The Evolution of Mass Transfer Techniques in Organic Photovoltaics

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OPV Mass Transfer Evolution and Objectives

Organic photovoltaics (OPVs) have evolved significantly since their inception in the 1980s, with mass transfer techniques playing a crucial role in their development trajectory. Initially, OPVs were fabricated using simple solution processing methods with limited control over morphology and interfacial properties. The early 1990s saw the introduction of basic spin-coating techniques, which represented the first systematic approach to controlling film thickness and uniformity in organic semiconductor layers.

A paradigm shift occurred in the early 2000s with the development of bulk heterojunction (BHJ) architectures, which fundamentally changed how mass transfer was conceptualized in OPVs. This innovation required precise control over the nanoscale phase separation between donor and acceptor materials, driving significant advancements in solvent engineering and thermal annealing processes to optimize mass transfer dynamics at interfaces.

The period from 2005 to 2015 witnessed the refinement of solution processing techniques, including the introduction of solvent additives, mixed-solvent approaches, and sequential deposition methods. These innovations enabled better control over the kinetics of film formation and consequently improved charge carrier mobility across interfaces, pushing power conversion efficiencies (PCEs) from below 3% to over 10%.

Recent years have seen the emergence of advanced mass transfer techniques including meniscus-guided coating, slot-die coating, and various printing methodologies that enable precise control over molecular orientation and crystallization processes. These techniques have been instrumental in addressing key challenges such as vertical phase segregation and interfacial energy level alignment, which are critical for efficient charge extraction.

The evolution of mass transfer techniques has been closely tied to advances in material science, particularly the development of new donor-acceptor systems with optimized molecular structures. Non-fullerene acceptors (NFAs), which emerged prominently after 2015, have demanded entirely new approaches to mass transfer optimization due to their distinct aggregation behaviors and interfacial properties.

The primary objective of current research in OPV mass transfer is to develop scalable fabrication techniques that maintain the precise nanoscale morphology control achieved in laboratory settings. This includes addressing challenges related to solvent evaporation rates in large-area processing, ensuring homogeneous film formation across substantial surface areas, and developing in-line quality control methods for continuous manufacturing.

Additional objectives include enhancing the environmental sustainability of mass transfer processes by reducing reliance on halogenated solvents, lowering processing temperatures to enable compatibility with flexible substrates, and developing techniques that are compatible with tandem and multi-junction architectures to push theoretical efficiency limits beyond 20%.

A paradigm shift occurred in the early 2000s with the development of bulk heterojunction (BHJ) architectures, which fundamentally changed how mass transfer was conceptualized in OPVs. This innovation required precise control over the nanoscale phase separation between donor and acceptor materials, driving significant advancements in solvent engineering and thermal annealing processes to optimize mass transfer dynamics at interfaces.

The period from 2005 to 2015 witnessed the refinement of solution processing techniques, including the introduction of solvent additives, mixed-solvent approaches, and sequential deposition methods. These innovations enabled better control over the kinetics of film formation and consequently improved charge carrier mobility across interfaces, pushing power conversion efficiencies (PCEs) from below 3% to over 10%.

Recent years have seen the emergence of advanced mass transfer techniques including meniscus-guided coating, slot-die coating, and various printing methodologies that enable precise control over molecular orientation and crystallization processes. These techniques have been instrumental in addressing key challenges such as vertical phase segregation and interfacial energy level alignment, which are critical for efficient charge extraction.

The evolution of mass transfer techniques has been closely tied to advances in material science, particularly the development of new donor-acceptor systems with optimized molecular structures. Non-fullerene acceptors (NFAs), which emerged prominently after 2015, have demanded entirely new approaches to mass transfer optimization due to their distinct aggregation behaviors and interfacial properties.

The primary objective of current research in OPV mass transfer is to develop scalable fabrication techniques that maintain the precise nanoscale morphology control achieved in laboratory settings. This includes addressing challenges related to solvent evaporation rates in large-area processing, ensuring homogeneous film formation across substantial surface areas, and developing in-line quality control methods for continuous manufacturing.

Additional objectives include enhancing the environmental sustainability of mass transfer processes by reducing reliance on halogenated solvents, lowering processing temperatures to enable compatibility with flexible substrates, and developing techniques that are compatible with tandem and multi-junction architectures to push theoretical efficiency limits beyond 20%.

Market Analysis for Organic Photovoltaic Technologies

The organic photovoltaic (OPV) market has shown remarkable growth potential in recent years, driven by increasing demand for renewable energy solutions and advancements in material science. The global OPV market was valued at approximately 86.7 million USD in 2022 and is projected to reach 357.4 million USD by 2030, representing a compound annual growth rate (CAGR) of 19.4% during the forecast period.

The market for OPV technologies can be segmented based on application areas, with building-integrated photovoltaics (BIPV) emerging as the dominant segment. This is primarily due to the aesthetic versatility, flexibility, and semi-transparency features of organic solar cells, making them ideal for integration into architectural elements. Other significant application segments include consumer electronics, automotive, military and defense, and wearable devices.

Geographically, Europe currently leads the OPV market, accounting for approximately 38% of the global share. This dominance can be attributed to favorable government policies promoting renewable energy adoption and substantial investments in research and development. North America follows closely, while the Asia-Pacific region is expected to witness the fastest growth rate due to increasing energy demands, expanding manufacturing capabilities, and supportive regulatory frameworks in countries like China, Japan, and South Korea.

Key market drivers include the declining costs of raw materials and manufacturing processes, improved power conversion efficiencies (PCEs), and growing environmental consciousness among consumers and businesses. The cost per watt for OPV modules has decreased by approximately 35% over the past five years, making them increasingly competitive with traditional silicon-based photovoltaics in certain applications.

However, several challenges continue to impact market growth. These include relatively lower efficiency rates compared to inorganic counterparts, concerns about long-term stability and operational lifetime, and scaling issues in mass production. The average lifespan of commercial OPV modules currently ranges from 5-7 years, significantly shorter than the 25+ years offered by silicon-based alternatives.

The competitive landscape features both established players and innovative startups. Key market participants include Heliatek GmbH, ARMOR Solar Power Films, Sunew, Epishine, and InfinityPV, among others. Strategic partnerships between material suppliers, technology developers, and end-users are becoming increasingly common, accelerating commercialization efforts and market penetration.

Looking ahead, the integration of advanced mass transfer techniques in OPV manufacturing processes is expected to significantly impact market dynamics by enabling higher throughput, reduced production costs, and improved device performance. This technological evolution could potentially unlock new application segments and accelerate market growth beyond current projections.

The market for OPV technologies can be segmented based on application areas, with building-integrated photovoltaics (BIPV) emerging as the dominant segment. This is primarily due to the aesthetic versatility, flexibility, and semi-transparency features of organic solar cells, making them ideal for integration into architectural elements. Other significant application segments include consumer electronics, automotive, military and defense, and wearable devices.

Geographically, Europe currently leads the OPV market, accounting for approximately 38% of the global share. This dominance can be attributed to favorable government policies promoting renewable energy adoption and substantial investments in research and development. North America follows closely, while the Asia-Pacific region is expected to witness the fastest growth rate due to increasing energy demands, expanding manufacturing capabilities, and supportive regulatory frameworks in countries like China, Japan, and South Korea.

Key market drivers include the declining costs of raw materials and manufacturing processes, improved power conversion efficiencies (PCEs), and growing environmental consciousness among consumers and businesses. The cost per watt for OPV modules has decreased by approximately 35% over the past five years, making them increasingly competitive with traditional silicon-based photovoltaics in certain applications.

However, several challenges continue to impact market growth. These include relatively lower efficiency rates compared to inorganic counterparts, concerns about long-term stability and operational lifetime, and scaling issues in mass production. The average lifespan of commercial OPV modules currently ranges from 5-7 years, significantly shorter than the 25+ years offered by silicon-based alternatives.

The competitive landscape features both established players and innovative startups. Key market participants include Heliatek GmbH, ARMOR Solar Power Films, Sunew, Epishine, and InfinityPV, among others. Strategic partnerships between material suppliers, technology developers, and end-users are becoming increasingly common, accelerating commercialization efforts and market penetration.

Looking ahead, the integration of advanced mass transfer techniques in OPV manufacturing processes is expected to significantly impact market dynamics by enabling higher throughput, reduced production costs, and improved device performance. This technological evolution could potentially unlock new application segments and accelerate market growth beyond current projections.

Current Mass Transfer Challenges in OPV Development

Despite significant advancements in organic photovoltaic (OPV) technology, mass transfer processes remain a critical bottleneck in achieving commercial viability. Current OPV manufacturing faces several interconnected challenges that limit efficiency, scalability, and cost-effectiveness. These challenges span from molecular-level phenomena to industrial-scale production considerations.

At the molecular level, charge carrier mobility within organic semiconductors continues to be substantially lower than in their inorganic counterparts. This fundamental limitation creates significant mass transfer constraints, as electrons and holes must navigate through disordered organic matrices with numerous traps and barriers. The heterogeneous nature of organic materials further complicates this process, with domain boundaries acting as recombination sites that diminish overall device performance.

Interface engineering presents another substantial challenge. The critical donor-acceptor interfaces where exciton dissociation occurs remain difficult to optimize at scale. Current techniques struggle to create ideally structured interfaces that maximize charge separation while minimizing recombination losses. This becomes particularly problematic when transitioning from laboratory-scale fabrication to industrial production methods.

Solvent-based processing techniques, while dominant in research settings, introduce significant mass transfer challenges in manufacturing environments. Solvent removal rates directly impact morphology development, with incomplete removal leading to trapped residues that compromise device performance. Additionally, the environmental and health concerns associated with many high-performance solvents create regulatory hurdles for mass production.

Scaling production from laboratory to industrial levels introduces further mass transfer complications. Roll-to-roll processing, considered essential for cost-effective manufacturing, demands precise control over drying kinetics, layer formation, and interlayer diffusion—all processes fundamentally governed by mass transfer principles. Current technologies struggle to maintain the delicate morphological control achieved in small-scale spin coating when transitioning to high-throughput methods.

Stability and degradation mechanisms represent perhaps the most persistent mass transfer challenge. Oxygen and moisture ingress, facilitated by the inherently porous nature of many organic materials, triggers degradation pathways that significantly reduce device lifetimes. Current encapsulation technologies provide insufficient barriers against these environmental factors, with mass transfer across protective layers remaining problematic.

Material compatibility issues further complicate manufacturing processes. The multi-layer architecture of modern OPVs requires careful consideration of solvent orthogonality and interlayer diffusion. Preventing unwanted mass transfer between adjacent functional layers during fabrication remains technically challenging, particularly when using solution-based deposition methods at industrial scales.

At the molecular level, charge carrier mobility within organic semiconductors continues to be substantially lower than in their inorganic counterparts. This fundamental limitation creates significant mass transfer constraints, as electrons and holes must navigate through disordered organic matrices with numerous traps and barriers. The heterogeneous nature of organic materials further complicates this process, with domain boundaries acting as recombination sites that diminish overall device performance.

Interface engineering presents another substantial challenge. The critical donor-acceptor interfaces where exciton dissociation occurs remain difficult to optimize at scale. Current techniques struggle to create ideally structured interfaces that maximize charge separation while minimizing recombination losses. This becomes particularly problematic when transitioning from laboratory-scale fabrication to industrial production methods.

Solvent-based processing techniques, while dominant in research settings, introduce significant mass transfer challenges in manufacturing environments. Solvent removal rates directly impact morphology development, with incomplete removal leading to trapped residues that compromise device performance. Additionally, the environmental and health concerns associated with many high-performance solvents create regulatory hurdles for mass production.

Scaling production from laboratory to industrial levels introduces further mass transfer complications. Roll-to-roll processing, considered essential for cost-effective manufacturing, demands precise control over drying kinetics, layer formation, and interlayer diffusion—all processes fundamentally governed by mass transfer principles. Current technologies struggle to maintain the delicate morphological control achieved in small-scale spin coating when transitioning to high-throughput methods.

Stability and degradation mechanisms represent perhaps the most persistent mass transfer challenge. Oxygen and moisture ingress, facilitated by the inherently porous nature of many organic materials, triggers degradation pathways that significantly reduce device lifetimes. Current encapsulation technologies provide insufficient barriers against these environmental factors, with mass transfer across protective layers remaining problematic.

Material compatibility issues further complicate manufacturing processes. The multi-layer architecture of modern OPVs requires careful consideration of solvent orthogonality and interlayer diffusion. Preventing unwanted mass transfer between adjacent functional layers during fabrication remains technically challenging, particularly when using solution-based deposition methods at industrial scales.

Contemporary Mass Transfer Solutions for OPVs

01 Vapor deposition techniques for organic photovoltaic layers

Vapor deposition is a key mass transfer technique used in the fabrication of organic photovoltaic devices. This process involves the evaporation of organic materials under vacuum conditions, followed by their controlled deposition onto substrates. The technique allows for precise control over layer thickness and uniformity, which are critical factors affecting the efficiency of organic solar cells. Various modifications of vapor deposition, including thermal evaporation and chemical vapor deposition, enable the formation of high-quality organic semiconductor layers with optimal morphology for charge transport.- Vapor deposition techniques for organic photovoltaic layers: Vapor deposition is a key mass transfer technique used in the fabrication of organic photovoltaic devices. This process involves the evaporation of organic materials under vacuum conditions, followed by their controlled deposition onto substrates. The technique allows for precise thickness control and formation of uniform thin films, which are critical for efficient charge transport in photovoltaic cells. Various modifications of vapor deposition, including thermal evaporation and chemical vapor deposition, enable the creation of complex multilayer structures with optimized interfaces.

- Solution-based processing methods for organic photovoltaics: Solution-based processing represents a significant mass transfer approach for fabricating organic photovoltaic devices. These methods include spin coating, spray coating, doctor blading, and inkjet printing, which enable the deposition of organic semiconductors from liquid solutions onto various substrates. Solution processing offers advantages such as low-cost manufacturing, compatibility with flexible substrates, and potential for large-area production. The technique involves controlling solvent evaporation rates and solution rheology to achieve optimal film morphology and phase separation in bulk heterojunction solar cells.

- Roll-to-roll manufacturing for large-scale organic photovoltaics: Roll-to-roll (R2R) manufacturing is an advanced mass transfer technique for scaling up organic photovoltaic production. This continuous processing method enables the transfer of organic materials onto flexible substrates moving between rollers, allowing for high-throughput fabrication. The process incorporates various deposition techniques such as slot-die coating, gravure printing, and flexographic printing. R2R manufacturing addresses challenges in maintaining uniform film thickness, controlling solvent evaporation, and ensuring proper layer alignment across large areas, which are crucial for commercialization of organic photovoltaic technology.

- Interface engineering and interlayer mass transfer: Interface engineering involves controlled mass transfer of materials between layers in organic photovoltaic devices to optimize charge extraction and reduce recombination losses. This includes the deposition of buffer layers, electron/hole transport layers, and interfacial modifiers. Techniques such as sequential layer deposition, gradient doping, and self-assembled monolayers are employed to create favorable energy level alignment and improve charge selectivity at interfaces. The precise control of mass transfer across these interfaces significantly impacts device performance by facilitating efficient charge separation and collection.

- Nanostructure formation and morphology control: Mass transfer techniques for controlling nanoscale morphology are essential in organic photovoltaic development. These methods include controlled phase separation, template-assisted growth, and self-assembly processes that create optimized donor-acceptor interfaces. Techniques such as solvent annealing, thermal annealing, and additive-assisted processing enable the manipulation of domain sizes and network formation in the active layer. The controlled mass transfer during these processes determines the exciton diffusion length, charge separation efficiency, and charge transport pathways, directly influencing the overall power conversion efficiency of organic photovoltaic devices.

02 Solution-based processing methods for organic photovoltaics

Solution-based processing represents a significant mass transfer approach for fabricating organic photovoltaic devices. These methods include spin coating, spray coating, doctor blading, and inkjet printing, which enable the deposition of organic materials from liquid solutions onto substrates. Solution processing offers advantages such as compatibility with flexible substrates, scalability for large-area manufacturing, and reduced production costs compared to vacuum-based techniques. The morphology and performance of the resulting organic photovoltaic layers can be controlled through solvent selection, solution concentration, and processing conditions.Expand Specific Solutions03 Roll-to-roll manufacturing for large-scale organic photovoltaics

Roll-to-roll (R2R) manufacturing is an advanced mass transfer technique for the continuous production of organic photovoltaic devices on flexible substrates. This process involves transferring organic materials onto moving substrate webs through various deposition methods, including slot-die coating, gravure printing, and flexographic printing. R2R technology enables high-throughput production of organic solar cells with reduced manufacturing costs. The technique requires precise control of web tension, alignment, and processing parameters to ensure uniform layer formation and maintain device performance across large areas.Expand Specific Solutions04 Interface engineering and interlayer mass transfer

Interface engineering involves the controlled mass transfer of materials to create functional interlayers between the various components of organic photovoltaic devices. These interlayers facilitate charge extraction, reduce recombination losses, and improve device stability. Techniques such as self-assembled monolayer deposition, buffer layer insertion, and gradient composition layers are employed to optimize the interfaces between electrodes and photoactive materials. The precise control of interlayer thickness and composition is crucial for enhancing power conversion efficiency and operational lifetime of organic solar cells.Expand Specific Solutions05 Nanostructuring and morphology control in organic photovoltaics

Nanostructuring techniques involve the controlled mass transfer of materials to create optimized morphologies within organic photovoltaic active layers. Methods such as nanoimprint lithography, template-assisted deposition, and phase separation control are used to create ordered nanostructures that enhance exciton diffusion and charge transport. The bulk heterojunction morphology, critical for efficient charge separation, can be controlled through processing additives, thermal annealing, and solvent vapor annealing. These approaches enable the formation of interpenetrating donor-acceptor networks with optimized domain sizes and connectivity for improved photovoltaic performance.Expand Specific Solutions

Leading Companies and Research Institutions in OPV

The organic photovoltaics (OPV) market is currently in a growth phase, transitioning from early-stage research to commercial applications, with a projected market size reaching $300 million by 2027. Mass transfer techniques in OPV have evolved significantly, with academic institutions leading fundamental research while industry players focus on scalable manufacturing processes. Universities like Michigan, California, and USC are pioneering novel transfer methods, while companies including Sharp, Toshiba, and Nitto Denko are advancing commercial applications. Chinese institutions such as Shandong University and UESTC are rapidly gaining ground in efficiency improvements. The technology maturity varies across applications, with established techniques for small-scale devices but ongoing challenges in large-area manufacturing that companies like Gree Electric and Toyota are addressing through proprietary mass transfer solutions.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has pioneered innovative mass transfer techniques for organic photovoltaics (OPVs), focusing on solution-based processing methods. Their research team has developed specialized blade coating and slot-die coating processes that enable precise deposition of organic semiconductor materials with controlled morphology. They've implemented a novel approach combining solvent engineering and temperature-controlled deposition that achieves nanoscale phase separation in bulk heterojunction OPVs, resulting in power conversion efficiencies exceeding 17% for single-junction devices. Their mass transfer techniques incorporate green solvents and additives that reduce environmental impact while maintaining high device performance. Additionally, they've developed scalable roll-to-roll compatible processes that maintain morphological control across large areas, addressing one of the key challenges in OPV commercialization.

Strengths: Superior morphological control at nanoscale, environmentally friendly processing methods, and demonstrated scalability for industrial applications. Weaknesses: Some techniques require precise temperature control and specialized equipment that may increase manufacturing complexity and costs.

Merck Patent GmbH

Technical Solution: Merck has developed proprietary mass transfer technologies for OPV manufacturing that focus on material optimization and process integration. Their approach centers on specially formulated semiconductor inks with tailored rheological properties that enable high-throughput printing processes. Merck's technology incorporates self-assembling additives that guide the formation of optimal donor-acceptor interfaces during solvent evaporation, enhancing charge separation efficiency. Their mass transfer techniques include precision-controlled meniscus-guided coating that achieves uniform thin films with thickness variations below 5% across large areas. Merck has also pioneered vacuum-assisted solution processing methods that accelerate solvent removal while preserving the desired morphology of the active layer. Their integrated approach combines material design with process optimization, resulting in OPV modules with improved stability and lifetimes exceeding 10 years under outdoor conditions. Recent advancements include the development of crosslinkable interfacial materials that enhance adhesion between layers and prevent delamination during thermal cycling.

Strengths: Comprehensive material-process integration approach, excellent film uniformity across large areas, and enhanced device stability. Weaknesses: Proprietary materials may increase costs and create supply chain dependencies for manufacturers adopting their technology.

Key Patents and Breakthroughs in OPV Mass Transfer

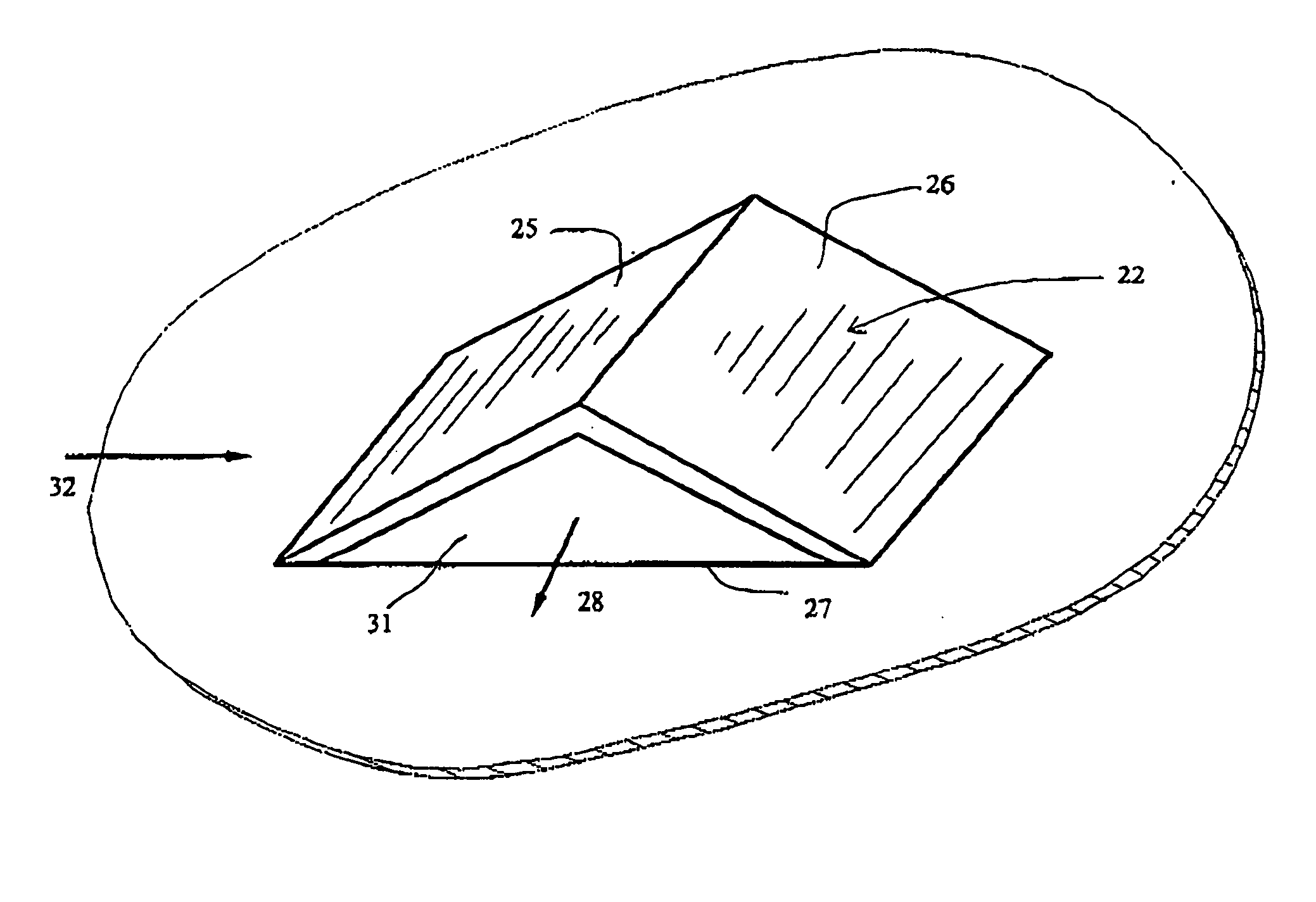

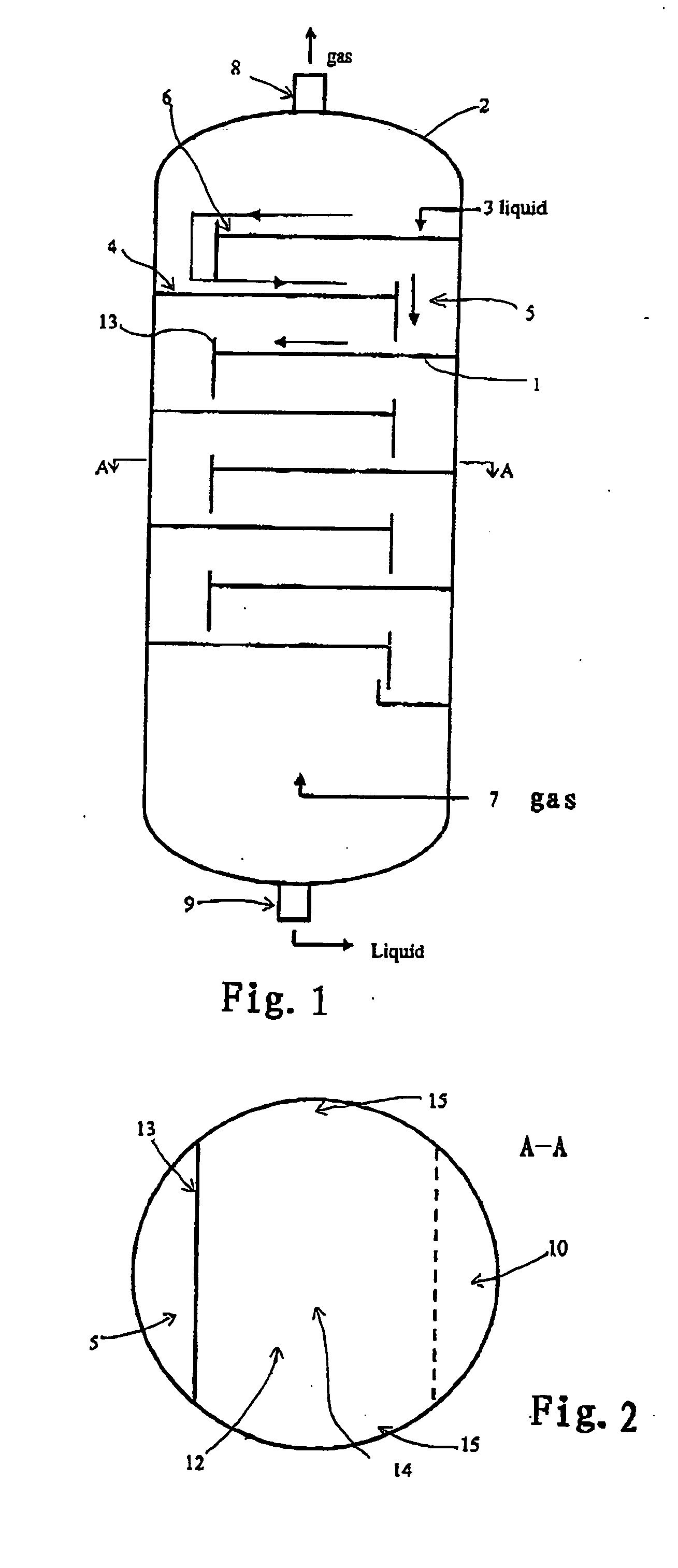

Gas-liquid contact tray with fixed valves for mass transfer

PatentInactiveUS20050280169A1

Innovation

- The design incorporates fixed valves with upstream and downstream portions integrated into the tray deck, featuring central plane portions and downward inclined margins, and includes perforations between valves to guide gas flow and prevent impinging, using a punch process to form deflectors that redirect gas jets downward, minimizing liquid entrainment and weeping while enhancing mass transfer efficiency.

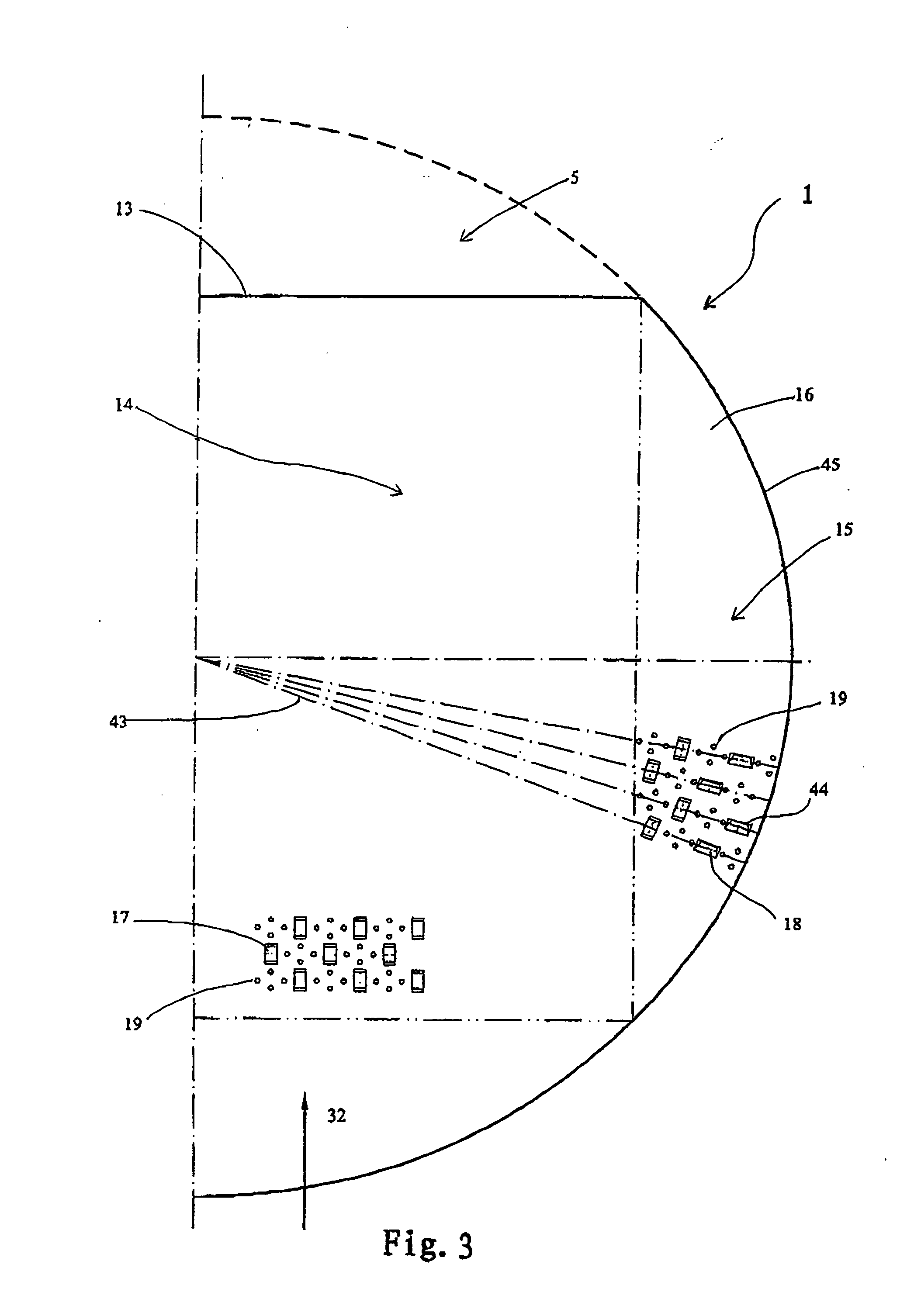

Method and system for simulating heat and mass transfer in cooling towers

PatentInactiveUS5661670A

Innovation

- A simulation system that uses geometric characteristics of cooling tower packings and environmental conditions to predict heat and mass transfer performance by integrating fundamental physical equations, providing outputs such as outlet liquid temperature, heat load, and pressure losses, and iteratively adjusts inputs to converge on reliable predictions.

Scalability and Manufacturing Considerations

The scalability of organic photovoltaic (OPV) manufacturing represents a critical factor in determining the commercial viability of this promising technology. Traditional laboratory-scale fabrication methods, while suitable for research purposes, face significant challenges when transitioning to industrial production volumes. The evolution of mass transfer techniques has directly addressed these scalability concerns, enabling the progression from small-area devices to large-area modules.

Roll-to-roll (R2R) processing has emerged as the most promising manufacturing approach for OPVs, offering continuous production capabilities that dramatically increase throughput compared to batch processing methods. This technique allows for the deposition of active materials on flexible substrates at speeds exceeding 10 meters per minute, representing orders of magnitude improvement over conventional methods. However, maintaining film uniformity and thickness control at these speeds remains challenging, particularly for multi-layer device architectures.

Material consumption efficiency presents another critical manufacturing consideration. Conventional solution processing methods like spin coating typically waste 90-95% of the organic materials, which becomes economically prohibitive at industrial scales. Advanced mass transfer techniques such as slot-die coating, spray coating, and doctor blading have significantly improved material utilization rates, with some approaches achieving over 90% efficiency. This reduction in material waste directly impacts production costs and environmental sustainability.

Process integration represents a significant manufacturing hurdle that has been progressively addressed through innovations in mass transfer techniques. The sequential deposition of multiple functional layers with precise thickness control requires careful optimization of process parameters including temperature, humidity, and solvent selection. Recent developments in orthogonal solvent systems have enabled wet-on-wet processing, eliminating the need for intermediate drying steps and substantially reducing production time.

Quality control and reproducibility at industrial scales demand sophisticated in-line monitoring systems. The integration of optical inspection tools, spectroscopic techniques, and electrical testing stations within R2R production lines has enabled real-time quality assessment. These systems can detect defects, thickness variations, and performance anomalies during manufacturing, allowing for immediate process adjustments and minimizing waste production.

Energy requirements for OPV manufacturing have decreased substantially through innovations in low-temperature processing techniques. Early manufacturing approaches required high-temperature annealing steps (>150°C), limiting substrate options and increasing energy consumption. Recent developments in solvent additives and post-treatment methods have enabled efficient device fabrication at temperatures below 120°C, expanding compatibility with low-cost flexible substrates while reducing energy inputs.

Roll-to-roll (R2R) processing has emerged as the most promising manufacturing approach for OPVs, offering continuous production capabilities that dramatically increase throughput compared to batch processing methods. This technique allows for the deposition of active materials on flexible substrates at speeds exceeding 10 meters per minute, representing orders of magnitude improvement over conventional methods. However, maintaining film uniformity and thickness control at these speeds remains challenging, particularly for multi-layer device architectures.

Material consumption efficiency presents another critical manufacturing consideration. Conventional solution processing methods like spin coating typically waste 90-95% of the organic materials, which becomes economically prohibitive at industrial scales. Advanced mass transfer techniques such as slot-die coating, spray coating, and doctor blading have significantly improved material utilization rates, with some approaches achieving over 90% efficiency. This reduction in material waste directly impacts production costs and environmental sustainability.

Process integration represents a significant manufacturing hurdle that has been progressively addressed through innovations in mass transfer techniques. The sequential deposition of multiple functional layers with precise thickness control requires careful optimization of process parameters including temperature, humidity, and solvent selection. Recent developments in orthogonal solvent systems have enabled wet-on-wet processing, eliminating the need for intermediate drying steps and substantially reducing production time.

Quality control and reproducibility at industrial scales demand sophisticated in-line monitoring systems. The integration of optical inspection tools, spectroscopic techniques, and electrical testing stations within R2R production lines has enabled real-time quality assessment. These systems can detect defects, thickness variations, and performance anomalies during manufacturing, allowing for immediate process adjustments and minimizing waste production.

Energy requirements for OPV manufacturing have decreased substantially through innovations in low-temperature processing techniques. Early manufacturing approaches required high-temperature annealing steps (>150°C), limiting substrate options and increasing energy consumption. Recent developments in solvent additives and post-treatment methods have enabled efficient device fabrication at temperatures below 120°C, expanding compatibility with low-cost flexible substrates while reducing energy inputs.

Environmental Impact and Sustainability Assessment

The environmental impact of organic photovoltaics (OPVs) is intrinsically linked to the mass transfer techniques employed in their production. Traditional silicon-based photovoltaics require energy-intensive manufacturing processes, whereas OPVs offer significantly reduced energy payback times—often less than one year compared to 1-4 years for silicon technologies. This advantage stems largely from the evolution of mass transfer techniques that enable low-temperature processing and reduced material consumption.

Solution-based mass transfer methods such as spin coating, blade coating, and spray coating demonstrate particularly favorable environmental profiles. These techniques operate at ambient or near-ambient temperatures, dramatically reducing energy requirements compared to vacuum-based deposition methods. Life cycle assessments indicate that solution processing can reduce manufacturing energy consumption by up to 90% compared to vacuum thermal evaporation techniques.

Material efficiency has also improved substantially through advanced mass transfer innovations. Roll-to-roll printing techniques have achieved material utilization rates exceeding 95%, compared to approximately 40-60% for earlier vacuum deposition methods. This reduction in material waste directly translates to lower environmental impact, particularly important considering that some OPV materials contain scarce elements or environmentally problematic compounds.

Water consumption represents another critical environmental consideration. Recent developments in green solvent systems for mass transfer have reduced water usage by approximately 70% compared to first-generation OPV manufacturing processes. Aqueous-based nanoparticle dispersions and water-processable interfacial layers have further contributed to reducing dependence on harmful organic solvents like chlorobenzene and dichlorobenzene.

End-of-life management has evolved alongside mass transfer techniques. The latest lamination and encapsulation methods facilitate easier separation of materials at disposal, improving recyclability. Research indicates that up to 90% of materials from modern OPVs can be recovered through appropriate recycling processes, compared to less than 50% for earlier generations.

Carbon footprint analyses demonstrate that current-generation OPVs produced using optimized mass transfer techniques generate approximately 10-25g CO2-equivalent per kWh over their lifetime, compared to 30-80g for silicon photovoltaics. This improvement is largely attributable to ambient processing conditions and reduced material requirements enabled by precision deposition techniques.

Toxicity profiles have also improved significantly. The transition from halogenated solvents to greener alternatives in solution processing has reduced the release of volatile organic compounds by approximately 85%. This shift represents not only an environmental benefit but also improves workplace safety conditions in manufacturing facilities.

Solution-based mass transfer methods such as spin coating, blade coating, and spray coating demonstrate particularly favorable environmental profiles. These techniques operate at ambient or near-ambient temperatures, dramatically reducing energy requirements compared to vacuum-based deposition methods. Life cycle assessments indicate that solution processing can reduce manufacturing energy consumption by up to 90% compared to vacuum thermal evaporation techniques.

Material efficiency has also improved substantially through advanced mass transfer innovations. Roll-to-roll printing techniques have achieved material utilization rates exceeding 95%, compared to approximately 40-60% for earlier vacuum deposition methods. This reduction in material waste directly translates to lower environmental impact, particularly important considering that some OPV materials contain scarce elements or environmentally problematic compounds.

Water consumption represents another critical environmental consideration. Recent developments in green solvent systems for mass transfer have reduced water usage by approximately 70% compared to first-generation OPV manufacturing processes. Aqueous-based nanoparticle dispersions and water-processable interfacial layers have further contributed to reducing dependence on harmful organic solvents like chlorobenzene and dichlorobenzene.

End-of-life management has evolved alongside mass transfer techniques. The latest lamination and encapsulation methods facilitate easier separation of materials at disposal, improving recyclability. Research indicates that up to 90% of materials from modern OPVs can be recovered through appropriate recycling processes, compared to less than 50% for earlier generations.

Carbon footprint analyses demonstrate that current-generation OPVs produced using optimized mass transfer techniques generate approximately 10-25g CO2-equivalent per kWh over their lifetime, compared to 30-80g for silicon photovoltaics. This improvement is largely attributable to ambient processing conditions and reduced material requirements enabled by precision deposition techniques.

Toxicity profiles have also improved significantly. The transition from halogenated solvents to greener alternatives in solution processing has reduced the release of volatile organic compounds by approximately 85%. This shift represents not only an environmental benefit but also improves workplace safety conditions in manufacturing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!