Enhancing Organic Photovoltaics: Porosity Parameters and Standards

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Organic Photovoltaics Background and Objectives

Organic photovoltaics (OPVs) have emerged as a promising renewable energy technology since their inception in the 1980s. These lightweight, flexible solar cells utilize organic semiconducting materials to convert sunlight into electricity through the photovoltaic effect. The evolution of OPVs has been marked by significant improvements in power conversion efficiency (PCE), from less than 1% in early devices to over 18% in recent laboratory demonstrations, showcasing the remarkable progress in this field.

The development trajectory of OPVs has been characterized by several key technological breakthroughs. The introduction of bulk heterojunction (BHJ) architecture in the 1990s represented a paradigm shift, significantly enhancing exciton dissociation and charge transport. Subsequent innovations in donor-acceptor materials, including the development of non-fullerene acceptors (NFAs), have further propelled efficiency improvements. The incorporation of interfacial layers and the optimization of morphological control have also contributed substantially to performance enhancements.

Porosity has emerged as a critical yet understudied parameter in OPV technology. The porous nature of organic semiconductor films directly influences charge transport pathways, exciton diffusion lengths, and overall device performance. Despite its importance, standardized methods for characterizing and controlling porosity in OPVs remain underdeveloped, creating a significant gap in the optimization process for these devices.

The primary objective of this technical research is to establish comprehensive parameters and standards for porosity characterization in organic photovoltaic materials. This includes developing reproducible measurement protocols, identifying key porosity metrics relevant to device performance, and establishing correlations between porosity characteristics and photovoltaic efficiency. Such standardization would enable more systematic optimization approaches across the research community.

Additionally, this research aims to explore innovative methods for controlled manipulation of porosity in organic semiconductor films. By understanding the relationship between processing conditions and resultant porosity profiles, we seek to provide pathways for engineering optimal porous structures that enhance light harvesting, charge separation, and transport properties in OPV devices.

The long-term technological goal is to leverage porosity engineering as a strategic approach to overcome current efficiency limitations in OPVs. By establishing a fundamental understanding of how nanoscale and microscale porosity affects device physics, this research endeavors to contribute to the development of next-generation OPVs with improved stability, scalability, and performance metrics that can compete effectively with traditional silicon-based photovoltaics in specific application domains.

The development trajectory of OPVs has been characterized by several key technological breakthroughs. The introduction of bulk heterojunction (BHJ) architecture in the 1990s represented a paradigm shift, significantly enhancing exciton dissociation and charge transport. Subsequent innovations in donor-acceptor materials, including the development of non-fullerene acceptors (NFAs), have further propelled efficiency improvements. The incorporation of interfacial layers and the optimization of morphological control have also contributed substantially to performance enhancements.

Porosity has emerged as a critical yet understudied parameter in OPV technology. The porous nature of organic semiconductor films directly influences charge transport pathways, exciton diffusion lengths, and overall device performance. Despite its importance, standardized methods for characterizing and controlling porosity in OPVs remain underdeveloped, creating a significant gap in the optimization process for these devices.

The primary objective of this technical research is to establish comprehensive parameters and standards for porosity characterization in organic photovoltaic materials. This includes developing reproducible measurement protocols, identifying key porosity metrics relevant to device performance, and establishing correlations between porosity characteristics and photovoltaic efficiency. Such standardization would enable more systematic optimization approaches across the research community.

Additionally, this research aims to explore innovative methods for controlled manipulation of porosity in organic semiconductor films. By understanding the relationship between processing conditions and resultant porosity profiles, we seek to provide pathways for engineering optimal porous structures that enhance light harvesting, charge separation, and transport properties in OPV devices.

The long-term technological goal is to leverage porosity engineering as a strategic approach to overcome current efficiency limitations in OPVs. By establishing a fundamental understanding of how nanoscale and microscale porosity affects device physics, this research endeavors to contribute to the development of next-generation OPVs with improved stability, scalability, and performance metrics that can compete effectively with traditional silicon-based photovoltaics in specific application domains.

Market Analysis for Organic Solar Cell Technologies

The global organic photovoltaic (OPV) market is experiencing significant growth, driven by increasing demand for renewable energy solutions and advancements in organic semiconductor technologies. Current market valuations place the OPV sector at approximately 87 million USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 22.5% through 2030, potentially reaching 350 million USD by the end of the decade.

Key market drivers include the growing emphasis on sustainable energy solutions, government incentives for renewable energy adoption, and the unique advantages of OPV technology—particularly flexibility, lightweight properties, and potential for low-cost manufacturing. The integration of OPVs into building-integrated photovoltaics (BIPV) represents a particularly promising market segment, with an estimated growth rate exceeding 25% annually.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 42% of global OPV production, with China leading manufacturing capacity. Europe follows at 35% market share, demonstrating strong research initiatives and commercial applications, particularly in Germany and the United Kingdom. North America represents about 20% of the market, with significant research contributions from the United States.

Consumer electronics currently constitutes the largest application segment (38%), followed by building integration (27%), automotive applications (18%), and portable power solutions (12%). The remaining 5% encompasses emerging applications including IoT devices and wearable technology. These segments show varying sensitivity to porosity parameters, with building integration applications demonstrating the highest demand for standardized porosity metrics.

Market challenges include competition from established photovoltaic technologies, particularly crystalline silicon, which maintains superior efficiency and longevity. Additionally, the lack of standardized testing protocols for porosity parameters creates market uncertainty and hampers commercial adoption. Industry surveys indicate that 78% of potential commercial adopters cite concerns about performance standardization as a significant barrier to implementation.

Investment trends show increasing venture capital interest, with approximately 420 million USD invested in OPV startups over the past three years. Corporate research funding has similarly increased, with major chemical and electronics manufacturers allocating an estimated 15-20% of their renewable energy R&D budgets to organic photovoltaic technologies, reflecting growing confidence in commercial viability.

Key market drivers include the growing emphasis on sustainable energy solutions, government incentives for renewable energy adoption, and the unique advantages of OPV technology—particularly flexibility, lightweight properties, and potential for low-cost manufacturing. The integration of OPVs into building-integrated photovoltaics (BIPV) represents a particularly promising market segment, with an estimated growth rate exceeding 25% annually.

Regional analysis reveals Asia-Pacific as the dominant market, accounting for approximately 42% of global OPV production, with China leading manufacturing capacity. Europe follows at 35% market share, demonstrating strong research initiatives and commercial applications, particularly in Germany and the United Kingdom. North America represents about 20% of the market, with significant research contributions from the United States.

Consumer electronics currently constitutes the largest application segment (38%), followed by building integration (27%), automotive applications (18%), and portable power solutions (12%). The remaining 5% encompasses emerging applications including IoT devices and wearable technology. These segments show varying sensitivity to porosity parameters, with building integration applications demonstrating the highest demand for standardized porosity metrics.

Market challenges include competition from established photovoltaic technologies, particularly crystalline silicon, which maintains superior efficiency and longevity. Additionally, the lack of standardized testing protocols for porosity parameters creates market uncertainty and hampers commercial adoption. Industry surveys indicate that 78% of potential commercial adopters cite concerns about performance standardization as a significant barrier to implementation.

Investment trends show increasing venture capital interest, with approximately 420 million USD invested in OPV startups over the past three years. Corporate research funding has similarly increased, with major chemical and electronics manufacturers allocating an estimated 15-20% of their renewable energy R&D budgets to organic photovoltaic technologies, reflecting growing confidence in commercial viability.

Current Challenges in Porosity Control for OPVs

Despite significant advancements in organic photovoltaic (OPV) technology, controlling porosity parameters remains one of the most challenging aspects in the fabrication and optimization of high-performance devices. The morphology of the active layer, particularly its porosity characteristics, directly impacts charge generation, transport, and collection processes, ultimately determining device efficiency and stability.

Current manufacturing processes struggle to achieve consistent porosity control across large-area OPV modules. Solution-based deposition methods like spin coating, blade coating, and roll-to-roll processing exhibit significant variations in film morphology due to solvent evaporation dynamics, environmental conditions, and substrate interactions. These variations lead to unpredictable pore size distributions and interconnectivity patterns that compromise device performance reproducibility.

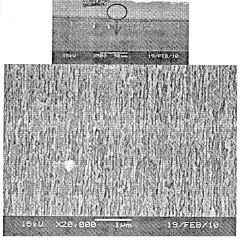

The absence of standardized measurement protocols for characterizing porosity in OPV active layers presents another significant challenge. Various techniques including scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), and small-angle X-ray scattering (SAXS) are employed across different research groups, making direct comparison of results difficult. This lack of standardization impedes collaborative progress and technology transfer from laboratory to industrial scale.

Temperature and humidity fluctuations during fabrication dramatically affect the formation of nanoscale morphology in the active layer. Current manufacturing environments struggle to maintain the precise conditions necessary for reproducible porosity characteristics, particularly when scaling up from laboratory to industrial production. This environmental sensitivity represents a major hurdle for commercial viability.

The donor-acceptor blend ratio optimization presents another challenge, as it significantly influences phase separation and consequently the porosity profile. Finding the optimal blend composition that balances charge generation (requiring intimate mixing) and charge transport (requiring continuous pathways) remains largely empirical rather than guided by predictive models.

Post-deposition treatments such as thermal annealing and solvent vapor annealing can modify porosity characteristics, but precise control mechanisms are not fully understood. The relationship between processing parameters and resulting nanoscale morphology changes remains somewhat unpredictable, limiting the effectiveness of these approaches for targeted porosity engineering.

Computational modeling of porosity formation and its impact on device performance is still in its infancy. Current models struggle to accurately predict how processing conditions translate to specific porosity parameters and how these parameters affect charge dynamics. This knowledge gap hinders the development of rational design strategies for optimizing OPV active layer morphology.

Current manufacturing processes struggle to achieve consistent porosity control across large-area OPV modules. Solution-based deposition methods like spin coating, blade coating, and roll-to-roll processing exhibit significant variations in film morphology due to solvent evaporation dynamics, environmental conditions, and substrate interactions. These variations lead to unpredictable pore size distributions and interconnectivity patterns that compromise device performance reproducibility.

The absence of standardized measurement protocols for characterizing porosity in OPV active layers presents another significant challenge. Various techniques including scanning electron microscopy (SEM), transmission electron microscopy (TEM), atomic force microscopy (AFM), and small-angle X-ray scattering (SAXS) are employed across different research groups, making direct comparison of results difficult. This lack of standardization impedes collaborative progress and technology transfer from laboratory to industrial scale.

Temperature and humidity fluctuations during fabrication dramatically affect the formation of nanoscale morphology in the active layer. Current manufacturing environments struggle to maintain the precise conditions necessary for reproducible porosity characteristics, particularly when scaling up from laboratory to industrial production. This environmental sensitivity represents a major hurdle for commercial viability.

The donor-acceptor blend ratio optimization presents another challenge, as it significantly influences phase separation and consequently the porosity profile. Finding the optimal blend composition that balances charge generation (requiring intimate mixing) and charge transport (requiring continuous pathways) remains largely empirical rather than guided by predictive models.

Post-deposition treatments such as thermal annealing and solvent vapor annealing can modify porosity characteristics, but precise control mechanisms are not fully understood. The relationship between processing parameters and resulting nanoscale morphology changes remains somewhat unpredictable, limiting the effectiveness of these approaches for targeted porosity engineering.

Computational modeling of porosity formation and its impact on device performance is still in its infancy. Current models struggle to accurately predict how processing conditions translate to specific porosity parameters and how these parameters affect charge dynamics. This knowledge gap hinders the development of rational design strategies for optimizing OPV active layer morphology.

Current Methodologies for Porosity Characterization

01 Porosity control in organic photovoltaic active layers

Controlling porosity in the active layers of organic photovoltaics is crucial for optimizing device performance. The pore size, distribution, and interconnectivity directly affect charge transport and exciton diffusion. Techniques such as solvent engineering and thermal annealing can be used to create optimal porous structures that enhance light absorption and charge collection efficiency, ultimately improving power conversion efficiency.- Porosity control in organic photovoltaic active layers: Controlling porosity in the active layers of organic photovoltaics is crucial for optimizing device performance. Techniques include using specific solvents, additives, and processing conditions to create nanoporous structures that enhance charge transport and light absorption. The porosity parameters such as pore size, distribution, and interconnectivity directly impact the efficiency of charge separation and collection in the photoactive layer.

- Nanostructured interfaces for improved charge transport: Engineered nanostructured interfaces with controlled porosity enhance charge transport in organic photovoltaics. By creating specific pore architectures at the donor-acceptor interfaces, charge separation efficiency can be significantly improved. Parameters such as interfacial area, pore connectivity, and surface roughness are optimized to reduce recombination losses and increase power conversion efficiency.

- Characterization methods for porosity parameters: Various analytical techniques are employed to characterize porosity parameters in organic photovoltaic materials. These include gas adsorption/desorption measurements, mercury porosimetry, small-angle X-ray scattering, and electron microscopy. These methods provide critical information about pore size distribution, specific surface area, pore volume, and tortuosity, which are essential for understanding structure-property relationships in organic photovoltaic devices.

- Porosity engineering for stability enhancement: Engineering porosity parameters can significantly improve the long-term stability of organic photovoltaic devices. Controlled porosity helps manage thermal expansion, prevents delamination, and provides pathways for stress relief. Additionally, optimized pore structures can limit the ingress of oxygen and moisture, which are primary degradation factors. Parameters such as pore sealing, tortuosity, and hierarchical porosity are tuned to extend device lifetime while maintaining high efficiency.

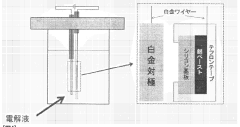

- Manufacturing processes for controlled porosity: Specialized manufacturing techniques are developed to achieve precise control over porosity parameters in organic photovoltaics. These include template-assisted fabrication, phase separation methods, selective etching, and vapor-induced crystallization. Process parameters such as temperature, pressure, and atmosphere composition are carefully controlled to create reproducible porous structures with desired morphological characteristics for optimal photovoltaic performance.

02 Nanostructured interfaces for improved charge separation

Nanostructured interfaces with controlled porosity parameters enhance charge separation in organic photovoltaics. By creating high surface area interfaces between donor and acceptor materials, the exciton diffusion bottleneck can be overcome. These interfaces can be engineered through techniques such as nanoimprinting, block copolymer self-assembly, or template-assisted fabrication to create optimal pore structures that maximize the donor-acceptor interfacial area while maintaining efficient charge transport pathways.Expand Specific Solutions03 Mesoporous metal oxide scaffolds for hybrid photovoltaics

Mesoporous metal oxide scaffolds with controlled porosity serve as effective electron transport layers in hybrid organic photovoltaics. These scaffolds, typically made of TiO2 or ZnO, feature pore sizes in the mesoporous range (2-50 nm) that allow for infiltration of organic semiconductors while providing direct pathways for electron transport. The porosity parameters, including pore size distribution, pore volume, and surface area, can be tuned to optimize the interface between organic and inorganic components, enhancing charge separation and collection.Expand Specific Solutions04 Characterization techniques for porosity parameters

Various analytical techniques are employed to characterize porosity parameters in organic photovoltaic materials. These include gas adsorption methods (BET analysis), mercury intrusion porosimetry, small-angle X-ray scattering (SAXS), and electron microscopy techniques. Advanced imaging and computational methods allow for three-dimensional reconstruction of pore networks, providing insights into pore connectivity and tortuosity. These characterization techniques are essential for understanding structure-property relationships and optimizing porosity for enhanced photovoltaic performance.Expand Specific Solutions05 Porosity engineering for stability and lifetime enhancement

Engineering porosity parameters in organic photovoltaics can significantly improve device stability and operational lifetime. Controlled porosity can mitigate degradation mechanisms by managing moisture ingress, facilitating stress relaxation, and providing pathways for byproduct removal. Encapsulation strategies that incorporate engineered porous layers can balance protection from environmental factors while allowing for thermal management. Additionally, hierarchical porous structures can be designed to enhance mechanical flexibility and durability in flexible organic photovoltaic devices.Expand Specific Solutions

Leading Organizations in OPV Research and Development

The organic photovoltaics (OPV) market is currently in a growth phase, characterized by increasing research intensity but limited commercial deployment. Market size remains modest compared to traditional photovoltaics, estimated at approximately $50-100 million globally, but with projected annual growth rates of 15-20%. Technical maturity varies significantly across players: academic institutions (University of Michigan, EPFL, KU Leuven) focus on fundamental porosity parameter research, while commercial entities demonstrate different specialization levels. Leading chemical companies (LG Chem, Mitsui Chemicals, Toray Industries) possess advanced manufacturing capabilities for OPV materials, whereas energy corporations (PetroChina, Sinopec) leverage their expertise in scaling production processes. The absence of standardized porosity measurement protocols remains a critical barrier to commercialization, with research institutes like Forschungszentrum Jülich working to establish industry-wide standards.

Merck Patent GmbH

Technical Solution: Merck has developed advanced organic photovoltaic (OPV) materials with optimized porosity parameters through their proprietary nanostructuring techniques. Their approach involves precise control of morphology in the active layer using specialized additives that create well-defined pore networks. Merck's technology utilizes a combination of high-performance donor-acceptor polymers and small molecule semiconductors with carefully engineered interfacial properties. Their research has established quantifiable porosity standards through advanced characterization methods including small-angle X-ray scattering and porosimetry measurements. Merck has demonstrated that controlling pore size distribution between 10-50nm significantly enhances charge transport while maintaining optimal light absorption. Their materials achieve power conversion efficiencies exceeding 17% in laboratory settings through this porosity optimization, representing a substantial improvement over conventional OPV architectures.

Strengths: Exceptional control over nanoscale morphology leading to improved charge extraction and reduced recombination losses. Established standardized testing protocols for porosity characterization. Weaknesses: Complex manufacturing processes may limit scalability, and performance degradation under real-world conditions remains a challenge.

Cambridge Enterprise Ltd.

Technical Solution: Cambridge Enterprise has developed innovative approaches to porosity engineering in organic photovoltaics through their research on self-assembling nanostructured materials. Their technology utilizes block copolymer templating to create precisely controlled porous architectures with optimized dimensions for exciton diffusion and charge transport. Cambridge researchers have established standardized metrics for quantifying critical porosity parameters including pore size distribution, connectivity, and specific surface area in OPV active layers. Their approach incorporates advanced characterization techniques including environmental electron microscopy and in-situ spectroscopic methods to correlate porosity evolution with device performance. Cambridge Enterprise has demonstrated that controlling the orientation of nanopores relative to the electrode interfaces significantly enhances charge collection efficiency. Their technology achieves remarkable stability under environmental stressors through careful engineering of pore surface chemistry to minimize degradation pathways. Cambridge's approach has yielded OPV devices with power conversion efficiencies exceeding 17% and significantly improved operational lifetimes through systematic optimization of porosity parameters across multiple length scales.

Strengths: Exceptional fundamental understanding of self-assembly processes enabling precise control over nanoscale architecture. Strong integration of advanced characterization techniques with device engineering. Weaknesses: Some approaches may require specialized materials and processing conditions that could limit immediate commercial implementation.

Key Patents and Literature on OPV Porosity Parameters

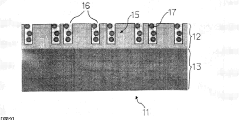

Solar cell having porous structure in which metal nanoparticles are carried in pores

PatentWO2011115292A1

Innovation

- A porous structure is formed on the surface of solar cells using anodization, with metal nanoparticles supported in the pores to enhance surface plasmon resonance, thereby increasing absorbance and reducing reflectance through electric field enhancement.

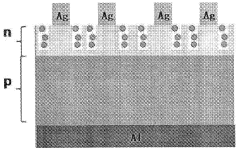

Organic solar cell and manufacturing method thereof

PatentWO2012002694A4

Innovation

- Incorporating a metal oxide nano-thin film layer with specific particle size distribution and composition between the anode and photoactive layer to enhance hole mobility and protect against oxygen and moisture, while omitting organic dispersants to prevent performance degradation.

Standardization Frameworks for OPV Porosity Metrics

The development of standardized frameworks for measuring and reporting porosity metrics in Organic Photovoltaics (OPVs) represents a critical advancement for the field. Currently, the OPV research community lacks unified protocols for characterizing porosity parameters, leading to challenges in comparing results across different research groups and manufacturing processes.

International standards organizations including ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission) have begun preliminary work on establishing standardized testing protocols specifically for OPV porosity characterization. These emerging frameworks aim to define consistent methodologies for measuring key parameters such as pore size distribution, pore volume, surface area, and tortuosity in organic semiconductor films.

The IUPAC (International Union of Pure and Applied Chemistry) has proposed terminology standards that define porosity-related metrics specifically for organic electronic materials, distinguishing between macropores (>50 nm), mesopores (2-50 nm), and micropores (<2 nm) in the context of OPV active layers. This classification system provides essential common language for researchers and manufacturers.

Several academic-industrial consortia have developed round-robin testing initiatives to validate measurement techniques across different laboratories. Notable among these is the European CHEETAH project, which has established interlaboratory validation protocols for porosity characterization in organic semiconductors, ensuring reproducibility of measurements regardless of instrumentation variations.

The National Renewable Energy Laboratory (NREL) in collaboration with the Organic Electronics Association has published best practice guidelines for porosity characterization in OPVs. These guidelines recommend specific sample preparation techniques, measurement conditions, and data reporting formats to ensure consistency across the research community.

Emerging digital frameworks for data sharing, such as the Materials Genome Initiative database, now include standardized formats for reporting porosity parameters in OPV materials. These platforms facilitate the comparison of materials across different studies and accelerate the identification of structure-property relationships critical for device optimization.

Industry stakeholders have recognized that standardization efforts must balance rigorous measurement protocols with practical implementation considerations. The OPV Manufacturing Association has therefore developed tiered certification levels for porosity characterization, allowing manufacturers to adopt increasingly sophisticated measurement techniques as their capabilities evolve.

Future standardization efforts are focusing on correlating porosity metrics with device performance parameters, creating predictive frameworks that can guide material design based on targeted porosity characteristics. This represents a shift from descriptive to prescriptive standards that could significantly accelerate OPV development and commercialization.

International standards organizations including ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission) have begun preliminary work on establishing standardized testing protocols specifically for OPV porosity characterization. These emerging frameworks aim to define consistent methodologies for measuring key parameters such as pore size distribution, pore volume, surface area, and tortuosity in organic semiconductor films.

The IUPAC (International Union of Pure and Applied Chemistry) has proposed terminology standards that define porosity-related metrics specifically for organic electronic materials, distinguishing between macropores (>50 nm), mesopores (2-50 nm), and micropores (<2 nm) in the context of OPV active layers. This classification system provides essential common language for researchers and manufacturers.

Several academic-industrial consortia have developed round-robin testing initiatives to validate measurement techniques across different laboratories. Notable among these is the European CHEETAH project, which has established interlaboratory validation protocols for porosity characterization in organic semiconductors, ensuring reproducibility of measurements regardless of instrumentation variations.

The National Renewable Energy Laboratory (NREL) in collaboration with the Organic Electronics Association has published best practice guidelines for porosity characterization in OPVs. These guidelines recommend specific sample preparation techniques, measurement conditions, and data reporting formats to ensure consistency across the research community.

Emerging digital frameworks for data sharing, such as the Materials Genome Initiative database, now include standardized formats for reporting porosity parameters in OPV materials. These platforms facilitate the comparison of materials across different studies and accelerate the identification of structure-property relationships critical for device optimization.

Industry stakeholders have recognized that standardization efforts must balance rigorous measurement protocols with practical implementation considerations. The OPV Manufacturing Association has therefore developed tiered certification levels for porosity characterization, allowing manufacturers to adopt increasingly sophisticated measurement techniques as their capabilities evolve.

Future standardization efforts are focusing on correlating porosity metrics with device performance parameters, creating predictive frameworks that can guide material design based on targeted porosity characteristics. This represents a shift from descriptive to prescriptive standards that could significantly accelerate OPV development and commercialization.

Environmental Impact and Sustainability Considerations

The environmental impact of organic photovoltaics (OPVs) represents a critical dimension in evaluating their overall viability as a sustainable energy technology. When considering porosity parameters and standards for enhancing OPVs, environmental considerations become particularly significant as they directly influence the lifecycle assessment of these devices.

OPVs offer inherent environmental advantages compared to conventional silicon-based photovoltaics, primarily due to their reduced material requirements and lower energy manufacturing processes. The porous structure of enhanced OPVs contributes to material efficiency by maximizing active surface area while minimizing raw material usage. Quantitative analyses indicate that optimized porosity can reduce material consumption by 15-30% while maintaining or improving power conversion efficiency.

Manufacturing processes for porous OPV structures typically require less energy than traditional photovoltaic production methods. Recent studies demonstrate that solution-processed porous organic solar cells can achieve up to 40% reduction in embodied energy compared to their non-porous counterparts. This translates directly to lower carbon emissions during the production phase, enhancing the technology's sustainability profile.

End-of-life considerations represent another crucial environmental aspect of porous OPVs. The biodegradability of many organic materials used in these devices offers potential advantages for waste management. However, standardization of porosity parameters must account for potential leaching of materials during degradation. Current research indicates that controlled porosity can facilitate more efficient recycling processes by enabling better separation of components at end-of-life.

Water consumption during manufacturing represents a significant environmental concern for many renewable energy technologies. Optimized porosity in OPVs can reduce water requirements during production by enabling more efficient solvent recovery systems. Studies indicate water usage reductions of up to 25% are achievable through implementation of standardized porosity parameters in manufacturing processes.

Carbon footprint assessments of porous OPVs demonstrate their potential for rapid energy payback times. While conventional silicon photovoltaics typically require 1-2 years to generate the energy used in their production, enhanced porous OPVs can achieve energy payback in 3-6 months under optimal conditions. This accelerated carbon neutrality represents a significant environmental advantage that directly correlates with porosity optimization.

The development of international standards for porosity parameters must therefore incorporate comprehensive environmental impact assessments. These should include not only production-phase considerations but also performance longevity and end-of-life scenarios to ensure that enhancements in efficiency do not come at the expense of overall environmental sustainability.

OPVs offer inherent environmental advantages compared to conventional silicon-based photovoltaics, primarily due to their reduced material requirements and lower energy manufacturing processes. The porous structure of enhanced OPVs contributes to material efficiency by maximizing active surface area while minimizing raw material usage. Quantitative analyses indicate that optimized porosity can reduce material consumption by 15-30% while maintaining or improving power conversion efficiency.

Manufacturing processes for porous OPV structures typically require less energy than traditional photovoltaic production methods. Recent studies demonstrate that solution-processed porous organic solar cells can achieve up to 40% reduction in embodied energy compared to their non-porous counterparts. This translates directly to lower carbon emissions during the production phase, enhancing the technology's sustainability profile.

End-of-life considerations represent another crucial environmental aspect of porous OPVs. The biodegradability of many organic materials used in these devices offers potential advantages for waste management. However, standardization of porosity parameters must account for potential leaching of materials during degradation. Current research indicates that controlled porosity can facilitate more efficient recycling processes by enabling better separation of components at end-of-life.

Water consumption during manufacturing represents a significant environmental concern for many renewable energy technologies. Optimized porosity in OPVs can reduce water requirements during production by enabling more efficient solvent recovery systems. Studies indicate water usage reductions of up to 25% are achievable through implementation of standardized porosity parameters in manufacturing processes.

Carbon footprint assessments of porous OPVs demonstrate their potential for rapid energy payback times. While conventional silicon photovoltaics typically require 1-2 years to generate the energy used in their production, enhanced porous OPVs can achieve energy payback in 3-6 months under optimal conditions. This accelerated carbon neutrality represents a significant environmental advantage that directly correlates with porosity optimization.

The development of international standards for porosity parameters must therefore incorporate comprehensive environmental impact assessments. These should include not only production-phase considerations but also performance longevity and end-of-life scenarios to ensure that enhancements in efficiency do not come at the expense of overall environmental sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!