Neopentane in Chemical Looping Combustion Applications

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane CLC Background and Objectives

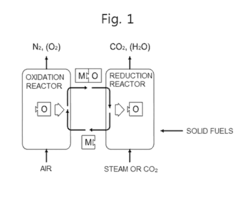

Chemical Looping Combustion (CLC) has emerged as a promising technology for carbon capture and storage in recent years. The evolution of CLC has been driven by the urgent need to mitigate greenhouse gas emissions, particularly CO2, from fossil fuel combustion. Neopentane, a branched alkane with the formula C(CH3)4, has recently gained attention as a potential fuel in CLC applications due to its unique properties and potential advantages over conventional fuels.

The development of CLC technology can be traced back to the early 1980s, with significant advancements made in the past two decades. Initially focused on gaseous fuels like methane and syngas, researchers have gradually expanded the scope to include liquid and solid fuels. The introduction of neopentane as a fuel for CLC represents a new frontier in this field, aiming to overcome some of the limitations associated with traditional fuels.

Neopentane's highly branched structure and symmetrical molecular geometry contribute to its distinct chemical and physical properties. These characteristics make it an intriguing candidate for CLC applications, potentially offering improved reactivity, reduced carbon deposition, and enhanced overall system efficiency. The exploration of neopentane in CLC aligns with the broader trend of diversifying fuel options to optimize the technology's performance and applicability across various industrial sectors.

The primary objectives of investigating neopentane in CLC applications are multifaceted. Firstly, researchers aim to comprehensively understand the reaction kinetics and mechanisms of neopentane oxidation in the context of chemical looping systems. This includes studying the interaction between neopentane and various oxygen carriers, as well as the formation and behavior of intermediate species during the combustion process.

Secondly, there is a focus on evaluating the potential benefits of neopentane over conventional fuels in terms of conversion efficiency, oxygen carrier utilization, and overall system performance. This involves comparative studies to quantify any improvements in reaction rates, heat transfer, and carbon capture efficiency that may be achieved through the use of neopentane.

Another key objective is to assess the technical feasibility and economic viability of integrating neopentane into existing CLC systems or developing new systems specifically optimized for neopentane combustion. This includes addressing challenges related to fuel handling, storage, and delivery, as well as any modifications required in reactor design or oxygen carrier selection.

Furthermore, researchers aim to explore the environmental implications of using neopentane in CLC, including its potential to reduce harmful emissions and improve the overall carbon footprint of the combustion process. This aligns with the broader goals of CLC technology in mitigating climate change and promoting sustainable energy solutions.

The development of CLC technology can be traced back to the early 1980s, with significant advancements made in the past two decades. Initially focused on gaseous fuels like methane and syngas, researchers have gradually expanded the scope to include liquid and solid fuels. The introduction of neopentane as a fuel for CLC represents a new frontier in this field, aiming to overcome some of the limitations associated with traditional fuels.

Neopentane's highly branched structure and symmetrical molecular geometry contribute to its distinct chemical and physical properties. These characteristics make it an intriguing candidate for CLC applications, potentially offering improved reactivity, reduced carbon deposition, and enhanced overall system efficiency. The exploration of neopentane in CLC aligns with the broader trend of diversifying fuel options to optimize the technology's performance and applicability across various industrial sectors.

The primary objectives of investigating neopentane in CLC applications are multifaceted. Firstly, researchers aim to comprehensively understand the reaction kinetics and mechanisms of neopentane oxidation in the context of chemical looping systems. This includes studying the interaction between neopentane and various oxygen carriers, as well as the formation and behavior of intermediate species during the combustion process.

Secondly, there is a focus on evaluating the potential benefits of neopentane over conventional fuels in terms of conversion efficiency, oxygen carrier utilization, and overall system performance. This involves comparative studies to quantify any improvements in reaction rates, heat transfer, and carbon capture efficiency that may be achieved through the use of neopentane.

Another key objective is to assess the technical feasibility and economic viability of integrating neopentane into existing CLC systems or developing new systems specifically optimized for neopentane combustion. This includes addressing challenges related to fuel handling, storage, and delivery, as well as any modifications required in reactor design or oxygen carrier selection.

Furthermore, researchers aim to explore the environmental implications of using neopentane in CLC, including its potential to reduce harmful emissions and improve the overall carbon footprint of the combustion process. This aligns with the broader goals of CLC technology in mitigating climate change and promoting sustainable energy solutions.

Market Analysis for CLC Technologies

The Chemical Looping Combustion (CLC) technology market is experiencing significant growth and attracting increasing attention from both industry and academia. This innovative combustion process offers substantial environmental benefits, particularly in reducing carbon dioxide emissions from fossil fuel combustion. The global CLC market is primarily driven by the growing demand for cleaner energy solutions and stringent environmental regulations aimed at mitigating climate change.

In recent years, the CLC market has witnessed a steady expansion, with a compound annual growth rate (CAGR) projected to remain strong over the next decade. This growth is attributed to the technology's potential to achieve near-zero emissions in power generation and industrial processes. The market is segmented based on fuel type, including solid fuels (coal, biomass) and gaseous fuels (natural gas, syngas), with each segment showing distinct growth patterns and adoption rates.

The power generation sector currently dominates the CLC market, followed by the oil and gas industry. However, emerging applications in the chemical and petrochemical sectors are expected to contribute significantly to market growth in the coming years. Geographically, North America and Europe lead in CLC technology adoption, driven by stringent emission regulations and substantial investments in research and development. Asia-Pacific is anticipated to emerge as a high-growth market, propelled by rapid industrialization and increasing environmental concerns in countries like China and India.

Key market players in the CLC technology space include established energy companies, innovative startups, and research institutions. These entities are actively engaged in pilot projects, technology demonstrations, and commercial-scale implementations. The competitive landscape is characterized by strategic partnerships, collaborations, and mergers and acquisitions aimed at accelerating technology development and market penetration.

Despite the promising outlook, the CLC market faces several challenges. These include high initial capital costs, technical complexities in scaling up the technology, and the need for further optimization of oxygen carrier materials. Additionally, the market's growth is influenced by factors such as government policies, carbon pricing mechanisms, and the overall transition towards renewable energy sources.

The integration of neopentane as a fuel in CLC applications represents a niche but potentially significant segment within the broader CLC market. Neopentane's unique properties, including its high energy density and clean combustion characteristics, make it an attractive option for specific CLC applications. However, the market for neopentane-based CLC systems is still in its early stages, with limited commercial deployments and ongoing research to fully exploit its potential.

In recent years, the CLC market has witnessed a steady expansion, with a compound annual growth rate (CAGR) projected to remain strong over the next decade. This growth is attributed to the technology's potential to achieve near-zero emissions in power generation and industrial processes. The market is segmented based on fuel type, including solid fuels (coal, biomass) and gaseous fuels (natural gas, syngas), with each segment showing distinct growth patterns and adoption rates.

The power generation sector currently dominates the CLC market, followed by the oil and gas industry. However, emerging applications in the chemical and petrochemical sectors are expected to contribute significantly to market growth in the coming years. Geographically, North America and Europe lead in CLC technology adoption, driven by stringent emission regulations and substantial investments in research and development. Asia-Pacific is anticipated to emerge as a high-growth market, propelled by rapid industrialization and increasing environmental concerns in countries like China and India.

Key market players in the CLC technology space include established energy companies, innovative startups, and research institutions. These entities are actively engaged in pilot projects, technology demonstrations, and commercial-scale implementations. The competitive landscape is characterized by strategic partnerships, collaborations, and mergers and acquisitions aimed at accelerating technology development and market penetration.

Despite the promising outlook, the CLC market faces several challenges. These include high initial capital costs, technical complexities in scaling up the technology, and the need for further optimization of oxygen carrier materials. Additionally, the market's growth is influenced by factors such as government policies, carbon pricing mechanisms, and the overall transition towards renewable energy sources.

The integration of neopentane as a fuel in CLC applications represents a niche but potentially significant segment within the broader CLC market. Neopentane's unique properties, including its high energy density and clean combustion characteristics, make it an attractive option for specific CLC applications. However, the market for neopentane-based CLC systems is still in its early stages, with limited commercial deployments and ongoing research to fully exploit its potential.

Neopentane CLC Technical Challenges

Chemical Looping Combustion (CLC) using neopentane as a fuel presents several technical challenges that need to be addressed for efficient and sustainable implementation. One of the primary obstacles is the high thermal stability of neopentane, which makes it resistant to decomposition at typical CLC operating temperatures. This characteristic necessitates the development of more active oxygen carriers capable of facilitating the oxidation of neopentane at lower temperatures without compromising the overall system efficiency.

Another significant challenge lies in the potential for carbon deposition on the oxygen carrier particles. Neopentane, being a branched alkane, has a higher tendency to form coke compared to linear hydrocarbons. This carbon deposition can lead to reduced reactivity of the oxygen carrier over time, affecting the long-term performance and stability of the CLC system. Strategies to mitigate coke formation, such as optimizing reactor design or incorporating catalytic materials, need to be explored.

The volatility of neopentane at room temperature poses additional challenges in terms of fuel handling and storage. Special containment systems and safety measures are required to prevent fuel losses and ensure safe operation. This aspect also complicates the fuel feeding mechanism in continuous CLC processes, necessitating the development of robust and reliable fuel introduction systems.

Furthermore, the combustion kinetics of neopentane in CLC systems are not as well understood as those of simpler hydrocarbons. This knowledge gap hampers the accurate modeling and optimization of CLC reactors for neopentane. Comprehensive kinetic studies and reaction mechanism elucidation are essential for improving reactor designs and operational strategies.

The selection of appropriate oxygen carrier materials for neopentane CLC is also challenging. The oxygen carrier must possess high reactivity towards neopentane, good mechanical strength to withstand multiple redox cycles, and resistance to agglomeration under CLC conditions. Additionally, the carrier should exhibit minimal tendency to promote side reactions that could lead to the formation of unwanted by-products or affect the purity of the CO2 stream produced.

Lastly, the integration of neopentane CLC into existing power generation or industrial processes presents technical hurdles. The unique properties of neopentane and its combustion characteristics may require modifications to heat exchange systems, gas separation units, and overall process configurations. Ensuring seamless integration while maintaining high energy efficiency and CO2 capture rates remains a significant challenge in the practical implementation of neopentane-based CLC technology.

Another significant challenge lies in the potential for carbon deposition on the oxygen carrier particles. Neopentane, being a branched alkane, has a higher tendency to form coke compared to linear hydrocarbons. This carbon deposition can lead to reduced reactivity of the oxygen carrier over time, affecting the long-term performance and stability of the CLC system. Strategies to mitigate coke formation, such as optimizing reactor design or incorporating catalytic materials, need to be explored.

The volatility of neopentane at room temperature poses additional challenges in terms of fuel handling and storage. Special containment systems and safety measures are required to prevent fuel losses and ensure safe operation. This aspect also complicates the fuel feeding mechanism in continuous CLC processes, necessitating the development of robust and reliable fuel introduction systems.

Furthermore, the combustion kinetics of neopentane in CLC systems are not as well understood as those of simpler hydrocarbons. This knowledge gap hampers the accurate modeling and optimization of CLC reactors for neopentane. Comprehensive kinetic studies and reaction mechanism elucidation are essential for improving reactor designs and operational strategies.

The selection of appropriate oxygen carrier materials for neopentane CLC is also challenging. The oxygen carrier must possess high reactivity towards neopentane, good mechanical strength to withstand multiple redox cycles, and resistance to agglomeration under CLC conditions. Additionally, the carrier should exhibit minimal tendency to promote side reactions that could lead to the formation of unwanted by-products or affect the purity of the CO2 stream produced.

Lastly, the integration of neopentane CLC into existing power generation or industrial processes presents technical hurdles. The unique properties of neopentane and its combustion characteristics may require modifications to heat exchange systems, gas separation units, and overall process configurations. Ensuring seamless integration while maintaining high energy efficiency and CO2 capture rates remains a significant challenge in the practical implementation of neopentane-based CLC technology.

Current Neopentane CLC Solutions

01 Production and purification of neopentane

Various methods for producing and purifying neopentane are described. These include processes for separating neopentane from other hydrocarbons, such as using distillation or membrane separation techniques. The purification methods aim to obtain high-purity neopentane for industrial applications.- Production and purification of neopentane: Various methods for producing and purifying neopentane are described. These include processes for separating neopentane from other hydrocarbons, such as using distillation or membrane separation techniques. The purification methods aim to obtain high-purity neopentane for industrial applications.

- Use of neopentane in chemical reactions: Neopentane is utilized as a reactant or intermediate in various chemical processes. It can be used in the production of other chemicals, such as specialty lubricants, refrigerants, or as a blowing agent. The unique structure of neopentane makes it valuable in certain chemical transformations.

- Neopentane as a refrigerant or propellant: The properties of neopentane make it suitable for use as a refrigerant or propellant in various applications. Its low boiling point and stability contribute to its effectiveness in these roles. Research focuses on optimizing its performance and addressing environmental concerns.

- Neopentane in polymer production: Neopentane is used in the production of certain polymers and plastics. It can serve as a blowing agent in foam production or as a component in polymer formulations. The incorporation of neopentane can impart specific properties to the resulting materials.

- Safety and handling of neopentane: Due to its flammability and volatility, special considerations are required for the safe handling and storage of neopentane. This includes proper containment methods, safety protocols, and equipment design to minimize risks associated with its use in industrial settings.

02 Use of neopentane in chemical reactions

Neopentane is utilized as a reactant or intermediate in various chemical processes. It can be used in the synthesis of other organic compounds, particularly in the production of specialty chemicals and pharmaceuticals. The unique structure of neopentane makes it valuable for certain chemical transformations.Expand Specific Solutions03 Applications of neopentane in refrigeration and aerosols

Neopentane finds applications in refrigeration systems and as a propellant in aerosol products. Its low boiling point and favorable thermodynamic properties make it suitable for use in cooling systems. In aerosols, it serves as an environmentally friendly alternative to certain conventional propellants.Expand Specific Solutions04 Neopentane in polymer production

Neopentane is used in the production of certain polymers and plastics. It can serve as a blowing agent in the manufacture of foam materials or as a component in polymer formulations. The incorporation of neopentane can impart specific properties to the resulting polymeric materials.Expand Specific Solutions05 Safety and handling of neopentane

Due to its flammability and volatility, special considerations are required for the safe handling and storage of neopentane. This includes proper containment methods, safety measures during transportation, and guidelines for its use in industrial settings to minimize risks associated with its physical properties.Expand Specific Solutions

Key Players in CLC Research and Development

The chemical looping combustion (CLC) technology utilizing neopentane is in an early development stage, with a growing market potential driven by increasing focus on clean energy solutions. The market size is relatively small but expected to expand as the technology matures. Currently, the technical readiness level is low to moderate, with ongoing research and development efforts. Key players in this field include ExxonMobil Chemical Patents, Inc., focusing on polymer manufacturing, and academic institutions like Southeast University and Qingdao University of Science & Technology, contributing to fundamental research. Companies such as The Chemours Co. and Wacker Chemie AG are also potential contributors, leveraging their expertise in chemical engineering and materials science to advance CLC applications with neopentane.

ExxonMobil Chemical Patents, Inc.

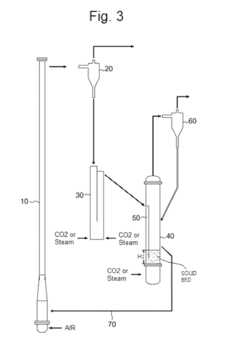

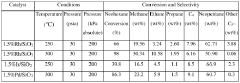

Technical Solution: ExxonMobil has developed an innovative approach to chemical looping combustion (CLC) using neopentane as a fuel. Their technology involves a dual-reactor system where neopentane is oxidized in one reactor using a metal oxide oxygen carrier, typically iron-based. The reduced oxygen carrier is then regenerated in a second reactor with air. This process allows for efficient combustion with inherent CO2 capture, as the fuel and air streams never mix directly[1]. ExxonMobil's system is designed to operate at high temperatures (800-1000°C) to maximize energy efficiency and reaction kinetics[2]. They have also developed specialized oxygen carriers that are resistant to carbon deposition, a common issue with hydrocarbon fuels in CLC[3].

Strengths: High CO2 capture efficiency, potential for integration with existing infrastructure, and reduced NOx emissions. Weaknesses: Complexity of dual-reactor system and potential for oxygen carrier degradation over time.

Shell Internationale Research Maatschappij BV

Technical Solution: Shell has pioneered a chemical looping combustion system that can utilize neopentane and other light hydrocarbons. Their approach focuses on a novel oxygen carrier material composed of mixed metal oxides, which demonstrates high reactivity with neopentane and excellent resistance to sintering[4]. The system operates in a circulating fluidized bed configuration, allowing for continuous operation and improved heat transfer. Shell's technology incorporates in-situ oxygen carrier regeneration, reducing the need for frequent material replacement[5]. Additionally, they have developed advanced process control algorithms to optimize the fuel-to-oxygen carrier ratio, ensuring complete combustion while minimizing excess oxygen[6].

Strengths: Highly efficient oxygen carrier utilization, scalable fluidized bed design, and advanced process control. Weaknesses: Potential for attrition of oxygen carrier particles in the fluidized bed and complexity of the circulation system.

Core Innovations in Neopentane CLC

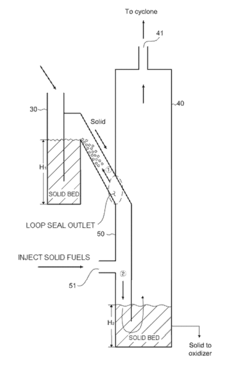

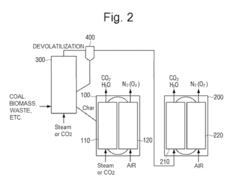

Chemical looping combustion method and apparatus for solid fuels using different oxygen carriers

PatentActiveUS9683737B2

Innovation

- The proposed solution involves a chemical looping combustion method and apparatus that separates solid fuels into volatile matter and char, using low-priced oxygen carriers for char combustion in a solid fuel combustor and high-priced oxygen carriers for volatile matter combustion in a gaseous fuel combustor, enhancing reaction rates and reducing the need for frequent oxygen carrier replacement.

Production of neopentane

PatentWO2018044592A1

Innovation

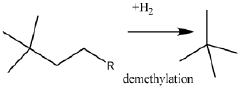

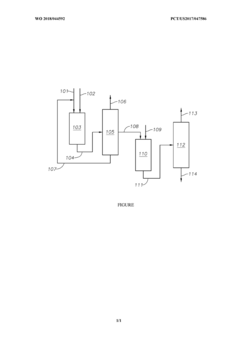

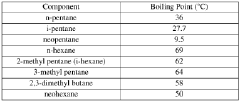

- A process involving the isomerization of C6-C7 paraffins to produce neohexane or neoheptane, followed by demethylation using a catalyst in the presence of hydrogen, which allows for the production of neopentane with yields greater than 40 wt% from readily available C4-C7 paraffinic feed streams, such as light virgin naphtha.

Environmental Impact of Neopentane CLC

The environmental impact of neopentane in Chemical Looping Combustion (CLC) applications is a critical consideration for the sustainable implementation of this technology. Neopentane, a branched alkane with the formula C5H12, presents unique challenges and opportunities in CLC systems.

One of the primary environmental benefits of using neopentane in CLC is its potential for reduced greenhouse gas emissions compared to conventional combustion methods. CLC technology inherently separates CO2 from other flue gases, facilitating easier capture and storage. When neopentane is used as a fuel in CLC, the process can achieve near-complete fuel conversion, resulting in minimal unburned hydrocarbon emissions.

However, the production and handling of neopentane itself may have environmental implications. As a volatile organic compound (VOC), neopentane can contribute to the formation of ground-level ozone if released into the atmosphere. Strict containment measures and proper handling protocols are essential to mitigate these risks throughout the CLC process.

The use of neopentane in CLC may also impact local air quality. While CLC generally produces fewer nitrogen oxides (NOx) than conventional combustion, the specific NOx formation characteristics with neopentane as a fuel require careful evaluation. Additionally, the potential for particulate matter emissions, although typically low in CLC systems, should be assessed for neopentane-based operations.

Water usage and thermal pollution are other environmental factors to consider. CLC systems using neopentane may require cooling processes, which could impact local water resources. The heat generated during the CLC process must be managed efficiently to minimize thermal pollution and maximize energy recovery.

Life cycle assessment (LCA) of neopentane in CLC applications is crucial for understanding its overall environmental footprint. This includes considering the energy and resources required for neopentane production, transportation, and storage, as well as the end-of-life management of CLC system components.

The potential for accidental releases and their environmental consequences must also be addressed. While neopentane is not highly toxic, its flammability and potential to form explosive mixtures with air necessitate robust safety measures to prevent environmental contamination and associated ecological impacts.

In terms of land use, CLC facilities using neopentane may have a smaller footprint compared to traditional power plants due to their higher efficiency and integrated CO2 capture capabilities. This could lead to reduced habitat disruption and land transformation associated with energy production.

As research in this field progresses, ongoing environmental monitoring and assessment will be crucial to fully understand and mitigate the long-term impacts of neopentane-based CLC systems on ecosystems and human health. Regulatory frameworks and industry standards will need to evolve to address the specific environmental challenges and opportunities presented by this technology.

One of the primary environmental benefits of using neopentane in CLC is its potential for reduced greenhouse gas emissions compared to conventional combustion methods. CLC technology inherently separates CO2 from other flue gases, facilitating easier capture and storage. When neopentane is used as a fuel in CLC, the process can achieve near-complete fuel conversion, resulting in minimal unburned hydrocarbon emissions.

However, the production and handling of neopentane itself may have environmental implications. As a volatile organic compound (VOC), neopentane can contribute to the formation of ground-level ozone if released into the atmosphere. Strict containment measures and proper handling protocols are essential to mitigate these risks throughout the CLC process.

The use of neopentane in CLC may also impact local air quality. While CLC generally produces fewer nitrogen oxides (NOx) than conventional combustion, the specific NOx formation characteristics with neopentane as a fuel require careful evaluation. Additionally, the potential for particulate matter emissions, although typically low in CLC systems, should be assessed for neopentane-based operations.

Water usage and thermal pollution are other environmental factors to consider. CLC systems using neopentane may require cooling processes, which could impact local water resources. The heat generated during the CLC process must be managed efficiently to minimize thermal pollution and maximize energy recovery.

Life cycle assessment (LCA) of neopentane in CLC applications is crucial for understanding its overall environmental footprint. This includes considering the energy and resources required for neopentane production, transportation, and storage, as well as the end-of-life management of CLC system components.

The potential for accidental releases and their environmental consequences must also be addressed. While neopentane is not highly toxic, its flammability and potential to form explosive mixtures with air necessitate robust safety measures to prevent environmental contamination and associated ecological impacts.

In terms of land use, CLC facilities using neopentane may have a smaller footprint compared to traditional power plants due to their higher efficiency and integrated CO2 capture capabilities. This could lead to reduced habitat disruption and land transformation associated with energy production.

As research in this field progresses, ongoing environmental monitoring and assessment will be crucial to fully understand and mitigate the long-term impacts of neopentane-based CLC systems on ecosystems and human health. Regulatory frameworks and industry standards will need to evolve to address the specific environmental challenges and opportunities presented by this technology.

Techno-economic Assessment of Neopentane CLC

The techno-economic assessment of neopentane in chemical looping combustion (CLC) applications reveals promising potential for this innovative technology. Neopentane, a branched alkane with the formula C(CH3)4, offers unique properties that make it an attractive candidate for CLC processes. Its high energy density and low boiling point contribute to efficient combustion and ease of handling in CLC systems.

From an economic perspective, the use of neopentane in CLC presents several advantages. The relatively low cost of neopentane production, coupled with its high reactivity, translates to potentially reduced operational expenses in CLC plants. Furthermore, the clean combustion characteristics of neopentane align well with increasingly stringent environmental regulations, potentially reducing compliance costs for industrial adopters.

The capital expenditure for neopentane CLC systems is comparable to other CLC technologies, with the added benefit of potentially smaller reactor sizes due to neopentane's high reactivity. This could lead to reduced construction costs and smaller plant footprints, which is particularly advantageous in space-constrained industrial settings.

Operational costs for neopentane CLC are expected to be competitive. The high conversion efficiency of neopentane in CLC processes results in lower fuel consumption compared to traditional combustion methods. Additionally, the reduced need for flue gas treatment due to the inherent CO2 capture in CLC further contributes to cost savings.

However, challenges remain in the widespread adoption of neopentane CLC. The current limited production scale of neopentane may lead to supply chain constraints and price volatility. Scaling up production to meet potential demand from CLC applications will require significant investment in manufacturing infrastructure.

The techno-economic assessment also considers the long-term viability of neopentane CLC. As carbon pricing mechanisms become more prevalent globally, the inherent CO2 capture capability of CLC technologies, including neopentane CLC, is expected to provide a significant economic advantage. This could potentially offset the higher initial costs associated with implementing CLC systems.

In terms of technology readiness, neopentane CLC is still in the early stages of development. While laboratory-scale experiments have shown promising results, further research and pilot-scale demonstrations are necessary to fully validate the techno-economic projections. This presents both a challenge and an opportunity for early adopters and investors in the technology.

From an economic perspective, the use of neopentane in CLC presents several advantages. The relatively low cost of neopentane production, coupled with its high reactivity, translates to potentially reduced operational expenses in CLC plants. Furthermore, the clean combustion characteristics of neopentane align well with increasingly stringent environmental regulations, potentially reducing compliance costs for industrial adopters.

The capital expenditure for neopentane CLC systems is comparable to other CLC technologies, with the added benefit of potentially smaller reactor sizes due to neopentane's high reactivity. This could lead to reduced construction costs and smaller plant footprints, which is particularly advantageous in space-constrained industrial settings.

Operational costs for neopentane CLC are expected to be competitive. The high conversion efficiency of neopentane in CLC processes results in lower fuel consumption compared to traditional combustion methods. Additionally, the reduced need for flue gas treatment due to the inherent CO2 capture in CLC further contributes to cost savings.

However, challenges remain in the widespread adoption of neopentane CLC. The current limited production scale of neopentane may lead to supply chain constraints and price volatility. Scaling up production to meet potential demand from CLC applications will require significant investment in manufacturing infrastructure.

The techno-economic assessment also considers the long-term viability of neopentane CLC. As carbon pricing mechanisms become more prevalent globally, the inherent CO2 capture capability of CLC technologies, including neopentane CLC, is expected to provide a significant economic advantage. This could potentially offset the higher initial costs associated with implementing CLC systems.

In terms of technology readiness, neopentane CLC is still in the early stages of development. While laboratory-scale experiments have shown promising results, further research and pilot-scale demonstrations are necessary to fully validate the techno-economic projections. This presents both a challenge and an opportunity for early adopters and investors in the technology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!