Enhancing Oral Thin Film Drug Delivery Systems with Microcrystalline Cellulose

JUL 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OTF Drug Delivery Background and Objectives

Oral thin film (OTF) drug delivery systems have emerged as a revolutionary approach in pharmaceutical technology, offering numerous advantages over traditional oral dosage forms. These innovative systems consist of thin, flexible sheets that dissolve rapidly when placed on the tongue or buccal mucosa, delivering the active pharmaceutical ingredient directly into the bloodstream. The development of OTF drug delivery systems has been driven by the need for more patient-friendly and efficient drug administration methods, particularly for pediatric and geriatric populations who may have difficulty swallowing conventional tablets or capsules.

The primary objective of enhancing OTF drug delivery systems with microcrystalline cellulose (MCC) is to improve the overall performance and efficacy of these formulations. MCC, a purified, partially depolymerized cellulose, has gained significant attention in pharmaceutical applications due to its excellent binding properties, high compressibility, and biocompatibility. By incorporating MCC into OTF formulations, researchers aim to address several key challenges associated with current OTF technologies, including mechanical strength, drug loading capacity, and dissolution profile.

The evolution of OTF drug delivery systems can be traced back to the early 2000s when the first commercial products were introduced to the market. Since then, continuous research and development efforts have focused on improving various aspects of OTF formulations, such as film-forming polymers, plasticizers, and active ingredient incorporation techniques. The integration of MCC into OTF systems represents a significant step forward in this technological progression, as it offers the potential to enhance both the physical and functional properties of the films.

One of the primary goals of incorporating MCC into OTF formulations is to improve the mechanical strength of the films without compromising their rapid dissolution characteristics. This is particularly important for ensuring the integrity of the films during manufacturing, packaging, and handling processes. Additionally, MCC may contribute to enhanced drug loading capacity, allowing for higher doses of active ingredients to be incorporated into a single film, thus expanding the range of therapeutic applications for OTF drug delivery systems.

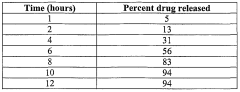

Another critical objective is to optimize the dissolution profile of OTF formulations containing MCC. By carefully controlling the particle size and distribution of MCC within the film matrix, researchers aim to achieve a balance between rapid disintegration and controlled release of the active pharmaceutical ingredient. This could potentially lead to improved bioavailability and more predictable pharmacokinetics, ultimately enhancing the therapeutic efficacy of drugs delivered via OTF systems.

The primary objective of enhancing OTF drug delivery systems with microcrystalline cellulose (MCC) is to improve the overall performance and efficacy of these formulations. MCC, a purified, partially depolymerized cellulose, has gained significant attention in pharmaceutical applications due to its excellent binding properties, high compressibility, and biocompatibility. By incorporating MCC into OTF formulations, researchers aim to address several key challenges associated with current OTF technologies, including mechanical strength, drug loading capacity, and dissolution profile.

The evolution of OTF drug delivery systems can be traced back to the early 2000s when the first commercial products were introduced to the market. Since then, continuous research and development efforts have focused on improving various aspects of OTF formulations, such as film-forming polymers, plasticizers, and active ingredient incorporation techniques. The integration of MCC into OTF systems represents a significant step forward in this technological progression, as it offers the potential to enhance both the physical and functional properties of the films.

One of the primary goals of incorporating MCC into OTF formulations is to improve the mechanical strength of the films without compromising their rapid dissolution characteristics. This is particularly important for ensuring the integrity of the films during manufacturing, packaging, and handling processes. Additionally, MCC may contribute to enhanced drug loading capacity, allowing for higher doses of active ingredients to be incorporated into a single film, thus expanding the range of therapeutic applications for OTF drug delivery systems.

Another critical objective is to optimize the dissolution profile of OTF formulations containing MCC. By carefully controlling the particle size and distribution of MCC within the film matrix, researchers aim to achieve a balance between rapid disintegration and controlled release of the active pharmaceutical ingredient. This could potentially lead to improved bioavailability and more predictable pharmacokinetics, ultimately enhancing the therapeutic efficacy of drugs delivered via OTF systems.

Market Analysis for OTF Drug Delivery Systems

The global market for oral thin film (OTF) drug delivery systems has been experiencing significant growth in recent years, driven by increasing demand for patient-friendly and convenient dosage forms. This market segment is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to be in the double digits over the next five years.

The pharmaceutical industry's focus on innovative drug delivery technologies has been a key factor in the expansion of the OTF market. These systems offer several advantages over traditional oral dosage forms, including improved bioavailability, faster onset of action, and enhanced patient compliance. These benefits have led to increased adoption across various therapeutic areas, particularly in the treatment of central nervous system disorders, gastrointestinal diseases, and pain management.

The geriatric population and pediatric patients represent significant market segments for OTF drug delivery systems. The ease of administration and potential for dose customization make these systems particularly attractive for these demographics. Additionally, the growing prevalence of chronic diseases and the need for long-term medication management have further fueled the demand for OTF products.

Geographically, North America currently holds the largest market share in the OTF drug delivery systems sector, followed by Europe. This dominance can be attributed to the presence of major pharmaceutical companies, advanced healthcare infrastructure, and favorable regulatory environments. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare access, rising disposable incomes, and increasing awareness of novel drug delivery technologies.

The market landscape for OTF drug delivery systems is characterized by both established pharmaceutical companies and innovative start-ups. Major players are investing heavily in research and development to expand their product portfolios and gain a competitive edge. Collaborations between drug manufacturers and OTF technology developers are becoming increasingly common, as companies seek to leverage complementary expertise and resources.

Despite the positive growth outlook, the OTF drug delivery systems market faces certain challenges. These include the need for specialized manufacturing processes, potential limitations in drug loading capacity, and regulatory hurdles associated with demonstrating bioequivalence to existing dosage forms. Overcoming these challenges presents opportunities for technological advancements and market differentiation.

The integration of microcrystalline cellulose into OTF formulations represents a promising avenue for addressing some of these challenges. This development has the potential to enhance drug loading capacity, improve film stability, and optimize dissolution profiles. As such, it is likely to attract significant interest from both manufacturers and end-users, potentially reshaping the competitive landscape of the OTF drug delivery systems market.

The pharmaceutical industry's focus on innovative drug delivery technologies has been a key factor in the expansion of the OTF market. These systems offer several advantages over traditional oral dosage forms, including improved bioavailability, faster onset of action, and enhanced patient compliance. These benefits have led to increased adoption across various therapeutic areas, particularly in the treatment of central nervous system disorders, gastrointestinal diseases, and pain management.

The geriatric population and pediatric patients represent significant market segments for OTF drug delivery systems. The ease of administration and potential for dose customization make these systems particularly attractive for these demographics. Additionally, the growing prevalence of chronic diseases and the need for long-term medication management have further fueled the demand for OTF products.

Geographically, North America currently holds the largest market share in the OTF drug delivery systems sector, followed by Europe. This dominance can be attributed to the presence of major pharmaceutical companies, advanced healthcare infrastructure, and favorable regulatory environments. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by improving healthcare access, rising disposable incomes, and increasing awareness of novel drug delivery technologies.

The market landscape for OTF drug delivery systems is characterized by both established pharmaceutical companies and innovative start-ups. Major players are investing heavily in research and development to expand their product portfolios and gain a competitive edge. Collaborations between drug manufacturers and OTF technology developers are becoming increasingly common, as companies seek to leverage complementary expertise and resources.

Despite the positive growth outlook, the OTF drug delivery systems market faces certain challenges. These include the need for specialized manufacturing processes, potential limitations in drug loading capacity, and regulatory hurdles associated with demonstrating bioequivalence to existing dosage forms. Overcoming these challenges presents opportunities for technological advancements and market differentiation.

The integration of microcrystalline cellulose into OTF formulations represents a promising avenue for addressing some of these challenges. This development has the potential to enhance drug loading capacity, improve film stability, and optimize dissolution profiles. As such, it is likely to attract significant interest from both manufacturers and end-users, potentially reshaping the competitive landscape of the OTF drug delivery systems market.

Current Challenges in OTF Technology

Oral thin film (OTF) drug delivery systems have gained significant attention in recent years due to their potential to enhance patient compliance and improve drug bioavailability. However, several challenges persist in the development and optimization of OTF technology, particularly when incorporating microcrystalline cellulose (MCC) as a key component.

One of the primary challenges in OTF technology is achieving uniform drug distribution throughout the film. The incorporation of MCC, while beneficial for its film-forming properties, can lead to inconsistencies in drug dispersion. This non-uniform distribution may result in variations in drug dosage across different sections of the film, potentially compromising therapeutic efficacy and safety.

Another significant hurdle is maintaining the mechanical integrity of the film while ensuring rapid disintegration upon oral administration. MCC, known for its excellent binding properties, can sometimes lead to increased film thickness and reduced flexibility. This trade-off between structural stability and disintegration time poses a challenge in optimizing OTF formulations for various drug molecules.

The moisture sensitivity of OTF systems presents an ongoing concern. MCC, being hygroscopic, can absorb moisture from the environment, potentially affecting the stability and shelf-life of the drug product. This necessitates careful consideration of packaging materials and storage conditions to maintain the integrity of the OTF throughout its intended shelf-life.

Scaling up production from laboratory to industrial scale remains a significant challenge. The process of incorporating MCC into OTF formulations often requires specialized equipment and precise control over manufacturing parameters. Ensuring consistency in film thickness, drug content uniformity, and disintegration properties across large-scale production batches can be particularly challenging.

The limited drug loading capacity of OTFs is another area of concern. While MCC can improve the film-forming properties, it may also reduce the available space for drug molecules, especially for high-dose medications. This limitation can restrict the applicability of OTF technology to certain drug classes and dosage regimens.

Taste masking is crucial for patient acceptability, particularly in pediatric and geriatric populations. Incorporating MCC into OTF formulations while effectively masking the taste of bitter drugs without compromising the film's rapid disintegration properties remains a complex challenge for formulators.

Regulatory considerations also pose challenges in the development of MCC-enhanced OTFs. Demonstrating bioequivalence to existing dosage forms and ensuring consistent quality attributes throughout the product's lifecycle are critical aspects that require extensive studies and documentation.

One of the primary challenges in OTF technology is achieving uniform drug distribution throughout the film. The incorporation of MCC, while beneficial for its film-forming properties, can lead to inconsistencies in drug dispersion. This non-uniform distribution may result in variations in drug dosage across different sections of the film, potentially compromising therapeutic efficacy and safety.

Another significant hurdle is maintaining the mechanical integrity of the film while ensuring rapid disintegration upon oral administration. MCC, known for its excellent binding properties, can sometimes lead to increased film thickness and reduced flexibility. This trade-off between structural stability and disintegration time poses a challenge in optimizing OTF formulations for various drug molecules.

The moisture sensitivity of OTF systems presents an ongoing concern. MCC, being hygroscopic, can absorb moisture from the environment, potentially affecting the stability and shelf-life of the drug product. This necessitates careful consideration of packaging materials and storage conditions to maintain the integrity of the OTF throughout its intended shelf-life.

Scaling up production from laboratory to industrial scale remains a significant challenge. The process of incorporating MCC into OTF formulations often requires specialized equipment and precise control over manufacturing parameters. Ensuring consistency in film thickness, drug content uniformity, and disintegration properties across large-scale production batches can be particularly challenging.

The limited drug loading capacity of OTFs is another area of concern. While MCC can improve the film-forming properties, it may also reduce the available space for drug molecules, especially for high-dose medications. This limitation can restrict the applicability of OTF technology to certain drug classes and dosage regimens.

Taste masking is crucial for patient acceptability, particularly in pediatric and geriatric populations. Incorporating MCC into OTF formulations while effectively masking the taste of bitter drugs without compromising the film's rapid disintegration properties remains a complex challenge for formulators.

Regulatory considerations also pose challenges in the development of MCC-enhanced OTFs. Demonstrating bioequivalence to existing dosage forms and ensuring consistent quality attributes throughout the product's lifecycle are critical aspects that require extensive studies and documentation.

Existing MCC-Enhanced OTF Solutions

01 Polymer-based film formulations

Utilizing various polymers to create thin films that dissolve quickly in the oral cavity, enhancing drug delivery and absorption. These formulations can improve bioavailability and patient compliance due to their ease of administration and rapid disintegration.- Polymer-based oral thin films: Utilizing various polymers to create thin films that dissolve rapidly in the oral cavity, enhancing drug delivery and absorption. These films can be designed to improve bioavailability, stability, and patient compliance.

- Mucoadhesive oral thin films: Developing oral thin films with mucoadhesive properties to prolong residence time in the oral cavity, allowing for sustained drug release and improved absorption through the oral mucosa.

- Multilayer oral thin films: Creating multilayer oral thin films to incorporate multiple drugs or to separate incompatible components, allowing for controlled release profiles and enhanced stability of the formulation.

- Nanoparticle-loaded oral thin films: Incorporating nanoparticles into oral thin films to enhance drug solubility, stability, and permeation across biological membranes, potentially improving bioavailability of poorly soluble drugs.

- pH-responsive oral thin films: Designing oral thin films with pH-responsive polymers to target specific regions of the gastrointestinal tract, allowing for site-specific drug release and improved therapeutic efficacy.

02 Mucoadhesive properties enhancement

Incorporating mucoadhesive agents to improve the adherence of the film to the oral mucosa, prolonging contact time and enhancing drug absorption. This approach can lead to sustained release and increased bioavailability of the active ingredients.Expand Specific Solutions03 Nanoparticle integration

Incorporating nanoparticles into oral thin films to enhance drug solubility, stability, and permeation across biological membranes. This technique can significantly improve the bioavailability of poorly soluble drugs and enable targeted delivery.Expand Specific Solutions04 Multi-layer film technology

Developing multi-layered oral thin films to achieve controlled release profiles or combine incompatible drugs. This approach allows for the incorporation of multiple active ingredients with different release kinetics in a single dosage form.Expand Specific Solutions05 Taste-masking techniques

Implementing various taste-masking strategies to improve palatability and patient acceptance of oral thin films, especially for bitter drugs. These techniques may include the use of flavoring agents, sweeteners, or encapsulation methods to mask unpleasant tastes.Expand Specific Solutions

Key Players in OTF and MCC Industry

The oral thin film drug delivery market is in a growth phase, driven by increasing demand for patient-friendly dosage forms. The global market size is projected to reach several billion dollars by 2025, with a compound annual growth rate of over 9%. Technological advancements in microcrystalline cellulose incorporation are enhancing the performance of these systems. Key players like LTS LOHMANN, Aquestive Therapeutics, and Novartis are investing heavily in R&D to improve film formulations and manufacturing processes. While the technology is maturing, there's still room for innovation in areas such as drug loading capacity and stability. Collaborations between pharmaceutical companies and research institutions are accelerating progress in this field.

LTS LOHMANN Therapie-Systeme AG

Technical Solution: LTS LOHMANN has developed a proprietary TTS (Transdermal Therapeutic System) technology for oral thin films incorporating microcrystalline cellulose (MCC). Their approach involves creating a multi-layered film structure where MCC is integrated into the drug-containing layer. This enhances drug stability and provides controlled release properties. The company utilizes a patented coating process that ensures uniform distribution of MCC particles within the polymer matrix, resulting in improved mechanical strength and dissolution characteristics of the oral film[1][3]. LTS LOHMANN's technology also incorporates a specialized drying method that preserves the crystalline structure of MCC, maintaining its beneficial properties in the final product[5].

Strengths: Improved drug stability, controlled release, enhanced mechanical properties. Weaknesses: Potential complexity in manufacturing process, possible limitations in drug loading capacity.

Aquestive Therapeutics, Inc.

Technical Solution: Aquestive Therapeutics has developed PharmFilm®, an advanced oral thin film technology that incorporates microcrystalline cellulose for enhanced drug delivery. Their approach involves a proprietary manufacturing process that creates a uniform dispersion of MCC within a polymer matrix. This results in films with improved mechanical strength and dissolution properties. The company's technology allows for precise control of film thickness and drug content, enabling customized release profiles for various therapeutic applications[2][4]. Aquestive's films are designed to rapidly disintegrate in the oral cavity, promoting fast absorption and improved bioavailability of the active pharmaceutical ingredients[6]. The incorporation of MCC also aids in masking bitter tastes and enhancing patient compliance.

Strengths: Rapid disintegration, improved bioavailability, taste-masking capabilities. Weaknesses: Potential limitations in drug loading, sensitivity to moisture.

Core Innovations in MCC for OTFs

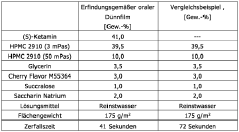

Oral thin film with high active agent loading

PatentWO2019110727A1

Innovation

- An oral thin film comprising a cellulose derivative and a pharmaceutically active ingredient with specific solubility and pH characteristics, combined with a mixture of hydroxypropylmethylcellulose derivatives of varying viscosities, achieves high active ingredient loading and rapid disintegration by optimizing the production process through controlled drying temperatures.

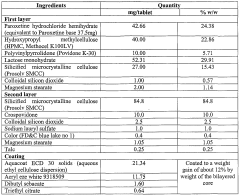

Oral drug delivery system providing a coating comprising both a cellulose and a methacrylic acid derivative

PatentWO2006123364A2

Innovation

- An oral drug delivery system featuring a core with a water-insoluble polymer and pH-dependent polymer coating, where the coating is designed to be partially or fully removed from preselected surfaces upon contact with intestinal fluids, using swellable or reactive compositions to ensure reliable and controlled release, avoiding premature coating detachment and manufacturing complexities.

Regulatory Framework for OTF Drug Delivery

The regulatory framework for oral thin film (OTF) drug delivery systems is a complex and evolving landscape that plays a crucial role in the development, approval, and commercialization of these innovative pharmaceutical products. In the United States, the Food and Drug Administration (FDA) is the primary regulatory body overseeing OTF drug delivery systems. The FDA categorizes OTFs as a novel drug delivery platform, which falls under the purview of the Center for Drug Evaluation and Research (CDER).

The regulatory pathway for OTF drug delivery systems typically follows the New Drug Application (NDA) process, as outlined in 21 CFR Part 314. This process requires extensive documentation, including comprehensive data on the drug's safety, efficacy, and quality. For OTFs incorporating microcrystalline cellulose, manufacturers must provide detailed information on the excipient's impact on drug stability, dissolution profile, and bioavailability.

The FDA's guidance document "Orally Disintegrating Tablets" (2008) provides valuable insights for OTF developers, although it is not specifically tailored to thin films. This guidance emphasizes the importance of demonstrating rapid disintegration, acceptable taste, and appropriate physical characteristics. Manufacturers must also address potential concerns related to dose uniformity and stability, particularly when incorporating microcrystalline cellulose into the OTF matrix.

In the European Union, the European Medicines Agency (EMA) oversees the regulatory process for OTF drug delivery systems. The EMA's approach is similar to the FDA's, requiring comprehensive data on quality, safety, and efficacy. However, the EMA places additional emphasis on the Quality by Design (QbD) approach, which encourages manufacturers to build quality into their products from the early stages of development.

Regulatory bodies in other major markets, such as Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA), have also developed specific guidelines for novel drug delivery systems, including OTFs. These guidelines often align with international standards but may include country-specific requirements that manufacturers must address.

A key regulatory consideration for OTF drug delivery systems enhanced with microcrystalline cellulose is the demonstration of bioequivalence to existing dosage forms. Regulatory agencies typically require in vivo bioequivalence studies to ensure that the OTF formulation delivers the active pharmaceutical ingredient (API) in a manner comparable to the reference product. This requirement can be particularly challenging for OTFs, as the unique dissolution and absorption characteristics of the thin film format may necessitate specialized study designs.

As the field of OTF drug delivery continues to advance, regulatory frameworks are likely to evolve. Manufacturers and researchers working on enhancing OTFs with microcrystalline cellulose must stay abreast of these changes and engage in early and frequent communication with regulatory authorities to ensure compliance and streamline the approval process.

The regulatory pathway for OTF drug delivery systems typically follows the New Drug Application (NDA) process, as outlined in 21 CFR Part 314. This process requires extensive documentation, including comprehensive data on the drug's safety, efficacy, and quality. For OTFs incorporating microcrystalline cellulose, manufacturers must provide detailed information on the excipient's impact on drug stability, dissolution profile, and bioavailability.

The FDA's guidance document "Orally Disintegrating Tablets" (2008) provides valuable insights for OTF developers, although it is not specifically tailored to thin films. This guidance emphasizes the importance of demonstrating rapid disintegration, acceptable taste, and appropriate physical characteristics. Manufacturers must also address potential concerns related to dose uniformity and stability, particularly when incorporating microcrystalline cellulose into the OTF matrix.

In the European Union, the European Medicines Agency (EMA) oversees the regulatory process for OTF drug delivery systems. The EMA's approach is similar to the FDA's, requiring comprehensive data on quality, safety, and efficacy. However, the EMA places additional emphasis on the Quality by Design (QbD) approach, which encourages manufacturers to build quality into their products from the early stages of development.

Regulatory bodies in other major markets, such as Japan's Pharmaceuticals and Medical Devices Agency (PMDA) and China's National Medical Products Administration (NMPA), have also developed specific guidelines for novel drug delivery systems, including OTFs. These guidelines often align with international standards but may include country-specific requirements that manufacturers must address.

A key regulatory consideration for OTF drug delivery systems enhanced with microcrystalline cellulose is the demonstration of bioequivalence to existing dosage forms. Regulatory agencies typically require in vivo bioequivalence studies to ensure that the OTF formulation delivers the active pharmaceutical ingredient (API) in a manner comparable to the reference product. This requirement can be particularly challenging for OTFs, as the unique dissolution and absorption characteristics of the thin film format may necessitate specialized study designs.

As the field of OTF drug delivery continues to advance, regulatory frameworks are likely to evolve. Manufacturers and researchers working on enhancing OTFs with microcrystalline cellulose must stay abreast of these changes and engage in early and frequent communication with regulatory authorities to ensure compliance and streamline the approval process.

Biocompatibility and Safety Considerations

Biocompatibility and safety considerations are paramount in the development and implementation of oral thin film drug delivery systems enhanced with microcrystalline cellulose (MCC). The integration of MCC into these systems necessitates a comprehensive evaluation of its interactions with biological systems and potential impacts on human health.

MCC, derived from natural cellulose sources, has generally been recognized as safe (GRAS) by regulatory agencies, including the FDA. Its long history of use in pharmaceutical formulations provides a foundation of safety data. However, the unique properties of oral thin films require specific considerations regarding the biocompatibility of MCC in this context.

One primary concern is the potential for MCC to interact with the oral mucosa. Studies have shown that MCC exhibits minimal cytotoxicity and does not typically induce significant inflammatory responses when in contact with oral tissues. This favorable profile contributes to its suitability for use in oral thin films, where prolonged contact with the buccal or sublingual mucosa may occur.

The particle size and morphology of MCC used in thin films must be carefully controlled to prevent any mechanical irritation or abrasion of the oral cavity. Nano-sized or highly fibrous MCC particles may pose different safety profiles compared to larger, more rounded particles. Manufacturers must conduct thorough characterization studies to ensure the MCC used does not compromise the integrity of the oral epithelium.

Absorption and systemic distribution of MCC from oral thin films are generally considered negligible due to its insoluble nature and large molecular size. However, the potential for local accumulation in the oral cavity should be assessed, particularly for patients using multiple doses or chronic treatments. Long-term safety studies may be necessary to rule out any adverse effects from repeated exposure.

The interaction between MCC and the active pharmaceutical ingredients (APIs) in the thin film formulation is another critical safety consideration. While MCC is known for its chemical inertness, its high surface area and potential to form hydrogen bonds could influence drug release kinetics or stability. Compatibility studies must be conducted to ensure that MCC does not alter the therapeutic efficacy or safety profile of the incorporated drugs.

Environmental factors, such as pH changes in the oral cavity or exposure to salivary enzymes, may affect the behavior of MCC in thin films. Safety assessments should account for these variables to predict any potential changes in MCC properties that could impact biocompatibility or drug delivery performance.

Regulatory compliance is a crucial aspect of safety considerations. Manufacturers must adhere to good manufacturing practices (GMP) and provide comprehensive documentation on the sourcing, processing, and quality control of MCC used in oral thin films. This includes demonstrating the absence of harmful contaminants and ensuring batch-to-batch consistency in MCC properties.

MCC, derived from natural cellulose sources, has generally been recognized as safe (GRAS) by regulatory agencies, including the FDA. Its long history of use in pharmaceutical formulations provides a foundation of safety data. However, the unique properties of oral thin films require specific considerations regarding the biocompatibility of MCC in this context.

One primary concern is the potential for MCC to interact with the oral mucosa. Studies have shown that MCC exhibits minimal cytotoxicity and does not typically induce significant inflammatory responses when in contact with oral tissues. This favorable profile contributes to its suitability for use in oral thin films, where prolonged contact with the buccal or sublingual mucosa may occur.

The particle size and morphology of MCC used in thin films must be carefully controlled to prevent any mechanical irritation or abrasion of the oral cavity. Nano-sized or highly fibrous MCC particles may pose different safety profiles compared to larger, more rounded particles. Manufacturers must conduct thorough characterization studies to ensure the MCC used does not compromise the integrity of the oral epithelium.

Absorption and systemic distribution of MCC from oral thin films are generally considered negligible due to its insoluble nature and large molecular size. However, the potential for local accumulation in the oral cavity should be assessed, particularly for patients using multiple doses or chronic treatments. Long-term safety studies may be necessary to rule out any adverse effects from repeated exposure.

The interaction between MCC and the active pharmaceutical ingredients (APIs) in the thin film formulation is another critical safety consideration. While MCC is known for its chemical inertness, its high surface area and potential to form hydrogen bonds could influence drug release kinetics or stability. Compatibility studies must be conducted to ensure that MCC does not alter the therapeutic efficacy or safety profile of the incorporated drugs.

Environmental factors, such as pH changes in the oral cavity or exposure to salivary enzymes, may affect the behavior of MCC in thin films. Safety assessments should account for these variables to predict any potential changes in MCC properties that could impact biocompatibility or drug delivery performance.

Regulatory compliance is a crucial aspect of safety considerations. Manufacturers must adhere to good manufacturing practices (GMP) and provide comprehensive documentation on the sourcing, processing, and quality control of MCC used in oral thin films. This includes demonstrating the absence of harmful contaminants and ensuring batch-to-batch consistency in MCC properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!