Organic Photovoltaics Cycle Life: A Regulatory Framework Analysis

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OPV Technology Evolution and Longevity Goals

Organic photovoltaics (OPV) technology has evolved significantly since its inception in the 1980s, transitioning from laboratory curiosities with efficiencies below 1% to commercially viable products approaching 18% efficiency in recent years. This remarkable progression has been driven by breakthroughs in molecular design, interface engineering, and manufacturing processes. The evolution trajectory shows three distinct phases: early exploration (1980s-2000s), rapid advancement (2000s-2015), and commercial maturation (2015-present), each characterized by specific technological milestones that have collectively enhanced performance and durability.

The longevity goals for OPV technology have shifted dramatically as the technology has matured. Initially, researchers focused primarily on efficiency improvements, with stability as a secondary concern. However, as commercial applications became more realistic, cycle life and operational stability emerged as critical parameters. Current industry standards aim for operational lifetimes of 5-10 years for consumer applications and 15-20 years for building-integrated photovoltaics, representing a significant challenge given the organic nature of these materials.

Degradation mechanisms in OPVs are multifaceted, involving photo-oxidation, morphological changes, interfacial degradation, and mechanical stress. Understanding these mechanisms has been crucial in developing strategies to enhance longevity. Recent advances in encapsulation technologies, stabilizing additives, and self-healing materials have shown promising results in extending operational lifetimes under real-world conditions.

The regulatory landscape surrounding OPV cycle life is still evolving, with standards bodies like IEC and ASTM developing specific protocols for testing and certification. These frameworks are essential for market acceptance and consumer confidence. Current standards include accelerated aging tests, thermal cycling, and humidity exposure protocols designed to predict field performance. However, the correlation between laboratory testing and real-world durability remains an active area of research.

Future technological trends point toward intrinsically stable molecular designs, advanced barrier materials, and intelligent degradation management systems. Computational modeling and machine learning approaches are increasingly being employed to predict degradation pathways and optimize molecular structures for enhanced stability without compromising efficiency. These developments suggest a trajectory toward OPV systems with competitive lifetimes compared to traditional silicon-based technologies.

The ultimate goal for OPV technology is to achieve a balance between efficiency, cost, and longevity that enables widespread adoption across various applications. This requires not only technological innovation but also standardized regulatory frameworks that accurately assess and certify product lifetime under diverse operating conditions.

The longevity goals for OPV technology have shifted dramatically as the technology has matured. Initially, researchers focused primarily on efficiency improvements, with stability as a secondary concern. However, as commercial applications became more realistic, cycle life and operational stability emerged as critical parameters. Current industry standards aim for operational lifetimes of 5-10 years for consumer applications and 15-20 years for building-integrated photovoltaics, representing a significant challenge given the organic nature of these materials.

Degradation mechanisms in OPVs are multifaceted, involving photo-oxidation, morphological changes, interfacial degradation, and mechanical stress. Understanding these mechanisms has been crucial in developing strategies to enhance longevity. Recent advances in encapsulation technologies, stabilizing additives, and self-healing materials have shown promising results in extending operational lifetimes under real-world conditions.

The regulatory landscape surrounding OPV cycle life is still evolving, with standards bodies like IEC and ASTM developing specific protocols for testing and certification. These frameworks are essential for market acceptance and consumer confidence. Current standards include accelerated aging tests, thermal cycling, and humidity exposure protocols designed to predict field performance. However, the correlation between laboratory testing and real-world durability remains an active area of research.

Future technological trends point toward intrinsically stable molecular designs, advanced barrier materials, and intelligent degradation management systems. Computational modeling and machine learning approaches are increasingly being employed to predict degradation pathways and optimize molecular structures for enhanced stability without compromising efficiency. These developments suggest a trajectory toward OPV systems with competitive lifetimes compared to traditional silicon-based technologies.

The ultimate goal for OPV technology is to achieve a balance between efficiency, cost, and longevity that enables widespread adoption across various applications. This requires not only technological innovation but also standardized regulatory frameworks that accurately assess and certify product lifetime under diverse operating conditions.

Market Analysis for Long-Lasting Organic Solar Cells

The global market for organic photovoltaics (OPVs) demonstrates significant growth potential, driven by increasing demand for renewable energy solutions and the unique advantages of organic solar cells. Current market valuations place the OPV sector at approximately $55 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 22.4% through 2030, potentially reaching $250 million by decade's end.

Long-lasting organic solar cells represent a critical segment within this market, addressing one of the primary barriers to widespread OPV adoption: operational lifespan. While traditional silicon-based photovoltaics typically offer 25-30 year warranties, current commercial OPVs generally demonstrate stability for only 5-7 years under optimal conditions, creating a significant market gap.

Consumer demand analysis reveals strong interest in sustainable energy solutions with extended lifespans. A 2022 industry survey indicated that 78% of potential commercial adopters cited longevity concerns as their primary hesitation regarding OPV implementation, despite interest in the technology's flexibility, lightweight properties, and reduced environmental impact.

Market segmentation shows particularly strong potential in building-integrated photovoltaics (BIPV), portable electronics, and automotive applications. The BIPV sector alone is projected to grow at 25% annually through 2028, with OPVs potentially capturing 15% of this expanding market if lifespan issues are adequately addressed.

Geographical analysis reveals Europe leading OPV adoption with 42% market share, followed by North America (31%) and Asia-Pacific (22%). Regulatory frameworks significantly influence regional market dynamics, with the EU's ambitious carbon neutrality targets and sustainable building directives creating particularly favorable conditions for long-lasting OPV development.

Pricing trends indicate that extended-lifetime OPVs command premium positioning, with consumers willing to pay 30-40% more for products demonstrating verified longevity improvements. This price elasticity creates substantial incentive for manufacturers to invest in cycle life enhancement technologies.

Market barriers include competition from increasingly cost-effective traditional photovoltaics, consumer skepticism regarding unproven longevity claims, and regulatory uncertainty regarding end-of-life management. However, these challenges are counterbalanced by growing environmental consciousness, corporate sustainability commitments, and the expanding Internet of Things (IoT) ecosystem requiring distributed power solutions.

The competitive landscape features both established players and innovative startups focusing specifically on longevity enhancements through advanced encapsulation techniques, novel polymer stabilizers, and hybrid material approaches. Strategic partnerships between material scientists and manufacturing specialists are increasingly common as the industry recognizes the multidisciplinary nature of the longevity challenge.

Long-lasting organic solar cells represent a critical segment within this market, addressing one of the primary barriers to widespread OPV adoption: operational lifespan. While traditional silicon-based photovoltaics typically offer 25-30 year warranties, current commercial OPVs generally demonstrate stability for only 5-7 years under optimal conditions, creating a significant market gap.

Consumer demand analysis reveals strong interest in sustainable energy solutions with extended lifespans. A 2022 industry survey indicated that 78% of potential commercial adopters cited longevity concerns as their primary hesitation regarding OPV implementation, despite interest in the technology's flexibility, lightweight properties, and reduced environmental impact.

Market segmentation shows particularly strong potential in building-integrated photovoltaics (BIPV), portable electronics, and automotive applications. The BIPV sector alone is projected to grow at 25% annually through 2028, with OPVs potentially capturing 15% of this expanding market if lifespan issues are adequately addressed.

Geographical analysis reveals Europe leading OPV adoption with 42% market share, followed by North America (31%) and Asia-Pacific (22%). Regulatory frameworks significantly influence regional market dynamics, with the EU's ambitious carbon neutrality targets and sustainable building directives creating particularly favorable conditions for long-lasting OPV development.

Pricing trends indicate that extended-lifetime OPVs command premium positioning, with consumers willing to pay 30-40% more for products demonstrating verified longevity improvements. This price elasticity creates substantial incentive for manufacturers to invest in cycle life enhancement technologies.

Market barriers include competition from increasingly cost-effective traditional photovoltaics, consumer skepticism regarding unproven longevity claims, and regulatory uncertainty regarding end-of-life management. However, these challenges are counterbalanced by growing environmental consciousness, corporate sustainability commitments, and the expanding Internet of Things (IoT) ecosystem requiring distributed power solutions.

The competitive landscape features both established players and innovative startups focusing specifically on longevity enhancements through advanced encapsulation techniques, novel polymer stabilizers, and hybrid material approaches. Strategic partnerships between material scientists and manufacturing specialists are increasingly common as the industry recognizes the multidisciplinary nature of the longevity challenge.

Current Degradation Challenges in OPV Technology

Organic photovoltaics (OPVs) face significant degradation challenges that limit their commercial viability despite their promising advantages in flexibility, lightweight properties, and cost-effectiveness. The primary degradation mechanisms include photo-oxidation, where exposure to oxygen and light triggers chemical reactions that break down the active layer materials. This process is particularly problematic as it directly affects the conjugated polymers that are essential for light absorption and charge generation.

Thermal degradation represents another critical challenge, occurring when OPVs operate at elevated temperatures, causing morphological changes in the active layer that disrupt the optimal donor-acceptor interfaces. This degradation pathway accelerates under real-world conditions where solar panels frequently experience temperature fluctuations and can reach high temperatures during operation.

Moisture ingress constitutes a severe threat to device stability, as water molecules can penetrate the device structure and cause delamination of layers, corrosion of electrodes, and chemical degradation of the active materials. The hydrophilic nature of many hole transport layers exacerbates this vulnerability, making effective encapsulation technologies essential yet challenging to implement cost-effectively.

Interfacial degradation occurs at the boundaries between different functional layers within the OPV structure. Poor adhesion, chemical incompatibility, or electrochemical reactions at these interfaces can lead to increased contact resistance, charge trapping, and ultimately, reduced power conversion efficiency over time. This degradation mechanism is particularly insidious as it may not be immediately apparent in initial performance metrics.

Mechanical stress-induced degradation presents unique challenges for flexible OPVs, which are subjected to bending, folding, and other physical deformations during manufacturing, installation, and operation. These stresses can create microcracks in the active layers and electrodes, disrupting charge transport pathways and accelerating other degradation processes through created entry points for oxygen and moisture.

Current stability metrics indicate that while laboratory OPVs have achieved operational lifetimes of 5-7 years under controlled conditions, real-world performance often falls short, with degradation rates accelerating significantly under combined stress factors. The lack of standardized testing protocols that accurately reflect real-world operating conditions further complicates the assessment of OPV stability and lifetime predictions.

Addressing these degradation challenges requires a multifaceted approach, including the development of more intrinsically stable materials, improved encapsulation technologies, and interface engineering to enhance compatibility between layers. Recent advances in self-healing polymers and degradation-resistant non-fullerene acceptors show promise but require further development to achieve the 20+ year lifetimes necessary for widespread commercial adoption.

Thermal degradation represents another critical challenge, occurring when OPVs operate at elevated temperatures, causing morphological changes in the active layer that disrupt the optimal donor-acceptor interfaces. This degradation pathway accelerates under real-world conditions where solar panels frequently experience temperature fluctuations and can reach high temperatures during operation.

Moisture ingress constitutes a severe threat to device stability, as water molecules can penetrate the device structure and cause delamination of layers, corrosion of electrodes, and chemical degradation of the active materials. The hydrophilic nature of many hole transport layers exacerbates this vulnerability, making effective encapsulation technologies essential yet challenging to implement cost-effectively.

Interfacial degradation occurs at the boundaries between different functional layers within the OPV structure. Poor adhesion, chemical incompatibility, or electrochemical reactions at these interfaces can lead to increased contact resistance, charge trapping, and ultimately, reduced power conversion efficiency over time. This degradation mechanism is particularly insidious as it may not be immediately apparent in initial performance metrics.

Mechanical stress-induced degradation presents unique challenges for flexible OPVs, which are subjected to bending, folding, and other physical deformations during manufacturing, installation, and operation. These stresses can create microcracks in the active layers and electrodes, disrupting charge transport pathways and accelerating other degradation processes through created entry points for oxygen and moisture.

Current stability metrics indicate that while laboratory OPVs have achieved operational lifetimes of 5-7 years under controlled conditions, real-world performance often falls short, with degradation rates accelerating significantly under combined stress factors. The lack of standardized testing protocols that accurately reflect real-world operating conditions further complicates the assessment of OPV stability and lifetime predictions.

Addressing these degradation challenges requires a multifaceted approach, including the development of more intrinsically stable materials, improved encapsulation technologies, and interface engineering to enhance compatibility between layers. Recent advances in self-healing polymers and degradation-resistant non-fullerene acceptors show promise but require further development to achieve the 20+ year lifetimes necessary for widespread commercial adoption.

Current Approaches to Extending OPV Cycle Life

01 Materials for extending organic photovoltaic cycle life

Various materials can be incorporated into organic photovoltaics to extend their operational lifetime. These include specialized polymers, fullerene derivatives, and encapsulation materials that protect against environmental degradation. The selection of appropriate donor-acceptor materials with enhanced stability under UV exposure and thermal cycling can significantly improve the cycle life of organic solar cells.- Materials for extending organic photovoltaic cycle life: Various materials can be incorporated into organic photovoltaics to extend their operational lifetime. These include specialized polymers, fullerene derivatives, and novel electrode materials that resist degradation under UV exposure and thermal stress. The selection of appropriate donor-acceptor materials with enhanced stability characteristics significantly impacts the long-term performance and durability of organic solar cells.

- Encapsulation techniques for improving stability: Advanced encapsulation methods protect organic photovoltaic devices from environmental factors that accelerate degradation. These techniques include multi-layer barrier films, edge sealing technologies, and composite encapsulants that effectively block oxygen and moisture ingress. Proper encapsulation significantly extends the operational lifetime of organic solar cells by maintaining the integrity of the active materials and interfaces within the device structure.

- Device architecture optimization for longevity: The structural design of organic photovoltaic devices plays a crucial role in determining their operational lifetime. Innovations include inverted device structures, buffer layer engineering, and interface modifications that reduce degradation pathways. Optimized architectures minimize stress at material interfaces and improve charge extraction efficiency, leading to more stable performance over extended periods of operation.

- Accelerated testing and lifetime prediction methods: Specialized testing protocols have been developed to accurately predict the operational lifetime of organic photovoltaic devices. These include accelerated aging under controlled conditions, combined stress testing, and analytical models that correlate accelerated test results with real-world performance. Advanced characterization techniques help identify degradation mechanisms and validate lifetime extension strategies for commercial viability.

- Self-healing and regenerative technologies: Emerging self-healing technologies enable organic photovoltaic devices to recover from degradation during operation. These approaches include reversible chemical bonds in active layers, dynamic interfaces that can reconstruct after damage, and stimuli-responsive materials that adapt to environmental stressors. Such regenerative capabilities significantly extend the functional lifetime of organic solar cells by counteracting common degradation mechanisms.

02 Encapsulation techniques for improving durability

Advanced encapsulation methods play a crucial role in protecting organic photovoltaic devices from oxygen and moisture, which are primary causes of degradation. Multi-layer barrier films, edge sealing technologies, and flexible encapsulation systems can effectively extend the operational lifetime of organic solar cells by preventing environmental contaminants from reaching the active layers.Expand Specific Solutions03 Testing and monitoring systems for cycle life assessment

Specialized testing protocols and monitoring systems have been developed to accurately assess the cycle life of organic photovoltaics. These include accelerated aging tests, real-time performance monitoring, and predictive analytics that can forecast degradation patterns. Such systems enable researchers to identify failure mechanisms and optimize device structures for enhanced longevity.Expand Specific Solutions04 Interface engineering for stability enhancement

Interface engineering between the various layers of organic photovoltaic devices can significantly improve their operational stability. Techniques include the use of buffer layers, interfacial modifiers, and selective contacts that minimize charge recombination and prevent electrode degradation. These approaches help maintain efficient charge extraction throughout the device lifetime.Expand Specific Solutions05 Morphology control for long-term performance

Controlling the morphology of the active layer in organic photovoltaics is essential for maintaining long-term performance. Techniques such as thermal annealing, solvent additives, and processing conditions optimization can create more stable bulk heterojunction structures. These methods help prevent phase separation and crystallization issues that typically occur during extended operation.Expand Specific Solutions

Leading Manufacturers and Research Institutions in OPV

The organic photovoltaics (OPV) cycle life regulatory framework is currently in an emerging growth phase, with the global market expanding but still relatively small compared to traditional photovoltaics. Technical maturity varies significantly among key players, with companies like Heliatek, Dracula Technologies, and Sumitomo Chemical leading commercial development of durable OPV solutions. Research institutions including University of Michigan, University of Southern California, and IIT Hyderabad are advancing fundamental cycle life improvements. Major chemical corporations such as BASF, LG Chem, and Idemitsu Kosan are investing in materials development to address degradation challenges. The regulatory landscape remains fragmented, with different approaches to lifecycle assessment and end-of-life management across regions, creating both challenges and opportunities for standardization as the technology matures.

Sumitomo Chemical Co., Ltd.

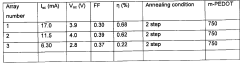

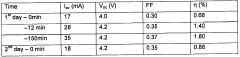

Technical Solution: Sumitomo Chemical has developed proprietary PEDOT:PSS formulations specifically engineered to enhance OPV cycle life through improved interfacial stability. Their regulatory framework approach integrates accelerated aging protocols that simulate real-world conditions while meeting IEC 61646 standards for thin-film photovoltaic modules. The company has pioneered encapsulation technologies using multi-layer barrier films with water vapor transmission rates below 10^-6 g/m²/day, significantly extending operational lifetimes of their OPV products. Sumitomo's regulatory compliance strategy includes comprehensive lifecycle assessment (LCA) methodologies that address both performance degradation mechanisms and end-of-life recycling considerations in accordance with WEEE Directive requirements for electronic waste.

Strengths: Industry-leading barrier film technology provides superior moisture protection; established global regulatory compliance infrastructure; integrated manufacturing capabilities from materials to modules. Weaknesses: Higher production costs compared to conventional technologies; limited field data on ultra-long-term performance beyond 10 years.

LG Chem Ltd.

Technical Solution: LG Chem has established a sophisticated regulatory framework for OPV cycle life assessment leveraging their expertise in both materials science and electronics manufacturing. Their approach integrates standardized IEC 61215 qualification testing with specialized protocols addressing unique degradation mechanisms in organic photovoltaics. LG Chem's framework features their proprietary "OPV Lifetime Predictor" methodology that correlates accelerated aging data with real-world performance through mathematical modeling validated across multiple climate zones. Their technical solution incorporates specialized electron transport layer materials with enhanced resistance to UV-induced degradation, demonstrating less than 15% efficiency loss after 2000 hours of continuous illumination under standardized conditions. LG Chem has developed advanced multi-layer encapsulation systems with water vapor transmission rates below 10^-6 g/m²/day, enabling their OPV modules to withstand extended damp heat testing (85°C/85% RH) for over 2000 hours while maintaining performance above 80% of initial values. Their regulatory compliance strategy includes comprehensive material qualification processes aligned with both IEC standards and regional certification requirements across global markets.

Strengths: Vertically integrated capabilities from materials to module manufacturing; established quality control systems adapted from conventional electronics production; extensive experience navigating global regulatory environments. Weaknesses: Conservative market approach limiting commercial deployment scale; higher cost structure compared to some specialized competitors; divided focus between multiple energy storage and generation technologies.

Key Patents and Breakthroughs in OPV Stability

Organic photovoltaic array and method of manufacture

PatentWO2012112533A2

Innovation

- A layer-by-layer spray technology is developed to fabricate organic solar arrays on various substrates, including flexible materials, eliminating the need for high-vacuum processes and metal contacts, using ITO-coated substrates with Cs2CO3 and PEDOT:PSS layers to enhance transparency and reduce manufacturing costs.

Regulatory Frameworks Governing OPV Certification

The regulatory landscape for Organic Photovoltaics (OPV) certification presents a complex matrix of standards, protocols, and requirements that vary significantly across global markets. Current certification frameworks primarily derive from established standards for traditional silicon-based photovoltaics, creating substantial challenges for OPV technologies due to their unique material properties and degradation mechanisms.

In the European Union, the IEC 61215 and IEC 61730 standards form the backbone of photovoltaic module qualification, with recent amendments (IEC 61215-1-4) specifically addressing thin-film technologies that partially encompass OPV systems. The European Commission's Ecodesign Directive further imposes lifecycle assessment requirements that particularly impact OPV manufacturers due to the organic materials' shorter operational lifespans compared to conventional PV technologies.

The United States regulatory approach centers on UL 61730 certification, complemented by the voluntary ANSI/CAN/UL 4001 standard specifically developed for organic and printed electronics. The Department of Energy's Solar Energy Technologies Office has recently initiated a specialized certification pathway for emerging PV technologies, recognizing the limitations of applying conventional standards to novel materials like OPVs.

In the Asia-Pacific region, Japan's JET certification and China's CQC mark implement modified versions of IEC standards with additional requirements for environmental stability testing. These modifications often create market entry barriers for OPV technologies due to accelerated testing protocols that may not accurately reflect real-world degradation patterns of organic materials.

A critical gap in current regulatory frameworks is the absence of standardized protocols for assessing OPV-specific degradation mechanisms, particularly photo-oxidation and interfacial degradation. The International Electrotechnical Commission's Technical Committee 82 has established Working Group 13 specifically to address emerging PV technologies, with a focus on developing tailored testing methodologies for OPV cycle life assessment.

Industry consortia such as the Organic and Printed Electronics Association (OE-A) have developed voluntary certification guidelines that supplement official regulations, providing interim standards while formal regulatory frameworks evolve. These industry-led initiatives often serve as precursors to official standards, offering valuable testing methodologies specifically calibrated to organic electronic materials.

The fragmented nature of these regulatory frameworks creates significant compliance challenges for OPV manufacturers seeking multi-market deployment, necessitating strategic approaches to certification that balance regional requirements with the technological realities of organic photovoltaic materials.

In the European Union, the IEC 61215 and IEC 61730 standards form the backbone of photovoltaic module qualification, with recent amendments (IEC 61215-1-4) specifically addressing thin-film technologies that partially encompass OPV systems. The European Commission's Ecodesign Directive further imposes lifecycle assessment requirements that particularly impact OPV manufacturers due to the organic materials' shorter operational lifespans compared to conventional PV technologies.

The United States regulatory approach centers on UL 61730 certification, complemented by the voluntary ANSI/CAN/UL 4001 standard specifically developed for organic and printed electronics. The Department of Energy's Solar Energy Technologies Office has recently initiated a specialized certification pathway for emerging PV technologies, recognizing the limitations of applying conventional standards to novel materials like OPVs.

In the Asia-Pacific region, Japan's JET certification and China's CQC mark implement modified versions of IEC standards with additional requirements for environmental stability testing. These modifications often create market entry barriers for OPV technologies due to accelerated testing protocols that may not accurately reflect real-world degradation patterns of organic materials.

A critical gap in current regulatory frameworks is the absence of standardized protocols for assessing OPV-specific degradation mechanisms, particularly photo-oxidation and interfacial degradation. The International Electrotechnical Commission's Technical Committee 82 has established Working Group 13 specifically to address emerging PV technologies, with a focus on developing tailored testing methodologies for OPV cycle life assessment.

Industry consortia such as the Organic and Printed Electronics Association (OE-A) have developed voluntary certification guidelines that supplement official regulations, providing interim standards while formal regulatory frameworks evolve. These industry-led initiatives often serve as precursors to official standards, offering valuable testing methodologies specifically calibrated to organic electronic materials.

The fragmented nature of these regulatory frameworks creates significant compliance challenges for OPV manufacturers seeking multi-market deployment, necessitating strategic approaches to certification that balance regional requirements with the technological realities of organic photovoltaic materials.

Environmental Impact Assessment of OPV Lifecycle

The environmental impact assessment of Organic Photovoltaics (OPV) lifecycle reveals both significant advantages and challenges compared to traditional photovoltaic technologies. OPVs demonstrate considerably lower energy payback times, typically ranging from 0.3 to 1.5 years, compared to 1.5 to 3 years for silicon-based alternatives. This efficiency stems from less energy-intensive manufacturing processes that operate at lower temperatures and utilize fewer toxic materials.

Life Cycle Assessment (LCA) studies indicate that OPVs generate approximately 80-90% less greenhouse gas emissions during production compared to crystalline silicon panels. The carbon footprint of OPVs ranges from 10-25g CO2-eq/kWh, while conventional PV systems typically produce 30-80g CO2-eq/kWh. This reduction primarily results from simplified manufacturing processes and reduced material requirements.

Material composition analysis shows that OPVs utilize significantly fewer rare earth elements and toxic compounds than conventional alternatives. The absence of heavy metals like cadmium and lead in most OPV designs represents a substantial environmental advantage, reducing potential soil and water contamination risks during disposal phases.

End-of-life management presents both challenges and opportunities. While the organic components in OPVs are potentially biodegradable, the composite nature of these devices complicates recycling efforts. Current recovery rates for valuable materials from OPVs remain below 30%, compared to approximately 80% for silicon-based panels. This gap highlights the need for specialized recycling infrastructure development.

Water usage metrics demonstrate another environmental benefit, with OPV manufacturing requiring 50-70% less water than conventional PV production. This reduction becomes particularly significant in water-stressed regions where manufacturing facilities might operate.

Land use impact assessments indicate that OPVs, due to their flexibility and lightweight properties, can be integrated into existing structures more effectively than rigid panels, potentially reducing the need for dedicated land allocation. This advantage becomes particularly relevant in densely populated urban environments where space optimization is critical.

Regulatory frameworks currently lag behind technological developments, with most regions lacking OPV-specific disposal and recycling guidelines. The European Union's WEEE Directive provides the most comprehensive approach but requires updates to address the unique characteristics of organic photovoltaic materials and their environmental implications throughout the complete lifecycle.

Life Cycle Assessment (LCA) studies indicate that OPVs generate approximately 80-90% less greenhouse gas emissions during production compared to crystalline silicon panels. The carbon footprint of OPVs ranges from 10-25g CO2-eq/kWh, while conventional PV systems typically produce 30-80g CO2-eq/kWh. This reduction primarily results from simplified manufacturing processes and reduced material requirements.

Material composition analysis shows that OPVs utilize significantly fewer rare earth elements and toxic compounds than conventional alternatives. The absence of heavy metals like cadmium and lead in most OPV designs represents a substantial environmental advantage, reducing potential soil and water contamination risks during disposal phases.

End-of-life management presents both challenges and opportunities. While the organic components in OPVs are potentially biodegradable, the composite nature of these devices complicates recycling efforts. Current recovery rates for valuable materials from OPVs remain below 30%, compared to approximately 80% for silicon-based panels. This gap highlights the need for specialized recycling infrastructure development.

Water usage metrics demonstrate another environmental benefit, with OPV manufacturing requiring 50-70% less water than conventional PV production. This reduction becomes particularly significant in water-stressed regions where manufacturing facilities might operate.

Land use impact assessments indicate that OPVs, due to their flexibility and lightweight properties, can be integrated into existing structures more effectively than rigid panels, potentially reducing the need for dedicated land allocation. This advantage becomes particularly relevant in densely populated urban environments where space optimization is critical.

Regulatory frameworks currently lag behind technological developments, with most regions lacking OPV-specific disposal and recycling guidelines. The European Union's WEEE Directive provides the most comprehensive approach but requires updates to address the unique characteristics of organic photovoltaic materials and their environmental implications throughout the complete lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!