, where neopentane finds its primary application, is anticipated to grow at an even faster rate due to increasing demand from aerospace, automotive, and consumer electronics industries.

Neopentane's ability to create micro-cellular structures in polymers used in 3D printing is driving its adoption in the production of high-performance, low-density parts. This property is particularly valuable in industries where weight reduction is critical, such as aerospace and automotive manufacturing. The aerospace industry, for instance, is projected to increase its use of 3D printed parts by 20% annually, creating a substantial market for neopentane-based materials.

The automotive sector, another key driver of demand, is increasingly turning to additive manufacturing for prototyping and production of lightweight components. With stringent fuel efficiency standards and the rise of electric vehicles, the need for lightweight materials in this sector is expected to grow by 15% year-over-year, further boosting the demand for neopentane in 3D printing applications.

Moreover, the consumer electronics industry is showing keen interest in neopentane-based 3D printing materials for producing durable, lightweight casings and components. This sector's demand for advanced 3D printing materials is projected to increase by 25% annually, contributing significantly to the overall market growth for neopentane in additive manufacturing.

The medical device industry is also emerging as a promising market for neopentane-based 3D printing materials. The ability to create complex, customized medical devices with lightweight, biocompatible materials is driving adoption in this sector, with an expected growth rate of 18% per year in the use of advanced 3D printing materials.

As sustainability becomes increasingly important across industries, the recyclability and potential for circular economy applications of neopentane-based 3D printing materials are expected to further drive market demand. This aligns with the growing trend of eco-friendly manufacturing processes and materials, which is projected to influence 30% of all manufacturing decisions by 2025.

The global additive manufacturing market, valued at $12.6 billion in 2020, is projected to reach $37.2 billion by 2026, growing at a CAGR of 19.8%. Within this rapidly expanding sector, the demand for advanced materials, including those utilizing neopentane, is expected to surge. The lightweight materials segment, where neopentane finds its primary application, is anticipated to grow at an even faster rate due to increasing demand from aerospace, automotive, and consumer electronics industries.

Neopentane's ability to create micro-cellular structures in polymers used in 3D printing is driving its adoption in the production of high-performance, low-density parts. This property is particularly valuable in industries where weight reduction is critical, such as aerospace and automotive manufacturing. The aerospace industry, for instance, is projected to increase its use of 3D printed parts by 20% annually, creating a substantial market for neopentane-based materials.

The automotive sector, another key driver of demand, is increasingly turning to additive manufacturing for prototyping and production of lightweight components. With stringent fuel efficiency standards and the rise of electric vehicles, the need for lightweight materials in this sector is expected to grow by 15% year-over-year, further boosting the demand for neopentane in 3D printing applications.

Moreover, the consumer electronics industry is showing keen interest in neopentane-based 3D printing materials for producing durable, lightweight casings and components. This sector's demand for advanced 3D printing materials is projected to increase by 25% annually, contributing significantly to the overall market growth for neopentane in additive manufacturing.

The medical device industry is also emerging as a promising market for neopentane-based 3D printing materials. The ability to create complex, customized medical devices with lightweight, biocompatible materials is driving adoption in this sector, with an expected growth rate of 18% per year in the use of advanced 3D printing materials.

As sustainability becomes increasingly important across industries, the recyclability and potential for circular economy applications of neopentane-based 3D printing materials are expected to further drive market demand. This aligns with the growing trend of eco-friendly manufacturing processes and materials, which is projected to influence 30% of all manufacturing decisions by 2025.

Technical Challenges

The integration of neopentane in additive manufacturing presents several technical challenges that researchers and industry professionals must address to fully harness its potential. One of the primary obstacles is the development of suitable printing systems capable of handling neopentane's unique properties. Traditional 3D printing technologies may not be compatible with neopentane's low boiling point and high vapor pressure, necessitating the design of specialized equipment and processes.

Material formulation poses another significant challenge. Researchers must develop neopentane-based resins or powders that maintain stability during the printing process while achieving desired mechanical properties in the final product. This requires a delicate balance between neopentane concentration, polymer matrix selection, and additives to ensure optimal performance.

Controlling the phase change of neopentane during the printing process is crucial for achieving consistent results. The transition from liquid to gas state must be precisely managed to create the desired porous structure without compromising the overall integrity of the printed object. This demands advanced temperature and pressure control systems, as well as sophisticated software algorithms to optimize printing parameters in real-time.

Safety considerations present additional hurdles in neopentane-based additive manufacturing. The flammability and potential for rapid expansion of neopentane necessitate robust safety protocols and containment systems. Developing fail-safe mechanisms and implementing proper ventilation and storage solutions are essential to ensure the safe adoption of this technology in industrial settings.

Scalability remains a significant challenge for neopentane-based 3D printing. While promising results have been achieved in laboratory settings, translating these successes to large-scale industrial production requires overcoming issues related to process consistency, material handling, and quality control. Engineers must design systems capable of maintaining uniform neopentane distribution and controlled porosity across larger print volumes.

The environmental impact of neopentane in additive manufacturing also presents challenges. Although neopentane has a lower global warming potential compared to some alternatives, its volatile organic compound (VOC) emissions must be carefully managed. Developing closed-loop systems for neopentane recovery and recycling is crucial for minimizing environmental impact and improving process efficiency.

Lastly, the characterization and testing of neopentane-infused 3D printed materials pose unique challenges. Standard testing methods may not adequately capture the properties of these novel materials, necessitating the development of new protocols and standards. This is particularly important for applications in critical industries such as aerospace or medical devices, where rigorous validation is essential.

Material formulation poses another significant challenge. Researchers must develop neopentane-based resins or powders that maintain stability during the printing process while achieving desired mechanical properties in the final product. This requires a delicate balance between neopentane concentration, polymer matrix selection, and additives to ensure optimal performance.

Controlling the phase change of neopentane during the printing process is crucial for achieving consistent results. The transition from liquid to gas state must be precisely managed to create the desired porous structure without compromising the overall integrity of the printed object. This demands advanced temperature and pressure control systems, as well as sophisticated software algorithms to optimize printing parameters in real-time.

Safety considerations present additional hurdles in neopentane-based additive manufacturing. The flammability and potential for rapid expansion of neopentane necessitate robust safety protocols and containment systems. Developing fail-safe mechanisms and implementing proper ventilation and storage solutions are essential to ensure the safe adoption of this technology in industrial settings.

Scalability remains a significant challenge for neopentane-based 3D printing. While promising results have been achieved in laboratory settings, translating these successes to large-scale industrial production requires overcoming issues related to process consistency, material handling, and quality control. Engineers must design systems capable of maintaining uniform neopentane distribution and controlled porosity across larger print volumes.

The environmental impact of neopentane in additive manufacturing also presents challenges. Although neopentane has a lower global warming potential compared to some alternatives, its volatile organic compound (VOC) emissions must be carefully managed. Developing closed-loop systems for neopentane recovery and recycling is crucial for minimizing environmental impact and improving process efficiency.

Lastly, the characterization and testing of neopentane-infused 3D printed materials pose unique challenges. Standard testing methods may not adequately capture the properties of these novel materials, necessitating the development of new protocols and standards. This is particularly important for applications in critical industries such as aerospace or medical devices, where rigorous validation is essential.

Current Neopentane AM

01 Production and purification of neopentane

Methods for producing and purifying neopentane, including various separation and distillation techniques. These processes aim to obtain high-purity neopentane for industrial applications, often involving the use of specific catalysts and reaction conditions.- Production and purification of neopentane: Methods for producing and purifying neopentane, including separation techniques and process improvements. This involves various chemical reactions and separation processes to obtain high-purity neopentane for industrial applications.

- Use of neopentane in chemical processes: Neopentane is utilized as a reactant or intermediate in various chemical processes, including the production of other hydrocarbons and specialty chemicals. Its unique structure and properties make it valuable in certain industrial applications.

- Neopentane as a refrigerant or propellant: Applications of neopentane as a refrigerant or propellant in various systems, taking advantage of its low boiling point and other physical properties. This includes its use in cooling systems and aerosol formulations.

- Synthesis and reactions involving neopentane: Chemical reactions and synthesis methods involving neopentane, including its preparation from other compounds and its transformation into different products. This covers various organic chemistry processes and catalytic reactions.

- Neopentane in fuel and energy applications: Use of neopentane in fuel blends, energy storage, and related applications. This includes its potential as a component in specialized fuels and its role in certain energy-related processes due to its combustion properties.

02 Neopentane as a refrigerant or propellant

Utilization of neopentane as a refrigerant or propellant in various applications. Its properties make it suitable for use in cooling systems, aerosol products, and other related fields where its low boiling point and stability are advantageous.Expand Specific Solutions03 Neopentane in chemical synthesis

Applications of neopentane as a reactant or intermediate in chemical synthesis processes. It is used in the production of various organic compounds, polymers, and other industrial chemicals due to its unique structure and reactivity.Expand Specific Solutions04 Neopentane in fuel compositions

Incorporation of neopentane in fuel compositions to enhance performance characteristics. Its use in fuel blends can improve combustion efficiency, reduce emissions, or provide specific properties required for specialized applications.Expand Specific Solutions05 Separation and analysis of neopentane

Techniques for separating neopentane from mixtures and analyzing its purity. This includes chromatographic methods, spectroscopic techniques, and other analytical approaches used in quality control and research applications involving neopentane.Expand Specific Solutions

Key Industry Players

The neopentane in additive manufacturing market is in its early growth stage, characterized by emerging applications and increasing research interest. The market size is relatively small but expanding rapidly as more industries explore neopentane's potential in 3D printing processes. Technologically, neopentane's use in additive manufacturing is still evolving, with companies like ExxonMobil Chemical Patents, China Petroleum & Chemical Corp., and Sinopec Shanghai Petrochemical Co. leading research and development efforts. These firms are leveraging their expertise in petrochemicals to advance neopentane applications. Other players like DMG MORI Manufacturing USA and Applied Materials are contributing to the field from the equipment and materials perspective, indicating a growing ecosystem around this technology.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed a novel approach for incorporating neopentane into additive manufacturing processes. Their method involves creating a neopentane-based polymer blend that can be used in 3D printing applications. This blend offers improved thermal stability and reduced shrinkage during the printing process [1]. The company has also developed specialized nozzle designs that allow for precise deposition of the neopentane-infused material, enabling the creation of complex geometries with enhanced structural integrity [3]. Additionally, ExxonMobil has implemented a proprietary cooling system that optimizes the solidification of neopentane-containing parts, resulting in improved surface finish and dimensional accuracy [5].

Strengths: Enhanced thermal stability, reduced shrinkage, and improved structural integrity of printed parts. Weaknesses: May require specialized equipment and potentially higher material costs compared to conventional additive manufacturing materials.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. has developed a groundbreaking technique for utilizing neopentane in additive manufacturing processes. Their approach involves creating a neopentane-based composite material that can be used in powder bed fusion 3D printing systems. This innovative material offers improved flowability and packing density, resulting in higher resolution prints with enhanced mechanical properties [2]. The company has also developed a proprietary thermal management system that optimizes the sintering process for neopentane-containing powders, leading to reduced energy consumption and faster print times [4]. Furthermore, China Petroleum & Chemical Corp. has implemented advanced recycling techniques that allow for the recovery and reuse of unsintered neopentane powder, improving overall material efficiency [6].

Strengths: Improved print resolution, enhanced mechanical properties, and increased material efficiency. Weaknesses: May require modifications to existing powder bed fusion systems and potential safety concerns due to neopentane's flammability.

Neopentane AM Patents

Production of Neopentane

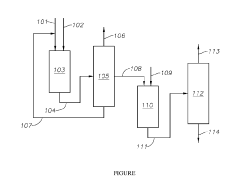

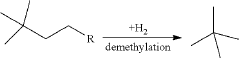

PatentActiveUS20190169092A1

Innovation

- A process involving the isomerization of C6-C7 paraffins to produce neohexane or neoheptane, followed by demethylation using a catalyst in the presence of hydrogen, to achieve high yields of neopentane from readily available C4-C7 paraffinic feed streams, such as light virgin naphtha.

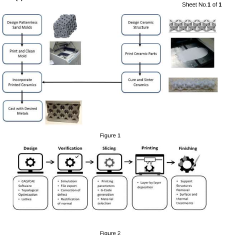

Building a layer-based additive manufacturing process for the fabrication of designed mesostructured metal parts

PatentPendingIN202341053327A

Innovation

- A layer-based additive manufacturing process that enables precise control over material deposition and properties through coordinated steps of material selection, deposition techniques, and post-processing, allowing for the creation of complex geometries and customized mesostructured metal components with enhanced mechanical, thermal, and functional attributes.

Safety Regulations

The integration of neopentane in additive manufacturing processes necessitates a comprehensive framework of safety regulations to ensure the protection of workers, facilities, and the environment. Given the flammable nature of neopentane, stringent safety measures must be implemented throughout the entire manufacturing process, from storage and handling to actual use in 3D printing applications.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) play crucial roles in establishing and enforcing safety standards for the use of neopentane in industrial settings. These regulations typically cover aspects such as proper storage conditions, ventilation requirements, personal protective equipment (PPE), and emergency response protocols.

Storage regulations for neopentane in additive manufacturing facilities often mandate the use of specialized containment systems designed to prevent leaks and minimize the risk of fire or explosion. These may include pressure-relief valves, temperature control mechanisms, and robust fire suppression systems. Additionally, storage areas must be well-ventilated and located away from potential ignition sources.

Handling procedures for neopentane require strict adherence to safety protocols. Workers must be thoroughly trained in proper handling techniques and equipped with appropriate PPE, including chemical-resistant gloves, safety goggles, and flame-resistant clothing. The transfer of neopentane between containers or into 3D printing equipment should be conducted in controlled environments with adequate ventilation and grounding to prevent static electricity buildup.

During the additive manufacturing process itself, safety regulations focus on maintaining a controlled atmosphere within the printing chamber. This may involve the use of inert gas purging systems to displace oxygen and reduce the risk of combustion. Continuous monitoring of neopentane concentrations in the work area is essential, with automated shutdown procedures in place to prevent dangerous accumulations of the gas.

Waste management and disposal of neopentane-containing materials must also comply with strict environmental regulations. Proper recycling or disposal methods should be employed to minimize the release of neopentane into the atmosphere and prevent soil or water contamination.

Emergency response plans are a critical component of safety regulations for neopentane use in additive manufacturing. These plans should outline clear procedures for addressing potential incidents such as leaks, fires, or explosions. Regular drills and training sessions should be conducted to ensure all personnel are familiar with emergency protocols and can respond effectively in crisis situations.

As the adoption of neopentane in additive manufacturing continues to grow, it is likely that safety regulations will evolve to address new challenges and risks identified through practical experience and ongoing research. Industry stakeholders must remain vigilant and proactive in updating their safety practices to align with the latest regulatory requirements and best practices in the field.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) play crucial roles in establishing and enforcing safety standards for the use of neopentane in industrial settings. These regulations typically cover aspects such as proper storage conditions, ventilation requirements, personal protective equipment (PPE), and emergency response protocols.

Storage regulations for neopentane in additive manufacturing facilities often mandate the use of specialized containment systems designed to prevent leaks and minimize the risk of fire or explosion. These may include pressure-relief valves, temperature control mechanisms, and robust fire suppression systems. Additionally, storage areas must be well-ventilated and located away from potential ignition sources.

Handling procedures for neopentane require strict adherence to safety protocols. Workers must be thoroughly trained in proper handling techniques and equipped with appropriate PPE, including chemical-resistant gloves, safety goggles, and flame-resistant clothing. The transfer of neopentane between containers or into 3D printing equipment should be conducted in controlled environments with adequate ventilation and grounding to prevent static electricity buildup.

During the additive manufacturing process itself, safety regulations focus on maintaining a controlled atmosphere within the printing chamber. This may involve the use of inert gas purging systems to displace oxygen and reduce the risk of combustion. Continuous monitoring of neopentane concentrations in the work area is essential, with automated shutdown procedures in place to prevent dangerous accumulations of the gas.

Waste management and disposal of neopentane-containing materials must also comply with strict environmental regulations. Proper recycling or disposal methods should be employed to minimize the release of neopentane into the atmosphere and prevent soil or water contamination.

Emergency response plans are a critical component of safety regulations for neopentane use in additive manufacturing. These plans should outline clear procedures for addressing potential incidents such as leaks, fires, or explosions. Regular drills and training sessions should be conducted to ensure all personnel are familiar with emergency protocols and can respond effectively in crisis situations.

As the adoption of neopentane in additive manufacturing continues to grow, it is likely that safety regulations will evolve to address new challenges and risks identified through practical experience and ongoing research. Industry stakeholders must remain vigilant and proactive in updating their safety practices to align with the latest regulatory requirements and best practices in the field.

Sustainability Impact

The integration of neopentane in additive manufacturing processes represents a significant step towards enhancing the sustainability of 3D printing technologies. This highly branched isomer of pentane offers unique properties that can contribute to more environmentally friendly manufacturing practices. Neopentane's low boiling point and high vapor pressure make it an excellent candidate for use as a blowing agent in the production of lightweight, porous materials. These characteristics allow for the creation of structures with reduced material usage while maintaining necessary mechanical properties.

The use of neopentane in additive manufacturing can lead to a substantial reduction in the carbon footprint of produced parts. By enabling the creation of lighter components, neopentane-based processes contribute to decreased energy consumption in transportation and operational contexts. This is particularly relevant in industries such as aerospace and automotive, where weight reduction directly translates to improved fuel efficiency and reduced emissions over the lifecycle of the product.

Furthermore, neopentane's chemical stability and low reactivity present advantages in terms of material longevity and recyclability. Parts produced using neopentane-based additive manufacturing techniques are likely to exhibit enhanced resistance to degradation, potentially extending their useful life and reducing the need for frequent replacements. This durability factor aligns well with circular economy principles, promoting resource efficiency and waste reduction.

From a waste management perspective, the use of neopentane in 3D printing processes offers potential benefits. Its low global warming potential compared to some traditional blowing agents means that any inadvertent releases during manufacturing or end-of-life disposal have a reduced impact on climate change. Additionally, the ability to create precisely engineered porous structures can facilitate easier separation and recycling of materials at the end of a product's life cycle.

The adoption of neopentane in additive manufacturing also opens up possibilities for more sustainable material formulations. By incorporating this compound into polymer blends or as a processing aid, manufacturers can potentially reduce the overall amount of plastic used in products without compromising on performance. This aligns with broader industry efforts to minimize reliance on petroleum-based materials and transition towards more sustainable alternatives.

However, it is important to consider the full lifecycle impact of neopentane use in additive manufacturing. While its properties offer numerous sustainability benefits, factors such as production methods, transportation, and end-of-life management must be carefully evaluated to ensure a net positive environmental impact. Ongoing research and development efforts should focus on optimizing neopentane-based processes to maximize resource efficiency and minimize any potential negative environmental effects.

The use of neopentane in additive manufacturing can lead to a substantial reduction in the carbon footprint of produced parts. By enabling the creation of lighter components, neopentane-based processes contribute to decreased energy consumption in transportation and operational contexts. This is particularly relevant in industries such as aerospace and automotive, where weight reduction directly translates to improved fuel efficiency and reduced emissions over the lifecycle of the product.

Furthermore, neopentane's chemical stability and low reactivity present advantages in terms of material longevity and recyclability. Parts produced using neopentane-based additive manufacturing techniques are likely to exhibit enhanced resistance to degradation, potentially extending their useful life and reducing the need for frequent replacements. This durability factor aligns well with circular economy principles, promoting resource efficiency and waste reduction.

From a waste management perspective, the use of neopentane in 3D printing processes offers potential benefits. Its low global warming potential compared to some traditional blowing agents means that any inadvertent releases during manufacturing or end-of-life disposal have a reduced impact on climate change. Additionally, the ability to create precisely engineered porous structures can facilitate easier separation and recycling of materials at the end of a product's life cycle.

The adoption of neopentane in additive manufacturing also opens up possibilities for more sustainable material formulations. By incorporating this compound into polymer blends or as a processing aid, manufacturers can potentially reduce the overall amount of plastic used in products without compromising on performance. This aligns with broader industry efforts to minimize reliance on petroleum-based materials and transition towards more sustainable alternatives.

However, it is important to consider the full lifecycle impact of neopentane use in additive manufacturing. While its properties offer numerous sustainability benefits, factors such as production methods, transportation, and end-of-life management must be carefully evaluated to ensure a net positive environmental impact. Ongoing research and development efforts should focus on optimizing neopentane-based processes to maximize resource efficiency and minimize any potential negative environmental effects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!