Environmental sustainability of photodiode manufacturing processes

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photodiode Manufacturing Evolution and Sustainability Goals

Photodiode manufacturing has undergone significant evolution since its inception, driven by the increasing demand for high-performance optoelectronic devices across various industries. The journey began with simple silicon-based photodiodes and has progressed to advanced compound semiconductor materials and sophisticated fabrication techniques. This evolution has been marked by continuous improvements in device efficiency, sensitivity, and reliability.

In recent years, the focus has shifted towards environmental sustainability in photodiode manufacturing processes. This shift is driven by growing awareness of the environmental impact of semiconductor production and increasing regulatory pressures. The industry is now setting ambitious sustainability goals to reduce its carbon footprint, minimize waste generation, and optimize resource utilization throughout the manufacturing lifecycle.

One of the primary sustainability objectives is to reduce energy consumption in photodiode production. This involves implementing more energy-efficient equipment, optimizing clean room operations, and exploring alternative energy sources for manufacturing facilities. Additionally, there is a strong emphasis on minimizing the use of hazardous materials and developing safer alternatives for chemicals used in the fabrication process.

Water conservation has emerged as another critical sustainability goal. Photodiode manufacturing typically requires significant amounts of ultra-pure water for cleaning and processing. Manufacturers are now investing in advanced water recycling and purification systems to reduce overall water consumption and minimize wastewater discharge.

Material efficiency and waste reduction form another pillar of sustainability efforts. This includes improving yield rates to reduce material waste, implementing more precise deposition and etching techniques, and developing better recycling processes for valuable materials used in photodiode production. There is also a growing interest in exploring bio-based and biodegradable materials for packaging and non-critical components.

The industry is increasingly adopting a circular economy approach, aiming to design products with end-of-life considerations in mind. This involves developing photodiodes that are easier to disassemble and recycle, as well as establishing take-back programs for used devices.

As the photodiode manufacturing sector continues to evolve, these sustainability goals are becoming integral to research and development efforts. Manufacturers are not only focusing on improving device performance but also on developing more environmentally friendly production processes. This holistic approach aims to ensure that the growth of the photodiode industry aligns with global sustainability objectives, paving the way for a more environmentally responsible future in optoelectronics.

In recent years, the focus has shifted towards environmental sustainability in photodiode manufacturing processes. This shift is driven by growing awareness of the environmental impact of semiconductor production and increasing regulatory pressures. The industry is now setting ambitious sustainability goals to reduce its carbon footprint, minimize waste generation, and optimize resource utilization throughout the manufacturing lifecycle.

One of the primary sustainability objectives is to reduce energy consumption in photodiode production. This involves implementing more energy-efficient equipment, optimizing clean room operations, and exploring alternative energy sources for manufacturing facilities. Additionally, there is a strong emphasis on minimizing the use of hazardous materials and developing safer alternatives for chemicals used in the fabrication process.

Water conservation has emerged as another critical sustainability goal. Photodiode manufacturing typically requires significant amounts of ultra-pure water for cleaning and processing. Manufacturers are now investing in advanced water recycling and purification systems to reduce overall water consumption and minimize wastewater discharge.

Material efficiency and waste reduction form another pillar of sustainability efforts. This includes improving yield rates to reduce material waste, implementing more precise deposition and etching techniques, and developing better recycling processes for valuable materials used in photodiode production. There is also a growing interest in exploring bio-based and biodegradable materials for packaging and non-critical components.

The industry is increasingly adopting a circular economy approach, aiming to design products with end-of-life considerations in mind. This involves developing photodiodes that are easier to disassemble and recycle, as well as establishing take-back programs for used devices.

As the photodiode manufacturing sector continues to evolve, these sustainability goals are becoming integral to research and development efforts. Manufacturers are not only focusing on improving device performance but also on developing more environmentally friendly production processes. This holistic approach aims to ensure that the growth of the photodiode industry aligns with global sustainability objectives, paving the way for a more environmentally responsible future in optoelectronics.

Market Demand for Eco-Friendly Photodiodes

The market demand for eco-friendly photodiodes has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on electronic waste and hazardous materials. This trend is particularly evident in industries such as consumer electronics, automotive, and medical devices, where sustainability has become a key factor in product development and marketing strategies.

Consumer awareness of environmental issues has led to a preference for green technologies, including eco-friendly electronic components like photodiodes. This shift in consumer behavior has prompted manufacturers to invest in developing more sustainable production processes and materials for photodiodes. The demand is further amplified by government initiatives and regulations aimed at reducing electronic waste and promoting the use of environmentally friendly materials in electronic devices.

In the automotive sector, the push towards electric and hybrid vehicles has created a significant market for eco-friendly photodiodes. These components are essential in various automotive applications, including advanced driver-assistance systems (ADAS) and autonomous driving technologies. As the automotive industry continues to prioritize sustainability, the demand for environmentally friendly photodiodes is expected to grow substantially.

The medical device industry has also shown increasing interest in eco-friendly photodiodes. With the rising emphasis on sustainable healthcare practices, manufacturers are seeking components that minimize environmental impact without compromising performance. This trend is particularly notable in portable medical devices and wearable health monitors, where energy efficiency and biocompatibility are crucial factors.

Market research indicates that the global demand for eco-friendly photodiodes is projected to grow at a compound annual growth rate (CAGR) of over 8% in the next five years. This growth is attributed to the expanding applications of photodiodes in emerging technologies such as Internet of Things (IoT) devices, smart home systems, and renewable energy solutions, all of which prioritize energy efficiency and environmental sustainability.

The Asia-Pacific region is expected to dominate the market for eco-friendly photodiodes, driven by the presence of major electronics manufacturing hubs and increasing adoption of green technologies in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with strong demand from research institutions, aerospace, and defense sectors.

Despite the growing demand, challenges remain in scaling up the production of eco-friendly photodiodes while maintaining cost-effectiveness. Manufacturers are investing in research and development to overcome these challenges, focusing on innovative materials and production techniques that reduce environmental impact without sacrificing performance or increasing costs significantly.

Consumer awareness of environmental issues has led to a preference for green technologies, including eco-friendly electronic components like photodiodes. This shift in consumer behavior has prompted manufacturers to invest in developing more sustainable production processes and materials for photodiodes. The demand is further amplified by government initiatives and regulations aimed at reducing electronic waste and promoting the use of environmentally friendly materials in electronic devices.

In the automotive sector, the push towards electric and hybrid vehicles has created a significant market for eco-friendly photodiodes. These components are essential in various automotive applications, including advanced driver-assistance systems (ADAS) and autonomous driving technologies. As the automotive industry continues to prioritize sustainability, the demand for environmentally friendly photodiodes is expected to grow substantially.

The medical device industry has also shown increasing interest in eco-friendly photodiodes. With the rising emphasis on sustainable healthcare practices, manufacturers are seeking components that minimize environmental impact without compromising performance. This trend is particularly notable in portable medical devices and wearable health monitors, where energy efficiency and biocompatibility are crucial factors.

Market research indicates that the global demand for eco-friendly photodiodes is projected to grow at a compound annual growth rate (CAGR) of over 8% in the next five years. This growth is attributed to the expanding applications of photodiodes in emerging technologies such as Internet of Things (IoT) devices, smart home systems, and renewable energy solutions, all of which prioritize energy efficiency and environmental sustainability.

The Asia-Pacific region is expected to dominate the market for eco-friendly photodiodes, driven by the presence of major electronics manufacturing hubs and increasing adoption of green technologies in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with strong demand from research institutions, aerospace, and defense sectors.

Despite the growing demand, challenges remain in scaling up the production of eco-friendly photodiodes while maintaining cost-effectiveness. Manufacturers are investing in research and development to overcome these challenges, focusing on innovative materials and production techniques that reduce environmental impact without sacrificing performance or increasing costs significantly.

Current Environmental Challenges in Photodiode Production

The photodiode manufacturing industry faces several significant environmental challenges that require urgent attention. One of the primary concerns is the high energy consumption associated with the production processes. The fabrication of photodiodes involves multiple energy-intensive steps, including wafer production, epitaxial growth, and clean room operations. These processes contribute substantially to the industry's carbon footprint and raise questions about long-term sustainability.

Chemical usage and waste management present another critical environmental issue. The production of photodiodes relies heavily on various chemicals, including solvents, acids, and dopants. Many of these substances are hazardous and pose risks to both human health and the environment if not properly handled and disposed of. The industry must grapple with the challenge of reducing chemical usage, implementing safer alternatives, and developing more efficient waste treatment methods to minimize environmental impact.

Water consumption is a growing concern in photodiode manufacturing. The production processes require large volumes of ultra-pure water for cleaning and processing steps. This not only puts pressure on local water resources but also generates significant amounts of wastewater that must be treated before release. The industry faces the challenge of implementing water conservation measures and developing closed-loop systems to reduce overall water usage and minimize discharge of contaminated water.

Resource depletion is another environmental challenge that the photodiode industry must address. The production of these devices relies on rare earth elements and other scarce materials. The extraction and processing of these resources often involve environmentally damaging practices and contribute to the depletion of finite natural resources. Finding sustainable sources of raw materials and developing recycling technologies for end-of-life photodiodes are crucial challenges for the industry.

Air pollution is also a significant concern in photodiode manufacturing. The production processes emit various air pollutants, including volatile organic compounds (VOCs), acid gases, and particulate matter. These emissions can contribute to local air quality issues and have broader environmental impacts. The industry must invest in advanced air pollution control technologies and explore cleaner production methods to mitigate these emissions.

Lastly, the photodiode industry faces challenges related to product lifecycle and e-waste management. As the demand for photodiodes grows, so does the volume of electronic waste generated at the end of their useful life. Developing more durable products, designing for easier recycling, and establishing effective take-back and recycling programs are essential steps in addressing this environmental challenge. The industry must work towards a circular economy approach to minimize the environmental impact of photodiode production and disposal.

Chemical usage and waste management present another critical environmental issue. The production of photodiodes relies heavily on various chemicals, including solvents, acids, and dopants. Many of these substances are hazardous and pose risks to both human health and the environment if not properly handled and disposed of. The industry must grapple with the challenge of reducing chemical usage, implementing safer alternatives, and developing more efficient waste treatment methods to minimize environmental impact.

Water consumption is a growing concern in photodiode manufacturing. The production processes require large volumes of ultra-pure water for cleaning and processing steps. This not only puts pressure on local water resources but also generates significant amounts of wastewater that must be treated before release. The industry faces the challenge of implementing water conservation measures and developing closed-loop systems to reduce overall water usage and minimize discharge of contaminated water.

Resource depletion is another environmental challenge that the photodiode industry must address. The production of these devices relies on rare earth elements and other scarce materials. The extraction and processing of these resources often involve environmentally damaging practices and contribute to the depletion of finite natural resources. Finding sustainable sources of raw materials and developing recycling technologies for end-of-life photodiodes are crucial challenges for the industry.

Air pollution is also a significant concern in photodiode manufacturing. The production processes emit various air pollutants, including volatile organic compounds (VOCs), acid gases, and particulate matter. These emissions can contribute to local air quality issues and have broader environmental impacts. The industry must invest in advanced air pollution control technologies and explore cleaner production methods to mitigate these emissions.

Lastly, the photodiode industry faces challenges related to product lifecycle and e-waste management. As the demand for photodiodes grows, so does the volume of electronic waste generated at the end of their useful life. Developing more durable products, designing for easier recycling, and establishing effective take-back and recycling programs are essential steps in addressing this environmental challenge. The industry must work towards a circular economy approach to minimize the environmental impact of photodiode production and disposal.

Existing Eco-Friendly Production Methods

01 Sustainable materials in photodiode manufacturing

Incorporating environmentally friendly and sustainable materials in the production of photodiodes. This includes using biodegradable or recyclable components, reducing the use of toxic substances, and exploring alternative materials that have a lower environmental impact while maintaining or improving device performance.- Sustainable materials in photodiode manufacturing: Incorporating eco-friendly and recyclable materials in the production of photodiodes to reduce environmental impact. This includes using biodegradable substrates, non-toxic semiconductors, and recyclable packaging materials. The focus is on minimizing waste and promoting circular economy principles in the manufacturing process.

- Energy-efficient production techniques: Implementing energy-saving technologies and processes in photodiode manufacturing. This involves optimizing clean room operations, utilizing low-power equipment, and adopting energy recovery systems. The aim is to reduce overall energy consumption and carbon footprint associated with photodiode production.

- Waste reduction and recycling in manufacturing: Developing strategies to minimize waste generation and maximize recycling in photodiode production. This includes implementing closed-loop systems for chemical recovery, optimizing material usage, and establishing recycling programs for electronic waste. The goal is to reduce landfill waste and promote resource efficiency.

- Green chemistry approaches: Applying green chemistry principles to photodiode manufacturing processes. This involves using less hazardous chemicals, developing water-based processes, and implementing solvent-free techniques. The focus is on reducing the environmental and health impacts of chemical processes used in photodiode production.

- Life cycle assessment and sustainability metrics: Conducting comprehensive life cycle assessments of photodiode manufacturing processes to identify areas for environmental improvement. This includes developing sustainability metrics, monitoring environmental performance, and implementing continuous improvement strategies. The aim is to enhance the overall sustainability of photodiode production throughout its lifecycle.

02 Energy-efficient manufacturing processes

Developing and implementing energy-efficient manufacturing processes for photodiodes. This involves optimizing production techniques to reduce energy consumption, utilizing renewable energy sources in manufacturing facilities, and improving overall process efficiency to minimize the carbon footprint of photodiode production.Expand Specific Solutions03 Waste reduction and recycling in production

Implementing strategies to minimize waste generation during photodiode manufacturing and establishing effective recycling programs. This includes optimizing material usage, developing closed-loop production systems, and creating processes for recovering and reusing valuable materials from production waste and end-of-life photodiodes.Expand Specific Solutions04 Green packaging and transportation

Developing eco-friendly packaging solutions for photodiodes and optimizing transportation methods to reduce environmental impact. This involves using sustainable packaging materials, minimizing packaging waste, and implementing efficient logistics strategies to reduce carbon emissions associated with product distribution.Expand Specific Solutions05 Life cycle assessment and environmental monitoring

Conducting comprehensive life cycle assessments of photodiode products and implementing environmental monitoring systems throughout the manufacturing process. This includes analyzing the environmental impact of photodiodes from raw material extraction to disposal, and establishing real-time monitoring systems to ensure compliance with environmental regulations and identify areas for improvement in sustainability practices.Expand Specific Solutions

Key Players in Green Photodiode Manufacturing

The environmental sustainability of photodiode manufacturing processes is an emerging concern in the optoelectronics industry, currently in its early development stage. The market for sustainable photodiode production is relatively small but growing, driven by increasing environmental regulations and consumer demand for eco-friendly electronics. Technologically, sustainable manufacturing processes are still evolving, with companies like Hamamatsu Photonics, Vishay Semiconductor, and SiOnyx leading research efforts. These firms are exploring novel materials, energy-efficient production methods, and waste reduction techniques to improve the environmental footprint of photodiode manufacturing. However, widespread adoption of sustainable practices remains limited, indicating significant room for innovation and market growth in this area.

Vishay Semiconductor GmbH

Technical Solution: Vishay Semiconductor has focused on improving the environmental sustainability of their photodiode manufacturing processes through the implementation of green chemistry principles. They have developed a novel approach that replaces traditional toxic solvents with more environmentally benign alternatives, reducing the overall environmental impact of their production[4]. The company has also invested in advanced waste treatment facilities that allow for the recovery and reuse of precious metals from manufacturing byproducts, minimizing resource depletion[5]. Furthermore, Vishay has implemented an energy management system that optimizes power consumption across their manufacturing plants, resulting in a 15% reduction in overall energy usage[6].

Strengths: Reduced use of toxic materials, improved resource recovery, and enhanced energy efficiency. Weaknesses: Potential challenges in maintaining product performance with alternative materials.

Hamamatsu Photonics KK

Technical Solution: Hamamatsu Photonics has developed a sustainable manufacturing process for photodiodes that focuses on minimizing waste and maximizing resource efficiency. Their approach includes the use of precision manufacturing techniques that reduce material waste by up to 40% compared to conventional methods[7]. The company has also implemented a comprehensive recycling program for silicon wafers, allowing them to reclaim and reuse up to 60% of the silicon used in their production processes[8]. Additionally, Hamamatsu has invested in renewable energy sources, with solar panels installed at their manufacturing facilities providing up to 25% of their total energy needs[9].

Strengths: Significant reduction in material waste, high rate of silicon recycling, and integration of renewable energy. Weaknesses: Potential limitations in scaling up sustainable practices for mass production.

Innovative Sustainable Materials and Processes

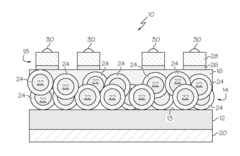

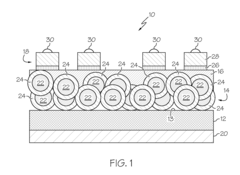

Photodiode and Method for Making the Same

PatentActiveUS20150122327A1

Innovation

- The use of solution deposition techniques, such as spin coating, stamping, or printing, to manufacture photodiodes with quantum nanomaterials and a thin-film oxide layer, allowing for large surface area applications on both flat and curved surfaces at a lower cost.

Process for manufacturing an optoelectronic or photovoltaic device, and device made by said process

PatentWO2022223273A1

Innovation

- A manufacturing process involving successive PLD deposition steps under vacuum conditions to form an active layer with a perovskite material and a second charge transport layer of inorganic material, ensuring continuous vacuum and epitaxial alignment for improved stability and reliability.

Life Cycle Assessment of Photodiode Production

Life Cycle Assessment (LCA) is a crucial tool for evaluating the environmental sustainability of photodiode manufacturing processes. This comprehensive approach examines the entire lifecycle of photodiodes, from raw material extraction to end-of-life disposal, providing valuable insights into the environmental impacts associated with each stage of production.

The LCA process for photodiode production typically begins with the extraction and processing of raw materials, such as silicon, gallium arsenide, or indium gallium arsenide. These materials are often sourced from mining operations, which can have significant environmental implications, including habitat disruption and energy consumption. The next stage involves the fabrication of the photodiode itself, which requires cleanroom environments and energy-intensive processes like chemical vapor deposition and photolithography.

During the manufacturing phase, various chemicals and gases are used, some of which may have high global warming potential or ozone depletion potential. Water consumption and wastewater generation are also significant factors to consider, as semiconductor manufacturing often requires ultra-pure water and produces contaminated effluents that require treatment.

The assembly and packaging stages of photodiode production involve additional materials and processes, such as wire bonding, encapsulation, and sometimes the integration of optical components. These steps contribute to the overall environmental footprint through energy use and material consumption.

Transportation and distribution of finished photodiodes to end-users represent another phase in the lifecycle that must be accounted for in a comprehensive LCA. The energy used and emissions produced during shipping can vary significantly depending on the mode of transport and distances involved.

The use phase of photodiodes generally has a lower environmental impact compared to production, as these devices are typically passive components with long lifespans. However, the energy savings and efficiency improvements they enable in various applications should be considered as positive environmental contributions.

End-of-life management of photodiodes presents both challenges and opportunities. While some materials used in photodiodes can be recycled, the complex nature of these devices often makes material recovery difficult. Proper disposal and recycling processes are essential to minimize environmental harm and recover valuable resources.

By conducting a thorough LCA, manufacturers can identify hotspots in their production processes where environmental impacts are most significant. This information can guide efforts to improve sustainability, such as implementing more efficient manufacturing techniques, using alternative materials with lower environmental impacts, or redesigning products for easier recycling and resource recovery.

The LCA process for photodiode production typically begins with the extraction and processing of raw materials, such as silicon, gallium arsenide, or indium gallium arsenide. These materials are often sourced from mining operations, which can have significant environmental implications, including habitat disruption and energy consumption. The next stage involves the fabrication of the photodiode itself, which requires cleanroom environments and energy-intensive processes like chemical vapor deposition and photolithography.

During the manufacturing phase, various chemicals and gases are used, some of which may have high global warming potential or ozone depletion potential. Water consumption and wastewater generation are also significant factors to consider, as semiconductor manufacturing often requires ultra-pure water and produces contaminated effluents that require treatment.

The assembly and packaging stages of photodiode production involve additional materials and processes, such as wire bonding, encapsulation, and sometimes the integration of optical components. These steps contribute to the overall environmental footprint through energy use and material consumption.

Transportation and distribution of finished photodiodes to end-users represent another phase in the lifecycle that must be accounted for in a comprehensive LCA. The energy used and emissions produced during shipping can vary significantly depending on the mode of transport and distances involved.

The use phase of photodiodes generally has a lower environmental impact compared to production, as these devices are typically passive components with long lifespans. However, the energy savings and efficiency improvements they enable in various applications should be considered as positive environmental contributions.

End-of-life management of photodiodes presents both challenges and opportunities. While some materials used in photodiodes can be recycled, the complex nature of these devices often makes material recovery difficult. Proper disposal and recycling processes are essential to minimize environmental harm and recover valuable resources.

By conducting a thorough LCA, manufacturers can identify hotspots in their production processes where environmental impacts are most significant. This information can guide efforts to improve sustainability, such as implementing more efficient manufacturing techniques, using alternative materials with lower environmental impacts, or redesigning products for easier recycling and resource recovery.

Regulatory Framework for Sustainable Electronics Manufacturing

The regulatory framework for sustainable electronics manufacturing plays a crucial role in shaping the environmental sustainability of photodiode manufacturing processes. As governments and international organizations increasingly recognize the importance of sustainable practices in the electronics industry, a complex web of regulations has emerged to guide manufacturers towards more environmentally friendly production methods.

At the forefront of these regulations are directives aimed at reducing hazardous substances in electronic products. The European Union's Restriction of Hazardous Substances (RoHS) Directive, for instance, limits the use of certain harmful materials in electrical and electronic equipment, including photodiodes. This directive has been widely adopted and adapted by other countries, creating a global standard for reducing toxic elements in manufacturing processes.

Energy efficiency regulations also significantly impact photodiode production. Many countries have implemented energy performance standards and labeling requirements for electronic components, encouraging manufacturers to develop more energy-efficient production processes. These regulations often extend to the entire lifecycle of the product, from manufacturing to disposal, promoting a holistic approach to sustainability.

Waste management and recycling regulations form another critical aspect of the regulatory framework. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, sets collection, recycling, and recovery targets for electronic waste. Such regulations incentivize manufacturers to design photodiodes and other electronic components with end-of-life considerations in mind, promoting easier disassembly and recycling.

Carbon emissions regulations are increasingly influencing manufacturing practices in the electronics industry. Many countries have implemented carbon pricing mechanisms or cap-and-trade systems, which encourage companies to reduce their carbon footprint. For photodiode manufacturers, this may involve investing in cleaner energy sources or more efficient production technologies to minimize greenhouse gas emissions.

Water usage and pollution control regulations also play a significant role in shaping sustainable manufacturing practices. Given the water-intensive nature of many electronics manufacturing processes, including those for photodiodes, regulations limiting water consumption and mandating proper treatment of wastewater are becoming more stringent in many jurisdictions.

As the regulatory landscape continues to evolve, manufacturers are increasingly adopting voluntary sustainability standards and certification programs. These initiatives, while not legally binding, often go beyond regulatory requirements and can provide a competitive advantage in the market. Examples include the Electronic Industry Citizenship Coalition (EICC) Code of Conduct and various ISO environmental management standards.

At the forefront of these regulations are directives aimed at reducing hazardous substances in electronic products. The European Union's Restriction of Hazardous Substances (RoHS) Directive, for instance, limits the use of certain harmful materials in electrical and electronic equipment, including photodiodes. This directive has been widely adopted and adapted by other countries, creating a global standard for reducing toxic elements in manufacturing processes.

Energy efficiency regulations also significantly impact photodiode production. Many countries have implemented energy performance standards and labeling requirements for electronic components, encouraging manufacturers to develop more energy-efficient production processes. These regulations often extend to the entire lifecycle of the product, from manufacturing to disposal, promoting a holistic approach to sustainability.

Waste management and recycling regulations form another critical aspect of the regulatory framework. The EU's Waste Electrical and Electronic Equipment (WEEE) Directive, for example, sets collection, recycling, and recovery targets for electronic waste. Such regulations incentivize manufacturers to design photodiodes and other electronic components with end-of-life considerations in mind, promoting easier disassembly and recycling.

Carbon emissions regulations are increasingly influencing manufacturing practices in the electronics industry. Many countries have implemented carbon pricing mechanisms or cap-and-trade systems, which encourage companies to reduce their carbon footprint. For photodiode manufacturers, this may involve investing in cleaner energy sources or more efficient production technologies to minimize greenhouse gas emissions.

Water usage and pollution control regulations also play a significant role in shaping sustainable manufacturing practices. Given the water-intensive nature of many electronics manufacturing processes, including those for photodiodes, regulations limiting water consumption and mandating proper treatment of wastewater are becoming more stringent in many jurisdictions.

As the regulatory landscape continues to evolve, manufacturers are increasingly adopting voluntary sustainability standards and certification programs. These initiatives, while not legally binding, often go beyond regulatory requirements and can provide a competitive advantage in the market. Examples include the Electronic Industry Citizenship Coalition (EICC) Code of Conduct and various ISO environmental management standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!