How to Assess the Lifecycle Impact of Neopentane Products?

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane LCA Background and Objectives

Neopentane, a branched alkane with the chemical formula C5H12, has gained significant attention in various industries due to its unique properties and potential applications. As environmental concerns continue to grow, assessing the lifecycle impact of neopentane products has become crucial for sustainable development and responsible resource management. This technical research report aims to provide a comprehensive overview of the background and objectives related to conducting a Life Cycle Assessment (LCA) for neopentane products.

The development of neopentane and its derivatives can be traced back to the early 20th century, with its industrial production beginning in the 1950s. Initially used primarily as a blowing agent in foam production, neopentane has since found applications in various sectors, including refrigerants, aerosols, and specialty chemicals. As the global demand for these products increases, so does the need for a thorough understanding of their environmental impact throughout their lifecycle.

The primary objective of conducting an LCA for neopentane products is to quantify and evaluate the environmental impacts associated with all stages of their life cycle, from raw material extraction to end-of-life disposal or recycling. This assessment aims to identify hotspots in the production process, highlight areas for potential improvement, and provide a basis for comparing neopentane products with alternative solutions.

Key aspects of the LCA process for neopentane products include analyzing energy consumption, greenhouse gas emissions, resource depletion, and potential toxicity effects. By examining these factors across the entire lifecycle, researchers and industry professionals can gain valuable insights into the overall sustainability of neopentane-based products and identify opportunities for optimization.

Another crucial objective of this LCA is to support decision-making processes in both industry and policy-making spheres. The results of a comprehensive lifecycle assessment can inform product design choices, guide manufacturing process improvements, and influence regulatory frameworks governing the production and use of neopentane products.

Furthermore, as global sustainability initiatives gain momentum, there is an increasing demand for transparent and scientifically sound environmental impact data. Conducting a thorough LCA for neopentane products aligns with this trend and can potentially enhance the competitiveness of companies operating in this sector by demonstrating their commitment to environmental stewardship.

In conclusion, assessing the lifecycle impact of neopentane products is a complex yet essential task that requires a multidisciplinary approach. By establishing clear objectives and a comprehensive background understanding, this technical research lays the foundation for a rigorous and informative LCA process. The insights gained from this assessment will not only contribute to the sustainable development of neopentane-based industries but also advance our overall knowledge of environmental impact assessment methodologies.

The development of neopentane and its derivatives can be traced back to the early 20th century, with its industrial production beginning in the 1950s. Initially used primarily as a blowing agent in foam production, neopentane has since found applications in various sectors, including refrigerants, aerosols, and specialty chemicals. As the global demand for these products increases, so does the need for a thorough understanding of their environmental impact throughout their lifecycle.

The primary objective of conducting an LCA for neopentane products is to quantify and evaluate the environmental impacts associated with all stages of their life cycle, from raw material extraction to end-of-life disposal or recycling. This assessment aims to identify hotspots in the production process, highlight areas for potential improvement, and provide a basis for comparing neopentane products with alternative solutions.

Key aspects of the LCA process for neopentane products include analyzing energy consumption, greenhouse gas emissions, resource depletion, and potential toxicity effects. By examining these factors across the entire lifecycle, researchers and industry professionals can gain valuable insights into the overall sustainability of neopentane-based products and identify opportunities for optimization.

Another crucial objective of this LCA is to support decision-making processes in both industry and policy-making spheres. The results of a comprehensive lifecycle assessment can inform product design choices, guide manufacturing process improvements, and influence regulatory frameworks governing the production and use of neopentane products.

Furthermore, as global sustainability initiatives gain momentum, there is an increasing demand for transparent and scientifically sound environmental impact data. Conducting a thorough LCA for neopentane products aligns with this trend and can potentially enhance the competitiveness of companies operating in this sector by demonstrating their commitment to environmental stewardship.

In conclusion, assessing the lifecycle impact of neopentane products is a complex yet essential task that requires a multidisciplinary approach. By establishing clear objectives and a comprehensive background understanding, this technical research lays the foundation for a rigorous and informative LCA process. The insights gained from this assessment will not only contribute to the sustainable development of neopentane-based industries but also advance our overall knowledge of environmental impact assessment methodologies.

Market Demand Analysis for Neopentane Products

The market demand for neopentane products has been steadily growing due to their unique properties and versatile applications across various industries. Neopentane, a branched alkane with the chemical formula C5H12, is primarily used as a blowing agent in the production of foam insulation materials, refrigerants, and aerosol propellants. The global market for neopentane products is driven by the increasing demand for energy-efficient construction materials and the growing automotive industry.

In the construction sector, neopentane-based foam insulation materials are gaining popularity due to their excellent thermal insulation properties and low environmental impact. The rising focus on green building practices and stringent energy efficiency regulations in many countries have further boosted the demand for these products. The automotive industry also contributes significantly to the market growth, as neopentane is used in the production of lightweight foam components for vehicles, helping to improve fuel efficiency and reduce emissions.

The refrigeration and air conditioning industry represents another key market for neopentane products. As countries phase out hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) due to their high global warming potential, neopentane-based refrigerants are emerging as environmentally friendly alternatives. This transition is expected to drive substantial growth in the neopentane market over the coming years.

The Asia-Pacific region is anticipated to be the fastest-growing market for neopentane products, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe also hold significant market shares, primarily due to their well-established automotive and construction industries, as well as stringent environmental regulations promoting the use of eco-friendly materials.

Despite the positive market outlook, the neopentane industry faces challenges related to raw material availability and price volatility. Neopentane is derived from petroleum, and fluctuations in oil prices can impact production costs and market dynamics. Additionally, the development of alternative blowing agents and refrigerants may pose a threat to the long-term growth of the neopentane market.

To assess the lifecycle impact of neopentane products, it is crucial to consider their entire value chain, from production to end-of-life disposal. While neopentane offers environmental benefits in terms of energy efficiency and low global warming potential during its use phase, its production process and end-of-life management require careful evaluation to ensure overall sustainability. This comprehensive assessment will be essential for stakeholders to make informed decisions and for the industry to address potential environmental concerns proactively.

In the construction sector, neopentane-based foam insulation materials are gaining popularity due to their excellent thermal insulation properties and low environmental impact. The rising focus on green building practices and stringent energy efficiency regulations in many countries have further boosted the demand for these products. The automotive industry also contributes significantly to the market growth, as neopentane is used in the production of lightweight foam components for vehicles, helping to improve fuel efficiency and reduce emissions.

The refrigeration and air conditioning industry represents another key market for neopentane products. As countries phase out hydrochlorofluorocarbons (HCFCs) and hydrofluorocarbons (HFCs) due to their high global warming potential, neopentane-based refrigerants are emerging as environmentally friendly alternatives. This transition is expected to drive substantial growth in the neopentane market over the coming years.

The Asia-Pacific region is anticipated to be the fastest-growing market for neopentane products, driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. North America and Europe also hold significant market shares, primarily due to their well-established automotive and construction industries, as well as stringent environmental regulations promoting the use of eco-friendly materials.

Despite the positive market outlook, the neopentane industry faces challenges related to raw material availability and price volatility. Neopentane is derived from petroleum, and fluctuations in oil prices can impact production costs and market dynamics. Additionally, the development of alternative blowing agents and refrigerants may pose a threat to the long-term growth of the neopentane market.

To assess the lifecycle impact of neopentane products, it is crucial to consider their entire value chain, from production to end-of-life disposal. While neopentane offers environmental benefits in terms of energy efficiency and low global warming potential during its use phase, its production process and end-of-life management require careful evaluation to ensure overall sustainability. This comprehensive assessment will be essential for stakeholders to make informed decisions and for the industry to address potential environmental concerns proactively.

Current State and Challenges in Neopentane LCA

The current state of Life Cycle Assessment (LCA) for neopentane products faces several challenges and limitations. Neopentane, a volatile organic compound used in various industrial applications, requires careful evaluation due to its potential environmental impacts throughout its lifecycle.

One of the primary challenges in neopentane LCA is the lack of comprehensive and standardized data. The production, use, and disposal of neopentane products involve complex processes that span multiple industries and geographical regions. This diversity makes it difficult to collect accurate and consistent data across the entire lifecycle, leading to potential gaps and uncertainties in the assessment.

Another significant challenge is the variability in production methods and applications of neopentane. Different manufacturing processes and end-use scenarios can result in vastly different environmental footprints. This variability complicates the development of a one-size-fits-all LCA approach for neopentane products, necessitating case-specific assessments that can be resource-intensive and time-consuming.

The global nature of neopentane production and use presents additional challenges in LCA. Transportation and distribution of neopentane products across international borders introduce complexities in tracking and quantifying environmental impacts. Furthermore, varying regulatory standards and reporting requirements in different countries can lead to inconsistencies in data quality and availability.

Assessing the end-of-life phase of neopentane products is particularly challenging. The volatile nature of neopentane means that a significant portion may be released into the atmosphere during use or disposal. Accurately quantifying these emissions and their environmental impacts requires sophisticated modeling and measurement techniques that are not always readily available or standardized.

The rapidly evolving technological landscape in neopentane production and application adds another layer of complexity to LCA efforts. As new production methods and applications emerge, existing LCA models and databases may quickly become outdated, necessitating continuous updates and refinements to maintain accuracy and relevance.

Methodological challenges also persist in neopentane LCA. Allocating environmental impacts across different co-products and by-products in neopentane production processes can be contentious and subject to different interpretations. Additionally, defining appropriate system boundaries for the assessment can significantly influence the results, leading to potential inconsistencies across different studies.

Despite these challenges, progress is being made in improving neopentane LCA methodologies. Efforts are underway to develop more comprehensive databases, standardize assessment protocols, and improve modeling techniques to better capture the complexities of neopentane's lifecycle. Collaborative initiatives between industry, academia, and regulatory bodies are working towards addressing data gaps and harmonizing assessment approaches.

One of the primary challenges in neopentane LCA is the lack of comprehensive and standardized data. The production, use, and disposal of neopentane products involve complex processes that span multiple industries and geographical regions. This diversity makes it difficult to collect accurate and consistent data across the entire lifecycle, leading to potential gaps and uncertainties in the assessment.

Another significant challenge is the variability in production methods and applications of neopentane. Different manufacturing processes and end-use scenarios can result in vastly different environmental footprints. This variability complicates the development of a one-size-fits-all LCA approach for neopentane products, necessitating case-specific assessments that can be resource-intensive and time-consuming.

The global nature of neopentane production and use presents additional challenges in LCA. Transportation and distribution of neopentane products across international borders introduce complexities in tracking and quantifying environmental impacts. Furthermore, varying regulatory standards and reporting requirements in different countries can lead to inconsistencies in data quality and availability.

Assessing the end-of-life phase of neopentane products is particularly challenging. The volatile nature of neopentane means that a significant portion may be released into the atmosphere during use or disposal. Accurately quantifying these emissions and their environmental impacts requires sophisticated modeling and measurement techniques that are not always readily available or standardized.

The rapidly evolving technological landscape in neopentane production and application adds another layer of complexity to LCA efforts. As new production methods and applications emerge, existing LCA models and databases may quickly become outdated, necessitating continuous updates and refinements to maintain accuracy and relevance.

Methodological challenges also persist in neopentane LCA. Allocating environmental impacts across different co-products and by-products in neopentane production processes can be contentious and subject to different interpretations. Additionally, defining appropriate system boundaries for the assessment can significantly influence the results, leading to potential inconsistencies across different studies.

Despite these challenges, progress is being made in improving neopentane LCA methodologies. Efforts are underway to develop more comprehensive databases, standardize assessment protocols, and improve modeling techniques to better capture the complexities of neopentane's lifecycle. Collaborative initiatives between industry, academia, and regulatory bodies are working towards addressing data gaps and harmonizing assessment approaches.

Existing LCA Approaches for Neopentane Products

01 Environmental impact assessment of neopentane products

Lifecycle impact analysis of neopentane products focuses on evaluating their environmental effects from production to disposal. This assessment includes factors such as energy consumption, greenhouse gas emissions, and resource depletion throughout the product's lifecycle. The analysis helps in identifying areas for improvement in sustainability and guides decision-making for more environmentally friendly alternatives.- Environmental impact assessment of neopentane products: Lifecycle impact analysis of neopentane products involves assessing their environmental effects from production to disposal. This includes evaluating energy consumption, emissions, and resource depletion throughout the product's lifecycle. Advanced modeling techniques and data analytics are used to quantify and analyze these impacts, helping manufacturers make informed decisions to reduce environmental footprint.

- Supply chain optimization for neopentane products: Optimizing the supply chain for neopentane products involves improving efficiency and reducing waste throughout the product lifecycle. This includes streamlining production processes, enhancing logistics, and implementing sustainable practices in transportation and storage. Advanced analytics and machine learning algorithms are used to identify bottlenecks and optimize resource allocation.

- Recycling and waste management of neopentane products: Developing effective recycling and waste management strategies for neopentane products is crucial for minimizing their environmental impact. This involves designing products for easier disassembly and recycling, implementing take-back programs, and exploring innovative recycling technologies. Life cycle assessments are used to evaluate the effectiveness of different waste management approaches.

- Energy efficiency improvements in neopentane product manufacturing: Enhancing energy efficiency in the manufacturing of neopentane products is essential for reducing their overall environmental impact. This includes optimizing production processes, implementing energy-saving technologies, and exploring alternative energy sources. Advanced monitoring systems and predictive maintenance techniques are used to minimize energy waste and improve overall efficiency.

- Lifecycle data management and reporting for neopentane products: Effective management and reporting of lifecycle data for neopentane products is crucial for regulatory compliance and continuous improvement. This involves implementing robust data collection systems, developing standardized reporting methodologies, and utilizing advanced analytics for data interpretation. Blockchain technology and IoT sensors are being explored to enhance data accuracy and traceability throughout the product lifecycle.

02 Supply chain management for neopentane products

Efficient supply chain management is crucial for minimizing the lifecycle impact of neopentane products. This involves optimizing logistics, reducing transportation emissions, and implementing sustainable sourcing practices. Advanced tracking systems and data analytics are used to monitor and improve the environmental performance of the supply chain, from raw material extraction to product distribution.Expand Specific Solutions03 Recycling and waste management of neopentane products

Developing effective recycling and waste management strategies is essential for reducing the lifecycle impact of neopentane products. This includes designing products for easier disassembly and recycling, implementing take-back programs, and exploring innovative recycling technologies. Proper waste management helps in minimizing landfill waste and recovering valuable materials, thus reducing the overall environmental footprint.Expand Specific Solutions04 Energy efficiency in neopentane product manufacturing

Improving energy efficiency in the manufacturing process of neopentane products is a key factor in reducing their lifecycle impact. This involves implementing energy-saving technologies, optimizing production processes, and utilizing renewable energy sources. By reducing energy consumption, manufacturers can significantly decrease the carbon footprint associated with neopentane product production.Expand Specific Solutions05 Lifecycle data management and analysis for neopentane products

Effective data management and analysis are crucial for understanding and improving the lifecycle impact of neopentane products. This involves collecting, storing, and analyzing data related to various stages of the product lifecycle. Advanced analytics and machine learning techniques are employed to identify patterns, predict environmental impacts, and suggest improvements in product design and manufacturing processes.Expand Specific Solutions

Key Players in Neopentane Production and LCA

The lifecycle impact assessment of neopentane products is in an emerging stage, with growing market interest driven by environmental concerns. The market size is relatively small but expanding as industries seek more sustainable alternatives. Technologically, the field is still developing, with varying levels of maturity across different assessment methodologies. Key players like The Regents of the University of California, F. Hoffmann-La Roche Ltd., and Regeneron Pharmaceuticals, Inc. are contributing to advancements in lifecycle analysis techniques. Companies such as SUMCO Corp. and China Petroleum & Chemical Corp. are likely focusing on improving the environmental performance of neopentane-based products throughout their lifecycle.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a comprehensive lifecycle assessment (LCA) approach for neopentane products. Their method incorporates raw material extraction, production, transportation, use, and end-of-life disposal. Sinopec utilizes advanced software tools to model the entire product lifecycle, considering energy consumption, emissions, and resource depletion at each stage[1]. They have implemented a cradle-to-grave analysis system that tracks carbon footprint, water usage, and waste generation throughout the neopentane product lifecycle[3]. Sinopec also employs eco-design principles to optimize product formulations and manufacturing processes, aiming to reduce environmental impact without compromising performance[5].

Strengths: Comprehensive approach covering entire product lifecycle; Advanced modeling tools for accurate assessments; Integration of eco-design principles. Weaknesses: Potential bias towards petroleum-based products; May not fully account for regional variations in environmental impact.

Intertek Testing Services Shenzhen Ltd.

Technical Solution: Intertek has developed a robust lifecycle impact assessment methodology for neopentane products. Their approach combines laboratory testing with data analysis to evaluate environmental, health, and safety impacts across the product lifecycle. Intertek's method includes a detailed chemical analysis of neopentane products, assessing potential toxicity and environmental persistence[2]. They utilize standardized protocols such as ISO 14040 and 14044 for lifecycle assessment, ensuring consistency and comparability of results[4]. Intertek's assessment also incorporates supply chain analysis to account for upstream impacts and end-of-life scenarios to evaluate disposal or recycling options[6]. Their methodology emphasizes the importance of data quality and uncertainty analysis in lifecycle impact assessments.

Strengths: Comprehensive laboratory testing capabilities; Adherence to international standards; Emphasis on data quality and uncertainty analysis. Weaknesses: May be more focused on regulatory compliance than innovative assessment techniques; Potential limitations in assessing long-term environmental impacts.

Core Innovations in Neopentane LCA Techniques

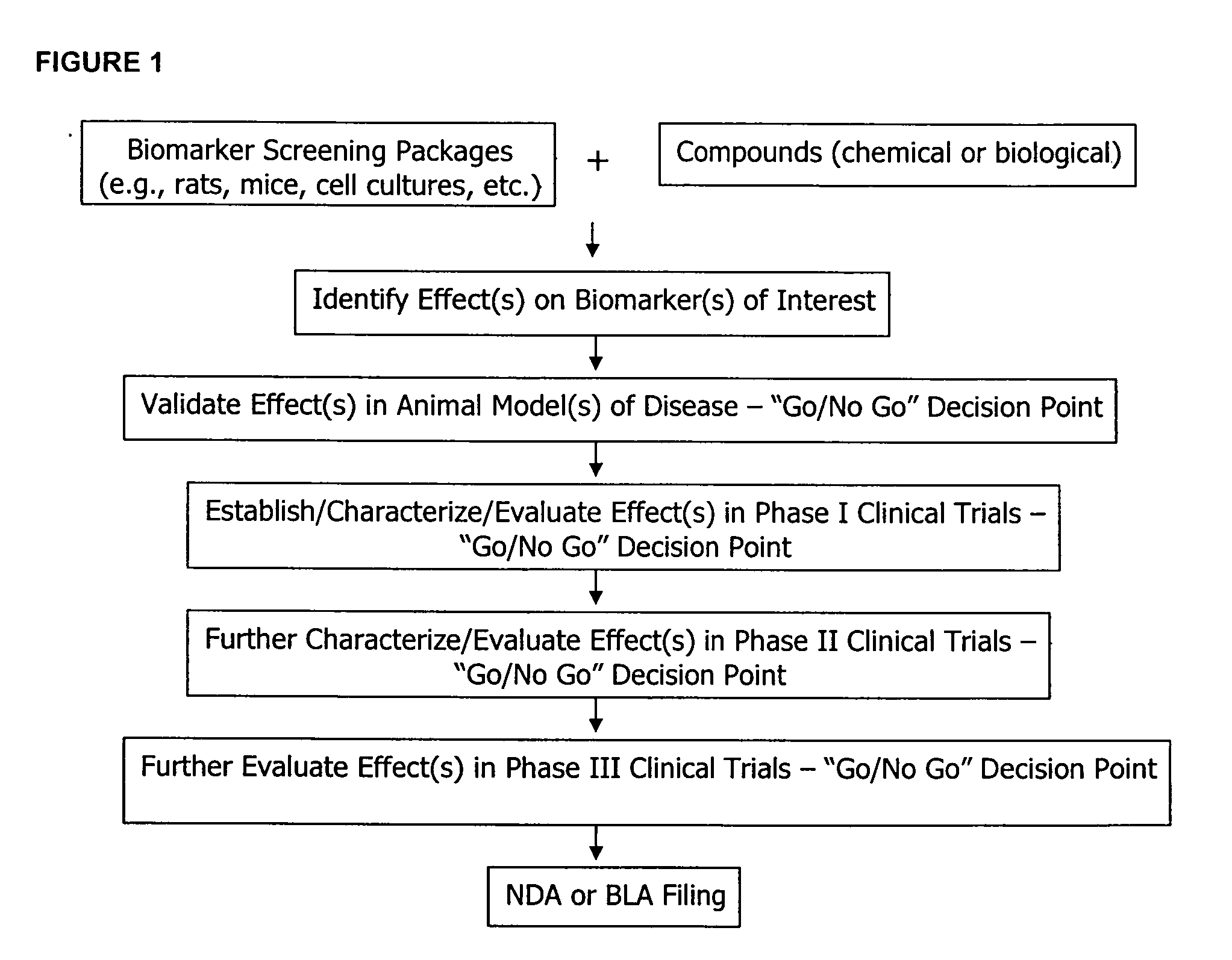

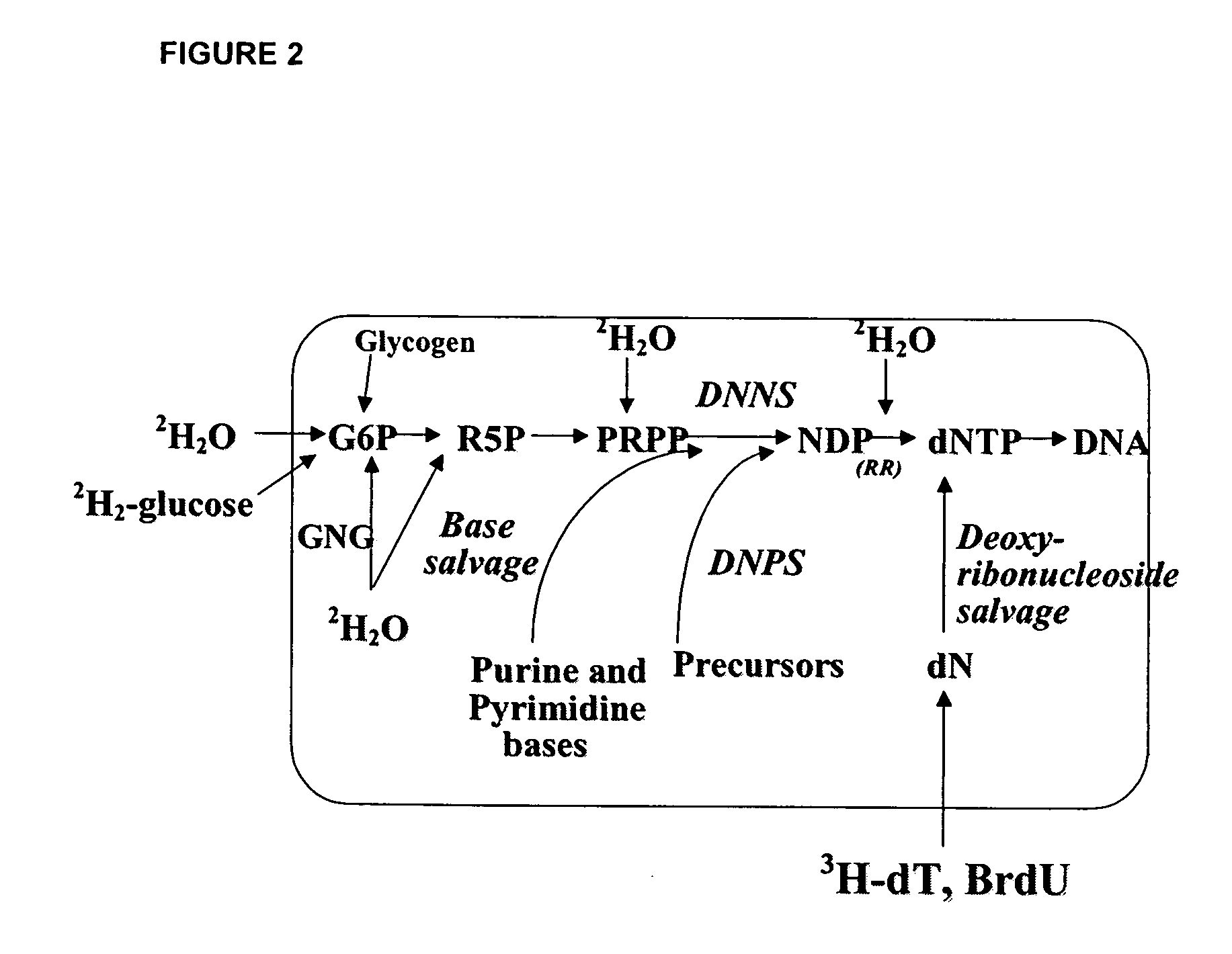

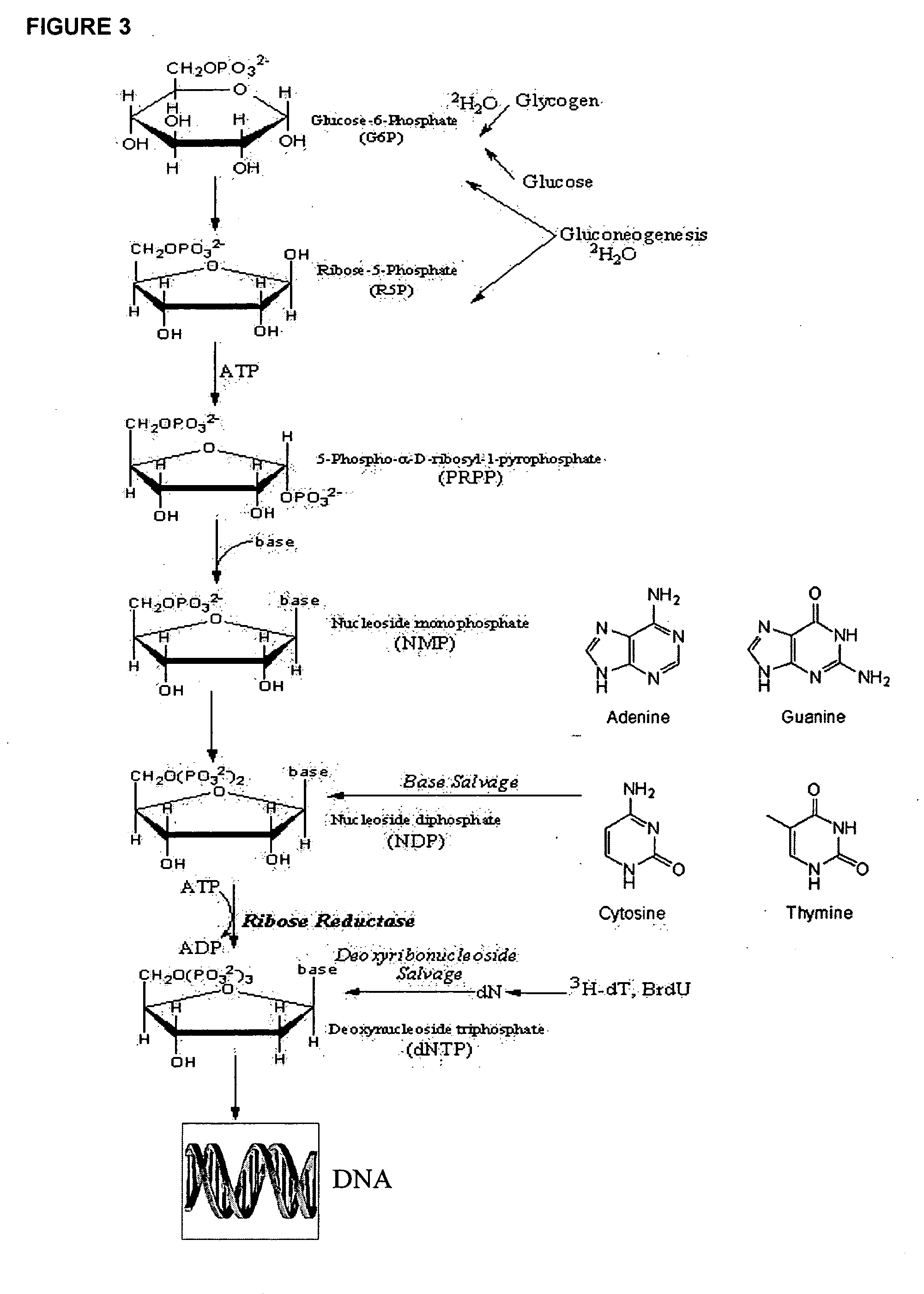

Molecular flux rates through critical pathways measured by stable isotope labeling in vivo, as biomarkers of drug action and disease activity

PatentInactiveUS20060020440A1

Innovation

- The development of methods to analyze and compare molecular flux rates in metabolic pathways of living organisms before and after exposure to compounds, using stable isotope labeling or radiolabeled substrates to determine the effects on biochemical processes, allowing for the evaluation of drug actions and toxicity.

Environmental Regulations on Neopentane Usage

Environmental regulations on neopentane usage have become increasingly stringent in recent years due to growing concerns about its potential impact on climate change and air quality. Neopentane, a volatile organic compound (VOC), is subject to various regulatory frameworks aimed at controlling emissions and ensuring responsible use throughout its lifecycle.

In the United States, the Environmental Protection Agency (EPA) regulates neopentane under the Clean Air Act as a VOC. Manufacturers and users of neopentane-containing products must adhere to strict emission limits and implement control technologies to minimize releases into the atmosphere. The EPA also requires facilities handling large quantities of neopentane to develop and implement risk management plans to prevent accidental releases.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to neopentane and its derivatives. Under REACH, manufacturers and importers must register neopentane with the European Chemicals Agency (ECHA) and provide comprehensive safety data. The regulation also mandates the communication of safety information throughout the supply chain.

Many countries have adopted regulations limiting the use of neopentane in certain consumer products due to its high global warming potential. For instance, some jurisdictions have banned or restricted the use of neopentane in aerosol propellants and foam blowing agents. These regulations often require manufacturers to explore alternative substances or technologies with lower environmental impacts.

The Montreal Protocol, an international treaty designed to protect the ozone layer, indirectly affects neopentane usage. While neopentane itself is not an ozone-depleting substance, it has been used as a replacement for some ozone-depleting chemicals. As a result, its use is subject to scrutiny to ensure it does not contribute to other environmental problems.

In the automotive industry, regulations on vehicle emissions have led to increased attention on neopentane and other VOCs used in fuel systems and manufacturing processes. Automakers must demonstrate compliance with evaporative emission standards, which often necessitates careful management of neopentane-containing components.

As global efforts to combat climate change intensify, it is likely that regulations on neopentane will continue to evolve. Future regulatory trends may include stricter emission limits, expanded reporting requirements, and increased pressure to develop and adopt more environmentally friendly alternatives. Companies working with neopentane must stay informed about these regulatory developments and proactively adapt their practices to ensure compliance and environmental responsibility.

In the United States, the Environmental Protection Agency (EPA) regulates neopentane under the Clean Air Act as a VOC. Manufacturers and users of neopentane-containing products must adhere to strict emission limits and implement control technologies to minimize releases into the atmosphere. The EPA also requires facilities handling large quantities of neopentane to develop and implement risk management plans to prevent accidental releases.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to neopentane and its derivatives. Under REACH, manufacturers and importers must register neopentane with the European Chemicals Agency (ECHA) and provide comprehensive safety data. The regulation also mandates the communication of safety information throughout the supply chain.

Many countries have adopted regulations limiting the use of neopentane in certain consumer products due to its high global warming potential. For instance, some jurisdictions have banned or restricted the use of neopentane in aerosol propellants and foam blowing agents. These regulations often require manufacturers to explore alternative substances or technologies with lower environmental impacts.

The Montreal Protocol, an international treaty designed to protect the ozone layer, indirectly affects neopentane usage. While neopentane itself is not an ozone-depleting substance, it has been used as a replacement for some ozone-depleting chemicals. As a result, its use is subject to scrutiny to ensure it does not contribute to other environmental problems.

In the automotive industry, regulations on vehicle emissions have led to increased attention on neopentane and other VOCs used in fuel systems and manufacturing processes. Automakers must demonstrate compliance with evaporative emission standards, which often necessitates careful management of neopentane-containing components.

As global efforts to combat climate change intensify, it is likely that regulations on neopentane will continue to evolve. Future regulatory trends may include stricter emission limits, expanded reporting requirements, and increased pressure to develop and adopt more environmentally friendly alternatives. Companies working with neopentane must stay informed about these regulatory developments and proactively adapt their practices to ensure compliance and environmental responsibility.

Sustainable Alternatives to Neopentane Products

In the pursuit of sustainable alternatives to neopentane products, several promising options have emerged that offer reduced environmental impact and improved lifecycle performance. One such alternative is the use of hydrofluoroolefins (HFOs), which have significantly lower global warming potential compared to traditional hydrofluorocarbons (HFCs) and neopentane. HFOs demonstrate excellent insulating properties and can be effectively used in foam blowing applications, making them a viable substitute in many industries.

Another sustainable option is the development of bio-based blowing agents derived from renewable resources. These agents, often produced from agricultural by-products or waste materials, offer a more environmentally friendly alternative to petroleum-based neopentane. They not only reduce reliance on fossil fuels but also contribute to a circular economy by repurposing waste streams.

Water-based systems have also gained traction as a sustainable alternative in certain applications. While they may not provide the same level of insulation as neopentane-based products, advancements in formulation and processing techniques have significantly improved their performance. These systems eliminate the need for volatile organic compounds (VOCs) and offer reduced flammability risks.

Vacuum insulated panels (VIPs) represent a cutting-edge technology that can replace traditional foam insulation in some applications. VIPs achieve superior insulation performance with minimal thickness, potentially reducing overall material usage and improving energy efficiency in buildings and appliances.

Carbon dioxide (CO2) has emerged as another eco-friendly alternative, particularly in spray foam applications. When used as a blowing agent, CO2 offers zero ozone depletion potential and negligible global warming potential. Recent advancements in CO2-based systems have improved their insulation properties and stability, making them increasingly competitive with neopentane-based products.

Innovative material science has also led to the development of aerogel-based insulation products. These ultra-lightweight materials offer exceptional thermal performance and can be produced using environmentally friendly processes. While currently more expensive than traditional options, ongoing research and scaling efforts are expected to make aerogels more accessible in the future.

As the industry continues to prioritize sustainability, research into novel materials and processes is ongoing. This includes exploring the potential of nanocellulose-based foams, which leverage abundant and renewable cellulose resources to create high-performance insulation materials. Additionally, the concept of phase-change materials (PCMs) is being investigated for their ability to provide dynamic thermal management, potentially reducing overall energy consumption in various applications.

Another sustainable option is the development of bio-based blowing agents derived from renewable resources. These agents, often produced from agricultural by-products or waste materials, offer a more environmentally friendly alternative to petroleum-based neopentane. They not only reduce reliance on fossil fuels but also contribute to a circular economy by repurposing waste streams.

Water-based systems have also gained traction as a sustainable alternative in certain applications. While they may not provide the same level of insulation as neopentane-based products, advancements in formulation and processing techniques have significantly improved their performance. These systems eliminate the need for volatile organic compounds (VOCs) and offer reduced flammability risks.

Vacuum insulated panels (VIPs) represent a cutting-edge technology that can replace traditional foam insulation in some applications. VIPs achieve superior insulation performance with minimal thickness, potentially reducing overall material usage and improving energy efficiency in buildings and appliances.

Carbon dioxide (CO2) has emerged as another eco-friendly alternative, particularly in spray foam applications. When used as a blowing agent, CO2 offers zero ozone depletion potential and negligible global warming potential. Recent advancements in CO2-based systems have improved their insulation properties and stability, making them increasingly competitive with neopentane-based products.

Innovative material science has also led to the development of aerogel-based insulation products. These ultra-lightweight materials offer exceptional thermal performance and can be produced using environmentally friendly processes. While currently more expensive than traditional options, ongoing research and scaling efforts are expected to make aerogels more accessible in the future.

As the industry continues to prioritize sustainability, research into novel materials and processes is ongoing. This includes exploring the potential of nanocellulose-based foams, which leverage abundant and renewable cellulose resources to create high-performance insulation materials. Additionally, the concept of phase-change materials (PCMs) is being investigated for their ability to provide dynamic thermal management, potentially reducing overall energy consumption in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!