Exploring QNED's Role in Future Automotive Displays

JUN 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

QNED Technology Evolution and Objectives

QNED (Quantum Nano Emitting Diode) technology represents a significant leap forward in display technology, particularly for automotive applications. This innovative approach combines the best aspects of QLED and MicroLED technologies, offering superior brightness, contrast, and color accuracy while addressing some of the limitations of existing display solutions.

The evolution of QNED technology can be traced back to the early 2010s when researchers began exploring ways to enhance the performance of quantum dot displays. The primary objective was to develop a display technology that could deliver exceptional visual quality while being energy-efficient and suitable for mass production. As automotive displays became increasingly sophisticated, the need for high-performance, durable, and adaptable display solutions grew more pressing.

QNED technology aims to meet several key objectives in the context of automotive displays. Firstly, it seeks to provide superior visibility in various lighting conditions, from bright sunlight to nighttime driving. This is crucial for ensuring driver safety and enhancing the overall user experience. Secondly, QNED displays aim to offer wider color gamuts and higher contrast ratios, enabling more vivid and realistic representations of information and entertainment content.

Another important objective of QNED technology is to improve energy efficiency. As electric vehicles become more prevalent, the power consumption of in-vehicle displays becomes a critical factor in overall vehicle range and performance. QNED displays promise to deliver high brightness and contrast while consuming less power than traditional LCD or OLED displays.

Durability and longevity are also key considerations in the development of QNED technology for automotive applications. The harsh environmental conditions inside a vehicle, including temperature fluctuations and vibrations, require displays that can maintain their performance over extended periods. QNED technology aims to provide a more robust solution compared to organic-based displays, which can suffer from degradation over time.

As QNED technology continues to evolve, researchers and manufacturers are focusing on scaling up production capabilities while maintaining consistent quality. The ultimate goal is to develop a display technology that can be mass-produced cost-effectively, making it viable for widespread adoption in the automotive industry. This includes refining manufacturing processes, improving yield rates, and reducing overall production costs.

Looking ahead, the evolution of QNED technology is expected to play a crucial role in enabling advanced driver assistance systems (ADAS) and autonomous driving features. The high-quality, responsive displays made possible by QNED could support more sophisticated human-machine interfaces, enhancing the communication between vehicle systems and occupants. This aligns with the broader trend towards more connected and intelligent vehicles, where display technology serves as a critical interface for information delivery and interaction.

The evolution of QNED technology can be traced back to the early 2010s when researchers began exploring ways to enhance the performance of quantum dot displays. The primary objective was to develop a display technology that could deliver exceptional visual quality while being energy-efficient and suitable for mass production. As automotive displays became increasingly sophisticated, the need for high-performance, durable, and adaptable display solutions grew more pressing.

QNED technology aims to meet several key objectives in the context of automotive displays. Firstly, it seeks to provide superior visibility in various lighting conditions, from bright sunlight to nighttime driving. This is crucial for ensuring driver safety and enhancing the overall user experience. Secondly, QNED displays aim to offer wider color gamuts and higher contrast ratios, enabling more vivid and realistic representations of information and entertainment content.

Another important objective of QNED technology is to improve energy efficiency. As electric vehicles become more prevalent, the power consumption of in-vehicle displays becomes a critical factor in overall vehicle range and performance. QNED displays promise to deliver high brightness and contrast while consuming less power than traditional LCD or OLED displays.

Durability and longevity are also key considerations in the development of QNED technology for automotive applications. The harsh environmental conditions inside a vehicle, including temperature fluctuations and vibrations, require displays that can maintain their performance over extended periods. QNED technology aims to provide a more robust solution compared to organic-based displays, which can suffer from degradation over time.

As QNED technology continues to evolve, researchers and manufacturers are focusing on scaling up production capabilities while maintaining consistent quality. The ultimate goal is to develop a display technology that can be mass-produced cost-effectively, making it viable for widespread adoption in the automotive industry. This includes refining manufacturing processes, improving yield rates, and reducing overall production costs.

Looking ahead, the evolution of QNED technology is expected to play a crucial role in enabling advanced driver assistance systems (ADAS) and autonomous driving features. The high-quality, responsive displays made possible by QNED could support more sophisticated human-machine interfaces, enhancing the communication between vehicle systems and occupants. This aligns with the broader trend towards more connected and intelligent vehicles, where display technology serves as a critical interface for information delivery and interaction.

Automotive Display Market Trends

The automotive display market is experiencing significant growth and transformation, driven by technological advancements and changing consumer preferences. As vehicles become more connected and autonomous, the demand for advanced display technologies is surging. The market is witnessing a shift from traditional instrument clusters to large, integrated touchscreen displays that offer enhanced functionality and user experience.

One of the key trends in the automotive display market is the increasing size of displays. Manufacturers are incorporating larger screens, with some high-end vehicles featuring displays spanning the entire dashboard. This trend is driven by the need for more information display and the desire for a more immersive in-car experience. The average size of center stack displays is expected to grow substantially in the coming years, with some premium vehicles already featuring displays exceeding 15 inches.

Another significant trend is the adoption of OLED (Organic Light-Emitting Diode) technology in automotive displays. OLED offers several advantages over traditional LCD displays, including better contrast ratios, wider viewing angles, and the ability to create flexible and curved displays. This technology is particularly attractive for automotive applications due to its superior performance in varying light conditions and its potential for innovative design implementations.

The integration of advanced driver assistance systems (ADAS) and infotainment features is also shaping the automotive display market. Displays are increasingly being used to show critical driving information, navigation data, and entertainment content simultaneously. This integration is leading to the development of more sophisticated display systems that can handle multiple inputs and provide a seamless user interface.

Augmented reality (AR) displays are emerging as a promising technology in the automotive sector. Head-up displays (HUDs) with AR capabilities are being developed to project information directly onto the windshield, enhancing driver safety and navigation. This technology is expected to see increased adoption in premium and mid-range vehicles in the coming years.

The market is also seeing a trend towards the use of free-form displays, which allow for more creative and ergonomic designs. These displays can be shaped to fit seamlessly into the vehicle's interior, improving aesthetics and functionality. Additionally, there is growing interest in transparent displays, which could revolutionize how information is presented in vehicles without obstructing the driver's view.

As vehicles become more autonomous, the role of displays is expected to evolve further. Future automotive displays may focus more on entertainment and productivity features, transforming the car into a mobile living space or office. This shift is likely to drive innovation in display technologies that can support these new use cases while maintaining safety and usability standards.

One of the key trends in the automotive display market is the increasing size of displays. Manufacturers are incorporating larger screens, with some high-end vehicles featuring displays spanning the entire dashboard. This trend is driven by the need for more information display and the desire for a more immersive in-car experience. The average size of center stack displays is expected to grow substantially in the coming years, with some premium vehicles already featuring displays exceeding 15 inches.

Another significant trend is the adoption of OLED (Organic Light-Emitting Diode) technology in automotive displays. OLED offers several advantages over traditional LCD displays, including better contrast ratios, wider viewing angles, and the ability to create flexible and curved displays. This technology is particularly attractive for automotive applications due to its superior performance in varying light conditions and its potential for innovative design implementations.

The integration of advanced driver assistance systems (ADAS) and infotainment features is also shaping the automotive display market. Displays are increasingly being used to show critical driving information, navigation data, and entertainment content simultaneously. This integration is leading to the development of more sophisticated display systems that can handle multiple inputs and provide a seamless user interface.

Augmented reality (AR) displays are emerging as a promising technology in the automotive sector. Head-up displays (HUDs) with AR capabilities are being developed to project information directly onto the windshield, enhancing driver safety and navigation. This technology is expected to see increased adoption in premium and mid-range vehicles in the coming years.

The market is also seeing a trend towards the use of free-form displays, which allow for more creative and ergonomic designs. These displays can be shaped to fit seamlessly into the vehicle's interior, improving aesthetics and functionality. Additionally, there is growing interest in transparent displays, which could revolutionize how information is presented in vehicles without obstructing the driver's view.

As vehicles become more autonomous, the role of displays is expected to evolve further. Future automotive displays may focus more on entertainment and productivity features, transforming the car into a mobile living space or office. This shift is likely to drive innovation in display technologies that can support these new use cases while maintaining safety and usability standards.

QNED Challenges in Automotive Applications

QNED (Quantum Nano Emitting Diode) technology faces several significant challenges in its application to automotive displays. One of the primary obstacles is the need for enhanced durability and reliability in the harsh automotive environment. Vehicles are subject to extreme temperature fluctuations, vibrations, and prolonged exposure to sunlight, which can potentially degrade QNED performance over time. Ensuring that QNED displays maintain their color accuracy, brightness, and overall functionality under these conditions is crucial for widespread adoption in the automotive sector.

Another challenge lies in the manufacturing process and scalability of QNED technology for automotive applications. The production of QNED displays requires precise control over quantum dot synthesis and integration into the display structure. Achieving consistent quality and yield rates at the scale necessary for automotive production presents a significant hurdle. Additionally, the automotive industry demands stringent quality control measures, which may necessitate the development of new testing and validation protocols specific to QNED displays.

Power efficiency is a critical factor in automotive applications, particularly with the growing emphasis on electric vehicles. While QNED technology promises improved energy efficiency compared to traditional display technologies, further optimization is required to meet the stringent power consumption requirements of modern vehicles. This includes developing more efficient driving circuits and refining the quantum dot emission process to maximize light output while minimizing energy input.

The integration of QNED displays with existing automotive systems and interfaces poses another challenge. Compatibility with current infotainment systems, driver assistance features, and vehicle control interfaces must be ensured. This may require the development of new software and hardware interfaces to fully leverage the capabilities of QNED displays while maintaining seamless integration with other vehicle systems.

Cost considerations also present a significant hurdle for QNED adoption in automotive applications. The automotive industry is highly cost-sensitive, and QNED technology must demonstrate a clear value proposition to justify its implementation over existing display solutions. Reducing production costs while maintaining performance advantages is crucial for widespread adoption in the automotive sector.

Lastly, regulatory compliance and safety standards pose challenges for QNED integration in automotive displays. Meeting stringent automotive safety regulations, including those related to electromagnetic compatibility, impact resistance, and glare reduction, requires extensive testing and potential design modifications. Ensuring that QNED displays comply with these standards without compromising their performance advantages is essential for successful implementation in vehicles.

Another challenge lies in the manufacturing process and scalability of QNED technology for automotive applications. The production of QNED displays requires precise control over quantum dot synthesis and integration into the display structure. Achieving consistent quality and yield rates at the scale necessary for automotive production presents a significant hurdle. Additionally, the automotive industry demands stringent quality control measures, which may necessitate the development of new testing and validation protocols specific to QNED displays.

Power efficiency is a critical factor in automotive applications, particularly with the growing emphasis on electric vehicles. While QNED technology promises improved energy efficiency compared to traditional display technologies, further optimization is required to meet the stringent power consumption requirements of modern vehicles. This includes developing more efficient driving circuits and refining the quantum dot emission process to maximize light output while minimizing energy input.

The integration of QNED displays with existing automotive systems and interfaces poses another challenge. Compatibility with current infotainment systems, driver assistance features, and vehicle control interfaces must be ensured. This may require the development of new software and hardware interfaces to fully leverage the capabilities of QNED displays while maintaining seamless integration with other vehicle systems.

Cost considerations also present a significant hurdle for QNED adoption in automotive applications. The automotive industry is highly cost-sensitive, and QNED technology must demonstrate a clear value proposition to justify its implementation over existing display solutions. Reducing production costs while maintaining performance advantages is crucial for widespread adoption in the automotive sector.

Lastly, regulatory compliance and safety standards pose challenges for QNED integration in automotive displays. Meeting stringent automotive safety regulations, including those related to electromagnetic compatibility, impact resistance, and glare reduction, requires extensive testing and potential design modifications. Ensuring that QNED displays comply with these standards without compromising their performance advantages is essential for successful implementation in vehicles.

Current QNED Solutions for Vehicles

01 Quantum dot structure and composition

QNED displays utilize advanced quantum dot structures and compositions to enhance display quality. These structures often involve specific arrangements of quantum dots and nanoparticles, which can be optimized for improved light emission, color purity, and efficiency. The composition of these quantum dots, including core-shell structures and doping materials, plays a crucial role in determining the overall display performance.- Quantum dot structure and composition: QNED displays utilize advanced quantum dot structures and compositions to enhance display quality. These include optimized core-shell structures, doping techniques, and material selections to improve color purity, brightness, and efficiency of light emission. The quantum dot composition and structure directly impact the overall display performance.

- Nano-emitting diode design: The design of nano-emitting diodes in QNED displays plays a crucial role in display quality. This includes optimizing the diode structure, electrode configuration, and current injection mechanisms to achieve high luminescence efficiency and color accuracy. Advanced designs aim to reduce power consumption while maintaining excellent display performance.

- Color conversion and light management: QNED displays employ sophisticated color conversion techniques and light management strategies to enhance display quality. This involves optimizing quantum dot color conversion layers, implementing advanced optical films, and designing efficient light extraction structures to improve color gamut, contrast, and viewing angles.

- Quantum dot synthesis and deposition methods: The quality of QNED displays is significantly influenced by quantum dot synthesis and deposition methods. Advanced techniques for precise control of quantum dot size, uniformity, and arrangement on the display substrate are crucial. These methods aim to achieve consistent and high-quality quantum dot layers for improved display performance.

- Integration with display backplane technology: The integration of QNED technology with advanced display backplane architectures is essential for overall display quality. This includes optimizing the interface between quantum dots and thin-film transistors, developing efficient driving schemes, and implementing advanced pixel circuits to enhance brightness, refresh rates, and image stability.

02 Light-emitting layer design

The design of the light-emitting layer is critical for QNED display quality. This includes the arrangement of quantum dots, the use of multiple emissive layers, and the incorporation of charge transport materials. Optimizing the light-emitting layer can lead to improved brightness, color gamut, and energy efficiency in QNED displays.Expand Specific Solutions03 Electrode and substrate configuration

The configuration of electrodes and substrates in QNED displays significantly impacts display quality. This includes the design of transparent electrodes, the use of reflective layers, and the implementation of novel substrate materials. Proper electrode and substrate configuration can enhance light extraction, reduce power consumption, and improve overall display performance.Expand Specific Solutions04 Color conversion and enhancement techniques

QNED displays employ various color conversion and enhancement techniques to improve display quality. These may include the use of color filters, phosphor materials, and specialized optical films. Such techniques can enhance color accuracy, expand the color gamut, and improve the overall visual experience of QNED displays.Expand Specific Solutions05 Driving and control methods

Advanced driving and control methods are crucial for optimizing QNED display quality. This includes innovative pixel driving schemes, voltage control techniques, and timing algorithms. These methods can improve display uniformity, reduce motion blur, and enhance overall image quality in QNED displays.Expand Specific Solutions

Key QNED and Automotive Display Players

The QNED (Quantum Nano Emitting Diode) technology in automotive displays is in its early development stage, with significant potential for growth. The market size is expected to expand rapidly as automakers seek advanced display solutions. While the technology is still maturing, several key players are actively involved in its development. Companies like Samsung Display, LG Display, and BOE Technology Group are at the forefront, leveraging their expertise in display technologies. Sharp Corp. and Apple Inc. are also exploring QNED applications, indicating growing interest from diverse sectors. The competition is intensifying as automotive manufacturers like Volkswagen AG, Ford Global Technologies, and Hyundai Motor Co. collaborate with display technology firms to integrate QNED into their vehicle designs, signaling a shift towards more sophisticated in-car display systems.

BOE Technology Group Co., Ltd.

Technical Solution: BOE is exploring QNED technology for automotive displays, leveraging their expertise in display manufacturing. Their approach focuses on integrating quantum dot technology with advanced LED backlighting systems to create high-performance QNED displays suitable for automotive use. BOE's QNED displays aim to offer superior color gamut, high brightness, and energy efficiency. They are developing these displays to meet the stringent requirements of the automotive industry, including durability in extreme temperatures and resistance to vibration. BOE is also working on flexible QNED displays that could enable curved or shaped displays in vehicle interiors.

Strengths: Large-scale manufacturing capabilities, potential for flexible displays. Weaknesses: Less experience in automotive-specific display requirements compared to some competitors.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display is at the forefront of QNED (Quantum Nano Emitting Diode) technology for automotive displays. Their approach combines quantum dot color conversion with nanorod LED technology. This results in displays with superior brightness, color accuracy, and energy efficiency compared to traditional LCD or OLED displays. Samsung's QNED displays utilize a blue nanorod LED backlight, which is then color-converted by quantum dots to produce red and green light. This architecture allows for precise color control and high luminance, crucial for visibility in varying light conditions in vehicles.

Strengths: Superior color accuracy and brightness, energy efficiency, and potential for high contrast ratios. Weaknesses: Higher production costs initially, and complexity in manufacturing process.

QNED Innovations for Automotive Displays

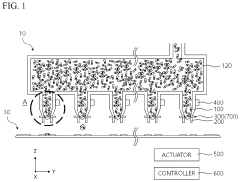

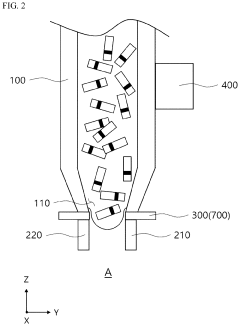

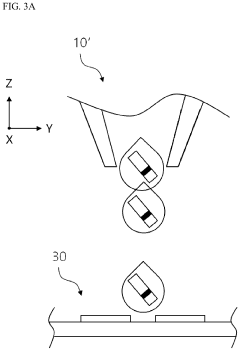

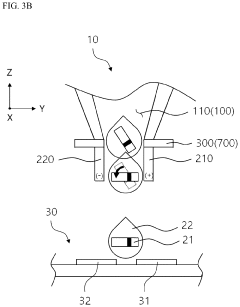

Inkjet head and method of ejecting ink using the same

PatentActiveUS11845276B2

Innovation

- An inkjet head with nozzles and pairs of electrodes that apply an electrode voltage to the light-emitting elements, including a first and second piezoelectric element, and a controller to independently control the electrode voltage, allowing for precise arrangement of light-emitting elements on a substrate with separate electrodes before and during the jetting process.

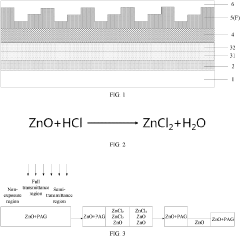

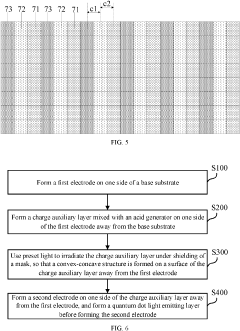

Display substrate, display device, and manufacturing method for display substrate

PatentPendingUS20230145503A1

Innovation

- A display substrate with a base substrate, a first electrode, a charge auxiliary layer featuring concave-convex structures and varying acid generator content, and a quantum dot light emitting layer, where the charge auxiliary layer is formed using a mask with different light transmittance regions to create periodic convex-concave structures that enhance light extraction by total reflection.

QNED Manufacturing and Supply Chain

The manufacturing and supply chain of QNED (Quantum Nano Emitting Diode) displays for automotive applications presents both challenges and opportunities. The production process involves several critical steps, including the fabrication of quantum dots, the integration of these nanoparticles into LED structures, and the assembly of the final display panels. Each stage requires precise control and advanced manufacturing techniques to ensure the high quality and performance demanded by the automotive industry.

One of the key challenges in QNED manufacturing is the scalability of quantum dot production. While laboratory-scale synthesis of quantum dots has been well-established, scaling up to industrial volumes while maintaining uniformity and quality is a significant hurdle. Companies are investing in advanced chemical processes and automated production lines to address this issue, aiming to increase yield and reduce costs.

The integration of quantum dots into LED structures is another critical aspect of the manufacturing process. This step requires careful control of the deposition and encapsulation of quantum dots to ensure optimal light emission and longevity. Advanced techniques such as photolithography and inkjet printing are being explored to improve the precision and efficiency of this process.

The supply chain for QNED displays is complex, involving multiple tiers of suppliers. Raw materials for quantum dot production, such as semiconductor precursors and organic ligands, are sourced from specialized chemical companies. LED manufacturers provide the base structures, while display panel assemblers integrate the QNED components into the final product. Ensuring a stable and reliable supply of these materials and components is crucial for the successful adoption of QNED technology in automotive displays.

Geographically, the QNED supply chain is currently concentrated in East Asia, with major players in South Korea, Japan, and Taiwan leading the development and production efforts. However, as the technology gains traction, we can expect to see a more globalized supply chain emerge, with potential manufacturing hubs developing in North America and Europe to cater to local automotive markets.

Environmental considerations are also shaping the QNED manufacturing and supply chain landscape. The industry is focusing on developing more sustainable production methods, reducing the use of toxic materials, and implementing recycling programs for end-of-life displays. These efforts are crucial for meeting increasingly stringent environmental regulations and consumer expectations in the automotive sector.

One of the key challenges in QNED manufacturing is the scalability of quantum dot production. While laboratory-scale synthesis of quantum dots has been well-established, scaling up to industrial volumes while maintaining uniformity and quality is a significant hurdle. Companies are investing in advanced chemical processes and automated production lines to address this issue, aiming to increase yield and reduce costs.

The integration of quantum dots into LED structures is another critical aspect of the manufacturing process. This step requires careful control of the deposition and encapsulation of quantum dots to ensure optimal light emission and longevity. Advanced techniques such as photolithography and inkjet printing are being explored to improve the precision and efficiency of this process.

The supply chain for QNED displays is complex, involving multiple tiers of suppliers. Raw materials for quantum dot production, such as semiconductor precursors and organic ligands, are sourced from specialized chemical companies. LED manufacturers provide the base structures, while display panel assemblers integrate the QNED components into the final product. Ensuring a stable and reliable supply of these materials and components is crucial for the successful adoption of QNED technology in automotive displays.

Geographically, the QNED supply chain is currently concentrated in East Asia, with major players in South Korea, Japan, and Taiwan leading the development and production efforts. However, as the technology gains traction, we can expect to see a more globalized supply chain emerge, with potential manufacturing hubs developing in North America and Europe to cater to local automotive markets.

Environmental considerations are also shaping the QNED manufacturing and supply chain landscape. The industry is focusing on developing more sustainable production methods, reducing the use of toxic materials, and implementing recycling programs for end-of-life displays. These efforts are crucial for meeting increasingly stringent environmental regulations and consumer expectations in the automotive sector.

Environmental Impact of QNED Displays

The environmental impact of QNED (Quantum Nano Emitting Diode) displays in automotive applications is a crucial consideration as this technology gains traction in the industry. QNED displays offer several potential environmental benefits compared to traditional display technologies, particularly in terms of energy efficiency and resource utilization.

One of the primary environmental advantages of QNED displays is their improved energy efficiency. These displays consume significantly less power than conventional LCD or OLED screens, potentially reducing the overall energy consumption of vehicles. This efficiency translates to lower carbon emissions, especially in electric and hybrid vehicles where energy conservation is paramount. The reduced power draw can also contribute to extended driving ranges, indirectly decreasing the frequency of charging or refueling.

In terms of manufacturing, QNED displays may have a lower environmental footprint compared to other display technologies. The production process for QNEDs potentially requires fewer rare earth elements and toxic materials, which are often associated with the manufacture of traditional displays. This reduction in harmful substances not only minimizes the environmental impact during production but also simplifies the recycling and disposal processes at the end of the product lifecycle.

The longevity of QNED displays is another factor that contributes to their environmental sustainability. These displays are expected to have a longer lifespan than current automotive display technologies, reducing the need for frequent replacements. This durability can lead to a decrease in electronic waste generation, addressing a growing environmental concern in the automotive sector.

Furthermore, the superior brightness and contrast ratios of QNED displays may contribute to improved visibility in various lighting conditions. This enhanced visibility could potentially reduce the need for additional lighting systems in vehicles, further conserving energy and resources.

However, it is important to note that the environmental impact of QNED displays is not entirely positive. The production of nano-scale materials used in these displays may involve energy-intensive processes. Additionally, the long-term effects of nanoparticles on the environment, should they be released during the product's lifecycle or disposal, are not yet fully understood and require further research.

As the automotive industry moves towards more sustainable practices, the adoption of QNED displays could play a significant role in reducing the overall environmental footprint of vehicles. However, a comprehensive life cycle assessment is necessary to fully quantify the environmental benefits and potential drawbacks of this technology compared to existing display solutions.

One of the primary environmental advantages of QNED displays is their improved energy efficiency. These displays consume significantly less power than conventional LCD or OLED screens, potentially reducing the overall energy consumption of vehicles. This efficiency translates to lower carbon emissions, especially in electric and hybrid vehicles where energy conservation is paramount. The reduced power draw can also contribute to extended driving ranges, indirectly decreasing the frequency of charging or refueling.

In terms of manufacturing, QNED displays may have a lower environmental footprint compared to other display technologies. The production process for QNEDs potentially requires fewer rare earth elements and toxic materials, which are often associated with the manufacture of traditional displays. This reduction in harmful substances not only minimizes the environmental impact during production but also simplifies the recycling and disposal processes at the end of the product lifecycle.

The longevity of QNED displays is another factor that contributes to their environmental sustainability. These displays are expected to have a longer lifespan than current automotive display technologies, reducing the need for frequent replacements. This durability can lead to a decrease in electronic waste generation, addressing a growing environmental concern in the automotive sector.

Furthermore, the superior brightness and contrast ratios of QNED displays may contribute to improved visibility in various lighting conditions. This enhanced visibility could potentially reduce the need for additional lighting systems in vehicles, further conserving energy and resources.

However, it is important to note that the environmental impact of QNED displays is not entirely positive. The production of nano-scale materials used in these displays may involve energy-intensive processes. Additionally, the long-term effects of nanoparticles on the environment, should they be released during the product's lifecycle or disposal, are not yet fully understood and require further research.

As the automotive industry moves towards more sustainable practices, the adoption of QNED displays could play a significant role in reducing the overall environmental footprint of vehicles. However, a comprehensive life cycle assessment is necessary to fully quantify the environmental benefits and potential drawbacks of this technology compared to existing display solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!