Neopentane in Coating Technologies: Current Research and Future

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neopentane Coating Tech Background and Objectives

Neopentane, a branched alkane with the chemical formula C(CH3)4, has emerged as a significant component in coating technologies over the past few decades. The evolution of neopentane-based coatings can be traced back to the mid-20th century when researchers began exploring alternative blowing agents for foam insulation and coating applications. Initially, the focus was on finding environmentally friendly substitutes for chlorofluorocarbons (CFCs) and hydrochlorofluorocarbons (HCFCs), which were known to deplete the ozone layer.

The development of neopentane in coating technologies has been driven by several key factors, including environmental regulations, energy efficiency requirements, and the demand for improved performance in various industrial applications. As global awareness of climate change and environmental protection grew, the coating industry sought innovative solutions that could meet stringent environmental standards while maintaining or enhancing product performance.

Neopentane's unique properties, such as its low boiling point, low thermal conductivity, and non-ozone depleting nature, have made it an attractive option for use in coating formulations. These characteristics have led to its widespread adoption in the production of insulating foams, particularly in the construction and refrigeration industries. The technology has since expanded to include various types of coatings, ranging from protective industrial coatings to specialized aerospace applications.

The current research landscape in neopentane coating technologies is focused on optimizing formulations to achieve specific performance criteria. This includes enhancing thermal insulation properties, improving fire resistance, and developing coatings with self-healing capabilities. Additionally, researchers are exploring ways to increase the sustainability of neopentane-based coatings by incorporating bio-based materials and improving end-of-life recyclability.

Looking towards the future, the objectives for neopentane coating technologies are multifaceted. One primary goal is to further reduce the environmental impact of these coatings by developing more efficient production processes and exploring alternative blowing agents that can work synergistically with neopentane. Another objective is to expand the application range of neopentane-based coatings into new industries and products, such as advanced electronics cooling systems and next-generation building materials.

Researchers are also aiming to enhance the durability and longevity of neopentane coatings, which could significantly reduce maintenance costs and material waste over time. This includes developing coatings that can withstand extreme weather conditions, resist chemical degradation, and maintain their insulating properties for extended periods. Furthermore, there is a growing interest in smart coating technologies that incorporate neopentane, potentially leading to coatings that can adapt to environmental changes or provide real-time monitoring of structural integrity.

The development of neopentane in coating technologies has been driven by several key factors, including environmental regulations, energy efficiency requirements, and the demand for improved performance in various industrial applications. As global awareness of climate change and environmental protection grew, the coating industry sought innovative solutions that could meet stringent environmental standards while maintaining or enhancing product performance.

Neopentane's unique properties, such as its low boiling point, low thermal conductivity, and non-ozone depleting nature, have made it an attractive option for use in coating formulations. These characteristics have led to its widespread adoption in the production of insulating foams, particularly in the construction and refrigeration industries. The technology has since expanded to include various types of coatings, ranging from protective industrial coatings to specialized aerospace applications.

The current research landscape in neopentane coating technologies is focused on optimizing formulations to achieve specific performance criteria. This includes enhancing thermal insulation properties, improving fire resistance, and developing coatings with self-healing capabilities. Additionally, researchers are exploring ways to increase the sustainability of neopentane-based coatings by incorporating bio-based materials and improving end-of-life recyclability.

Looking towards the future, the objectives for neopentane coating technologies are multifaceted. One primary goal is to further reduce the environmental impact of these coatings by developing more efficient production processes and exploring alternative blowing agents that can work synergistically with neopentane. Another objective is to expand the application range of neopentane-based coatings into new industries and products, such as advanced electronics cooling systems and next-generation building materials.

Researchers are also aiming to enhance the durability and longevity of neopentane coatings, which could significantly reduce maintenance costs and material waste over time. This includes developing coatings that can withstand extreme weather conditions, resist chemical degradation, and maintain their insulating properties for extended periods. Furthermore, there is a growing interest in smart coating technologies that incorporate neopentane, potentially leading to coatings that can adapt to environmental changes or provide real-time monitoring of structural integrity.

Market Analysis for Neopentane-based Coatings

The neopentane-based coatings market has shown significant growth potential in recent years, driven by increasing demand for high-performance and environmentally friendly coating solutions across various industries. The global market for neopentane-based coatings is expected to experience steady growth over the next decade, with a compound annual growth rate (CAGR) projected to be in the mid-single digits.

Key factors contributing to market growth include the superior properties of neopentane-based coatings, such as excellent thermal insulation, low thermal conductivity, and resistance to moisture and chemicals. These characteristics make them particularly attractive for applications in construction, automotive, and aerospace industries. The construction sector, in particular, is anticipated to be a major driver of demand, as energy-efficient building materials gain prominence in both residential and commercial projects.

The automotive industry represents another significant market segment for neopentane-based coatings. With increasing focus on lightweight materials and improved fuel efficiency, these coatings offer valuable solutions for thermal management and weight reduction in vehicles. Additionally, the aerospace sector is showing growing interest in neopentane-based coatings for their potential in enhancing the performance of aircraft components and reducing overall weight.

Geographically, North America and Europe currently lead the market for neopentane-based coatings, owing to stringent environmental regulations and a strong focus on energy efficiency. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing awareness of sustainable building practices in countries like China and India.

Despite the positive outlook, the neopentane-based coatings market faces certain challenges. The volatility of raw material prices, particularly neopentane, can impact production costs and market dynamics. Additionally, the development of alternative coating technologies and materials poses a potential threat to market growth.

Environmental concerns and regulatory pressures are also shaping the market landscape. As governments worldwide implement stricter regulations on volatile organic compounds (VOCs) and greenhouse gas emissions, manufacturers are increasingly focusing on developing eco-friendly formulations of neopentane-based coatings. This trend is expected to drive innovation in the sector and open up new market opportunities for sustainable coating solutions.

In conclusion, the market for neopentane-based coatings shows promising growth potential, driven by their unique properties and diverse applications across multiple industries. However, success in this market will depend on continued innovation, cost-effective production methods, and the ability to meet evolving environmental standards.

Key factors contributing to market growth include the superior properties of neopentane-based coatings, such as excellent thermal insulation, low thermal conductivity, and resistance to moisture and chemicals. These characteristics make them particularly attractive for applications in construction, automotive, and aerospace industries. The construction sector, in particular, is anticipated to be a major driver of demand, as energy-efficient building materials gain prominence in both residential and commercial projects.

The automotive industry represents another significant market segment for neopentane-based coatings. With increasing focus on lightweight materials and improved fuel efficiency, these coatings offer valuable solutions for thermal management and weight reduction in vehicles. Additionally, the aerospace sector is showing growing interest in neopentane-based coatings for their potential in enhancing the performance of aircraft components and reducing overall weight.

Geographically, North America and Europe currently lead the market for neopentane-based coatings, owing to stringent environmental regulations and a strong focus on energy efficiency. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and increasing awareness of sustainable building practices in countries like China and India.

Despite the positive outlook, the neopentane-based coatings market faces certain challenges. The volatility of raw material prices, particularly neopentane, can impact production costs and market dynamics. Additionally, the development of alternative coating technologies and materials poses a potential threat to market growth.

Environmental concerns and regulatory pressures are also shaping the market landscape. As governments worldwide implement stricter regulations on volatile organic compounds (VOCs) and greenhouse gas emissions, manufacturers are increasingly focusing on developing eco-friendly formulations of neopentane-based coatings. This trend is expected to drive innovation in the sector and open up new market opportunities for sustainable coating solutions.

In conclusion, the market for neopentane-based coatings shows promising growth potential, driven by their unique properties and diverse applications across multiple industries. However, success in this market will depend on continued innovation, cost-effective production methods, and the ability to meet evolving environmental standards.

Current Challenges in Neopentane Coating Technologies

Neopentane coating technologies face several significant challenges that hinder their widespread adoption and optimal performance. One of the primary issues is the volatility of neopentane, which can lead to difficulties in maintaining consistent coating thickness and quality. The low boiling point of neopentane (9.5°C) makes it prone to rapid evaporation during the coating process, resulting in uneven distribution and potential defects in the final product.

Another challenge lies in the flammability and explosive nature of neopentane. This characteristic poses safety concerns during storage, handling, and application processes. Stringent safety measures and specialized equipment are required to mitigate risks, which can increase operational costs and complexity for manufacturers.

The environmental impact of neopentane is also a growing concern. As a volatile organic compound (VOC), neopentane contributes to air pollution and the formation of ground-level ozone. Regulatory pressures to reduce VOC emissions are pushing the industry to seek alternative solutions or develop more efficient containment methods.

Achieving optimal insulation properties while maintaining coating durability presents another technical hurdle. Neopentane's excellent insulating capabilities must be balanced with the need for coatings that can withstand mechanical stress, weathering, and chemical exposure. Developing formulations that provide both high insulation performance and long-term durability remains a challenge for researchers and manufacturers.

The scalability of neopentane coating technologies for large-scale industrial applications is also problematic. Ensuring uniform coating thickness and quality across large surface areas, such as in the construction or automotive industries, requires sophisticated application techniques and equipment. This scalability issue can limit the adoption of neopentane coatings in certain sectors.

Furthermore, the cost-effectiveness of neopentane coatings compared to alternative insulation materials is a persistent challenge. While neopentane offers superior insulation properties, the overall production and application costs may be higher than traditional materials, making it less attractive for price-sensitive markets.

Lastly, the long-term stability and aging characteristics of neopentane coatings require further investigation. As these coatings are exposed to various environmental conditions over time, there is a need to better understand and mitigate potential degradation mechanisms that could affect their performance and lifespan.

Another challenge lies in the flammability and explosive nature of neopentane. This characteristic poses safety concerns during storage, handling, and application processes. Stringent safety measures and specialized equipment are required to mitigate risks, which can increase operational costs and complexity for manufacturers.

The environmental impact of neopentane is also a growing concern. As a volatile organic compound (VOC), neopentane contributes to air pollution and the formation of ground-level ozone. Regulatory pressures to reduce VOC emissions are pushing the industry to seek alternative solutions or develop more efficient containment methods.

Achieving optimal insulation properties while maintaining coating durability presents another technical hurdle. Neopentane's excellent insulating capabilities must be balanced with the need for coatings that can withstand mechanical stress, weathering, and chemical exposure. Developing formulations that provide both high insulation performance and long-term durability remains a challenge for researchers and manufacturers.

The scalability of neopentane coating technologies for large-scale industrial applications is also problematic. Ensuring uniform coating thickness and quality across large surface areas, such as in the construction or automotive industries, requires sophisticated application techniques and equipment. This scalability issue can limit the adoption of neopentane coatings in certain sectors.

Furthermore, the cost-effectiveness of neopentane coatings compared to alternative insulation materials is a persistent challenge. While neopentane offers superior insulation properties, the overall production and application costs may be higher than traditional materials, making it less attractive for price-sensitive markets.

Lastly, the long-term stability and aging characteristics of neopentane coatings require further investigation. As these coatings are exposed to various environmental conditions over time, there is a need to better understand and mitigate potential degradation mechanisms that could affect their performance and lifespan.

Existing Neopentane Coating Solutions

01 Production and purification of neopentane

Methods for producing and purifying neopentane, including various separation and distillation techniques. These processes aim to obtain high-purity neopentane for industrial applications, often involving the use of specific catalysts and reaction conditions.- Production and purification of neopentane: Methods for producing and purifying neopentane, including various separation and distillation techniques. These processes aim to obtain high-purity neopentane for industrial applications, often involving the use of specific catalysts and reaction conditions.

- Neopentane as a refrigerant or propellant: Utilization of neopentane as a refrigerant or propellant in various applications due to its thermodynamic properties. This includes its use in cooling systems, aerosol formulations, and other industrial processes where its low boiling point and stability are advantageous.

- Neopentane in chemical synthesis: Applications of neopentane as a reactant or intermediate in chemical synthesis processes. This includes its use in the production of various organic compounds, polymers, and specialty chemicals, often taking advantage of its unique structural properties.

- Neopentane in fuel compositions: Incorporation of neopentane in fuel compositions to improve performance characteristics. This may include its use as an additive or blending component in gasoline, diesel, or other fuel formulations to enhance combustion properties or reduce emissions.

- Separation and analysis of neopentane: Techniques for separating neopentane from mixtures and analyzing its purity. This includes chromatographic methods, spectroscopic techniques, and other analytical approaches used in quality control and research applications involving neopentane.

02 Neopentane as a refrigerant or propellant

Utilization of neopentane as a refrigerant or propellant in various applications due to its thermodynamic properties. This includes its use in cooling systems, aerosol products, and other industrial processes where its low boiling point and stability are advantageous.Expand Specific Solutions03 Neopentane in chemical synthesis

Applications of neopentane as a reactant or intermediate in chemical synthesis processes. This includes its use in the production of various organic compounds, polymers, and specialty chemicals, often taking advantage of its unique structural properties.Expand Specific Solutions04 Neopentane in fuel compositions

Incorporation of neopentane in fuel compositions to enhance performance characteristics. This may include its use as an additive in gasoline or other fuel blends to improve combustion properties or reduce emissions.Expand Specific Solutions05 Neopentane in separation processes

Use of neopentane in various separation and extraction processes, particularly in the petrochemical industry. This may involve its application in gas chromatography, distillation, or as a solvent for specific separation tasks.Expand Specific Solutions

Key Players in Neopentane Coating Industry

The neopentane coating technology market is in its early growth stage, characterized by ongoing research and development efforts. The market size is relatively small but expanding, driven by increasing demand for high-performance coatings in various industries. Technologically, the field is still evolving, with major players like BASF Coatings GmbH, ExxonMobil Chemical Patents, and Covestro Deutschland AG leading innovation. These companies are investing in R&D to improve neopentane-based coating properties, such as durability, chemical resistance, and environmental sustainability. Collaboration between industry leaders and research institutions, like Purdue Research Foundation and University of Jinan, is accelerating technological advancements, indicating a promising future for neopentane in coating technologies.

BASF Coatings GmbH

Technical Solution: BASF Coatings GmbH has developed innovative coating technologies incorporating neopentane as a key component. Their research focuses on utilizing neopentane's unique properties to enhance coating performance. The company has engineered neopentane-based formulations that offer improved durability and weather resistance. These coatings demonstrate superior adhesion and flexibility, making them ideal for automotive and industrial applications[1]. BASF's neopentane-infused coatings also exhibit excellent chemical resistance and low VOC emissions, aligning with stringent environmental regulations[3]. The company has invested in advanced manufacturing processes to optimize the integration of neopentane into their coating systems, resulting in more efficient production and consistent quality[5].

Strengths: Industry-leading research capabilities, extensive product portfolio, and global market presence. Weaknesses: Higher production costs associated with specialized formulations and potential supply chain dependencies for neopentane.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents, Inc. has made significant strides in neopentane-based coating technologies. Their research has led to the development of high-performance coatings that leverage neopentane's low boiling point and excellent solvency properties. The company has patented several neopentane-containing coating formulations that offer enhanced drying speeds and improved film formation[2]. These coatings demonstrate superior resistance to weathering and UV degradation, making them particularly suitable for outdoor applications[4]. ExxonMobil's neopentane coatings also show improved adhesion to various substrates, including metals and plastics, expanding their potential use across multiple industries[6]. The company has invested in scaling up production of these specialized coatings to meet growing market demand.

Strengths: Strong R&D capabilities, extensive patent portfolio, and vertical integration with neopentane production. Weaknesses: Potential regulatory challenges related to VOC emissions and the need for specialized application equipment.

Core Innovations in Neopentane Coating Research

Production of neopentane

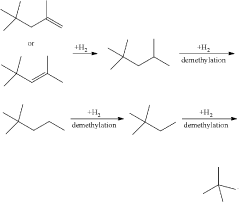

PatentWO2018044592A1

Innovation

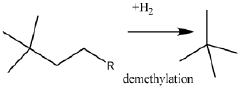

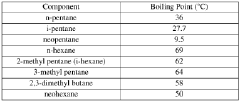

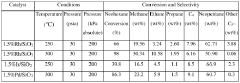

- A process involving the isomerization of C6-C7 paraffins to produce neohexane or neoheptane, followed by demethylation using a catalyst in the presence of hydrogen, which allows for the production of neopentane with yields greater than 40 wt% from readily available C4-C7 paraffinic feed streams, such as light virgin naphtha.

Production of Neopentane

PatentActiveUS20190177248A1

Innovation

- A process involving the dimerization of isobutylene to form diisobutylene, followed by demethylation using a catalyst in the presence of hydrogen, which utilizes readily available isobutylene from refinery raffinate streams to produce neopentane with high yield and selectivity.

Environmental Impact of Neopentane Coatings

The environmental impact of neopentane coatings is a critical consideration in the development and application of this technology. Neopentane, a volatile organic compound (VOC), has been widely used in coating technologies due to its excellent properties as a blowing agent and solvent. However, its potential environmental effects have raised concerns among researchers and regulatory bodies.

One of the primary environmental concerns associated with neopentane coatings is their contribution to air pollution. When released into the atmosphere, neopentane can react with other pollutants to form ground-level ozone, a key component of smog. This can lead to respiratory issues and other health problems in urban areas. Additionally, neopentane has a high global warming potential, contributing to climate change when released into the atmosphere.

Water pollution is another potential environmental impact of neopentane coatings. During the application and disposal processes, neopentane may leach into water systems, potentially affecting aquatic ecosystems. The long-term effects of neopentane exposure on marine life and water quality are still being studied, but initial findings suggest potential risks to biodiversity and water resources.

The production and disposal of neopentane coatings also raise concerns about resource depletion and waste management. The manufacturing process of neopentane requires significant energy inputs and relies on non-renewable fossil fuel resources. Furthermore, the disposal of neopentane-containing products can be challenging, as improper handling may lead to the release of harmful chemicals into the environment.

To address these environmental concerns, researchers and industry professionals are exploring alternative coating technologies and improved handling methods. Some promising approaches include the development of water-based coatings, the use of bio-based solvents, and the implementation of more efficient application techniques to reduce VOC emissions. Additionally, advancements in recycling and waste management technologies are being pursued to minimize the environmental impact of neopentane-containing products at the end of their lifecycle.

Regulatory bodies worldwide have implemented stricter guidelines for the use and disposal of neopentane coatings. These regulations aim to reduce VOC emissions, improve air quality, and protect water resources. As a result, many companies are investing in research and development to create more environmentally friendly coating solutions that maintain the desired performance characteristics while minimizing negative environmental impacts.

In conclusion, while neopentane coatings offer valuable properties for various applications, their environmental impact remains a significant concern. Ongoing research and technological advancements are crucial in finding a balance between performance and sustainability in coating technologies.

One of the primary environmental concerns associated with neopentane coatings is their contribution to air pollution. When released into the atmosphere, neopentane can react with other pollutants to form ground-level ozone, a key component of smog. This can lead to respiratory issues and other health problems in urban areas. Additionally, neopentane has a high global warming potential, contributing to climate change when released into the atmosphere.

Water pollution is another potential environmental impact of neopentane coatings. During the application and disposal processes, neopentane may leach into water systems, potentially affecting aquatic ecosystems. The long-term effects of neopentane exposure on marine life and water quality are still being studied, but initial findings suggest potential risks to biodiversity and water resources.

The production and disposal of neopentane coatings also raise concerns about resource depletion and waste management. The manufacturing process of neopentane requires significant energy inputs and relies on non-renewable fossil fuel resources. Furthermore, the disposal of neopentane-containing products can be challenging, as improper handling may lead to the release of harmful chemicals into the environment.

To address these environmental concerns, researchers and industry professionals are exploring alternative coating technologies and improved handling methods. Some promising approaches include the development of water-based coatings, the use of bio-based solvents, and the implementation of more efficient application techniques to reduce VOC emissions. Additionally, advancements in recycling and waste management technologies are being pursued to minimize the environmental impact of neopentane-containing products at the end of their lifecycle.

Regulatory bodies worldwide have implemented stricter guidelines for the use and disposal of neopentane coatings. These regulations aim to reduce VOC emissions, improve air quality, and protect water resources. As a result, many companies are investing in research and development to create more environmentally friendly coating solutions that maintain the desired performance characteristics while minimizing negative environmental impacts.

In conclusion, while neopentane coatings offer valuable properties for various applications, their environmental impact remains a significant concern. Ongoing research and technological advancements are crucial in finding a balance between performance and sustainability in coating technologies.

Regulatory Framework for Neopentane Use in Coatings

The regulatory framework for neopentane use in coatings is a complex and evolving landscape that significantly impacts the development and application of coating technologies. Neopentane, a volatile organic compound (VOC), is subject to stringent regulations due to its potential environmental and health effects.

In the United States, the Environmental Protection Agency (EPA) regulates neopentane under the Clean Air Act. The EPA has established National Ambient Air Quality Standards (NAAQS) that limit the concentration of VOCs in the atmosphere. Coating manufacturers must adhere to these standards when formulating products containing neopentane. Additionally, many states have implemented their own VOC regulations, which are often more stringent than federal standards.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of neopentane in coatings. Under REACH, manufacturers and importers must register chemicals and provide safety data. Neopentane is subject to these requirements, and its use may be restricted or require authorization depending on the specific application and quantity.

In Asia, countries like China and Japan have also introduced regulations to control VOC emissions from coatings. China's Air Pollution Prevention and Control Law sets limits on VOC content in various products, including coatings. Japan's Air Pollution Control Law similarly regulates VOC emissions and requires manufacturers to report usage and implement reduction measures.

The regulatory landscape is continuously evolving, with a trend towards stricter controls on VOC emissions. This has led to increased research and development efforts in low-VOC and VOC-free coating technologies. Manufacturers are exploring alternative blowing agents and formulations to reduce or eliminate neopentane use while maintaining coating performance.

Compliance with these regulations presents challenges for coating manufacturers. They must invest in research and development to reformulate products, implement emission control technologies, and establish robust testing and reporting procedures. The cost of compliance can be significant, potentially impacting product pricing and market competitiveness.

However, the regulatory framework also drives innovation in the coating industry. Companies are developing novel technologies and processes to meet regulatory requirements while improving product performance. This has led to advancements in water-based coatings, powder coatings, and other low-VOC alternatives that may eventually replace neopentane-based formulations in many applications.

As environmental concerns continue to grow, it is likely that regulations governing neopentane and other VOCs will become increasingly stringent. Coating manufacturers must stay informed about regulatory changes and proactively adapt their product portfolios to ensure compliance and maintain market competitiveness in this dynamic regulatory environment.

In the United States, the Environmental Protection Agency (EPA) regulates neopentane under the Clean Air Act. The EPA has established National Ambient Air Quality Standards (NAAQS) that limit the concentration of VOCs in the atmosphere. Coating manufacturers must adhere to these standards when formulating products containing neopentane. Additionally, many states have implemented their own VOC regulations, which are often more stringent than federal standards.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which affects the use of neopentane in coatings. Under REACH, manufacturers and importers must register chemicals and provide safety data. Neopentane is subject to these requirements, and its use may be restricted or require authorization depending on the specific application and quantity.

In Asia, countries like China and Japan have also introduced regulations to control VOC emissions from coatings. China's Air Pollution Prevention and Control Law sets limits on VOC content in various products, including coatings. Japan's Air Pollution Control Law similarly regulates VOC emissions and requires manufacturers to report usage and implement reduction measures.

The regulatory landscape is continuously evolving, with a trend towards stricter controls on VOC emissions. This has led to increased research and development efforts in low-VOC and VOC-free coating technologies. Manufacturers are exploring alternative blowing agents and formulations to reduce or eliminate neopentane use while maintaining coating performance.

Compliance with these regulations presents challenges for coating manufacturers. They must invest in research and development to reformulate products, implement emission control technologies, and establish robust testing and reporting procedures. The cost of compliance can be significant, potentially impacting product pricing and market competitiveness.

However, the regulatory framework also drives innovation in the coating industry. Companies are developing novel technologies and processes to meet regulatory requirements while improving product performance. This has led to advancements in water-based coatings, powder coatings, and other low-VOC alternatives that may eventually replace neopentane-based formulations in many applications.

As environmental concerns continue to grow, it is likely that regulations governing neopentane and other VOCs will become increasingly stringent. Coating manufacturers must stay informed about regulatory changes and proactively adapt their product portfolios to ensure compliance and maintain market competitiveness in this dynamic regulatory environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!