Patent Innovations in Organic Photovoltaics: A Material Microstructure Focus

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OPV Technology Evolution and Objectives

Organic photovoltaics (OPVs) have evolved significantly since their inception in the 1970s, transitioning from simple bilayer structures to complex bulk heterojunction architectures. The initial OPV devices demonstrated by Tang in 1986 achieved merely 1% power conversion efficiency (PCE), whereas contemporary systems now regularly exceed 18% for single-junction cells. This remarkable progress stems from systematic advancements in understanding and controlling material microstructure at the nanoscale level.

The evolution of OPV technology has been characterized by three distinct phases. The first phase (1986-2005) focused on fundamental material discovery and basic device architectures, with primary emphasis on polythiophene derivatives and fullerene acceptors. The second phase (2006-2015) witnessed significant improvements in processing techniques and morphology control, introducing concepts such as solvent additives and thermal annealing to optimize domain sizes. The current phase (2016-present) has been revolutionized by non-fullerene acceptors and ternary blend systems, enabling unprecedented control over energy levels and phase separation.

Material microstructure has emerged as the critical factor determining OPV performance. The intricate balance between donor-acceptor interfaces, domain size, crystallinity, and molecular orientation directly impacts exciton diffusion, charge separation, and transport processes. Patent innovations increasingly focus on methods to precisely engineer these microstructural features through molecular design strategies, processing techniques, and interfacial engineering approaches.

The primary technical objectives in this field now center on achieving three interconnected goals: enhancing power conversion efficiency beyond 20% for single-junction devices, extending operational lifetime to exceed 10 years under real-world conditions, and developing scalable manufacturing processes compatible with roll-to-roll production. These objectives necessitate fundamental breakthroughs in controlling material microstructure across multiple length scales.

Recent patent landscapes reveal growing interest in several promising approaches: side-chain engineering to control molecular packing, non-covalent interactions to direct self-assembly, ternary systems with precisely positioned energy levels, and hierarchical structures that optimize both local and long-range order. Additionally, there is increasing focus on developing in-situ characterization techniques that enable real-time monitoring of microstructure formation during device fabrication.

The convergence of advanced synthetic chemistry, computational modeling, and high-resolution characterization techniques has accelerated innovation in this domain. Machine learning algorithms are increasingly being deployed to navigate the vast parameter space of molecular design and processing conditions, enabling more efficient optimization of material microstructure for specific applications ranging from building-integrated photovoltaics to portable power sources.

The evolution of OPV technology has been characterized by three distinct phases. The first phase (1986-2005) focused on fundamental material discovery and basic device architectures, with primary emphasis on polythiophene derivatives and fullerene acceptors. The second phase (2006-2015) witnessed significant improvements in processing techniques and morphology control, introducing concepts such as solvent additives and thermal annealing to optimize domain sizes. The current phase (2016-present) has been revolutionized by non-fullerene acceptors and ternary blend systems, enabling unprecedented control over energy levels and phase separation.

Material microstructure has emerged as the critical factor determining OPV performance. The intricate balance between donor-acceptor interfaces, domain size, crystallinity, and molecular orientation directly impacts exciton diffusion, charge separation, and transport processes. Patent innovations increasingly focus on methods to precisely engineer these microstructural features through molecular design strategies, processing techniques, and interfacial engineering approaches.

The primary technical objectives in this field now center on achieving three interconnected goals: enhancing power conversion efficiency beyond 20% for single-junction devices, extending operational lifetime to exceed 10 years under real-world conditions, and developing scalable manufacturing processes compatible with roll-to-roll production. These objectives necessitate fundamental breakthroughs in controlling material microstructure across multiple length scales.

Recent patent landscapes reveal growing interest in several promising approaches: side-chain engineering to control molecular packing, non-covalent interactions to direct self-assembly, ternary systems with precisely positioned energy levels, and hierarchical structures that optimize both local and long-range order. Additionally, there is increasing focus on developing in-situ characterization techniques that enable real-time monitoring of microstructure formation during device fabrication.

The convergence of advanced synthetic chemistry, computational modeling, and high-resolution characterization techniques has accelerated innovation in this domain. Machine learning algorithms are increasingly being deployed to navigate the vast parameter space of molecular design and processing conditions, enabling more efficient optimization of material microstructure for specific applications ranging from building-integrated photovoltaics to portable power sources.

Market Analysis for Organic Photovoltaic Applications

The organic photovoltaic (OPV) market has shown remarkable growth potential, driven by increasing demand for renewable energy solutions and advancements in material science. Current market valuations place the global OPV sector at approximately $55 million, with projections suggesting growth to reach $300 million by 2027, representing a compound annual growth rate of 21.5% during the forecast period.

The market segmentation for OPV applications reveals diverse implementation opportunities across multiple sectors. Building-integrated photovoltaics (BIPV) currently dominates the application landscape, accounting for nearly 40% of market share due to the aesthetic advantages and flexibility of organic materials. Consumer electronics follows as the second-largest segment, where lightweight and flexible OPV solutions are increasingly incorporated into portable charging devices and wearable technology.

Automotive applications represent an emerging high-growth segment, with major manufacturers exploring OPV integration in vehicle surfaces and sunroofs. Military applications, though smaller in volume, command premium pricing for specialized OPV solutions designed for field operations and remote power generation.

Geographically, Europe leads OPV market adoption, particularly in Germany and Denmark where government incentives for renewable energy have accelerated commercialization. Asia-Pacific demonstrates the highest growth rate, with China and Japan making substantial investments in manufacturing infrastructure and research facilities dedicated to organic photovoltaic technologies.

Market drivers include increasing environmental regulations favoring renewable energy, declining manufacturing costs through process optimization, and growing consumer preference for sustainable energy solutions. The price-performance ratio of OPV technology has improved significantly, with production costs decreasing by approximately 35% over the past five years while efficiency metrics have improved.

Key market restraints include competition from established silicon-based photovoltaics and emerging thin-film technologies. The efficiency gap between OPV (currently averaging 12-15% in commercial applications) and crystalline silicon (18-22%) remains a significant barrier to widespread adoption in utility-scale implementations.

Consumer willingness to pay premiums for sustainable technology varies significantly by region and application. Market research indicates that architectural and design-focused applications command up to 30% price premiums, while cost-sensitive consumer electronics applications face more stringent price competition, limiting margin potential despite growing demand.

The market segmentation for OPV applications reveals diverse implementation opportunities across multiple sectors. Building-integrated photovoltaics (BIPV) currently dominates the application landscape, accounting for nearly 40% of market share due to the aesthetic advantages and flexibility of organic materials. Consumer electronics follows as the second-largest segment, where lightweight and flexible OPV solutions are increasingly incorporated into portable charging devices and wearable technology.

Automotive applications represent an emerging high-growth segment, with major manufacturers exploring OPV integration in vehicle surfaces and sunroofs. Military applications, though smaller in volume, command premium pricing for specialized OPV solutions designed for field operations and remote power generation.

Geographically, Europe leads OPV market adoption, particularly in Germany and Denmark where government incentives for renewable energy have accelerated commercialization. Asia-Pacific demonstrates the highest growth rate, with China and Japan making substantial investments in manufacturing infrastructure and research facilities dedicated to organic photovoltaic technologies.

Market drivers include increasing environmental regulations favoring renewable energy, declining manufacturing costs through process optimization, and growing consumer preference for sustainable energy solutions. The price-performance ratio of OPV technology has improved significantly, with production costs decreasing by approximately 35% over the past five years while efficiency metrics have improved.

Key market restraints include competition from established silicon-based photovoltaics and emerging thin-film technologies. The efficiency gap between OPV (currently averaging 12-15% in commercial applications) and crystalline silicon (18-22%) remains a significant barrier to widespread adoption in utility-scale implementations.

Consumer willingness to pay premiums for sustainable technology varies significantly by region and application. Market research indicates that architectural and design-focused applications command up to 30% price premiums, while cost-sensitive consumer electronics applications face more stringent price competition, limiting margin potential despite growing demand.

Current Challenges in OPV Material Microstructure

Despite significant advancements in organic photovoltaic (OPV) technology over the past decade, material microstructure remains a critical bottleneck limiting commercial viability. Current OPV devices face efficiency plateaus around 18% for single-junction cells, substantially below the theoretical Shockley-Queisser limit of approximately 33%. This efficiency gap is largely attributed to microstructural challenges at multiple scales.

At the molecular level, researchers struggle with controlling crystallinity and molecular orientation in active layer materials. The donor-acceptor interface morphology directly impacts exciton dissociation and charge transport, yet precise engineering of these interfaces remains elusive. Conventional processing methods produce inconsistent domain sizes, leading to suboptimal charge separation and increased recombination losses.

Phase separation dynamics present another significant challenge. The bulk heterojunction (BHJ) architecture requires precise control of donor and acceptor domain sizes (ideally 10-20 nm), but current manufacturing processes produce highly variable morphologies. This variability stems from the complex interplay between solvent evaporation kinetics, substrate interactions, and material self-assembly properties during film formation.

Stability issues related to microstructure represent perhaps the most pressing challenge. OPV materials undergo significant morphological changes during operation, including phase segregation, crystallization, and molecular reorientation. These changes accelerate performance degradation, with many high-efficiency materials showing rapid efficiency losses within hours or days under standard operating conditions.

Interface engineering between active layers and electrodes presents additional complications. Contact resistance and energy level misalignment at these interfaces create barriers to efficient charge extraction. Current buffer layer technologies only partially address these issues, with significant room for improvement in interface design and material selection.

Scale-up challenges further compound these problems. Laboratory-scale processing techniques that achieve optimal microstructures (such as solvent vapor annealing or thermal gradient treatments) often prove incompatible with roll-to-roll manufacturing requirements. The transition from spin-coating to slot-die coating or similar industrial processes frequently results in dramatically different microstructural properties and reduced device performance.

Characterization limitations hinder progress in addressing these challenges. Real-time, in-situ monitoring of microstructure formation remains difficult, particularly at the nanoscale. Advanced techniques like grazing-incidence X-ray scattering provide valuable insights but are not readily accessible for routine development work. This characterization gap slows the feedback loop between material design, processing optimization, and performance evaluation.

At the molecular level, researchers struggle with controlling crystallinity and molecular orientation in active layer materials. The donor-acceptor interface morphology directly impacts exciton dissociation and charge transport, yet precise engineering of these interfaces remains elusive. Conventional processing methods produce inconsistent domain sizes, leading to suboptimal charge separation and increased recombination losses.

Phase separation dynamics present another significant challenge. The bulk heterojunction (BHJ) architecture requires precise control of donor and acceptor domain sizes (ideally 10-20 nm), but current manufacturing processes produce highly variable morphologies. This variability stems from the complex interplay between solvent evaporation kinetics, substrate interactions, and material self-assembly properties during film formation.

Stability issues related to microstructure represent perhaps the most pressing challenge. OPV materials undergo significant morphological changes during operation, including phase segregation, crystallization, and molecular reorientation. These changes accelerate performance degradation, with many high-efficiency materials showing rapid efficiency losses within hours or days under standard operating conditions.

Interface engineering between active layers and electrodes presents additional complications. Contact resistance and energy level misalignment at these interfaces create barriers to efficient charge extraction. Current buffer layer technologies only partially address these issues, with significant room for improvement in interface design and material selection.

Scale-up challenges further compound these problems. Laboratory-scale processing techniques that achieve optimal microstructures (such as solvent vapor annealing or thermal gradient treatments) often prove incompatible with roll-to-roll manufacturing requirements. The transition from spin-coating to slot-die coating or similar industrial processes frequently results in dramatically different microstructural properties and reduced device performance.

Characterization limitations hinder progress in addressing these challenges. Real-time, in-situ monitoring of microstructure formation remains difficult, particularly at the nanoscale. Advanced techniques like grazing-incidence X-ray scattering provide valuable insights but are not readily accessible for routine development work. This characterization gap slows the feedback loop between material design, processing optimization, and performance evaluation.

State-of-the-Art Microstructure Control Techniques

01 Morphology control in organic photovoltaic materials

Controlling the morphology of organic photovoltaic materials at the microstructural level is crucial for optimizing device performance. This includes manipulating the crystallinity, domain size, and phase separation between donor and acceptor materials. Various processing techniques such as thermal annealing, solvent vapor annealing, and additive incorporation can be employed to achieve the desired microstructure, leading to improved charge carrier mobility and reduced recombination losses.- Morphology control in organic photovoltaic materials: Controlling the morphology of organic photovoltaic materials is crucial for optimizing device performance. This includes manipulating the crystallinity, domain size, and phase separation between donor and acceptor materials. Various processing techniques such as thermal annealing, solvent annealing, and additive incorporation can be employed to achieve the desired microstructure, which directly impacts charge generation, transport, and collection efficiency in organic solar cells.

- Interfacial engineering for improved charge transport: The interfaces between different layers in organic photovoltaic devices significantly influence charge transport and collection. Engineering these interfaces through the incorporation of buffer layers, self-assembled monolayers, or surface treatments can reduce recombination losses and improve charge extraction. Optimizing the microstructure at these interfaces leads to enhanced power conversion efficiency and device stability.

- Nanostructured materials for enhanced light harvesting: Incorporating nanostructured materials into organic photovoltaics can enhance light harvesting capabilities through increased surface area and improved light trapping. These nanostructures include quantum dots, nanowires, nanotubes, and nanoparticles that can be integrated into the active layer to create beneficial microstructural features. The controlled arrangement of these nanostructures within the photoactive layer optimizes exciton diffusion and charge separation.

- Polymer blend microstructure optimization: The microstructure of polymer blends in organic photovoltaics significantly affects device performance. Optimizing the blend ratio, molecular weight distribution, and regioregularity of polymers can lead to favorable morphologies with improved charge mobility. Techniques such as controlled crystallization, miscibility engineering, and processing condition optimization help achieve the ideal microstructure for efficient charge generation and transport.

- Advanced characterization techniques for microstructure analysis: Advanced characterization techniques are essential for understanding and optimizing the microstructure of organic photovoltaic materials. Methods such as grazing-incidence X-ray diffraction, atomic force microscopy, transmission electron microscopy, and scanning probe techniques provide valuable insights into morphology, crystallinity, and phase separation. These analytical approaches enable the correlation between processing conditions, resulting microstructures, and device performance.

02 Interfacial engineering for improved charge transport

Engineering the interfaces between different layers in organic photovoltaic devices is essential for efficient charge transport and collection. This involves modifying the microstructure at interfaces to reduce energy barriers, minimize recombination losses, and enhance charge extraction. Techniques include the use of buffer layers, self-assembled monolayers, and surface treatments to optimize the interfacial microstructure and improve overall device efficiency.Expand Specific Solutions03 Nanostructured materials for enhanced light harvesting

Incorporating nanostructured materials into organic photovoltaics can significantly enhance light harvesting capabilities through increased surface area and improved light trapping. These nanostructures, including nanowires, nanoparticles, and nanoporous architectures, create unique microstructural features that facilitate exciton dissociation and charge transport. The controlled synthesis and integration of these nanostructures are key to optimizing the performance of organic photovoltaic devices.Expand Specific Solutions04 Polymer blend microstructure optimization

Optimizing the microstructure of polymer blends in organic photovoltaics involves controlling the phase separation, crystallinity, and molecular orientation of the constituent polymers. The microstructural characteristics of these blends significantly impact charge generation, transport, and collection processes. Various approaches, including thermal treatments, solvent selection, and molecular design, can be employed to achieve the desired microstructural properties and enhance device performance.Expand Specific Solutions05 Characterization techniques for microstructure analysis

Advanced characterization techniques are essential for analyzing and understanding the microstructure of organic photovoltaic materials. These include microscopy methods (AFM, TEM, SEM), spectroscopic techniques (XRD, GIWAXS, FTIR), and computational modeling approaches. These tools provide valuable insights into morphological features, crystalline order, molecular orientation, and phase separation, enabling the development of structure-property relationships and guiding the design of more efficient organic photovoltaic materials.Expand Specific Solutions

Leading Entities in OPV Patent Landscape

The organic photovoltaics (OPV) market is currently in a growth phase, characterized by increasing patent activity focused on material microstructure innovations. The global OPV market is projected to expand significantly, driven by demand for flexible, lightweight solar solutions. Key players demonstrate varying levels of technical maturity: established corporations like LG Chem, Samsung Electronics, and BASF bring manufacturing expertise and commercialization capabilities, while academic institutions including MIT, University of California, and Chinese Academy of Sciences contribute fundamental research breakthroughs. Specialized companies such as Heliatek, Ubiquitous Energy, and Novaled are advancing niche applications with proprietary technologies. The competitive landscape reveals a collaborative ecosystem where partnerships between industry and academia are accelerating material innovations to overcome efficiency and stability challenges that currently limit widespread OPV adoption.

The Regents of the University of California

Technical Solution: The University of California has pioneered innovative approaches in organic photovoltaics (OPV) focusing on material microstructure optimization. Their research teams have developed novel polymer:fullerene blend systems with controlled nanomorphology to enhance charge separation and transport. They've implemented advanced processing techniques such as solvent additives and thermal annealing to optimize the bulk heterojunction (BHJ) morphology, achieving power conversion efficiencies exceeding 11% in single-junction devices. Their patents cover methods for controlling domain size and purity in the active layer through systematic molecular design principles. Notably, their work on non-fullerene acceptors (NFAs) has demonstrated improved light absorption in the near-infrared region and reduced energy losses at the donor-acceptor interface. The university's research has established correlations between molecular packing, crystallinity, and device performance through advanced characterization techniques including GIWAXS and TEM imaging.

Strengths: Strong fundamental research capabilities with access to advanced characterization facilities enabling detailed microstructure analysis. Extensive intellectual property portfolio covering multiple aspects of OPV materials and processing. Weaknesses: As an academic institution, may face challenges in scaling technologies to commercial production levels and navigating industrial manufacturing constraints.

Massachusetts Institute of Technology

Technical Solution: MIT has developed groundbreaking approaches to organic photovoltaic microstructure engineering through molecular design and processing innovations. Their patented technologies include block copolymer templating methods that create self-assembled nanostructures with precisely controlled domain sizes and interfacial areas. MIT researchers have pioneered the use of ternary blend systems incorporating specialized compatibilizers that modify the donor-acceptor interface to reduce energy losses while maintaining optimal phase separation. Their patents cover novel processing techniques using controlled solvent evaporation gradients to induce vertical stratification of components, creating favorable charge transport pathways perpendicular to the electrodes. MIT has also developed advanced characterization methodologies combining in-situ X-ray scattering with device measurements to establish structure-property relationships. Their innovations include specialized interlayers with engineered work functions that improve charge extraction while simultaneously templating the growth and orientation of the photoactive layer. Additionally, MIT has patented approaches for stabilizing metastable morphologies through rapid post-deposition treatments, preventing unfavorable reorganization during device operation.

Strengths: Cutting-edge fundamental research capabilities with access to advanced characterization facilities; interdisciplinary approach combining chemistry, physics, and materials science expertise. Weaknesses: As an academic institution, faces challenges in technology transfer and scaling innovations to commercial production; research may prioritize scientific novelty over practical manufacturing considerations.

Key Patent Analysis in OPV Material Architecture

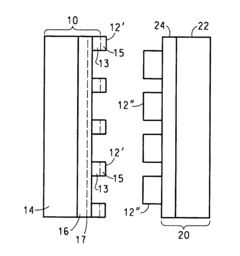

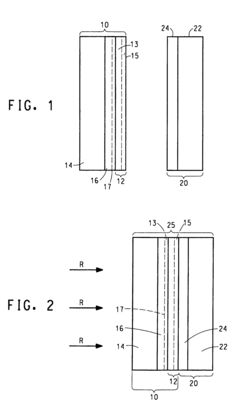

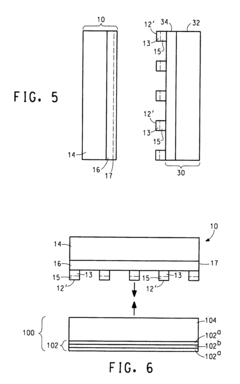

Thermal imaging processes and products of electroactive organic material

PatentInactiveUS7229676B2

Innovation

- A method involving a donor element with a thermally imageable transfer layer of electroactive organic material, where unwanted portions are selectively exposed to heat to form a patterned layer without excessive heat exposure, allowing for transfer to a substrate without decomposition, using a heating layer that absorbs laser radiation and an optional ejection layer to facilitate transfer without damaging the material.

Patent

Innovation

- Novel donor-acceptor interface engineering in organic photovoltaics that optimizes charge separation and transport through controlled molecular orientation at heterojunctions.

- Development of ternary blend systems incorporating small molecule additives that enhance morphological stability and improve power conversion efficiency through complementary absorption profiles.

- Implementation of hierarchical nanostructures in active layers that facilitate exciton diffusion while maintaining efficient charge extraction pathways.

Manufacturing Scalability of Advanced OPV Materials

The scalability of organic photovoltaic (OPV) manufacturing represents a critical challenge in transitioning promising laboratory innovations to commercial viability. Current manufacturing processes for advanced OPV materials face significant hurdles when scaling from small-area devices to large-area modules. The primary challenge lies in maintaining the optimal material microstructure that delivers high efficiency at laboratory scale when transitioning to industrial production methods.

Roll-to-roll (R2R) processing has emerged as the most promising approach for large-scale OPV manufacturing, offering throughput rates exceeding 100 m²/min. However, this process introduces unique challenges for microstructure control. The rapid solvent evaporation during high-speed coating significantly alters the self-assembly dynamics of donor-acceptor blends, often resulting in suboptimal morphology compared to spin-coated laboratory devices.

Recent patent innovations have focused on addressing these scalability issues through several approaches. Solution engineering patents have introduced novel solvent additives specifically designed to modulate drying kinetics during high-speed deposition. These additives create a more controlled phase separation process, allowing sufficient time for optimal domain formation despite faster processing speeds. Notable examples include patents from Merck and BASF introducing branched alkyl thiols that selectively modify the solubility of fullerene derivatives.

Post-deposition treatment technologies represent another significant patent cluster, with innovations centered on controlled thermal annealing and solvent vapor annealing systems compatible with continuous manufacturing. These technologies enable microstructure refinement after the initial deposition, correcting morphological deficiencies that occur during rapid coating processes.

Material engineering approaches have yielded patents for self-assembling block copolymers and small molecules with enhanced crystallization properties that maintain optimal domain sizes regardless of processing speed. These materials incorporate structural elements that promote rapid self-organization, making them particularly suitable for industrial manufacturing conditions.

The economic implications of these innovations are substantial, with techno-economic analyses suggesting that achieving manufacturing scalability could reduce OPV module costs to below $0.20/Wp. However, significant challenges remain in simultaneously optimizing multiple manufacturing parameters while maintaining the delicate microstructure required for high-performance devices.

Cross-industry collaborations between material suppliers and equipment manufacturers have accelerated in recent years, resulting in integrated patent portfolios that address both material formulation and processing equipment design. This holistic approach appears most promising for overcoming the complex interdependencies between material properties and manufacturing conditions that have historically limited OPV commercialization.

Roll-to-roll (R2R) processing has emerged as the most promising approach for large-scale OPV manufacturing, offering throughput rates exceeding 100 m²/min. However, this process introduces unique challenges for microstructure control. The rapid solvent evaporation during high-speed coating significantly alters the self-assembly dynamics of donor-acceptor blends, often resulting in suboptimal morphology compared to spin-coated laboratory devices.

Recent patent innovations have focused on addressing these scalability issues through several approaches. Solution engineering patents have introduced novel solvent additives specifically designed to modulate drying kinetics during high-speed deposition. These additives create a more controlled phase separation process, allowing sufficient time for optimal domain formation despite faster processing speeds. Notable examples include patents from Merck and BASF introducing branched alkyl thiols that selectively modify the solubility of fullerene derivatives.

Post-deposition treatment technologies represent another significant patent cluster, with innovations centered on controlled thermal annealing and solvent vapor annealing systems compatible with continuous manufacturing. These technologies enable microstructure refinement after the initial deposition, correcting morphological deficiencies that occur during rapid coating processes.

Material engineering approaches have yielded patents for self-assembling block copolymers and small molecules with enhanced crystallization properties that maintain optimal domain sizes regardless of processing speed. These materials incorporate structural elements that promote rapid self-organization, making them particularly suitable for industrial manufacturing conditions.

The economic implications of these innovations are substantial, with techno-economic analyses suggesting that achieving manufacturing scalability could reduce OPV module costs to below $0.20/Wp. However, significant challenges remain in simultaneously optimizing multiple manufacturing parameters while maintaining the delicate microstructure required for high-performance devices.

Cross-industry collaborations between material suppliers and equipment manufacturers have accelerated in recent years, resulting in integrated patent portfolios that address both material formulation and processing equipment design. This holistic approach appears most promising for overcoming the complex interdependencies between material properties and manufacturing conditions that have historically limited OPV commercialization.

Sustainability Impact of OPV Material Innovations

The sustainability impact of organic photovoltaic (OPV) material innovations represents a critical dimension in evaluating their long-term viability and contribution to global environmental goals. Recent patent innovations focusing on material microstructure have demonstrated significant potential for reducing the environmental footprint of solar energy technologies.

OPV technologies inherently offer sustainability advantages through their minimal material requirements, with active layers typically less than 100 nm thick. This characteristic substantially reduces resource consumption compared to traditional silicon-based photovoltaics, which require energy-intensive processing of high-purity silicon. Material microstructure innovations have further enhanced this advantage by enabling higher efficiency with even thinner films.

Life cycle assessment (LCA) studies of recent OPV material innovations reveal impressive environmental credentials. Patents focusing on optimized donor-acceptor interfaces have led to devices with energy payback times as short as a few months, compared to 1-2 years for silicon technologies. The carbon footprint of these advanced OPV systems has been calculated at approximately 10-25g CO₂-eq/kWh, representing a fraction of conventional energy sources.

Water usage represents another critical sustainability metric where microstructure-focused OPV innovations demonstrate excellence. Manufacturing processes for these advanced materials typically consume 10-20 liters per square meter of panel area, compared to 1,500-3,000 liters for conventional silicon panels. Patents describing water-based processing methods for controlling material morphology have further reduced this impact.

End-of-life considerations have been addressed through recent innovations in material design. Patents describing biodegradable substrates and environmentally benign additives for controlling microstructure stability have emerged, potentially solving one of the most significant sustainability challenges in photovoltaic technology. These innovations enable recovery of valuable materials while minimizing landfill impact.

The scalability of these sustainable material innovations presents both opportunities and challenges. While laboratory demonstrations have proven the concepts, industrial implementation requires further development. Patents describing roll-to-roll compatible microstructure control methods represent particularly promising approaches for maintaining sustainability benefits at commercial scale.

Regulatory frameworks increasingly recognize the sustainability advantages of these material innovations. The European Union's Ecodesign Directive and similar policies worldwide are creating market incentives for technologies with demonstrable life-cycle benefits, positioning microstructure-optimized OPV technologies favorably in future energy markets.

OPV technologies inherently offer sustainability advantages through their minimal material requirements, with active layers typically less than 100 nm thick. This characteristic substantially reduces resource consumption compared to traditional silicon-based photovoltaics, which require energy-intensive processing of high-purity silicon. Material microstructure innovations have further enhanced this advantage by enabling higher efficiency with even thinner films.

Life cycle assessment (LCA) studies of recent OPV material innovations reveal impressive environmental credentials. Patents focusing on optimized donor-acceptor interfaces have led to devices with energy payback times as short as a few months, compared to 1-2 years for silicon technologies. The carbon footprint of these advanced OPV systems has been calculated at approximately 10-25g CO₂-eq/kWh, representing a fraction of conventional energy sources.

Water usage represents another critical sustainability metric where microstructure-focused OPV innovations demonstrate excellence. Manufacturing processes for these advanced materials typically consume 10-20 liters per square meter of panel area, compared to 1,500-3,000 liters for conventional silicon panels. Patents describing water-based processing methods for controlling material morphology have further reduced this impact.

End-of-life considerations have been addressed through recent innovations in material design. Patents describing biodegradable substrates and environmentally benign additives for controlling microstructure stability have emerged, potentially solving one of the most significant sustainability challenges in photovoltaic technology. These innovations enable recovery of valuable materials while minimizing landfill impact.

The scalability of these sustainable material innovations presents both opportunities and challenges. While laboratory demonstrations have proven the concepts, industrial implementation requires further development. Patents describing roll-to-roll compatible microstructure control methods represent particularly promising approaches for maintaining sustainability benefits at commercial scale.

Regulatory frameworks increasingly recognize the sustainability advantages of these material innovations. The European Union's Ecodesign Directive and similar policies worldwide are creating market incentives for technologies with demonstrable life-cycle benefits, positioning microstructure-optimized OPV technologies favorably in future energy markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!