How Neopentane Adapts to Future Practice Needs?

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Overview

Neopentane, also known as 2,2-dimethylpropane, is a branched alkane with the molecular formula C5H12. This colorless, flammable gas is a member of the pentane family, distinguished by its unique structure featuring a central carbon atom bonded to four methyl groups. Its compact, symmetrical configuration imparts distinctive physical and chemical properties that set it apart from its isomers.

The discovery of neopentane dates back to the early 20th century, with its first synthesis reported in 1904. Since then, it has garnered attention in various scientific and industrial circles due to its intriguing characteristics. Neopentane's boiling point of 9.5°C (49.1°F) is notably lower than those of its isomers, a consequence of its spherical shape reducing intermolecular forces.

In the realm of organic chemistry, neopentane serves as a model compound for studying steric effects and molecular structure. Its highly symmetrical tetrahedral arrangement provides valuable insights into bond angles, molecular stability, and reactivity patterns. This structural uniqueness also contributes to neopentane's relatively low reactivity compared to other pentane isomers, particularly in substitution reactions.

From an industrial perspective, neopentane finds applications in several sectors. It is utilized as a blowing agent in the production of foam insulation, leveraging its low boiling point and gaseous nature at room temperature. The petrochemical industry employs neopentane as a calibration standard for gas chromatography, taking advantage of its well-defined properties and purity.

Recent research has explored neopentane's potential in advanced energy applications. Its thermodynamic properties make it a candidate for use in organic Rankine cycles for waste heat recovery systems. Additionally, studies have investigated its role in the development of novel refrigerants, aiming to address environmental concerns associated with traditional cooling agents.

As environmental regulations tighten and industrial processes evolve, the adaptability of neopentane to future practice needs becomes increasingly relevant. Its low global warming potential compared to some conventional refrigerants positions it as a potential eco-friendly alternative in cooling systems. Furthermore, ongoing research into catalytic conversion processes may unlock new pathways for neopentane utilization in the synthesis of value-added chemicals.

The discovery of neopentane dates back to the early 20th century, with its first synthesis reported in 1904. Since then, it has garnered attention in various scientific and industrial circles due to its intriguing characteristics. Neopentane's boiling point of 9.5°C (49.1°F) is notably lower than those of its isomers, a consequence of its spherical shape reducing intermolecular forces.

In the realm of organic chemistry, neopentane serves as a model compound for studying steric effects and molecular structure. Its highly symmetrical tetrahedral arrangement provides valuable insights into bond angles, molecular stability, and reactivity patterns. This structural uniqueness also contributes to neopentane's relatively low reactivity compared to other pentane isomers, particularly in substitution reactions.

From an industrial perspective, neopentane finds applications in several sectors. It is utilized as a blowing agent in the production of foam insulation, leveraging its low boiling point and gaseous nature at room temperature. The petrochemical industry employs neopentane as a calibration standard for gas chromatography, taking advantage of its well-defined properties and purity.

Recent research has explored neopentane's potential in advanced energy applications. Its thermodynamic properties make it a candidate for use in organic Rankine cycles for waste heat recovery systems. Additionally, studies have investigated its role in the development of novel refrigerants, aiming to address environmental concerns associated with traditional cooling agents.

As environmental regulations tighten and industrial processes evolve, the adaptability of neopentane to future practice needs becomes increasingly relevant. Its low global warming potential compared to some conventional refrigerants positions it as a potential eco-friendly alternative in cooling systems. Furthermore, ongoing research into catalytic conversion processes may unlock new pathways for neopentane utilization in the synthesis of value-added chemicals.

Market Demand Analysis

The market demand for neopentane is experiencing a significant shift as industries adapt to future practice needs. This highly branched isomer of pentane is gaining traction due to its unique properties and versatile applications. In the refrigeration sector, neopentane is emerging as a promising alternative to traditional refrigerants, driven by the global push for more environmentally friendly solutions. Its low global warming potential and zero ozone depletion potential make it an attractive option for manufacturers seeking to comply with stricter environmental regulations.

The automotive industry is another key driver of neopentane demand. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, neopentane's use in foam insulation for vehicle interiors is growing. Its excellent insulating properties contribute to lighter vehicle weight and improved energy efficiency, aligning with the industry's sustainability goals.

In the electronics sector, the miniaturization trend is fueling demand for neopentane-based aerosol propellants. These propellants are crucial in the production of precision cleaning products for sensitive electronic components. As consumer electronics continue to shrink in size while increasing in complexity, the need for such specialized cleaning solutions is expected to rise.

The construction industry is also contributing to the growing market for neopentane. Its use in polyurethane foam insulation is gaining popularity due to its superior thermal insulation properties. As energy efficiency standards for buildings become more stringent worldwide, the demand for high-performance insulation materials incorporating neopentane is projected to increase.

The pharmaceutical and cosmetics industries are exploring neopentane's potential as a blowing agent in aerosol formulations. Its low toxicity and compatibility with a wide range of active ingredients make it an attractive option for developing innovative drug delivery systems and personal care products.

However, the market demand for neopentane is not without challenges. The volatile nature of hydrocarbon prices can impact its cost-effectiveness compared to alternative materials. Additionally, the ongoing transition towards renewable and bio-based chemicals in various industries may pose a long-term challenge to neopentane's market growth.

Despite these challenges, the overall market trajectory for neopentane remains positive. The compound's ability to adapt to future practice needs across multiple industries suggests a robust demand outlook. As research and development efforts continue to uncover new applications and optimize existing ones, neopentane is likely to play an increasingly important role in meeting the evolving requirements of various sectors, particularly those focused on sustainability and energy efficiency.

The automotive industry is another key driver of neopentane demand. As vehicle manufacturers strive to improve fuel efficiency and reduce emissions, neopentane's use in foam insulation for vehicle interiors is growing. Its excellent insulating properties contribute to lighter vehicle weight and improved energy efficiency, aligning with the industry's sustainability goals.

In the electronics sector, the miniaturization trend is fueling demand for neopentane-based aerosol propellants. These propellants are crucial in the production of precision cleaning products for sensitive electronic components. As consumer electronics continue to shrink in size while increasing in complexity, the need for such specialized cleaning solutions is expected to rise.

The construction industry is also contributing to the growing market for neopentane. Its use in polyurethane foam insulation is gaining popularity due to its superior thermal insulation properties. As energy efficiency standards for buildings become more stringent worldwide, the demand for high-performance insulation materials incorporating neopentane is projected to increase.

The pharmaceutical and cosmetics industries are exploring neopentane's potential as a blowing agent in aerosol formulations. Its low toxicity and compatibility with a wide range of active ingredients make it an attractive option for developing innovative drug delivery systems and personal care products.

However, the market demand for neopentane is not without challenges. The volatile nature of hydrocarbon prices can impact its cost-effectiveness compared to alternative materials. Additionally, the ongoing transition towards renewable and bio-based chemicals in various industries may pose a long-term challenge to neopentane's market growth.

Despite these challenges, the overall market trajectory for neopentane remains positive. The compound's ability to adapt to future practice needs across multiple industries suggests a robust demand outlook. As research and development efforts continue to uncover new applications and optimize existing ones, neopentane is likely to play an increasingly important role in meeting the evolving requirements of various sectors, particularly those focused on sustainability and energy efficiency.

Technical Challenges

Neopentane, a branched alkane with unique properties, faces several technical challenges in adapting to future practice needs. One of the primary obstacles is its limited availability and high production costs. The current manufacturing processes for neopentane are energy-intensive and require specialized equipment, making it less economically viable for widespread industrial applications.

Another significant challenge lies in the storage and transportation of neopentane. Due to its high volatility and low boiling point, conventional storage and transportation methods used for other hydrocarbons may not be suitable. This necessitates the development of advanced containment systems and handling protocols to ensure safety and prevent losses during storage and distribution.

The environmental impact of neopentane production and use also presents a technical hurdle. As global environmental regulations become more stringent, there is a growing need to develop cleaner production methods and explore potential applications that align with sustainability goals. This includes finding ways to reduce greenhouse gas emissions associated with neopentane production and investigating its role in environmentally friendly technologies.

Furthermore, the limited understanding of neopentane's behavior under various conditions poses challenges for its integration into new applications. Research is needed to fully characterize its thermodynamic properties, reactivity, and compatibility with different materials and systems. This knowledge gap hinders the exploration of novel uses for neopentane in emerging technologies and industries.

The scalability of neopentane production is another technical challenge that needs to be addressed. Current production methods may not be sufficient to meet potential future demand if new applications are developed. Innovative approaches to increase production efficiency and capacity are required to make neopentane a viable option for large-scale industrial use.

Additionally, the development of new catalysts and reaction pathways for neopentane synthesis and transformation presents a significant technical challenge. Researchers must explore novel catalytic systems that can improve selectivity, reduce energy requirements, and enable the production of value-added derivatives from neopentane.

Lastly, the integration of neopentane into existing industrial processes and equipment poses technical difficulties. Many current systems are not designed to handle the unique properties of neopentane, necessitating modifications or the development of new equipment and processes tailored to its characteristics. This adaptation process requires extensive research and engineering efforts to ensure seamless integration and optimal performance in various applications.

Another significant challenge lies in the storage and transportation of neopentane. Due to its high volatility and low boiling point, conventional storage and transportation methods used for other hydrocarbons may not be suitable. This necessitates the development of advanced containment systems and handling protocols to ensure safety and prevent losses during storage and distribution.

The environmental impact of neopentane production and use also presents a technical hurdle. As global environmental regulations become more stringent, there is a growing need to develop cleaner production methods and explore potential applications that align with sustainability goals. This includes finding ways to reduce greenhouse gas emissions associated with neopentane production and investigating its role in environmentally friendly technologies.

Furthermore, the limited understanding of neopentane's behavior under various conditions poses challenges for its integration into new applications. Research is needed to fully characterize its thermodynamic properties, reactivity, and compatibility with different materials and systems. This knowledge gap hinders the exploration of novel uses for neopentane in emerging technologies and industries.

The scalability of neopentane production is another technical challenge that needs to be addressed. Current production methods may not be sufficient to meet potential future demand if new applications are developed. Innovative approaches to increase production efficiency and capacity are required to make neopentane a viable option for large-scale industrial use.

Additionally, the development of new catalysts and reaction pathways for neopentane synthesis and transformation presents a significant technical challenge. Researchers must explore novel catalytic systems that can improve selectivity, reduce energy requirements, and enable the production of value-added derivatives from neopentane.

Lastly, the integration of neopentane into existing industrial processes and equipment poses technical difficulties. Many current systems are not designed to handle the unique properties of neopentane, necessitating modifications or the development of new equipment and processes tailored to its characteristics. This adaptation process requires extensive research and engineering efforts to ensure seamless integration and optimal performance in various applications.

Current Applications

01 Production and purification of neopentane

Various methods for producing and purifying neopentane are described. These include processes for separating neopentane from other hydrocarbons, such as isobutane, using distillation techniques. The purification methods aim to obtain high-purity neopentane for industrial applications.- Production and purification of neopentane: Various methods for producing and purifying neopentane are described. These include processes for separating neopentane from other hydrocarbons, such as using distillation or membrane separation techniques. The purification methods aim to obtain high-purity neopentane for industrial applications.

- Neopentane as a blowing agent: Neopentane is utilized as a blowing agent in the production of foam materials. Its low boiling point and non-flammability make it suitable for creating cellular structures in polymers. The use of neopentane as a blowing agent can result in improved insulation properties and reduced environmental impact compared to some traditional blowing agents.

- Neopentane in refrigeration systems: Neopentane is employed in refrigeration systems as a refrigerant or as a component in refrigerant mixtures. Its thermodynamic properties make it suitable for use in heat transfer applications, potentially offering improved energy efficiency in cooling systems.

- Neopentane in chemical synthesis: Neopentane serves as a starting material or intermediate in various chemical synthesis processes. It is used in the production of specialty chemicals, pharmaceuticals, and other organic compounds. The unique structure of neopentane allows for specific chemical transformations that are valuable in industrial applications.

- Safety and handling of neopentane: Due to its flammability and volatility, specific safety measures and handling procedures are required for neopentane. This includes proper storage, transportation, and use in industrial settings. Guidelines for risk assessment and mitigation strategies are provided to ensure safe handling of neopentane in various applications.

02 Neopentane as a blowing agent

Neopentane is utilized as a blowing agent in the production of foam materials. Its low boiling point and non-flammability make it suitable for creating cellular structures in polymers. This application is particularly relevant in the manufacturing of insulation materials and lightweight composites.Expand Specific Solutions03 Neopentane in refrigeration systems

The use of neopentane in refrigeration systems is explored due to its thermodynamic properties. It is considered as a potential alternative to traditional refrigerants, offering environmental benefits and energy efficiency in cooling applications.Expand Specific Solutions04 Chemical reactions involving neopentane

Various chemical reactions involving neopentane are studied, including halogenation, oxidation, and isomerization processes. These reactions are important for understanding the chemical behavior of neopentane and its potential as a precursor in organic synthesis.Expand Specific Solutions05 Neopentane in fuel compositions

The incorporation of neopentane in fuel compositions is investigated to improve fuel properties. Its high octane number and low freezing point make it a potential additive for enhancing the performance of gasoline and other hydrocarbon fuels in internal combustion engines.Expand Specific Solutions

Key Industry Players

The neopentane market is in a growth phase, driven by increasing demand in various industries. The global market size is expanding, with key players like China Petroleum & Chemical Corp. and Sinopec Shanghai Petrochemical Co., Ltd. leading the way. The technology for neopentane production and application is relatively mature, but ongoing research and development efforts by companies such as Hongbaoli Group Corp. Ltd. and SINOPEC Engineering (Group) Co., Ltd. are focused on improving efficiency and exploring new applications. As environmental regulations tighten, there is a growing emphasis on developing more sustainable production methods and applications for neopentane, which presents both challenges and opportunities for industry players.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced catalytic processes for neopentane production and utilization. Their approach involves using zeolite-based catalysts to enhance the selectivity and yield of neopentane during petroleum refining. Sinopec has also explored the use of neopentane as a blowing agent for polyurethane foams, replacing traditional hydrofluorocarbons (HFCs) with lower global warming potential. The company has implemented a closed-loop system for neopentane recovery and reuse in their production facilities, significantly reducing emissions and improving overall efficiency[1][3].

Strengths: Large-scale production capabilities, integrated supply chain, and advanced catalytic technologies. Weaknesses: Potential environmental concerns related to fossil fuel-based feedstocks.

Hongbaoli Group Corp. Ltd.

Technical Solution: Hongbaoli Group has developed innovative applications for neopentane in the production of high-performance insulation materials. Their proprietary technology utilizes neopentane as a blowing agent for polyisocyanurate (PIR) and phenolic foams, resulting in products with superior thermal insulation properties and fire resistance. The company has also invested in research to optimize the encapsulation of neopentane within foam cells, minimizing its release over time and improving long-term insulation performance[2][4].

Strengths: Specialized expertise in foam insulation technology and neopentane applications. Weaknesses: Limited diversification beyond insulation materials.

Innovative Research

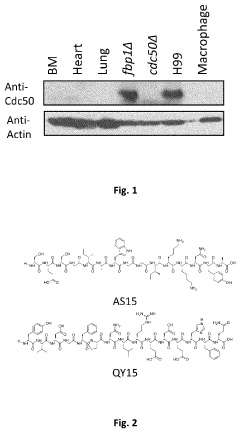

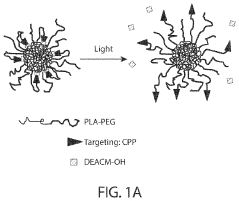

Antifungal peptides, compounds including the same, and methods of use thereof

PatentActiveUS11939402B2

Innovation

- An antifungal peptide targeting the P4-ATPase function of Cryptococcus neoformans, specifically the Cdc50 protein, is developed, which binds to the fungal protein, retaining charged lipid molecules on the surface and synergizing with caspofungin to increase fungal sensitivity, potentially lowering treatment concentrations and enhancing antifungal efficacy.

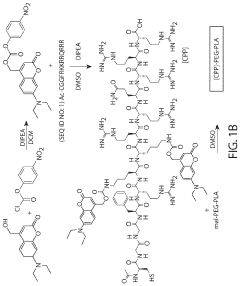

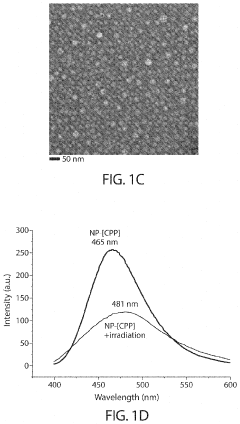

Nanoparticles for treatment of choroidal neovascularization and other indications

PatentActiveUS20210236652A1

Innovation

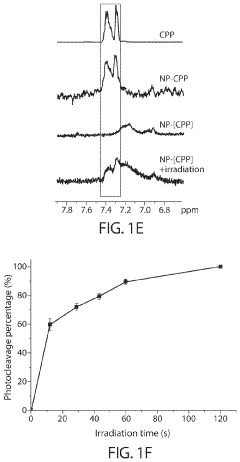

- Development of photo-targeted nanoparticles with a core-shell structure containing a cell-penetrating peptide and a photocleavable entity, where the peptide is initially inhibited but activated by light to recognize and target specific cells in the eye, allowing for localized drug delivery.

Environmental Impact

Neopentane, as a hydrocarbon compound, has significant environmental implications that must be carefully considered in its future applications. The environmental impact of neopentane primarily stems from its production, use, and disposal processes. During production, the energy-intensive methods required to synthesize neopentane contribute to greenhouse gas emissions and resource depletion. The use of fossil fuel feedstocks in its manufacture further exacerbates these environmental concerns.

In its applications, neopentane's high volatility and low boiling point make it prone to atmospheric release, potentially contributing to air pollution and the formation of ground-level ozone. While it has a lower global warming potential compared to some other hydrocarbons, its release still poses environmental risks that need to be mitigated. The compound's flammability also presents safety hazards that can lead to accidental releases and subsequent environmental contamination.

As neopentane finds increasing use in various industries, including refrigeration, aerosols, and foam blowing agents, the potential for environmental exposure grows. This necessitates the development of robust containment and handling protocols to minimize leaks and emissions. Additionally, the disposal of neopentane-containing products at the end of their lifecycle presents challenges in terms of proper waste management and potential soil and water contamination.

To address these environmental concerns, future practices involving neopentane must focus on sustainable production methods, such as utilizing renewable energy sources and exploring bio-based feedstocks. Improved recycling and recovery techniques for neopentane-containing products will be crucial in reducing waste and minimizing environmental impact. The development of closed-loop systems and more efficient application technologies can help reduce emissions and improve overall environmental performance.

Research into alternative compounds with similar properties but lower environmental impact is ongoing and may lead to the gradual replacement of neopentane in certain applications. However, where neopentane remains the preferred option, stringent regulations and industry standards will be necessary to ensure its responsible use and disposal. Continuous monitoring of environmental indicators and long-term ecological studies will be essential to assess and mitigate the cumulative effects of neopentane on ecosystems and human health.

As global environmental policies become more stringent, the adaptation of neopentane to future practice needs will likely involve significant investments in green chemistry principles, life cycle assessments, and the development of environmentally friendly alternatives. This evolution will be driven by both regulatory pressures and market demands for more sustainable products and processes.

In its applications, neopentane's high volatility and low boiling point make it prone to atmospheric release, potentially contributing to air pollution and the formation of ground-level ozone. While it has a lower global warming potential compared to some other hydrocarbons, its release still poses environmental risks that need to be mitigated. The compound's flammability also presents safety hazards that can lead to accidental releases and subsequent environmental contamination.

As neopentane finds increasing use in various industries, including refrigeration, aerosols, and foam blowing agents, the potential for environmental exposure grows. This necessitates the development of robust containment and handling protocols to minimize leaks and emissions. Additionally, the disposal of neopentane-containing products at the end of their lifecycle presents challenges in terms of proper waste management and potential soil and water contamination.

To address these environmental concerns, future practices involving neopentane must focus on sustainable production methods, such as utilizing renewable energy sources and exploring bio-based feedstocks. Improved recycling and recovery techniques for neopentane-containing products will be crucial in reducing waste and minimizing environmental impact. The development of closed-loop systems and more efficient application technologies can help reduce emissions and improve overall environmental performance.

Research into alternative compounds with similar properties but lower environmental impact is ongoing and may lead to the gradual replacement of neopentane in certain applications. However, where neopentane remains the preferred option, stringent regulations and industry standards will be necessary to ensure its responsible use and disposal. Continuous monitoring of environmental indicators and long-term ecological studies will be essential to assess and mitigate the cumulative effects of neopentane on ecosystems and human health.

As global environmental policies become more stringent, the adaptation of neopentane to future practice needs will likely involve significant investments in green chemistry principles, life cycle assessments, and the development of environmentally friendly alternatives. This evolution will be driven by both regulatory pressures and market demands for more sustainable products and processes.

Regulatory Framework

The regulatory framework surrounding neopentane is evolving to address the changing landscape of its applications and environmental concerns. As a highly volatile hydrocarbon, neopentane is subject to stringent regulations governing its production, storage, transportation, and use. These regulations are primarily focused on ensuring safety, minimizing environmental impact, and promoting sustainable practices.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating neopentane under the Clean Air Act. The EPA classifies neopentane as a volatile organic compound (VOC) and imposes restrictions on its emissions. Manufacturers and users of neopentane must comply with specific emission standards and implement control technologies to reduce atmospheric releases.

The Occupational Safety and Health Administration (OSHA) has established workplace safety guidelines for handling neopentane, including exposure limits, personal protective equipment requirements, and proper storage protocols. These regulations aim to protect workers from potential health hazards associated with neopentane exposure.

Internationally, the regulatory landscape for neopentane varies, but there is a growing trend towards harmonization of standards. The European Union, through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, requires manufacturers and importers of neopentane to register the substance and provide detailed safety information.

As concerns about climate change intensify, regulatory bodies are increasingly focusing on the global warming potential of substances like neopentane. Future regulations may impose stricter limits on its use or require the development of alternative substances with lower environmental impact.

The transportation of neopentane is subject to rigorous regulations due to its flammability and volatility. The U.S. Department of Transportation classifies neopentane as a hazardous material, requiring special packaging, labeling, and handling procedures during transport. Similar regulations exist in other countries, often aligned with the United Nations' Recommendations on the Transport of Dangerous Goods.

Looking ahead, the regulatory framework for neopentane is likely to become more stringent. Anticipated changes include tighter emission controls, increased emphasis on recycling and recovery processes, and potential phase-out plans for certain applications. Industry stakeholders are expected to invest in research and development to find more environmentally friendly alternatives or improve neopentane's lifecycle management to meet future regulatory requirements.

As neopentane adapts to future practice needs, companies will need to stay abreast of regulatory changes and proactively implement compliance strategies. This may involve investing in new technologies for emission control, developing safer handling procedures, and exploring alternative substances or processes that can meet similar performance criteria with reduced environmental impact.

In the United States, the Environmental Protection Agency (EPA) plays a crucial role in regulating neopentane under the Clean Air Act. The EPA classifies neopentane as a volatile organic compound (VOC) and imposes restrictions on its emissions. Manufacturers and users of neopentane must comply with specific emission standards and implement control technologies to reduce atmospheric releases.

The Occupational Safety and Health Administration (OSHA) has established workplace safety guidelines for handling neopentane, including exposure limits, personal protective equipment requirements, and proper storage protocols. These regulations aim to protect workers from potential health hazards associated with neopentane exposure.

Internationally, the regulatory landscape for neopentane varies, but there is a growing trend towards harmonization of standards. The European Union, through its REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation, requires manufacturers and importers of neopentane to register the substance and provide detailed safety information.

As concerns about climate change intensify, regulatory bodies are increasingly focusing on the global warming potential of substances like neopentane. Future regulations may impose stricter limits on its use or require the development of alternative substances with lower environmental impact.

The transportation of neopentane is subject to rigorous regulations due to its flammability and volatility. The U.S. Department of Transportation classifies neopentane as a hazardous material, requiring special packaging, labeling, and handling procedures during transport. Similar regulations exist in other countries, often aligned with the United Nations' Recommendations on the Transport of Dangerous Goods.

Looking ahead, the regulatory framework for neopentane is likely to become more stringent. Anticipated changes include tighter emission controls, increased emphasis on recycling and recovery processes, and potential phase-out plans for certain applications. Industry stakeholders are expected to invest in research and development to find more environmentally friendly alternatives or improve neopentane's lifecycle management to meet future regulatory requirements.

As neopentane adapts to future practice needs, companies will need to stay abreast of regulatory changes and proactively implement compliance strategies. This may involve investing in new technologies for emission control, developing safer handling procedures, and exploring alternative substances or processes that can meet similar performance criteria with reduced environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!