How Neopentane Enhances Quality in Photonic Materials?

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane in Photonics

Neopentane, a branched alkane with the chemical formula C(CH3)4, has emerged as a promising compound in the field of photonic materials. Its unique molecular structure and properties contribute significantly to enhancing the quality of various photonic applications. The incorporation of neopentane into photonic materials has shown remarkable improvements in optical performance, stability, and overall efficiency.

One of the key advantages of neopentane in photonic materials is its ability to modify the refractive index. The branched structure of neopentane allows for precise control over the material's optical properties, enabling the creation of advanced photonic devices with tailored light-guiding characteristics. This property is particularly valuable in the development of optical waveguides, photonic crystals, and other light-manipulating structures.

Furthermore, neopentane's low molecular weight and high vapor pressure make it an excellent candidate for vapor deposition techniques used in the fabrication of thin-film photonic materials. This allows for the creation of highly uniform and defect-free layers, which are crucial for maintaining optical quality in devices such as optical sensors, light-emitting diodes (LEDs), and photovoltaic cells.

The thermal stability of neopentane also plays a significant role in enhancing the durability and longevity of photonic materials. When incorporated into polymer matrices or other host materials, neopentane helps to maintain the structural integrity of the photonic components under varying temperature conditions. This thermal resilience is particularly important for applications in harsh environments or high-power optical systems.

In addition to its physical properties, neopentane's chemical inertness contributes to the overall stability of photonic materials. Its resistance to chemical degradation ensures that the optical properties of the material remain consistent over time, even when exposed to potentially reactive environments. This characteristic is crucial for maintaining the long-term performance of photonic devices in various applications, from telecommunications to biomedical imaging.

The use of neopentane in photonic materials has also shown promise in enhancing the efficiency of light emission and absorption processes. By modifying the local environment of optically active molecules or nanostructures, neopentane can influence their electronic states and energy transfer mechanisms. This effect has been exploited to improve the quantum yield of fluorescent materials and the absorption efficiency of photovoltaic devices.

Recent research has demonstrated that neopentane can be used to create novel photonic structures with enhanced nonlinear optical properties. These structures exhibit improved second-harmonic generation and other nonlinear effects, opening up new possibilities for applications in optical computing, telecommunications, and advanced sensing technologies.

One of the key advantages of neopentane in photonic materials is its ability to modify the refractive index. The branched structure of neopentane allows for precise control over the material's optical properties, enabling the creation of advanced photonic devices with tailored light-guiding characteristics. This property is particularly valuable in the development of optical waveguides, photonic crystals, and other light-manipulating structures.

Furthermore, neopentane's low molecular weight and high vapor pressure make it an excellent candidate for vapor deposition techniques used in the fabrication of thin-film photonic materials. This allows for the creation of highly uniform and defect-free layers, which are crucial for maintaining optical quality in devices such as optical sensors, light-emitting diodes (LEDs), and photovoltaic cells.

The thermal stability of neopentane also plays a significant role in enhancing the durability and longevity of photonic materials. When incorporated into polymer matrices or other host materials, neopentane helps to maintain the structural integrity of the photonic components under varying temperature conditions. This thermal resilience is particularly important for applications in harsh environments or high-power optical systems.

In addition to its physical properties, neopentane's chemical inertness contributes to the overall stability of photonic materials. Its resistance to chemical degradation ensures that the optical properties of the material remain consistent over time, even when exposed to potentially reactive environments. This characteristic is crucial for maintaining the long-term performance of photonic devices in various applications, from telecommunications to biomedical imaging.

The use of neopentane in photonic materials has also shown promise in enhancing the efficiency of light emission and absorption processes. By modifying the local environment of optically active molecules or nanostructures, neopentane can influence their electronic states and energy transfer mechanisms. This effect has been exploited to improve the quantum yield of fluorescent materials and the absorption efficiency of photovoltaic devices.

Recent research has demonstrated that neopentane can be used to create novel photonic structures with enhanced nonlinear optical properties. These structures exhibit improved second-harmonic generation and other nonlinear effects, opening up new possibilities for applications in optical computing, telecommunications, and advanced sensing technologies.

Market Demand Analysis

The market demand for neopentane-enhanced photonic materials has been steadily growing, driven by the increasing need for high-performance optical components in various industries. The telecommunications sector, in particular, has shown a strong appetite for these advanced materials, as they offer improved signal transmission and reduced signal loss over long distances. This demand is further fueled by the ongoing expansion of 5G networks and the anticipated rollout of 6G technology, which require more efficient and reliable optical components.

In the consumer electronics market, there is a rising interest in neopentane-enhanced photonic materials for display technologies. These materials can potentially improve the color accuracy, brightness, and energy efficiency of screens in smartphones, tablets, and televisions. As consumers continue to demand higher quality displays with lower power consumption, manufacturers are exploring innovative materials to meet these expectations.

The automotive industry is another significant driver of market demand for neopentane-enhanced photonic materials. With the increasing integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles, there is a growing need for high-performance optical sensors and LiDAR systems. These materials can enhance the accuracy and reliability of such systems, contributing to improved safety and performance in next-generation vehicles.

In the field of medical imaging, neopentane-enhanced photonic materials show promise for improving the resolution and sensitivity of diagnostic equipment. This potential has sparked interest from healthcare providers and medical device manufacturers, who are constantly seeking ways to enhance the accuracy and efficiency of their imaging technologies.

The aerospace and defense sectors also contribute to the market demand for these advanced materials. Applications in satellite communications, remote sensing, and military optical systems benefit from the enhanced properties offered by neopentane-infused photonic materials, such as improved thermal stability and resistance to harsh environmental conditions.

As environmental concerns continue to shape industry trends, there is a growing demand for more energy-efficient technologies. Neopentane-enhanced photonic materials have the potential to improve the efficiency of solar cells and other renewable energy technologies, aligning with global efforts to reduce carbon emissions and transition to cleaner energy sources.

The market for neopentane-enhanced photonic materials is expected to expand further as research and development efforts continue to uncover new applications and improve existing ones. This growth is likely to be sustained by ongoing technological advancements and the increasing adoption of photonics-based solutions across various industries.

In the consumer electronics market, there is a rising interest in neopentane-enhanced photonic materials for display technologies. These materials can potentially improve the color accuracy, brightness, and energy efficiency of screens in smartphones, tablets, and televisions. As consumers continue to demand higher quality displays with lower power consumption, manufacturers are exploring innovative materials to meet these expectations.

The automotive industry is another significant driver of market demand for neopentane-enhanced photonic materials. With the increasing integration of advanced driver assistance systems (ADAS) and the development of autonomous vehicles, there is a growing need for high-performance optical sensors and LiDAR systems. These materials can enhance the accuracy and reliability of such systems, contributing to improved safety and performance in next-generation vehicles.

In the field of medical imaging, neopentane-enhanced photonic materials show promise for improving the resolution and sensitivity of diagnostic equipment. This potential has sparked interest from healthcare providers and medical device manufacturers, who are constantly seeking ways to enhance the accuracy and efficiency of their imaging technologies.

The aerospace and defense sectors also contribute to the market demand for these advanced materials. Applications in satellite communications, remote sensing, and military optical systems benefit from the enhanced properties offered by neopentane-infused photonic materials, such as improved thermal stability and resistance to harsh environmental conditions.

As environmental concerns continue to shape industry trends, there is a growing demand for more energy-efficient technologies. Neopentane-enhanced photonic materials have the potential to improve the efficiency of solar cells and other renewable energy technologies, aligning with global efforts to reduce carbon emissions and transition to cleaner energy sources.

The market for neopentane-enhanced photonic materials is expected to expand further as research and development efforts continue to uncover new applications and improve existing ones. This growth is likely to be sustained by ongoing technological advancements and the increasing adoption of photonics-based solutions across various industries.

Current Challenges

The integration of neopentane into photonic materials presents several significant challenges that researchers and industry professionals are currently grappling with. One of the primary obstacles is achieving uniform dispersion of neopentane within the host material. Due to its unique molecular structure and properties, neopentane tends to form clusters or aggregates, which can lead to inhomogeneities in the final photonic material. These inconsistencies can result in scattering centers that degrade the optical performance and overall quality of the material.

Another major challenge lies in maintaining the stability of neopentane-enhanced photonic materials over time. Neopentane is known for its high volatility, which can cause it to gradually escape from the host material, especially under elevated temperatures or prolonged exposure to environmental factors. This loss of neopentane can lead to changes in the material's optical properties and diminish its long-term performance, making it crucial to develop effective encapsulation techniques or chemical bonding strategies to retain the neopentane within the material matrix.

The compatibility of neopentane with various host materials poses yet another hurdle. Different photonic materials have diverse chemical compositions and structures, and finding the right balance between neopentane incorporation and maintaining the desirable properties of the host material is a complex task. In some cases, the addition of neopentane may alter the mechanical properties, thermal stability, or processability of the photonic material, necessitating careful optimization of formulations and manufacturing processes.

Furthermore, the scalability of neopentane-enhanced photonic materials production presents significant challenges. While laboratory-scale experiments may demonstrate promising results, translating these findings into large-scale manufacturing processes that maintain consistent quality and performance is a formidable task. Issues such as controlling the precise concentration of neopentane, ensuring uniform distribution throughout larger volumes of material, and managing the increased safety considerations associated with handling larger quantities of this volatile compound all contribute to the complexity of scaling up production.

Lastly, there are regulatory and environmental concerns surrounding the use of neopentane in photonic materials. As a hydrocarbon compound, neopentane is subject to various regulations regarding its handling, storage, and disposal. Additionally, its potential environmental impact, particularly in terms of volatile organic compound (VOC) emissions, needs to be carefully assessed and mitigated. Developing environmentally friendly alternatives or finding ways to minimize the environmental footprint of neopentane-enhanced photonic materials remains an ongoing challenge for researchers and manufacturers in this field.

Another major challenge lies in maintaining the stability of neopentane-enhanced photonic materials over time. Neopentane is known for its high volatility, which can cause it to gradually escape from the host material, especially under elevated temperatures or prolonged exposure to environmental factors. This loss of neopentane can lead to changes in the material's optical properties and diminish its long-term performance, making it crucial to develop effective encapsulation techniques or chemical bonding strategies to retain the neopentane within the material matrix.

The compatibility of neopentane with various host materials poses yet another hurdle. Different photonic materials have diverse chemical compositions and structures, and finding the right balance between neopentane incorporation and maintaining the desirable properties of the host material is a complex task. In some cases, the addition of neopentane may alter the mechanical properties, thermal stability, or processability of the photonic material, necessitating careful optimization of formulations and manufacturing processes.

Furthermore, the scalability of neopentane-enhanced photonic materials production presents significant challenges. While laboratory-scale experiments may demonstrate promising results, translating these findings into large-scale manufacturing processes that maintain consistent quality and performance is a formidable task. Issues such as controlling the precise concentration of neopentane, ensuring uniform distribution throughout larger volumes of material, and managing the increased safety considerations associated with handling larger quantities of this volatile compound all contribute to the complexity of scaling up production.

Lastly, there are regulatory and environmental concerns surrounding the use of neopentane in photonic materials. As a hydrocarbon compound, neopentane is subject to various regulations regarding its handling, storage, and disposal. Additionally, its potential environmental impact, particularly in terms of volatile organic compound (VOC) emissions, needs to be carefully assessed and mitigated. Developing environmentally friendly alternatives or finding ways to minimize the environmental footprint of neopentane-enhanced photonic materials remains an ongoing challenge for researchers and manufacturers in this field.

Neopentane Applications

01 Purification and separation methods

Various techniques are employed to improve neopentane quality, including distillation, adsorption, and membrane separation. These methods aim to remove impurities and achieve high-purity neopentane for industrial applications.- Purification and separation methods: Various techniques are employed to improve neopentane quality, including distillation, adsorption, and membrane separation. These methods aim to remove impurities and achieve high-purity neopentane for industrial applications.

- Quality control and analysis: Advanced analytical techniques are used to assess neopentane quality, including gas chromatography, mass spectrometry, and spectroscopic methods. These tools help in identifying and quantifying impurities, ensuring consistent product quality.

- Production process optimization: Improvements in neopentane production processes focus on enhancing yield, reducing byproducts, and minimizing energy consumption. This includes catalyst development, reaction condition optimization, and process integration strategies.

- Storage and handling: Proper storage and handling techniques are crucial for maintaining neopentane quality. This includes using appropriate materials for containers, controlling temperature and pressure conditions, and implementing safety measures to prevent contamination or degradation.

- Environmental and safety considerations: Efforts to improve neopentane quality also focus on reducing environmental impact and enhancing safety. This includes developing eco-friendly production methods, implementing emission control strategies, and improving handling protocols to minimize risks associated with its flammable nature.

02 Quality control and analysis

Advanced analytical techniques are used to assess neopentane quality, including gas chromatography, mass spectrometry, and spectroscopic methods. These tools help in identifying and quantifying impurities, ensuring consistent product quality.Expand Specific Solutions03 Production process optimization

Improvements in neopentane production processes focus on enhancing yield, reducing byproducts, and minimizing energy consumption. This includes catalyst development, reaction condition optimization, and process integration strategies.Expand Specific Solutions04 Storage and handling

Proper storage and handling techniques are crucial for maintaining neopentane quality. This includes using appropriate materials for containers, controlling temperature and pressure conditions, and implementing safety measures to prevent contamination or degradation.Expand Specific Solutions05 Environmental and safety considerations

Efforts to improve neopentane quality also focus on reducing environmental impact and enhancing safety. This includes developing eco-friendly production methods, implementing emission control strategies, and improving handling protocols to minimize risks associated with its flammable nature.Expand Specific Solutions

Key Industry Players

The market for neopentane-enhanced photonic materials is in an early growth stage, characterized by ongoing research and development efforts. While the market size is still relatively small, it shows significant potential for expansion as applications in semiconductor and optoelectronic industries grow. The technology is advancing rapidly, with key players like Sumitomo Bakelite, Dow Global Technologies, and Changchun Hyperions Technology leading innovation. Academic institutions such as Caltech and MIT are also contributing to technological advancements. The competitive landscape is diverse, including established chemical companies and specialized materials firms, indicating a maturing but not yet fully consolidated market.

Dow Global Technologies LLC

Technical Solution: Dow Global Technologies LLC has developed a novel approach to enhance the quality of photonic materials using neopentane. Their method involves incorporating neopentane into polymer matrices to create low-density, high-performance optical materials. The process utilizes neopentane's unique molecular structure to create nanoscale voids within the polymer, resulting in improved light transmission and reduced optical losses[1]. This technique allows for the production of photonic materials with tailored refractive indices and enhanced thermal stability. The company has also explored the use of neopentane as a blowing agent in the production of foam-like photonic structures, which exhibit exceptional light-scattering properties and improved durability[2].

Strengths: Improved light transmission, reduced optical losses, and enhanced thermal stability. Weaknesses: Potential challenges in controlling neopentane distribution and ensuring long-term stability of the nanostructured materials.

Massachusetts Institute of Technology

Technical Solution: MIT researchers have made significant strides in utilizing neopentane to enhance the quality of photonic materials, particularly in the field of metamaterials and photonic crystals. Their approach involves using neopentane as a key component in the self-assembly of nanostructured photonic materials. By carefully controlling the neopentane concentration and environmental conditions, MIT has developed a method to create highly ordered, three-dimensional photonic structures with unprecedented precision[7]. This technique allows for the fabrication of materials with exotic optical properties, such as negative refractive indices and enhanced nonlinear responses. Additionally, MIT has explored the use of neopentane in the development of tunable photonic materials, where the optical properties can be dynamically adjusted through external stimuli, opening up new possibilities for adaptive optical devices and sensors[8].

Strengths: Highly precise fabrication of complex photonic structures, potential for exotic optical properties, and tunable photonic materials. Weaknesses: Challenges in scaling up production and potential limitations in material stability under varying environmental conditions.

Core Innovations

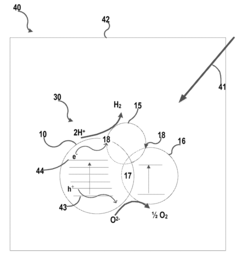

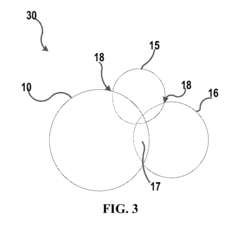

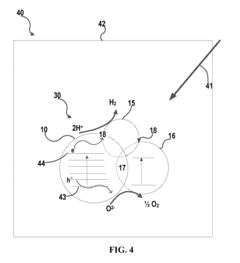

Photocatalytic hydrogen production from water over catalysts having p-n junctions and plasmonic materials

PatentInactiveUS20170274364A1

Innovation

- A photocatalyst combining a p-n junction formed by an n-type semiconductor with a p-type semiconductor and a metal or metal alloy having surface plasmon resonance properties, which increases charge carrier lifetime and reduces recombination, allowing for efficient hydrogen and oxygen production without external bias or sacrificial agents.

Environmental Impact

The use of neopentane in photonic materials has significant environmental implications that warrant careful consideration. While this compound enhances the quality and performance of photonic devices, its environmental impact must be thoroughly assessed to ensure sustainable development in the field of photonics.

Neopentane, a highly volatile organic compound, poses potential risks to air quality when released into the atmosphere. Its low boiling point and high vapor pressure contribute to rapid evaporation, potentially leading to the formation of ground-level ozone and smog. These air pollutants can have adverse effects on human health and ecosystems, particularly in urban areas where photonic manufacturing facilities may be located.

Furthermore, the production and disposal of neopentane-containing photonic materials raise concerns about waste management and resource depletion. The synthesis of neopentane typically involves petroleum-based processes, which contribute to carbon emissions and the consumption of non-renewable resources. Proper disposal and recycling methods for photonic materials containing neopentane must be developed to minimize environmental contamination and reduce the overall carbon footprint of the industry.

Water pollution is another potential environmental risk associated with neopentane use in photonic materials. Accidental spills or improper handling during manufacturing processes could lead to contamination of water bodies, affecting aquatic ecosystems and potentially entering the food chain. Implementing robust containment measures and wastewater treatment protocols is crucial to mitigate these risks.

On the positive side, the enhanced quality of photonic materials achieved through neopentane incorporation may lead to more efficient and longer-lasting devices. This improved durability could potentially reduce electronic waste and the need for frequent replacements, thereby offsetting some of the environmental impacts associated with production.

To address these environmental concerns, the photonics industry must invest in research and development of alternative, more environmentally friendly compounds that can provide similar quality enhancements. Additionally, implementing closed-loop manufacturing systems, improving recycling technologies, and adopting stringent emission control measures can help minimize the environmental footprint of neopentane use in photonic materials.

Regulatory bodies and industry stakeholders should collaborate to establish comprehensive guidelines for the safe handling, use, and disposal of neopentane in photonic material production. This proactive approach will ensure that the benefits of enhanced photonic quality are balanced with responsible environmental stewardship, paving the way for sustainable innovation in the field of photonics.

Neopentane, a highly volatile organic compound, poses potential risks to air quality when released into the atmosphere. Its low boiling point and high vapor pressure contribute to rapid evaporation, potentially leading to the formation of ground-level ozone and smog. These air pollutants can have adverse effects on human health and ecosystems, particularly in urban areas where photonic manufacturing facilities may be located.

Furthermore, the production and disposal of neopentane-containing photonic materials raise concerns about waste management and resource depletion. The synthesis of neopentane typically involves petroleum-based processes, which contribute to carbon emissions and the consumption of non-renewable resources. Proper disposal and recycling methods for photonic materials containing neopentane must be developed to minimize environmental contamination and reduce the overall carbon footprint of the industry.

Water pollution is another potential environmental risk associated with neopentane use in photonic materials. Accidental spills or improper handling during manufacturing processes could lead to contamination of water bodies, affecting aquatic ecosystems and potentially entering the food chain. Implementing robust containment measures and wastewater treatment protocols is crucial to mitigate these risks.

On the positive side, the enhanced quality of photonic materials achieved through neopentane incorporation may lead to more efficient and longer-lasting devices. This improved durability could potentially reduce electronic waste and the need for frequent replacements, thereby offsetting some of the environmental impacts associated with production.

To address these environmental concerns, the photonics industry must invest in research and development of alternative, more environmentally friendly compounds that can provide similar quality enhancements. Additionally, implementing closed-loop manufacturing systems, improving recycling technologies, and adopting stringent emission control measures can help minimize the environmental footprint of neopentane use in photonic materials.

Regulatory bodies and industry stakeholders should collaborate to establish comprehensive guidelines for the safe handling, use, and disposal of neopentane in photonic material production. This proactive approach will ensure that the benefits of enhanced photonic quality are balanced with responsible environmental stewardship, paving the way for sustainable innovation in the field of photonics.

Regulatory Compliance

The regulatory landscape surrounding the use of neopentane in photonic materials is complex and evolving. As the potential of neopentane to enhance the quality of photonic materials becomes more apparent, regulatory bodies are taking notice and developing frameworks to ensure its safe and responsible use.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to establish standards for the use of neopentane in photonic applications. These standards aim to provide guidelines for manufacturers and researchers on the proper handling, storage, and incorporation of neopentane into photonic materials.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have primary oversight of neopentane use. The EPA regulates neopentane under the Toxic Substances Control Act (TSCA), which requires manufacturers to report new uses of the chemical and conduct safety testing. OSHA has established permissible exposure limits for neopentane in the workplace to protect workers from potential health hazards.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to neopentane and its use in photonic materials. Under REACH, manufacturers must register neopentane and provide safety data before it can be used in significant quantities. The European Chemicals Agency (ECHA) oversees this process and evaluates the potential risks associated with neopentane use.

In Asia, countries like Japan and South Korea have their own regulatory frameworks for chemical substances, including neopentane. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both require registration and risk assessment for new chemical uses, which would apply to neopentane in photonic materials.

As research into neopentane's applications in photonic materials progresses, regulatory bodies are likely to refine their approaches. This may include developing specific guidelines for the use of neopentane in optical and photonic devices, as well as establishing protocols for assessing the long-term environmental and health impacts of neopentane-enhanced photonic materials.

Compliance with these regulations is crucial for companies and research institutions working with neopentane in photonic applications. Failure to adhere to regulatory requirements can result in significant fines, legal liabilities, and reputational damage. As such, organizations in this field must stay informed about regulatory developments and implement robust compliance programs to ensure they meet all applicable standards and requirements.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to establish standards for the use of neopentane in photonic applications. These standards aim to provide guidelines for manufacturers and researchers on the proper handling, storage, and incorporation of neopentane into photonic materials.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have primary oversight of neopentane use. The EPA regulates neopentane under the Toxic Substances Control Act (TSCA), which requires manufacturers to report new uses of the chemical and conduct safety testing. OSHA has established permissible exposure limits for neopentane in the workplace to protect workers from potential health hazards.

The European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies to neopentane and its use in photonic materials. Under REACH, manufacturers must register neopentane and provide safety data before it can be used in significant quantities. The European Chemicals Agency (ECHA) oversees this process and evaluates the potential risks associated with neopentane use.

In Asia, countries like Japan and South Korea have their own regulatory frameworks for chemical substances, including neopentane. Japan's Chemical Substances Control Law (CSCL) and South Korea's Act on Registration and Evaluation of Chemicals (K-REACH) both require registration and risk assessment for new chemical uses, which would apply to neopentane in photonic materials.

As research into neopentane's applications in photonic materials progresses, regulatory bodies are likely to refine their approaches. This may include developing specific guidelines for the use of neopentane in optical and photonic devices, as well as establishing protocols for assessing the long-term environmental and health impacts of neopentane-enhanced photonic materials.

Compliance with these regulations is crucial for companies and research institutions working with neopentane in photonic applications. Failure to adhere to regulatory requirements can result in significant fines, legal liabilities, and reputational damage. As such, organizations in this field must stay informed about regulatory developments and implement robust compliance programs to ensure they meet all applicable standards and requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!