Evaluating Organic Photovoltaics: Regulatory Impact on Cycle Life Strategies

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OPV Technology Background and Objectives

Organic Photovoltaics (OPVs) represent a significant advancement in renewable energy technology, emerging in the early 1990s as a promising alternative to conventional silicon-based solar cells. The evolution of OPV technology has been characterized by steady improvements in efficiency, from less than 1% in early iterations to exceeding 18% in recent laboratory demonstrations, marking a remarkable trajectory of innovation in photovoltaic science.

The fundamental principle of OPVs relies on organic semiconducting materials that convert light into electricity through the photovoltaic effect. Unlike traditional inorganic solar cells, OPVs utilize carbon-based compounds, offering advantages such as flexibility, lightweight properties, and potential for low-cost manufacturing through solution processing techniques. This technological approach aligns with broader sustainability goals by reducing reliance on rare or toxic materials common in conventional photovoltaics.

Recent technological trends in OPV development have focused on enhancing three critical parameters: power conversion efficiency, operational stability, and manufacturing scalability. Innovations in molecular design, interface engineering, and morphology control have contributed significantly to performance improvements. The introduction of non-fullerene acceptors and the development of ternary blend systems represent pivotal breakthroughs that have accelerated efficiency gains in the past decade.

The primary objective of current OPV research centers on addressing the cycle life limitations that have historically restricted commercial viability. Regulatory frameworks increasingly emphasize lifecycle assessment and end-of-life management for renewable energy technologies, creating both challenges and opportunities for OPV development. Understanding how these regulatory requirements impact design strategies for extending operational lifetimes is essential for advancing OPV technology toward widespread adoption.

Another critical goal involves optimizing the balance between efficiency and longevity while maintaining the inherent advantages of OPVs in terms of environmental footprint and production costs. This necessitates a comprehensive approach to materials selection, device architecture, and encapsulation strategies that can withstand environmental stressors while meeting regulatory standards for safety and sustainability.

The technological roadmap for OPVs aims to achieve commercial viability through parallel advancement in performance metrics and manufacturing processes. Transitioning from laboratory-scale fabrication to industrial production represents a significant challenge that requires innovations in coating technologies, quality control methods, and process optimization. The ultimate objective is to position OPVs as a complementary technology within the broader photovoltaic landscape, particularly for applications where conventional solar panels face limitations due to weight, rigidity, or aesthetic considerations.

The fundamental principle of OPVs relies on organic semiconducting materials that convert light into electricity through the photovoltaic effect. Unlike traditional inorganic solar cells, OPVs utilize carbon-based compounds, offering advantages such as flexibility, lightweight properties, and potential for low-cost manufacturing through solution processing techniques. This technological approach aligns with broader sustainability goals by reducing reliance on rare or toxic materials common in conventional photovoltaics.

Recent technological trends in OPV development have focused on enhancing three critical parameters: power conversion efficiency, operational stability, and manufacturing scalability. Innovations in molecular design, interface engineering, and morphology control have contributed significantly to performance improvements. The introduction of non-fullerene acceptors and the development of ternary blend systems represent pivotal breakthroughs that have accelerated efficiency gains in the past decade.

The primary objective of current OPV research centers on addressing the cycle life limitations that have historically restricted commercial viability. Regulatory frameworks increasingly emphasize lifecycle assessment and end-of-life management for renewable energy technologies, creating both challenges and opportunities for OPV development. Understanding how these regulatory requirements impact design strategies for extending operational lifetimes is essential for advancing OPV technology toward widespread adoption.

Another critical goal involves optimizing the balance between efficiency and longevity while maintaining the inherent advantages of OPVs in terms of environmental footprint and production costs. This necessitates a comprehensive approach to materials selection, device architecture, and encapsulation strategies that can withstand environmental stressors while meeting regulatory standards for safety and sustainability.

The technological roadmap for OPVs aims to achieve commercial viability through parallel advancement in performance metrics and manufacturing processes. Transitioning from laboratory-scale fabrication to industrial production represents a significant challenge that requires innovations in coating technologies, quality control methods, and process optimization. The ultimate objective is to position OPVs as a complementary technology within the broader photovoltaic landscape, particularly for applications where conventional solar panels face limitations due to weight, rigidity, or aesthetic considerations.

Market Analysis for Organic Photovoltaics

The global market for organic photovoltaics (OPVs) is experiencing significant growth, driven by increasing demand for renewable energy solutions and advancements in materials science. Current market valuations place the OPV sector at approximately 86 million USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 21.5% through 2030, potentially reaching 370 million USD by the end of the decade.

Key market segments for OPV technology include building-integrated photovoltaics (BIPV), consumer electronics, automotive applications, and portable power solutions. The BIPV segment currently dominates market share at 42%, followed by consumer electronics at 28%. This distribution reflects the unique advantages of OPVs, particularly their flexibility, lightweight properties, and aesthetic versatility.

Regional analysis reveals Europe leading the OPV market with 38% share, followed by North America (31%) and Asia-Pacific (24%). Europe's dominance stems from favorable regulatory frameworks promoting renewable energy adoption and substantial research investments. The Asia-Pacific region, particularly China and South Korea, demonstrates the fastest growth trajectory with increasing manufacturing capabilities and government support programs.

Regulatory environments significantly impact market dynamics across regions. The European Union's Green Deal and carbon neutrality targets have created strong market pull for OPV technologies. Similarly, incentive programs in the United States, including tax credits for renewable energy installations, have stimulated market growth. Conversely, regulatory uncertainties in emerging markets present barriers to widespread adoption.

Consumer demand patterns indicate growing preference for sustainable energy solutions with minimal environmental impact. OPVs benefit from positive consumer perception regarding their eco-friendly manufacturing processes and end-of-life recyclability compared to traditional silicon-based photovoltaics. This perception translates to premium pricing potential in certain market segments, particularly high-end consumer products and architectural applications.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, particularly for specialized polymers and fullerene derivatives. Current production capacity remains limited, with approximately 85% concentrated among five major manufacturers. This concentration presents both risks and opportunities for market entrants.

Market barriers include cost competitiveness challenges against established silicon photovoltaics, performance concerns regarding efficiency and stability, and limited awareness among potential end-users. However, recent technological breakthroughs addressing stability issues and efficiency improvements are gradually mitigating these concerns, expanding potential market applications.

Key market segments for OPV technology include building-integrated photovoltaics (BIPV), consumer electronics, automotive applications, and portable power solutions. The BIPV segment currently dominates market share at 42%, followed by consumer electronics at 28%. This distribution reflects the unique advantages of OPVs, particularly their flexibility, lightweight properties, and aesthetic versatility.

Regional analysis reveals Europe leading the OPV market with 38% share, followed by North America (31%) and Asia-Pacific (24%). Europe's dominance stems from favorable regulatory frameworks promoting renewable energy adoption and substantial research investments. The Asia-Pacific region, particularly China and South Korea, demonstrates the fastest growth trajectory with increasing manufacturing capabilities and government support programs.

Regulatory environments significantly impact market dynamics across regions. The European Union's Green Deal and carbon neutrality targets have created strong market pull for OPV technologies. Similarly, incentive programs in the United States, including tax credits for renewable energy installations, have stimulated market growth. Conversely, regulatory uncertainties in emerging markets present barriers to widespread adoption.

Consumer demand patterns indicate growing preference for sustainable energy solutions with minimal environmental impact. OPVs benefit from positive consumer perception regarding their eco-friendly manufacturing processes and end-of-life recyclability compared to traditional silicon-based photovoltaics. This perception translates to premium pricing potential in certain market segments, particularly high-end consumer products and architectural applications.

Supply chain analysis reveals potential vulnerabilities in raw material sourcing, particularly for specialized polymers and fullerene derivatives. Current production capacity remains limited, with approximately 85% concentrated among five major manufacturers. This concentration presents both risks and opportunities for market entrants.

Market barriers include cost competitiveness challenges against established silicon photovoltaics, performance concerns regarding efficiency and stability, and limited awareness among potential end-users. However, recent technological breakthroughs addressing stability issues and efficiency improvements are gradually mitigating these concerns, expanding potential market applications.

Technical Challenges and Global Development Status

Organic Photovoltaics (OPVs) currently face significant technical challenges that limit their widespread commercial adoption despite their promising advantages. The primary obstacle remains their relatively low power conversion efficiency (PCE), which typically ranges between 10-17% for laboratory devices, substantially lower than silicon-based photovoltaics that achieve 20-26% efficiency in commercial applications. This efficiency gap represents a critical barrier to market competitiveness.

Stability and degradation issues constitute another major technical hurdle. OPVs demonstrate accelerated degradation when exposed to oxygen, moisture, and UV radiation, resulting in significantly shorter operational lifetimes compared to inorganic alternatives. Current OPV technologies typically maintain optimal performance for 5-7 years, whereas silicon-based systems routinely operate effectively for 25+ years, creating a substantial disparity in lifecycle value.

Manufacturing scalability presents ongoing challenges, with laboratory techniques often proving difficult to translate to mass production environments without compromising device performance. The transition from spin-coating processes used in research settings to roll-to-roll manufacturing introduces quality control issues and performance variability that must be addressed for commercial viability.

Globally, OPV development demonstrates distinct regional characteristics. Europe leads in fundamental research and regulatory framework development, with Germany, Switzerland, and the UK hosting prominent research institutions focused on improving OPV efficiency and stability. The European Union has established comprehensive regulatory guidelines addressing the environmental impact and end-of-life management of photovoltaic technologies.

The Asia-Pacific region, particularly China, Japan, and South Korea, dominates in manufacturing capacity and applied research. China has made substantial investments in OPV production infrastructure, while maintaining less stringent regulatory requirements regarding lifecycle management compared to European standards.

North America contributes significantly to innovation through university-corporate partnerships, with the United States focusing on next-generation materials and novel device architectures. However, regulatory approaches vary considerably across states, creating a fragmented landscape for manufacturers.

Emerging economies in Africa and South America represent growing markets for OPV technology, particularly for off-grid applications, though local manufacturing capabilities remain limited. These regions typically adopt regulatory frameworks modeled after established markets rather than developing indigenous standards.

The regulatory landscape significantly impacts OPV development trajectories, with stricter environmental regulations in Europe driving research toward environmentally benign materials and recyclable designs, while less regulated markets often prioritize cost reduction and immediate performance metrics over lifecycle considerations.

Stability and degradation issues constitute another major technical hurdle. OPVs demonstrate accelerated degradation when exposed to oxygen, moisture, and UV radiation, resulting in significantly shorter operational lifetimes compared to inorganic alternatives. Current OPV technologies typically maintain optimal performance for 5-7 years, whereas silicon-based systems routinely operate effectively for 25+ years, creating a substantial disparity in lifecycle value.

Manufacturing scalability presents ongoing challenges, with laboratory techniques often proving difficult to translate to mass production environments without compromising device performance. The transition from spin-coating processes used in research settings to roll-to-roll manufacturing introduces quality control issues and performance variability that must be addressed for commercial viability.

Globally, OPV development demonstrates distinct regional characteristics. Europe leads in fundamental research and regulatory framework development, with Germany, Switzerland, and the UK hosting prominent research institutions focused on improving OPV efficiency and stability. The European Union has established comprehensive regulatory guidelines addressing the environmental impact and end-of-life management of photovoltaic technologies.

The Asia-Pacific region, particularly China, Japan, and South Korea, dominates in manufacturing capacity and applied research. China has made substantial investments in OPV production infrastructure, while maintaining less stringent regulatory requirements regarding lifecycle management compared to European standards.

North America contributes significantly to innovation through university-corporate partnerships, with the United States focusing on next-generation materials and novel device architectures. However, regulatory approaches vary considerably across states, creating a fragmented landscape for manufacturers.

Emerging economies in Africa and South America represent growing markets for OPV technology, particularly for off-grid applications, though local manufacturing capabilities remain limited. These regions typically adopt regulatory frameworks modeled after established markets rather than developing indigenous standards.

The regulatory landscape significantly impacts OPV development trajectories, with stricter environmental regulations in Europe driving research toward environmentally benign materials and recyclable designs, while less regulated markets often prioritize cost reduction and immediate performance metrics over lifecycle considerations.

Current Cycle Life Enhancement Solutions

01 Materials for extending organic photovoltaic cycle life

Various materials can be incorporated into organic photovoltaics to extend their operational lifetime. These include specialized polymers, fullerene derivatives, and encapsulation materials that protect against environmental degradation. The selection of appropriate donor and acceptor materials with enhanced stability under UV exposure and thermal cycling can significantly improve the cycle life of organic photovoltaic devices.- Materials for extending organic photovoltaic cycle life: Various materials can be incorporated into organic photovoltaics to extend their operational lifetime. These include specialized polymers, fullerene derivatives, and encapsulation materials that protect against degradation factors such as oxygen and moisture. The selection of appropriate donor-acceptor materials with enhanced stability can significantly improve the cycle life of organic solar cells while maintaining power conversion efficiency.

- Encapsulation techniques for improved durability: Advanced encapsulation methods play a crucial role in protecting organic photovoltaic devices from environmental factors that accelerate degradation. Multi-layer barrier films, edge sealing technologies, and flexible encapsulation systems can effectively prevent oxygen and moisture ingress. These techniques significantly extend the operational lifetime of organic solar cells by maintaining the integrity of the active materials and interfaces within the device structure.

- Testing and prediction methods for cycle life assessment: Accelerated aging protocols and predictive modeling approaches have been developed to evaluate and forecast the cycle life of organic photovoltaic devices. These methods include controlled exposure to light, temperature, and humidity conditions to simulate real-world degradation. Machine learning algorithms and data analytics are employed to analyze degradation patterns and predict long-term performance, enabling more accurate lifetime estimations without requiring years of testing.

- Interface engineering for stability enhancement: The interfaces between different layers in organic photovoltaic devices are critical points where degradation often begins. Engineering these interfaces through the use of buffer layers, selective contacts, and interfacial modifiers can significantly improve device stability. Techniques such as incorporating transition metal oxides, self-assembled monolayers, or cross-linkable interlayers help maintain electrical properties and prevent delamination over extended operational periods.

- Morphology control for long-term performance: The morphological stability of the active layer blend is crucial for maintaining performance over the lifetime of organic photovoltaic devices. Techniques to control and stabilize the nanoscale morphology include thermal annealing, solvent additives, and cross-linking strategies. Preventing phase separation and crystallization during operation helps maintain the optimal donor-acceptor network structure, preserving charge generation and extraction pathways throughout the device's operational life.

02 Encapsulation techniques for improved durability

Advanced encapsulation methods play a crucial role in protecting organic photovoltaic cells from moisture, oxygen, and other environmental factors that accelerate degradation. Multi-layer barrier films, edge sealing technologies, and flexible encapsulation systems can effectively extend the operational lifetime of organic photovoltaics by preventing the ingress of degradation agents while maintaining device flexibility and performance.Expand Specific Solutions03 Testing and prediction methods for cycle life assessment

Accelerated aging protocols and predictive modeling techniques are essential for evaluating the long-term stability of organic photovoltaics. These methods include thermal cycling tests, light soaking experiments, and computational models that can predict degradation pathways. Advanced analytics and machine learning approaches help correlate accelerated test results with real-world performance, enabling more accurate lifetime predictions for organic photovoltaic technologies.Expand Specific Solutions04 Interface engineering for stability enhancement

The interfaces between different layers in organic photovoltaic devices are critical points of failure that affect cycle life. Engineering these interfaces through buffer layers, self-assembled monolayers, and gradient heterojunctions can significantly improve device stability. Techniques such as crosslinking, surface modification, and the introduction of interfacial dipoles help prevent delamination and reduce degradation mechanisms at these critical boundaries.Expand Specific Solutions05 Operational strategies for maximizing service life

Implementing intelligent operational strategies can extend the functional lifetime of organic photovoltaic systems. These include maximum power point tracking algorithms optimized for degradation minimization, load management systems that reduce stress during adverse conditions, and adaptive control systems that modify operating parameters based on environmental conditions. Periodic recovery cycles and stress-minimizing operational protocols can significantly enhance the overall cycle life of organic photovoltaic installations.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The organic photovoltaics (OPV) market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. Market size remains relatively small compared to traditional photovoltaics, estimated at under $50 million globally, but with projected annual growth rates exceeding 20%. Technologically, OPVs are still evolving toward commercial maturity, with key players demonstrating varying levels of advancement. Companies like Sumitomo Chemical, LG Chem, and Merck Patent GmbH lead in materials development, while Dracula Technologies has pioneered indoor light harvesting solutions. Research institutions including CNRS, University of Michigan, and Korea Research Institute of Chemical Technology are advancing fundamental science, while energy giants such as TotalEnergies, Électricité de France, and State Grid Corporation of China are exploring integration possibilities. Regulatory frameworks significantly impact cycle life strategies, with companies focusing on sustainability metrics to meet emerging standards.

Sumitomo Chemical Co., Ltd.

Technical Solution: Sumitomo Chemical has developed a comprehensive approach to organic photovoltaics with particular emphasis on regulatory compliance and extended cycle life. Their technology platform incorporates specially engineered polymer semiconductors with optimized molecular structures that resist photo-oxidation, a primary degradation mechanism in OPVs. Sumitomo's materials feature a proprietary bulk heterojunction architecture that maintains morphological stability under thermal cycling, significantly enhancing operational lifespan. Their manufacturing process implements stringent quality control measures that comply with both Japanese Industrial Standards (JIS) and international IEC standards for photovoltaic modules. Sumitomo has pioneered advanced encapsulation technologies using multi-layer barrier films that achieve water vapor transmission rates below 10^-6 g/m²/day, effectively preventing moisture ingress. Their lifecycle management approach includes comprehensive material safety assessments and end-of-life recycling protocols that address emerging global regulations on electronic waste management.

Strengths: Extensive experience in polymer chemistry and materials science provides advantages in developing stable organic semiconductors. Established global supply chain and manufacturing capabilities enable consistent quality and scale. Weaknesses: Higher material costs compared to some competitors and relatively slower technology commercialization timeline due to rigorous testing protocols.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a comprehensive approach to organic photovoltaics focusing on regulatory-compliant cycle life enhancement. Their technology incorporates multi-layer encapsulation systems specifically designed to prevent oxygen and moisture ingress, the primary degradation factors in OPVs. LG's proprietary active layer formulations utilize specially engineered donor-acceptor polymer systems with improved photo-stability. Their manufacturing process implements strict quality control measures that comply with international standards including IEC 61215 for photovoltaic module durability. LG Chem has developed accelerated testing protocols that simulate various environmental stressors to predict real-world performance over 10+ years of operation. Their latest generation OPVs maintain over 80% of initial efficiency after 2000 hours of damp heat testing (85°C/85% relative humidity), representing a significant advancement in organic photovoltaic stability.

Strengths: Extensive manufacturing infrastructure allows for rapid scaling of production and consistent quality control. Strong integration with other LG energy products creates synergistic market opportunities. Weaknesses: Higher initial investment costs compared to some competitors and relatively lower efficiency rates in low-light conditions compared to some specialized OPV technologies.

Critical Patents and Research in OPV Stability

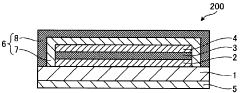

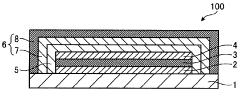

Organic photoelectric conversion element

PatentWO2011052573A1

Innovation

- A barrier layer comprising an inorganic layer and an organic layer, with both layers capable of blocking ultraviolet rays, is integrated into the organic photoelectric conversion element to protect it from oxygen, water, and ultraviolet radiation, improving its lifespan and manufacturing efficiency.

Regulatory Framework Impact on OPV Development

The regulatory landscape surrounding organic photovoltaics (OPVs) has evolved significantly over the past decade, creating both challenges and opportunities for technology development. Environmental regulations, particularly those focused on hazardous substances and end-of-life management, have become increasingly stringent across major markets including the EU, North America, and Asia. The EU's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations have placed limitations on certain materials traditionally used in OPV manufacturing, necessitating research into alternative compounds.

Energy certification frameworks have also shaped OPV development trajectories, with standards such as IEC 61215 and IEC 61730 establishing performance and safety benchmarks. These standards, while initially developed for traditional photovoltaics, have been adapted for emerging technologies like OPVs, creating regulatory hurdles that developers must overcome to achieve market acceptance. The certification process often requires extensive cycle life testing under various environmental conditions, directly influencing product design decisions.

Carbon footprint regulations and sustainability requirements have emerged as significant drivers for OPV innovation. The EU's Carbon Border Adjustment Mechanism (CBAM) and similar policies worldwide are creating market advantages for technologies with demonstrably lower environmental impacts. OPVs, with their potential for reduced embodied energy compared to silicon-based alternatives, stand to benefit from these regulatory trends if manufacturers can document and verify their sustainability claims throughout the product lifecycle.

Waste management directives, particularly the Waste Electrical and Electronic Equipment (WEEE) directive in Europe, have placed increased responsibility on manufacturers for end-of-life product management. These regulations have accelerated research into recyclable and biodegradable OPV components, shifting design priorities toward materials and architectures that facilitate disassembly and recovery of valuable materials. The regulatory emphasis on circular economy principles has catalyzed innovation in degradable substrates and encapsulants.

Regional variations in regulatory frameworks create complex compliance challenges for global OPV manufacturers. China's rapid implementation of photovoltaic manufacturing standards, Japan's focus on durability requirements for extreme weather conditions, and California's aggressive renewable energy mandates represent distinct regulatory environments that influence product development strategies. Companies must navigate these diverse requirements while maintaining cost-competitiveness, often leading to modular design approaches that can be adapted to different market requirements.

Energy certification frameworks have also shaped OPV development trajectories, with standards such as IEC 61215 and IEC 61730 establishing performance and safety benchmarks. These standards, while initially developed for traditional photovoltaics, have been adapted for emerging technologies like OPVs, creating regulatory hurdles that developers must overcome to achieve market acceptance. The certification process often requires extensive cycle life testing under various environmental conditions, directly influencing product design decisions.

Carbon footprint regulations and sustainability requirements have emerged as significant drivers for OPV innovation. The EU's Carbon Border Adjustment Mechanism (CBAM) and similar policies worldwide are creating market advantages for technologies with demonstrably lower environmental impacts. OPVs, with their potential for reduced embodied energy compared to silicon-based alternatives, stand to benefit from these regulatory trends if manufacturers can document and verify their sustainability claims throughout the product lifecycle.

Waste management directives, particularly the Waste Electrical and Electronic Equipment (WEEE) directive in Europe, have placed increased responsibility on manufacturers for end-of-life product management. These regulations have accelerated research into recyclable and biodegradable OPV components, shifting design priorities toward materials and architectures that facilitate disassembly and recovery of valuable materials. The regulatory emphasis on circular economy principles has catalyzed innovation in degradable substrates and encapsulants.

Regional variations in regulatory frameworks create complex compliance challenges for global OPV manufacturers. China's rapid implementation of photovoltaic manufacturing standards, Japan's focus on durability requirements for extreme weather conditions, and California's aggressive renewable energy mandates represent distinct regulatory environments that influence product development strategies. Companies must navigate these diverse requirements while maintaining cost-competitiveness, often leading to modular design approaches that can be adapted to different market requirements.

Environmental Sustainability and End-of-Life Management

The environmental impact of organic photovoltaics (OPVs) extends beyond their operational phase to encompass their entire lifecycle, particularly their end-of-life management. As regulatory frameworks evolve globally, manufacturers and stakeholders must adapt their cycle life strategies to ensure compliance while maximizing sustainability benefits.

Current regulations affecting OPVs vary significantly across regions, with the European Union leading through its Waste Electrical and Electronic Equipment (WEEE) Directive, which mandates collection and recycling targets for photovoltaic panels. The EU's Restriction of Hazardous Substances (RoHS) Directive further limits the use of certain hazardous materials in electronic equipment, directly impacting OPV manufacturing processes and material selection.

In contrast, regulatory frameworks in North America and Asia remain less stringent, creating a fragmented global landscape that complicates international deployment and end-of-life management strategies for OPV manufacturers. This regulatory divergence necessitates adaptable cycle life approaches that can accommodate varying requirements across markets.

The biodegradability of organic materials in OPVs presents both opportunities and challenges for end-of-life management. While these materials potentially offer reduced environmental impact compared to conventional silicon-based photovoltaics, their degradation pathways must be carefully controlled to prevent leaching of potentially harmful substances into ecosystems. Recent research indicates that controlled biodegradation under specific conditions could be incorporated into cycle life strategies, potentially reducing recycling costs.

Recycling technologies for OPVs are advancing rapidly, with solvent-based separation techniques showing promise for recovering valuable organic semiconductors and electrode materials. However, the economic viability of these processes remains challenging due to the relatively low concentration of high-value materials compared to traditional photovoltaics. Regulatory incentives could significantly influence the development and adoption of these recycling technologies.

Extended Producer Responsibility (EPR) schemes are increasingly being implemented worldwide, shifting the burden of waste management from consumers to manufacturers. For OPV producers, this trend necessitates proactive design for recyclability and the establishment of take-back programs. Companies that integrate these considerations into their cycle life strategies gain competitive advantages in markets with stringent EPR requirements.

Carbon footprint assessments reveal that end-of-life management can contribute significantly to the overall environmental impact of OPVs. Life Cycle Assessment (LCA) studies suggest that optimized recycling processes could reduce the carbon footprint of OPVs by 15-30%, highlighting the importance of integrating environmental considerations into cycle life planning from the design phase onward.

Current regulations affecting OPVs vary significantly across regions, with the European Union leading through its Waste Electrical and Electronic Equipment (WEEE) Directive, which mandates collection and recycling targets for photovoltaic panels. The EU's Restriction of Hazardous Substances (RoHS) Directive further limits the use of certain hazardous materials in electronic equipment, directly impacting OPV manufacturing processes and material selection.

In contrast, regulatory frameworks in North America and Asia remain less stringent, creating a fragmented global landscape that complicates international deployment and end-of-life management strategies for OPV manufacturers. This regulatory divergence necessitates adaptable cycle life approaches that can accommodate varying requirements across markets.

The biodegradability of organic materials in OPVs presents both opportunities and challenges for end-of-life management. While these materials potentially offer reduced environmental impact compared to conventional silicon-based photovoltaics, their degradation pathways must be carefully controlled to prevent leaching of potentially harmful substances into ecosystems. Recent research indicates that controlled biodegradation under specific conditions could be incorporated into cycle life strategies, potentially reducing recycling costs.

Recycling technologies for OPVs are advancing rapidly, with solvent-based separation techniques showing promise for recovering valuable organic semiconductors and electrode materials. However, the economic viability of these processes remains challenging due to the relatively low concentration of high-value materials compared to traditional photovoltaics. Regulatory incentives could significantly influence the development and adoption of these recycling technologies.

Extended Producer Responsibility (EPR) schemes are increasingly being implemented worldwide, shifting the burden of waste management from consumers to manufacturers. For OPV producers, this trend necessitates proactive design for recyclability and the establishment of take-back programs. Companies that integrate these considerations into their cycle life strategies gain competitive advantages in markets with stringent EPR requirements.

Carbon footprint assessments reveal that end-of-life management can contribute significantly to the overall environmental impact of OPVs. Life Cycle Assessment (LCA) studies suggest that optimized recycling processes could reduce the carbon footprint of OPVs by 15-30%, highlighting the importance of integrating environmental considerations into cycle life planning from the design phase onward.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!